A slurry bed loop reactor and its application and method for producing hydrogen peroxide

A loop reactor, slurry bed technology, applied in chemical instruments and methods, peroxide/peroxyhydrate/peroxyacid/superoxide/ozone oxide, inorganic chemistry, etc., can solve the temperature in the bed Uneven distribution, low catalyst utilization efficiency, large catalyst liquid holding capacity, etc., to achieve uniform concentration and temperature distribution, avoid excessive liquid holding capacity, and eliminate the effect of flow dead zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

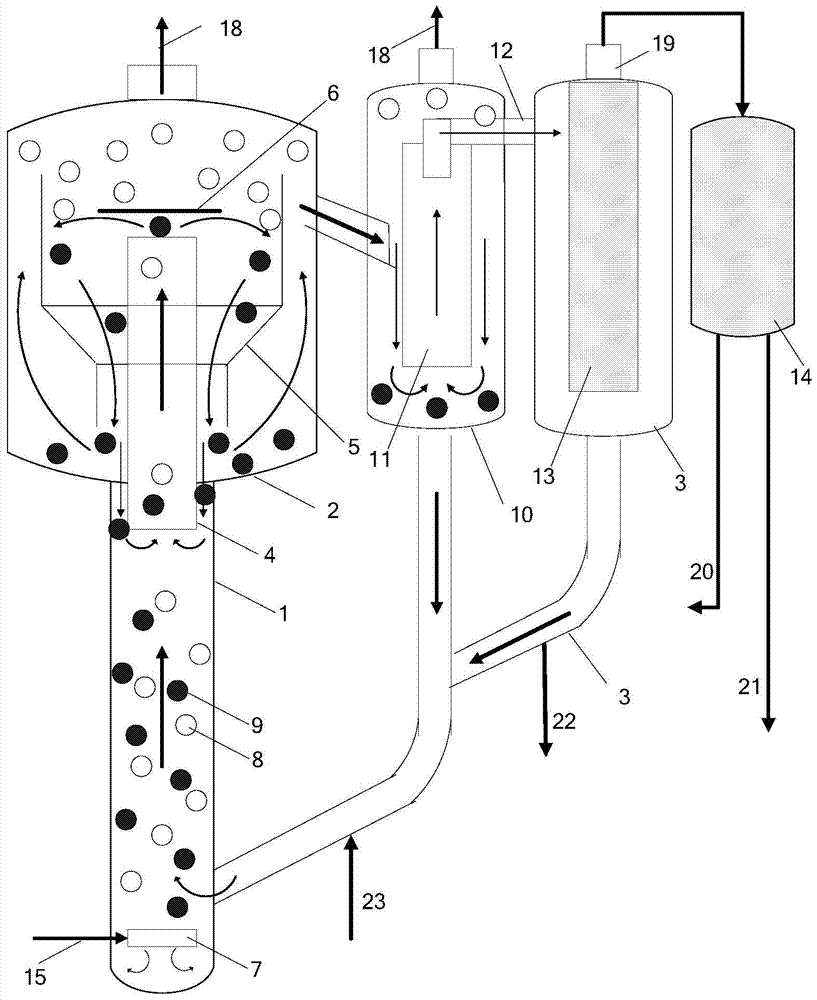

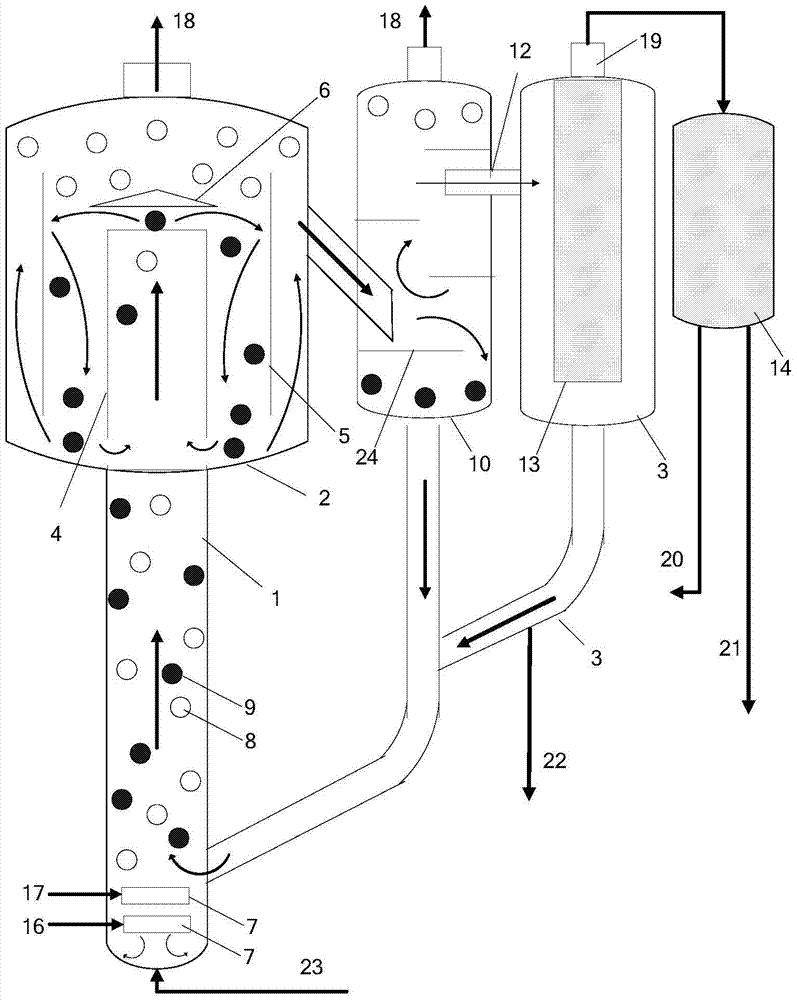

[0024] The slurry bed circulation reactor provided by the present invention is composed of a riser, a separation tank and a downcomer which are connected in sequence. The upper part of the riser is an enlarged section with enlarged pipe diameter. The liquid phase outlet is connected to the upper part of the downcomer, the bottom of the downcomer is connected to the bottom of the riser, and the bottom of the separation tank is connected to the lower part of the downcomer; the bottom of the riser is provided with a raw material inlet, and the top of the enlarged section of the riser and the top of the separation tank are provided with a gas outlet , the filter assembly is arranged in the downcomer, and the upper part of the downcomer is provided with a clear liquid outlet through the filter assembly.

[0025]Preferably, internal components are arranged in the separation tank. The internal member is preferably an overflow sleeve or an overflow baffle. The overflow sleeve inside ...

Embodiment 1

[0061] Example 1 illustrates the effect of the slurry bed reactor provided by the present invention applied to the preparation of hydrogen peroxide by anthraquinone method.

[0062] Attached figure 1 The slurry bed reactor shown, wherein: the diameter ratio of the expansion section to the riser is 3:1, the height ratio of the expansion section to the riser is: 1:3; the diameter ratio of the riser to the downcomer is 4:1, The diameter ratio of the riser tube to the inner cylinder in the expansion section is 1.2:1, the outer cylinder is a two-stage structure with the upper part larger than the lower part, the diameter ratio of the upper part to the lower part is 2:1, and the diameter ratio of the upper part of the outer tube to the inner tube is 3:1, the demister is a circular plate, 30mm away from the top of the inner cylinder, the ratio of the diameter of the demister to the diameter of the inner cylinder is 2.5:1, the length of the inner cylinder extending into the riser unde...

Embodiment 2

[0070] Example 2 illustrates the effect of the slurry bed reactor provided by the present invention applied to the preparation of hydrogen peroxide by anthraquinone method.

[0071] Attached figure 2 The slurry bed reactor shown is different from Example 1 in that the hydrogen-containing gas and the working fluid enter the bottom of the riser from the independent gas distributor and liquid distributor respectively, and in the sleeve structure in the riser, the outer cylinder is A cylinder with a uniform diameter, the diameter of the inner cylinder is the same as the lower part of the riser, the diameter ratio of the outer cylinder to the inner cylinder is 3.5:1, the demister is a conical plate, the bottom of the demister is 50mm from the top of the inner cylinder, and the demister The ratio of the diameter of the device to the diameter of the inner cylinder is 3:1, and there are 8 round holes with a diameter of 3 mm at the connection between the bottom of the inner cylinder a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com