Fan-shaped cylinder assembly of reforming reactor

A technology of reforming reactors and fan-shaped cylinders, applied in chemical instruments and methods, chemical/physical processes, etc., can solve the problems of less flow of raw materials, increased catalyst dust, and increased catalyst consumption, so as to reduce operating investment costs , Eliminate flow dead zone, reduce filling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] To make the objectives, technical solutions, and advantages of the present disclosure clearer, the following with reference to embodiments of the present application will be described in further detail.

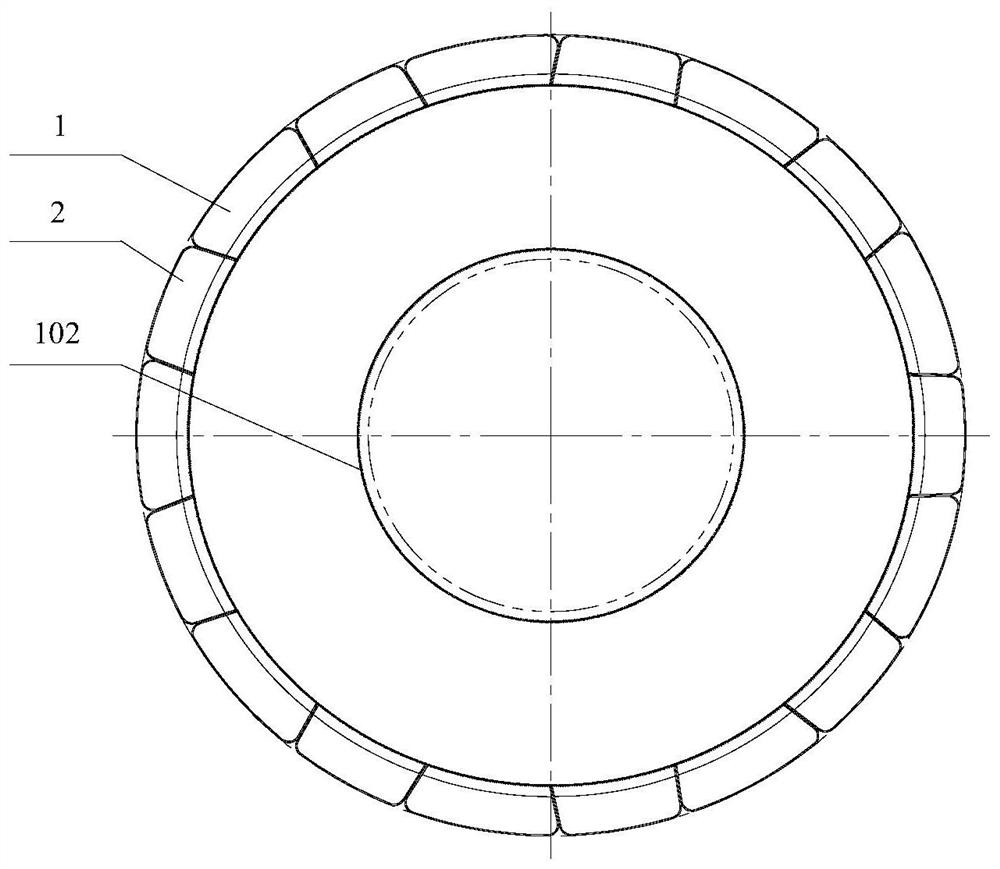

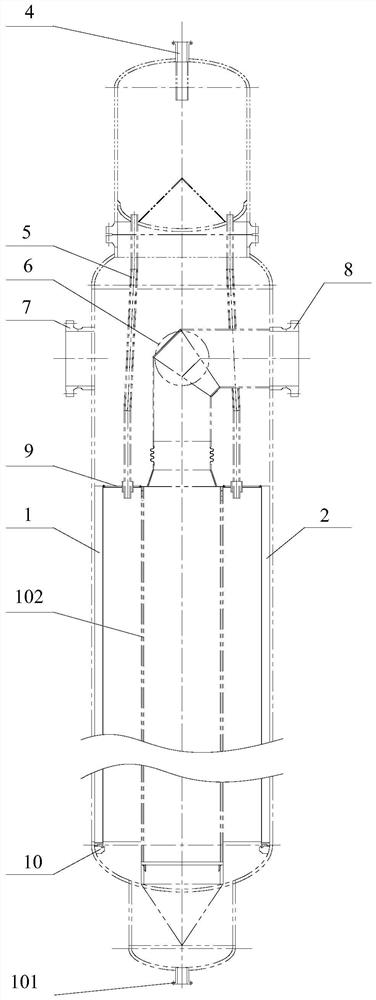

[0056] figure 1 It is a structural diagram of a fan assembly provided a cylindrical reforming reactor according to the present embodiment of the application;

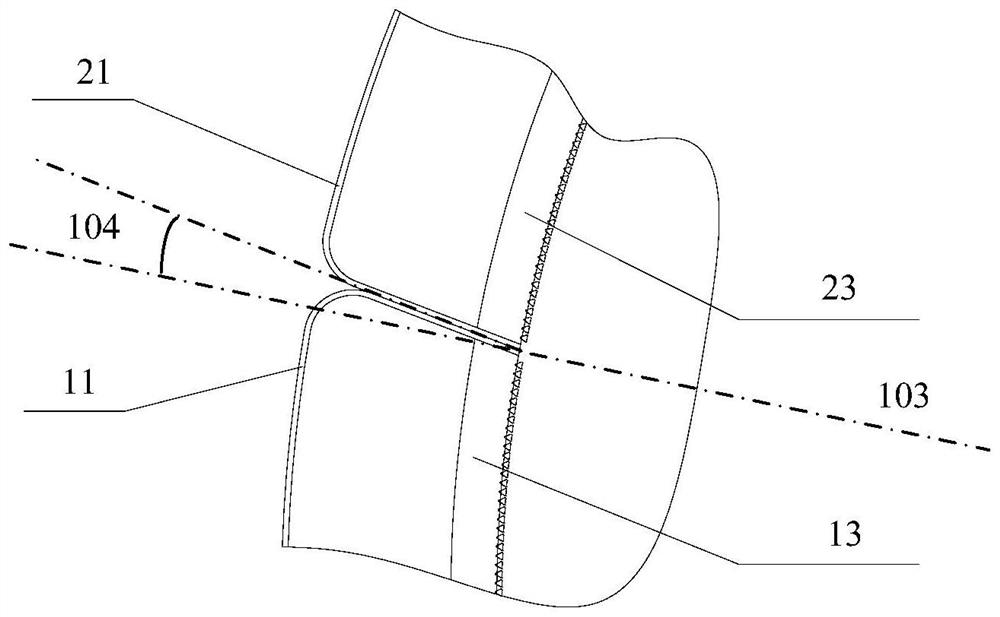

[0057] figure 2 Is a diagram showing the sector structure of a cartridge assembly of the contact surface provided by the embodiment of the present application; see figure 1 and figure 2 The sector tube assembly comprising: at least two female sector tube 1 and at least two convex cylinder sectors 2; said concave cylindrical sector 1 and the sector of the convex cylinder 2 are arranged at intervals, a cylindrical shape, the adjacent concave cylindrical sector 1 and the contact surface between the convex cylindrical sector close contact, and the angle 104 between the contact surface 103 of the radial line segment of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com