Wound tube heat exchanger with baffle plates

A technology of winding tube type and baffle plate, which is applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc. It can improve the uniformity of heat exchange, eliminate the dead zone of flow, and achieve the effect of simple and reasonable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

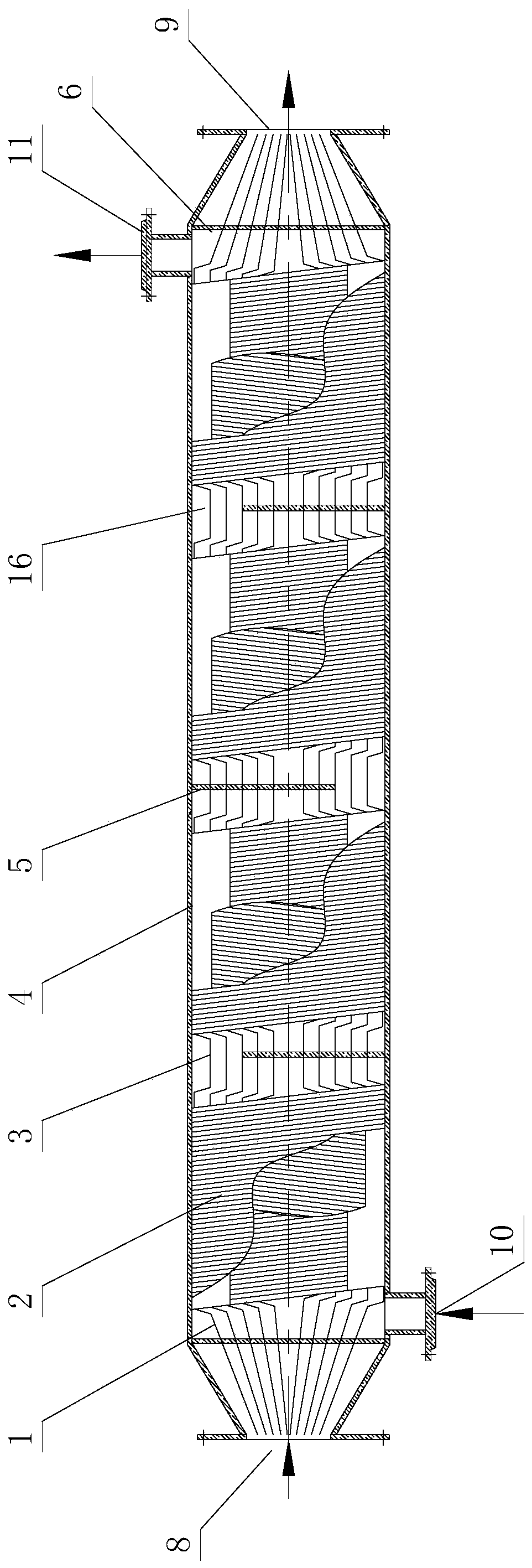

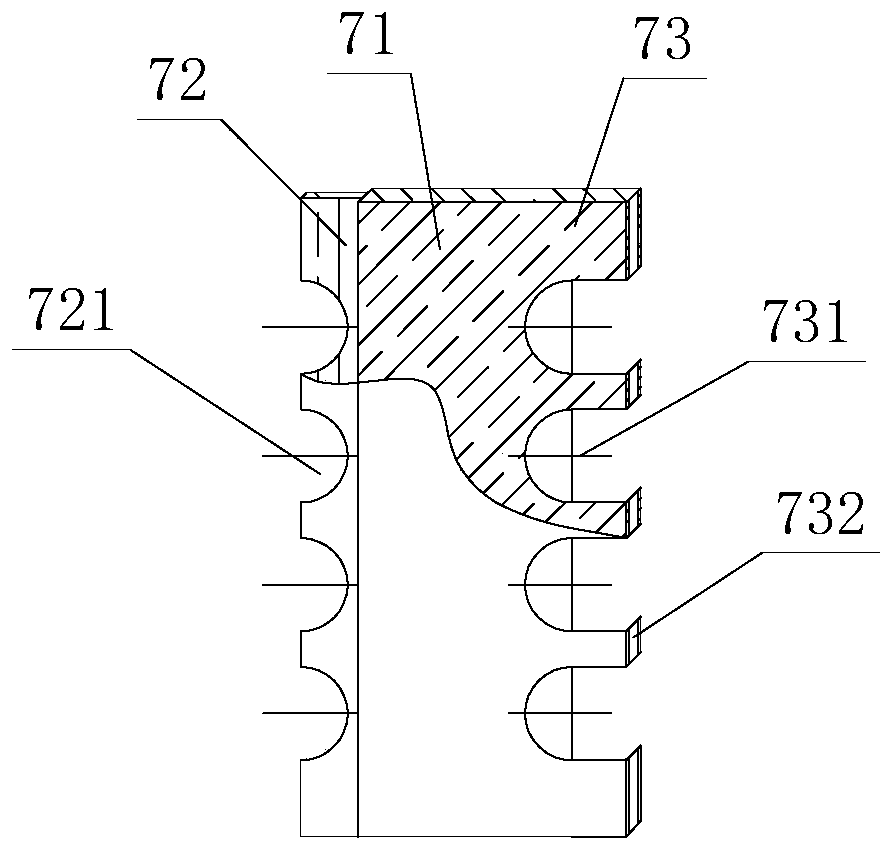

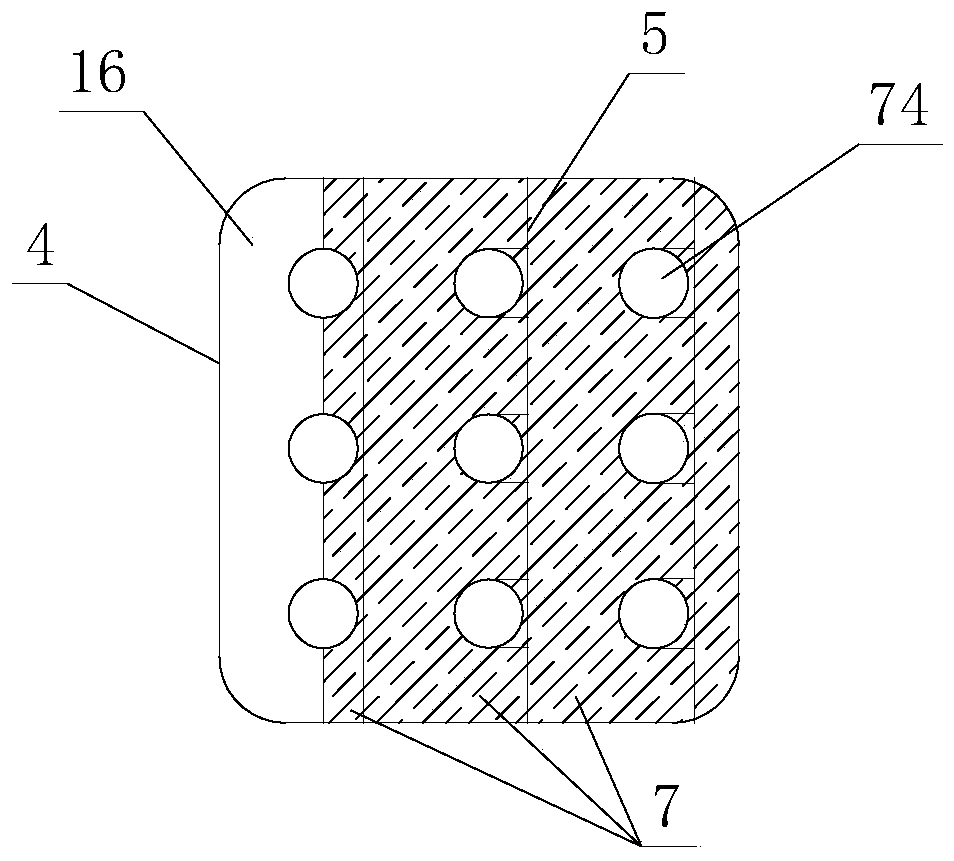

[0024] see Figure 1-Figure 4 , the wound tube heat exchanger with baffles includes a shell 4, and the shell 4 is provided with a plurality of spirally wound heat transfer tubes 1, and the multi-stage spirally wound heat transfer tube 1 is composed of several spirally wound tube segments 2 and several The straight pipe sections 3 are wound alternately; wherein, a plurality of combined baffles 5 are arranged between the straight pipe section 3 and the shell 4, and several combined baffles 5 are arranged vertically along the axis of the shell 4; The two ends of the shell 4 are also provided with tube sheets 6 respectively, and the tube sheets 6 at both ends are separated into a tube side and a shell side heat exchange area.

[0025] The side of the shell 4 is provided with a shell-side inlet 10 and a shell-side outlet 11, and the end is provided with a tube-side inlet 8 and a tube-side outlet 9; the tube-side of the evaporator passes through the evaporation fluid, and the shell-...

no. 2 example

[0041] see Figure 5 , the wound tube heat exchanger with baffles is different from the first embodiment in that: the shell side has multiple processes, and the multi-stage spirally wound heat exchange tubes 1 of different processes are parallel to each other and are not arranged superimposed.

[0042] The shell of this example is two shells. Its multi-section spirally wound heat exchange tube 1 is composed of a spirally wound pipe section 2 and a straight pipe section 3, which are wound in sections. The straight pipe section 3 is arranged between the front and rear spirally wound pipe sections 2, and the tube plates 6 at both ends separate the heat exchanger. Into the tube side and shell side heat exchange area. Two bundles of multi-segment spirally wound heat exchange tubes 1 are arranged in parallel, respectively placed on both sides of the U-shaped shell side, and a shell-side partition 14 is arranged between the two bundles of multi-segment spirally wound heat-exchange t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com