Patents

Literature

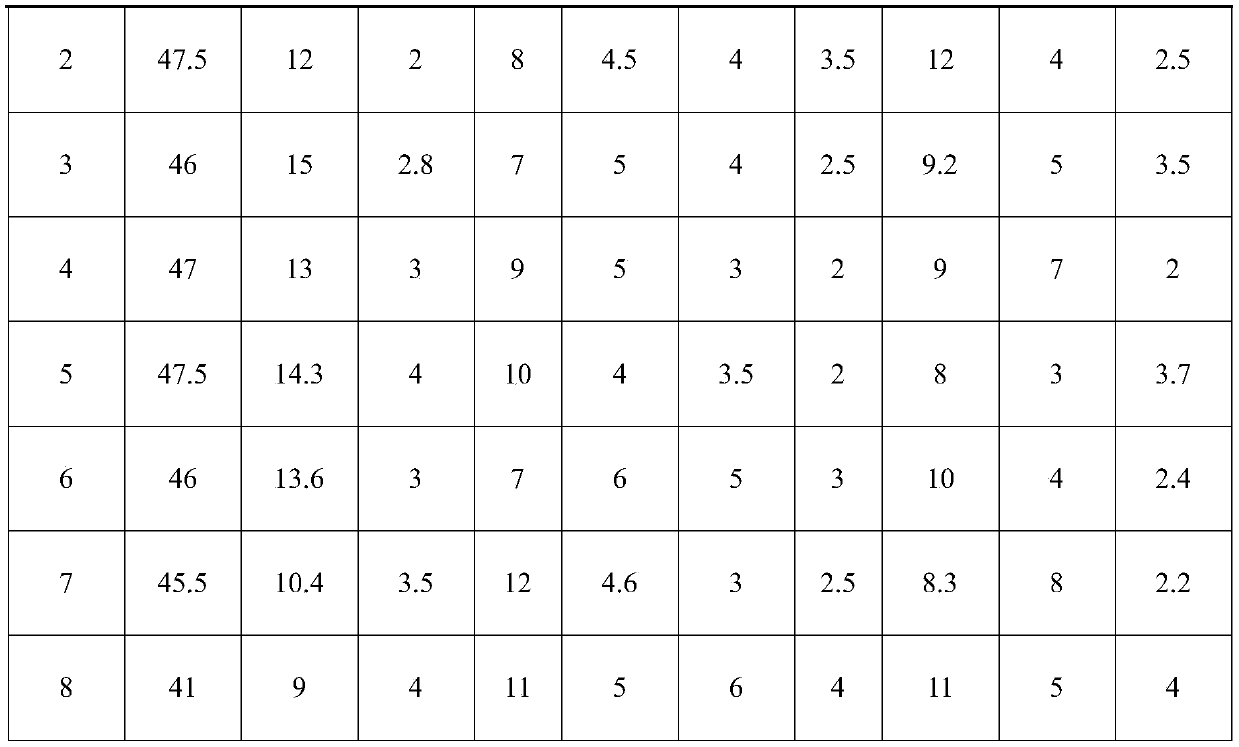

69results about How to "Improve heat transfer uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

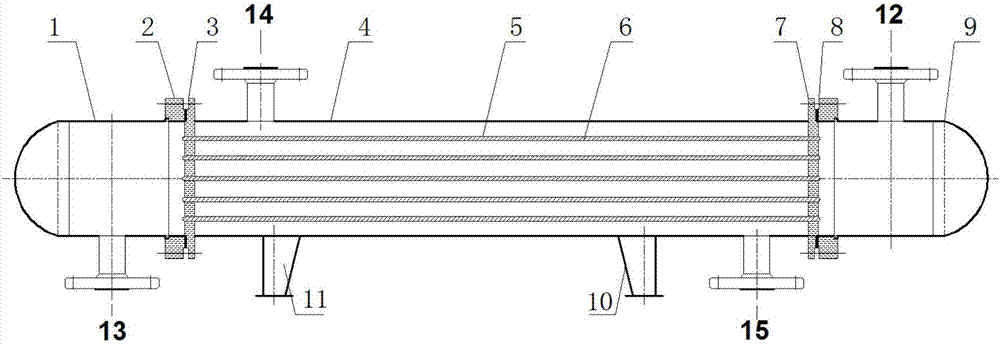

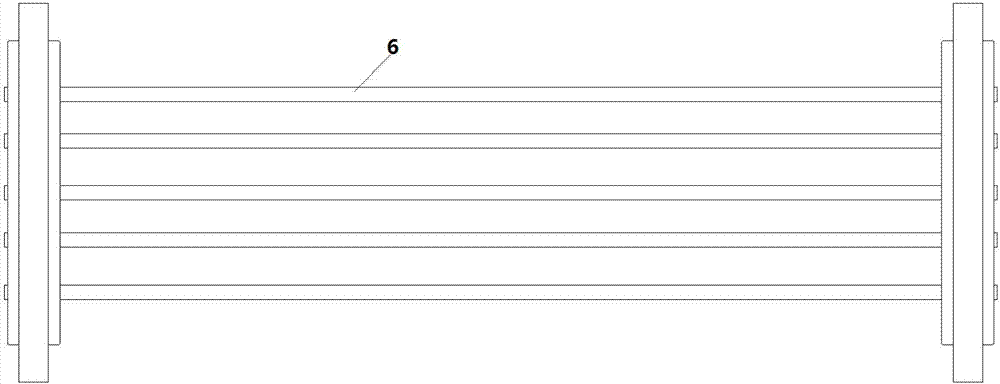

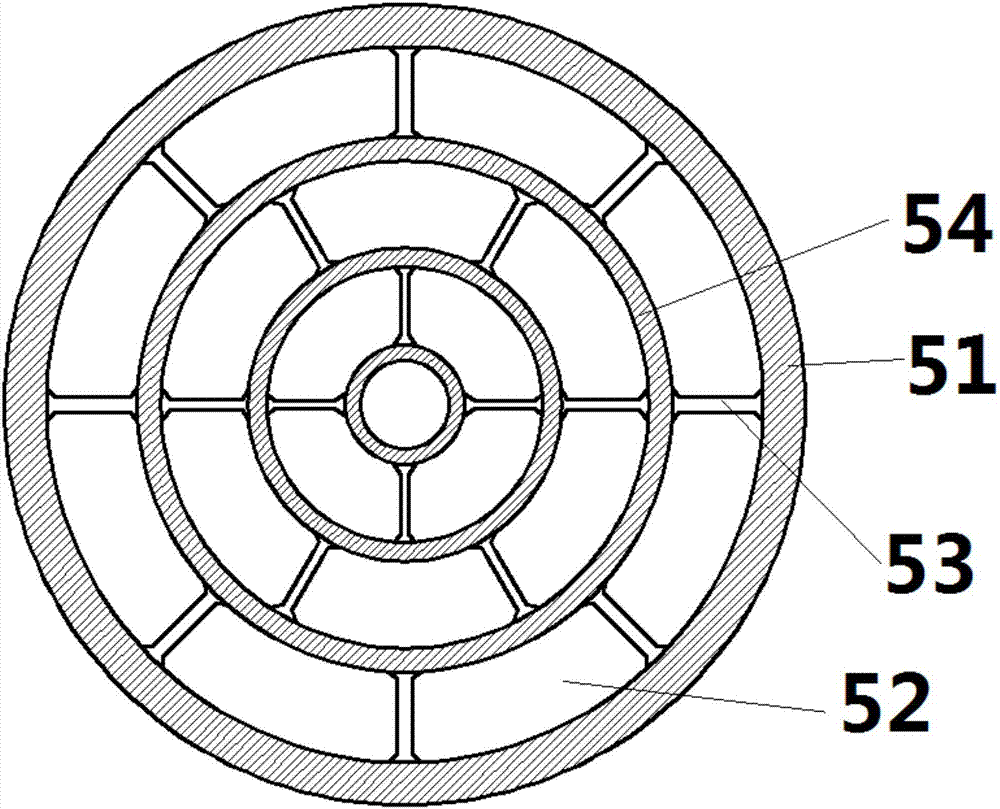

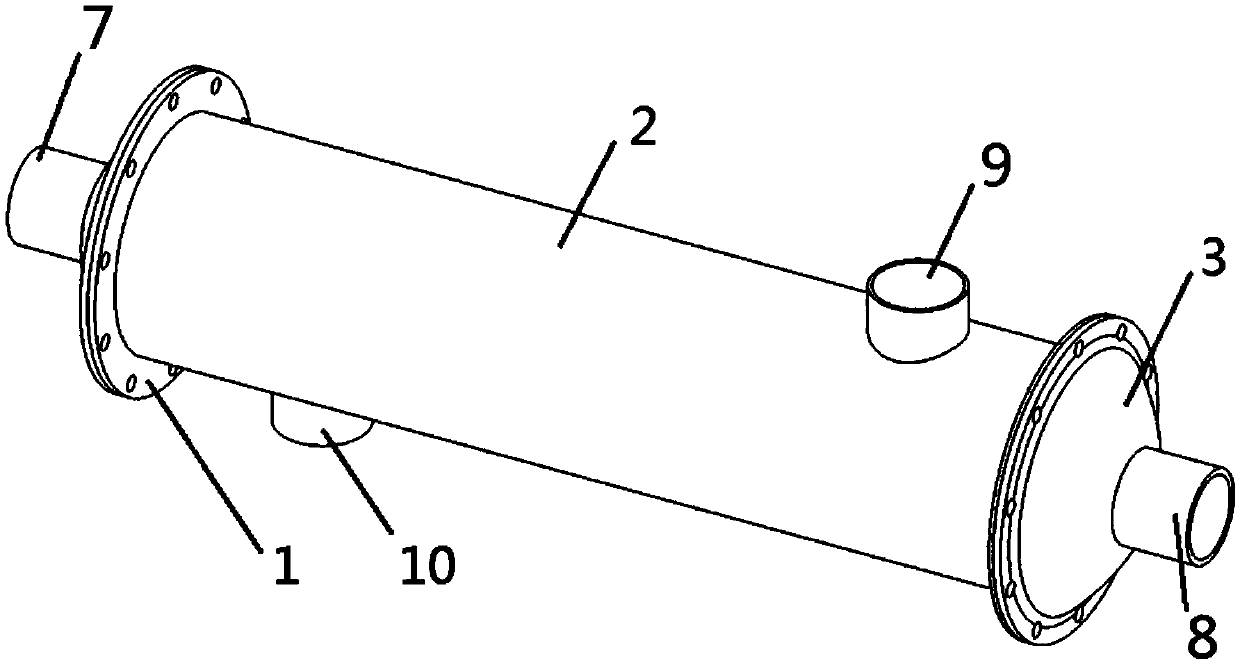

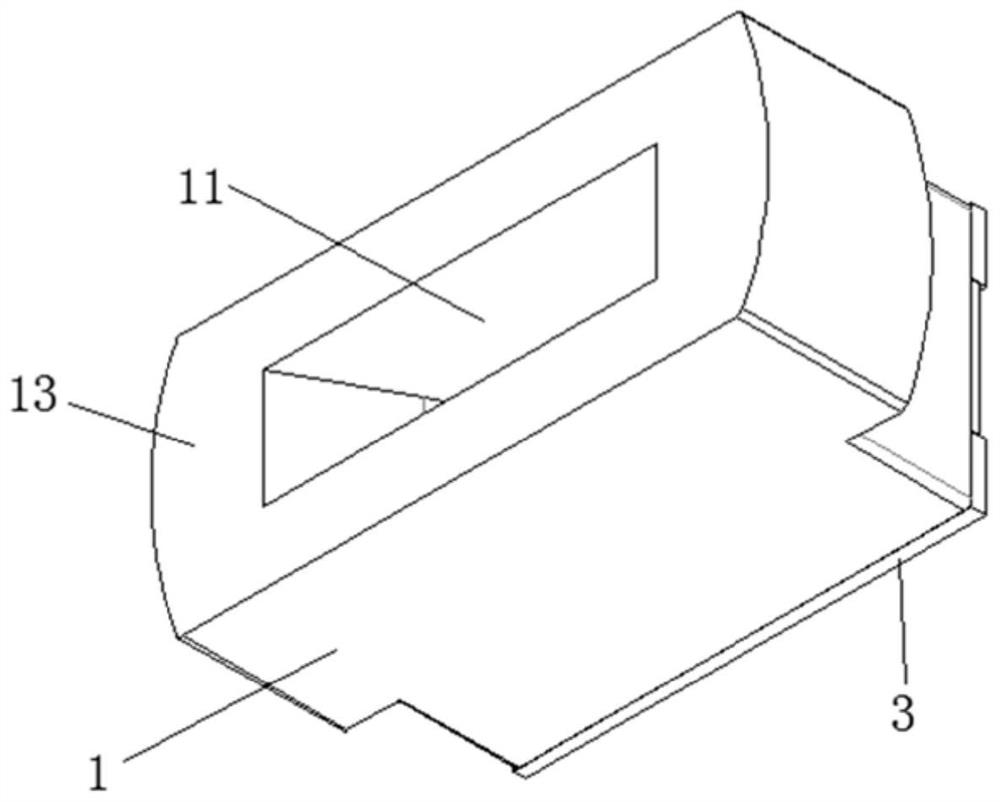

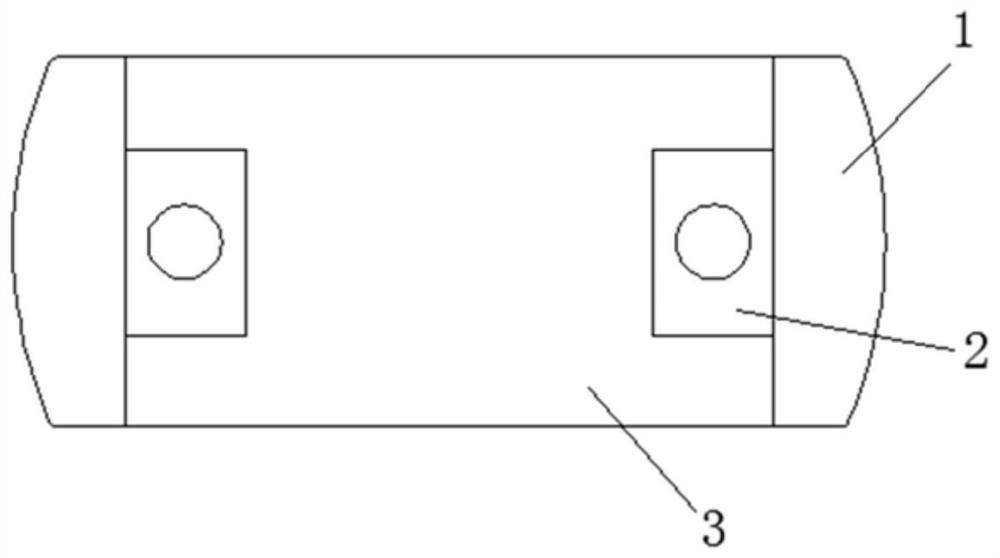

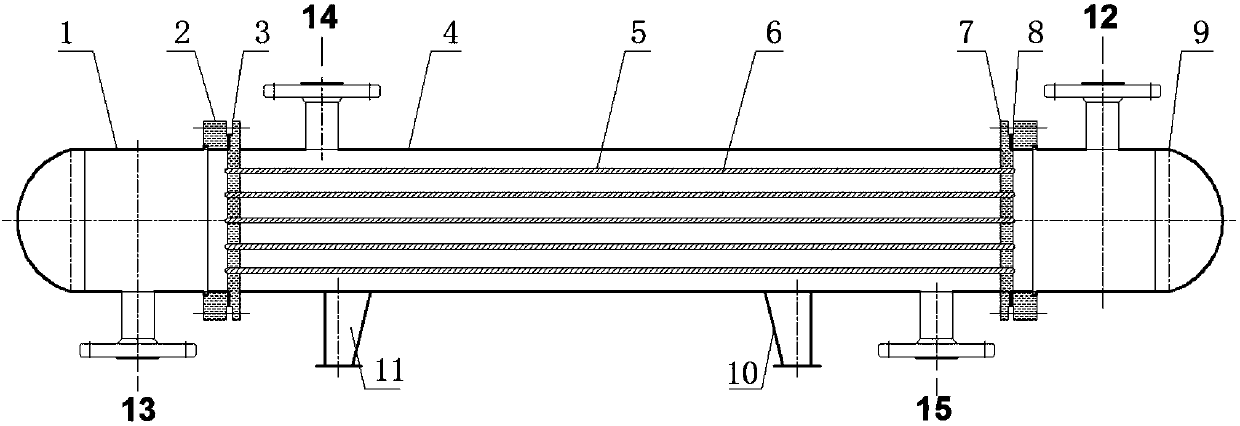

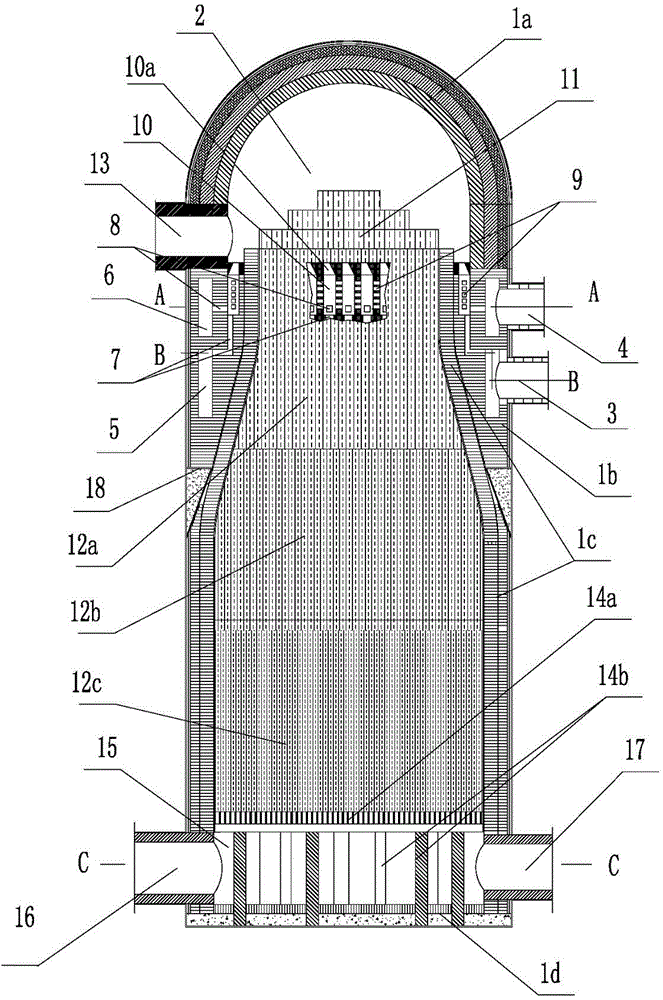

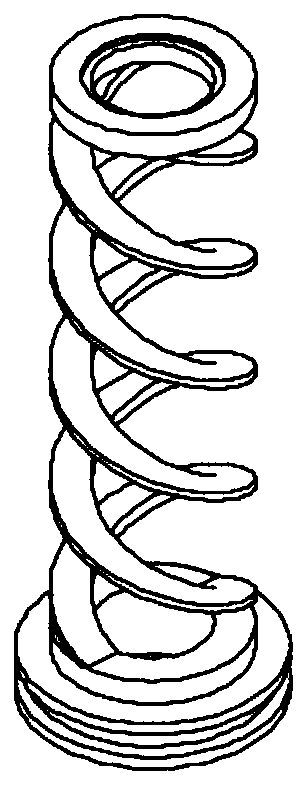

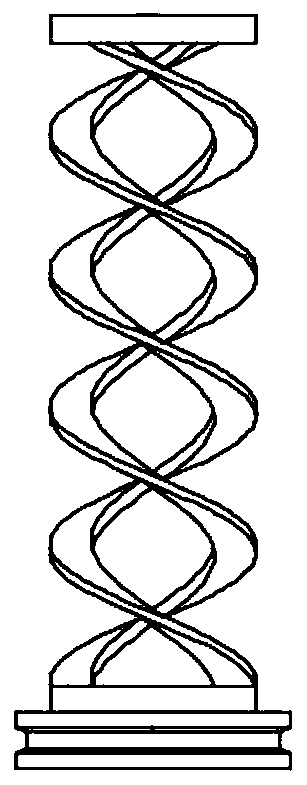

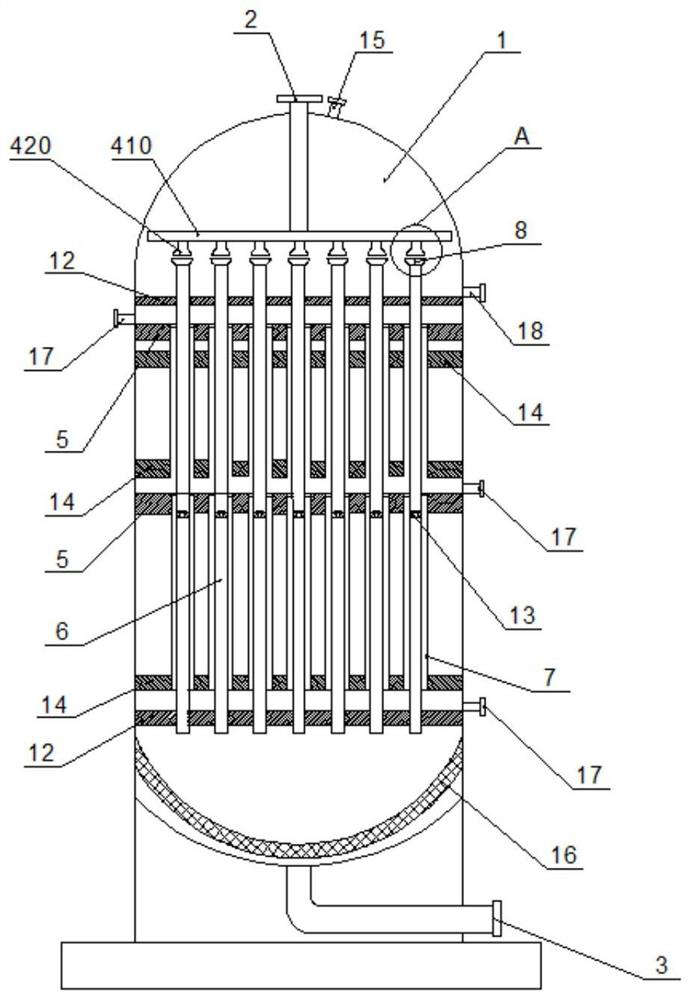

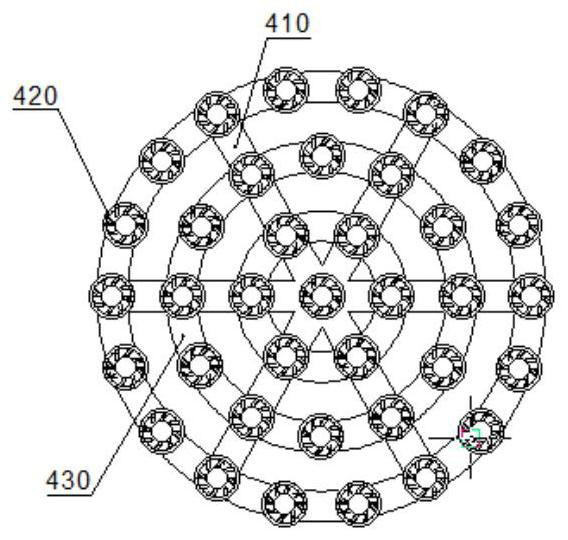

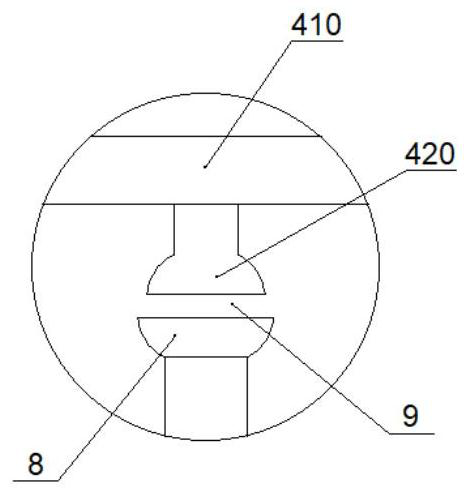

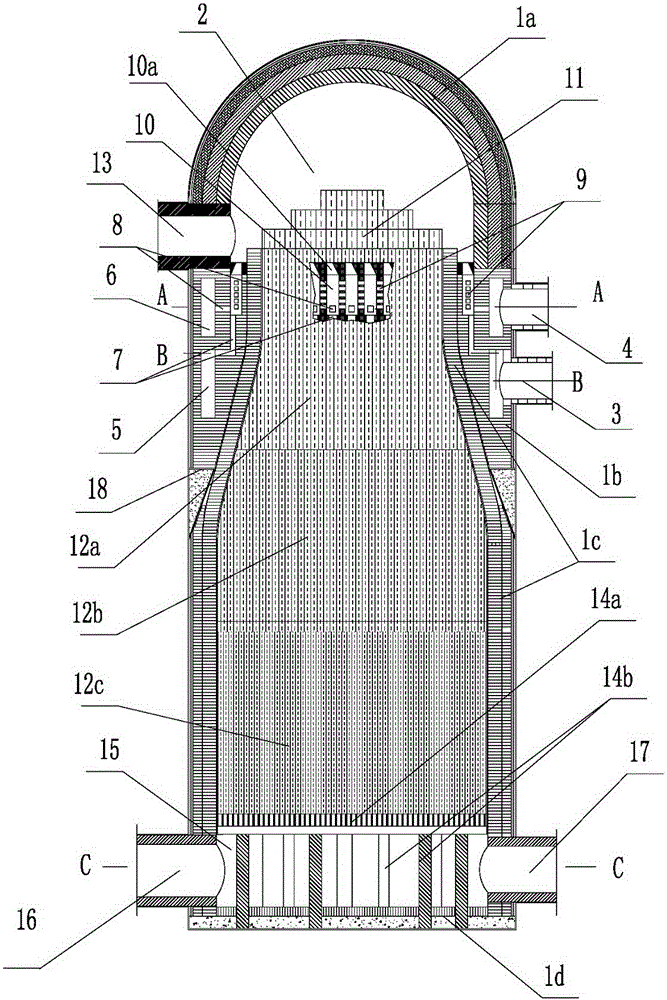

Length-variable condensable annular separation device heat exchanger

ActiveCN106969652AShorten the lengthReduce vibrationStationary tubular conduit assembliesHeat transfer modificationVapor liquidNoise level

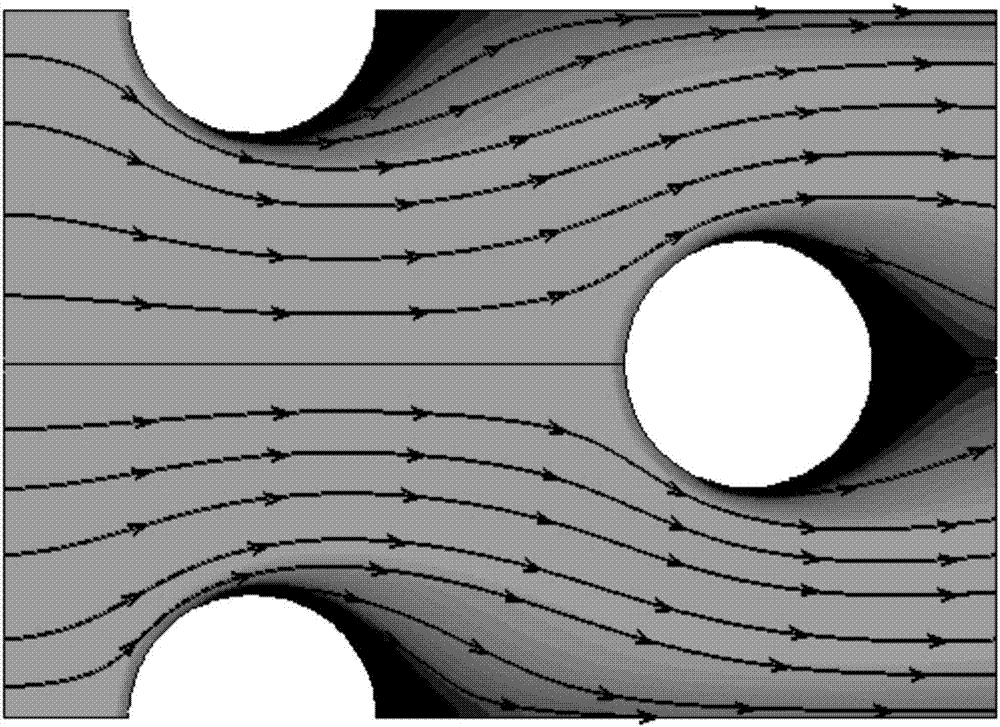

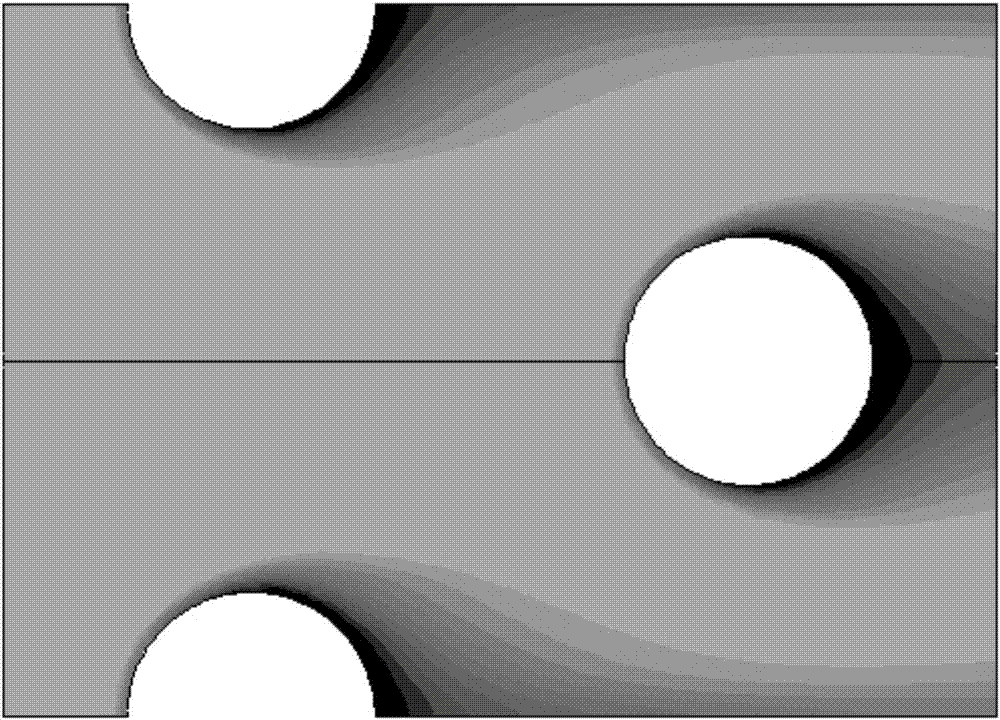

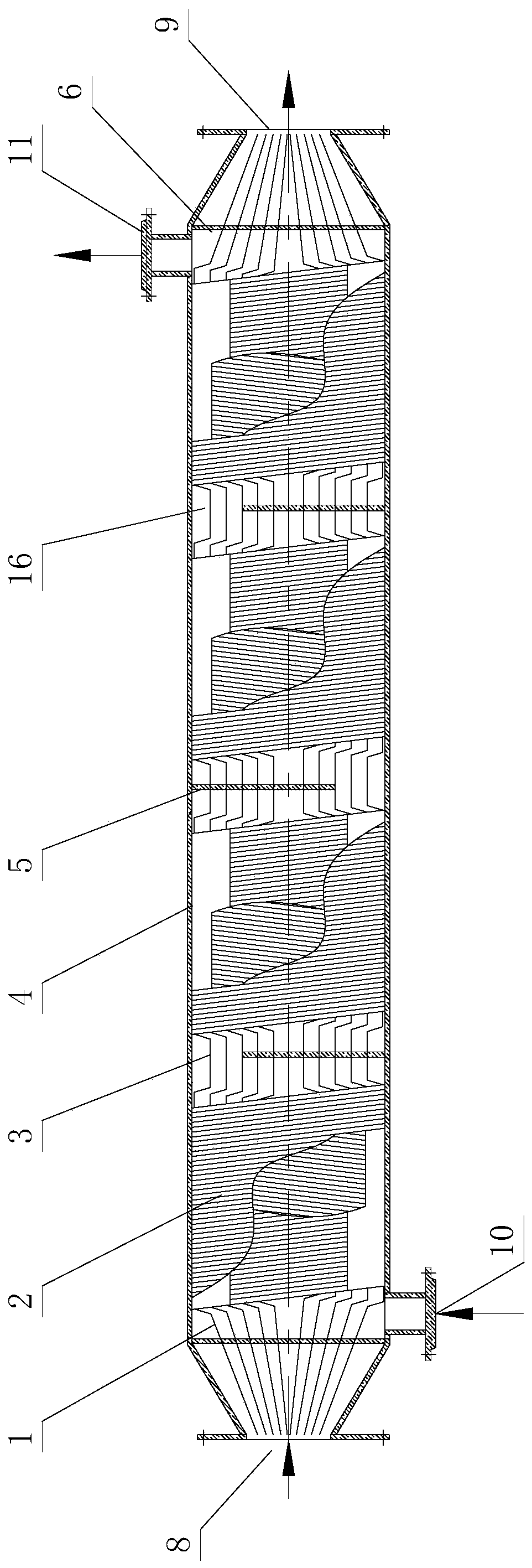

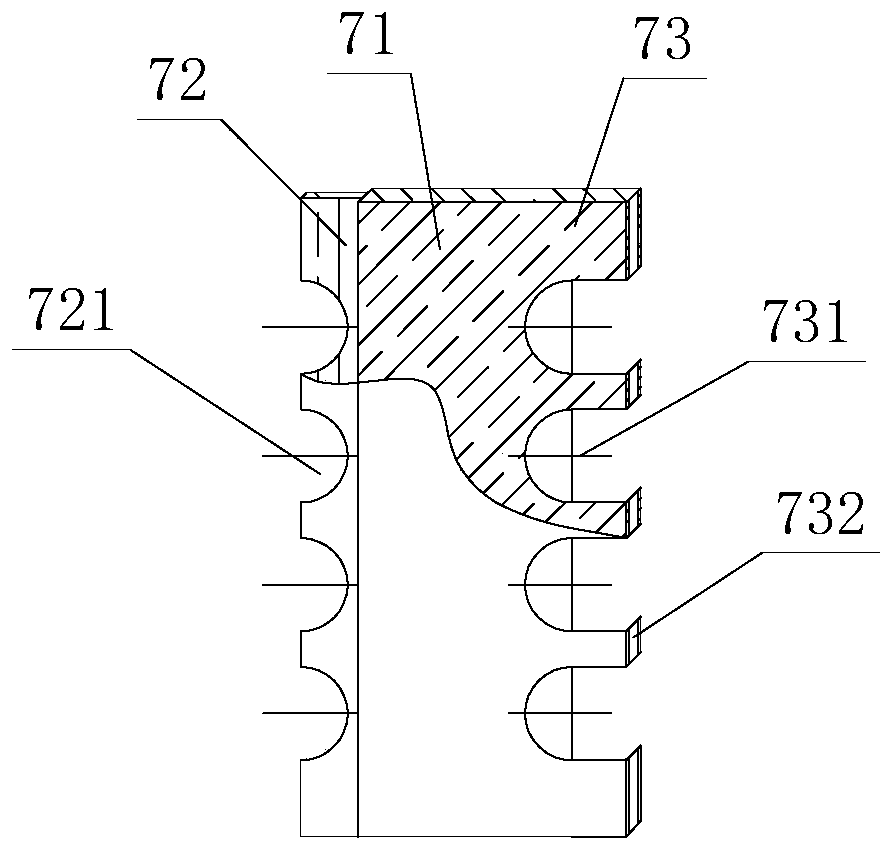

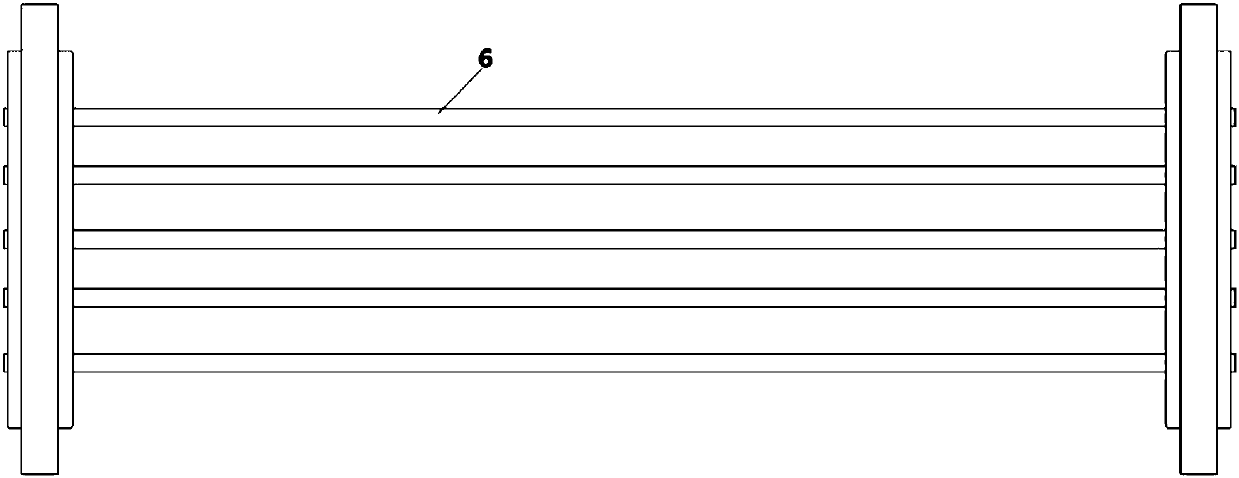

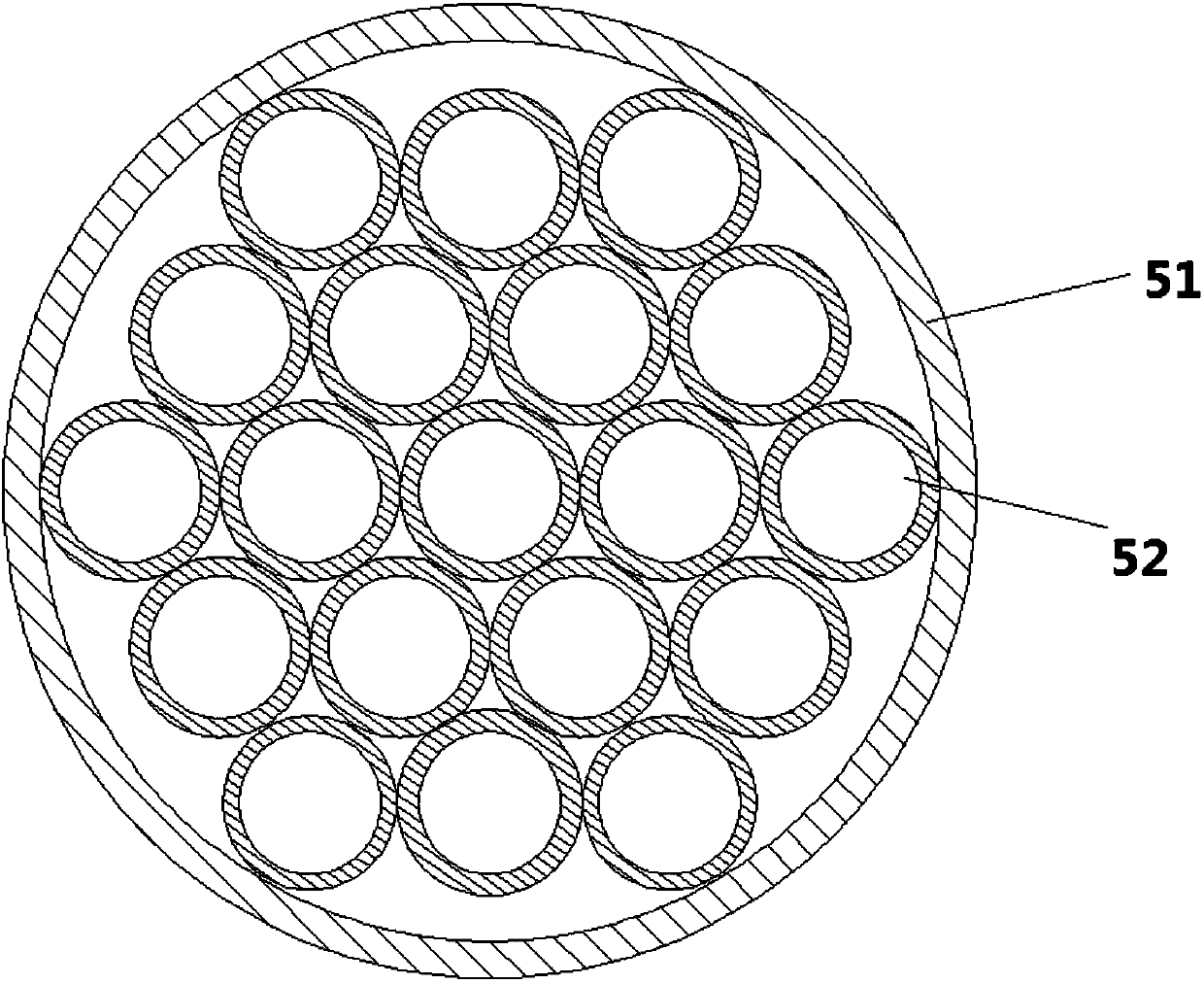

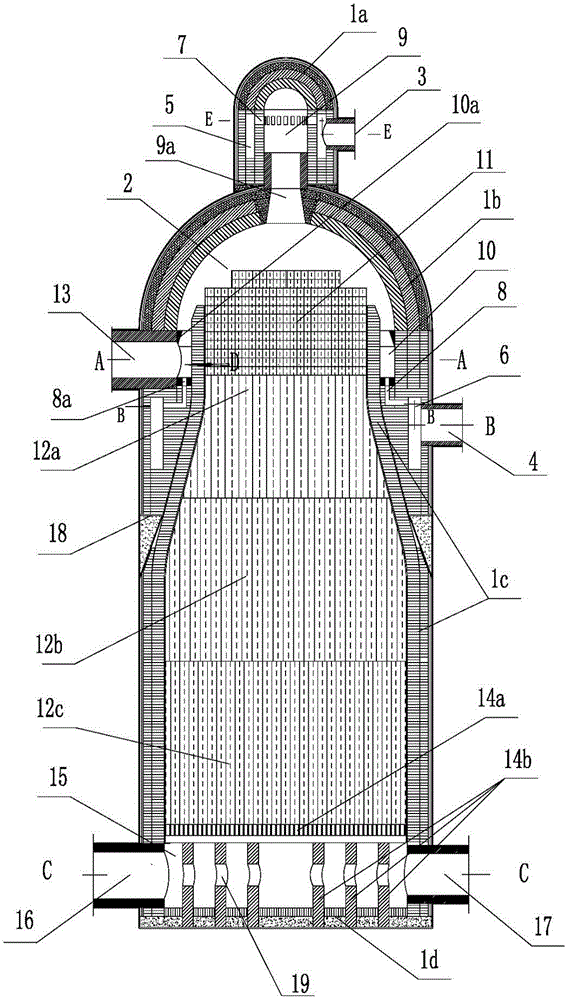

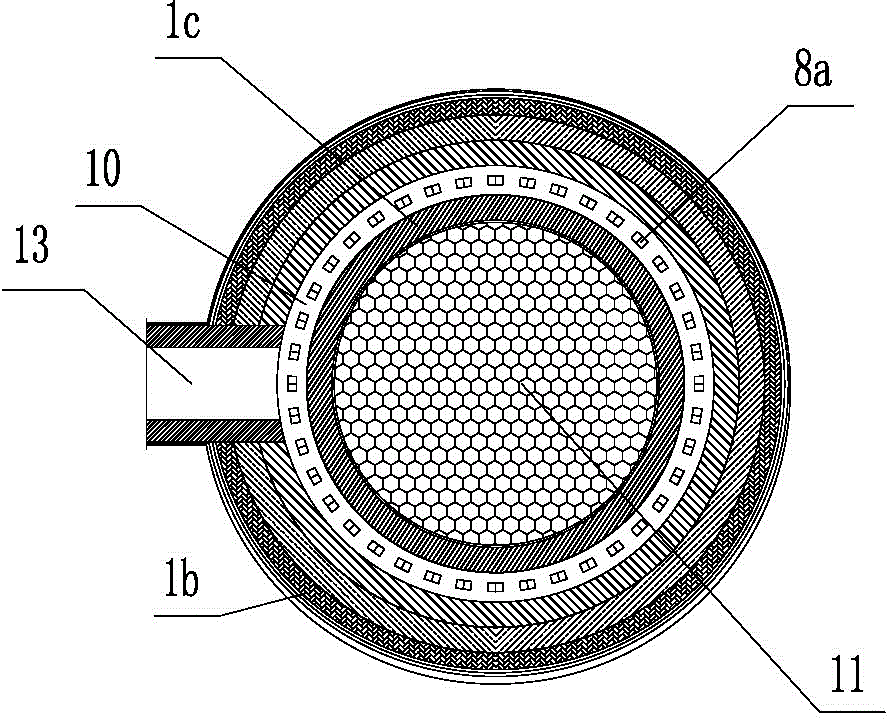

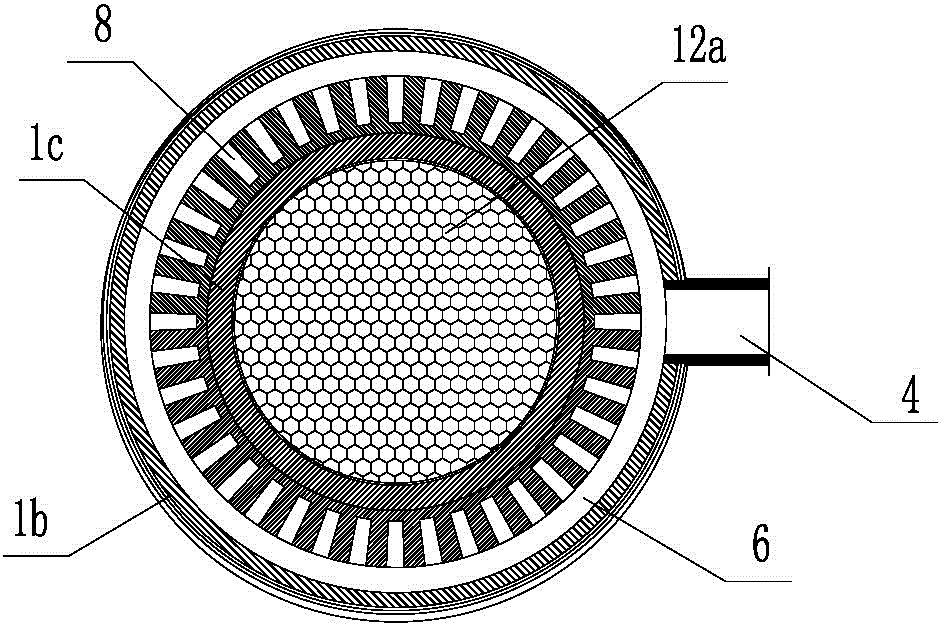

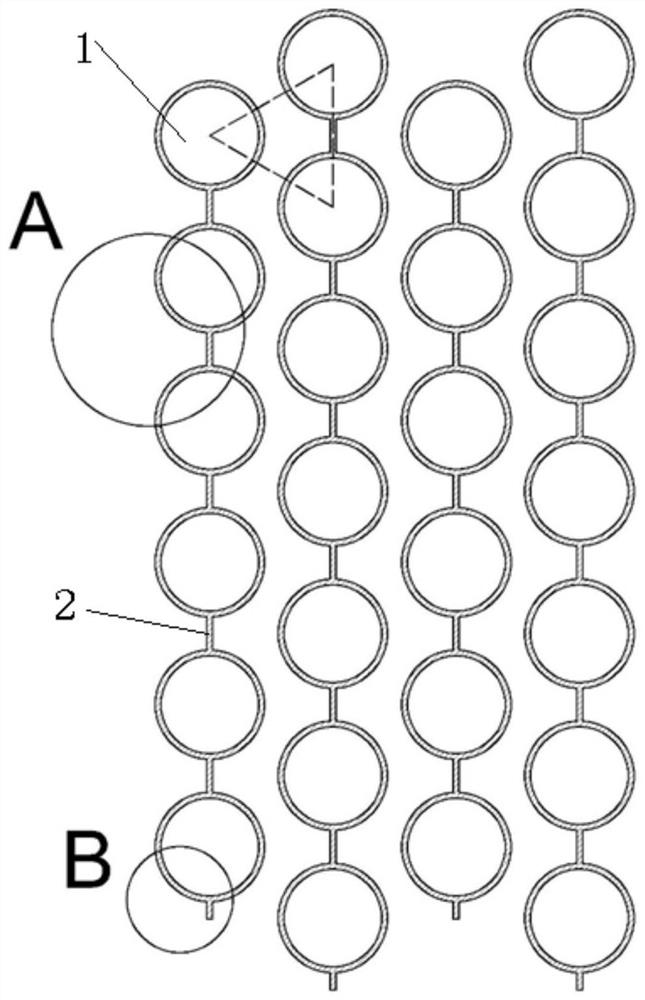

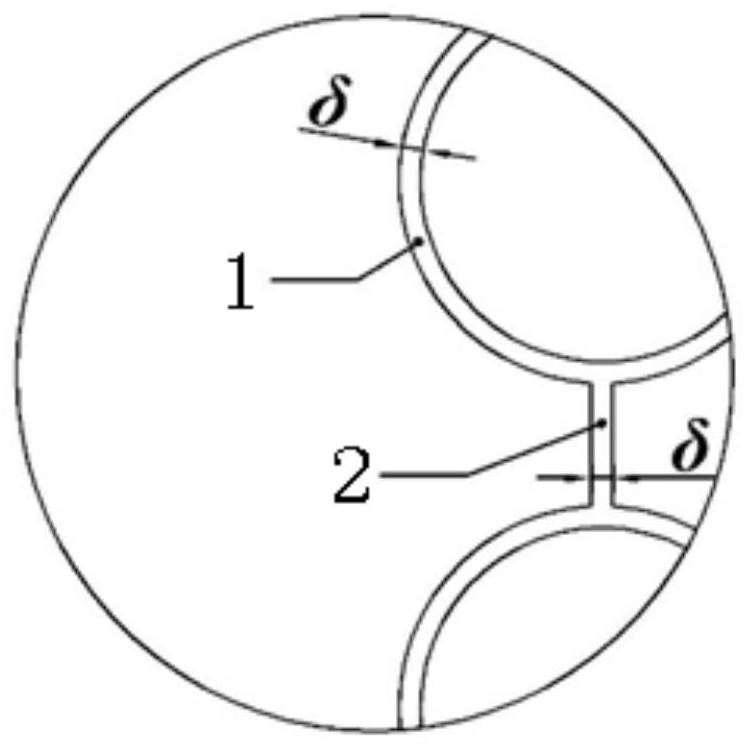

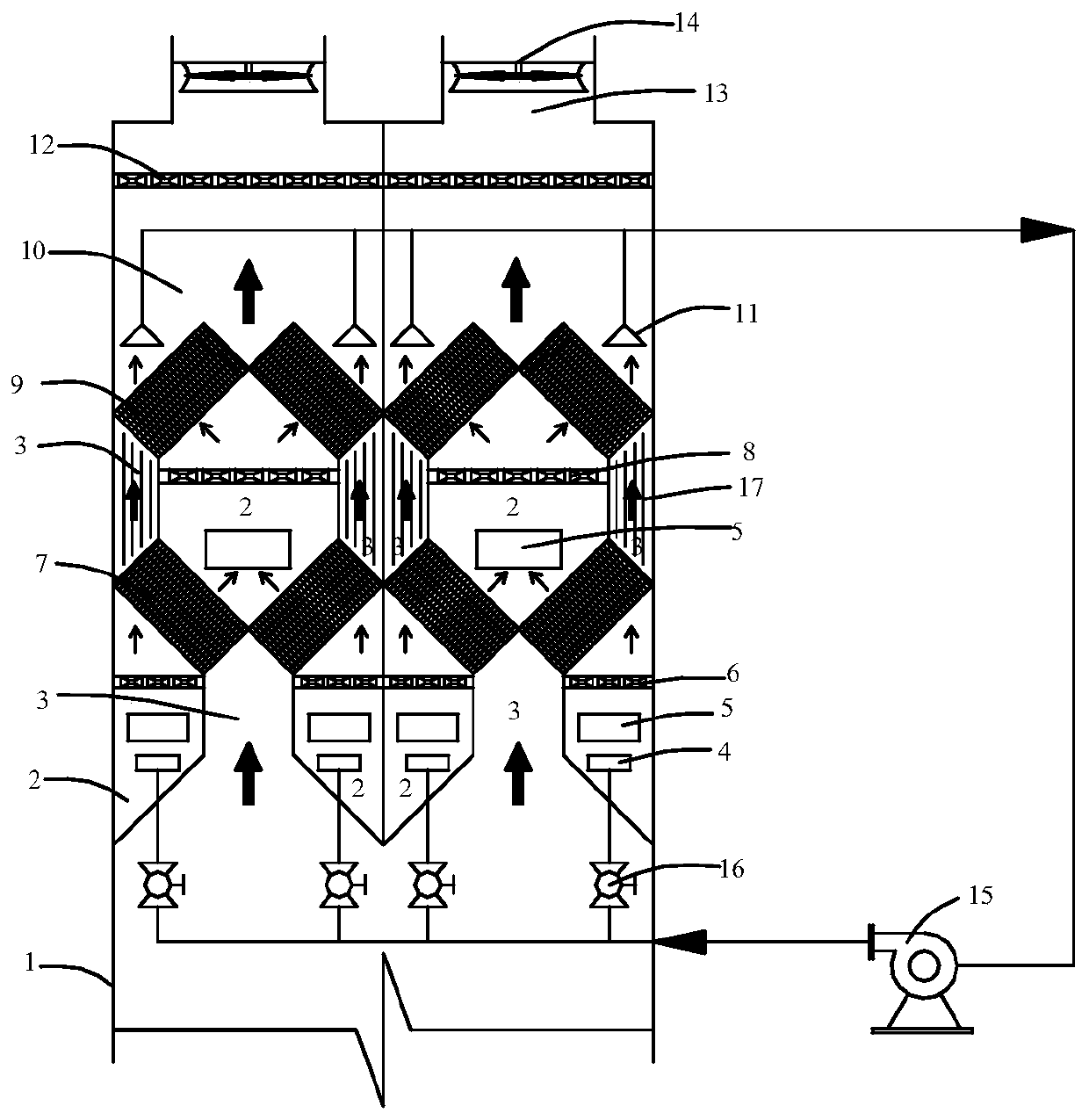

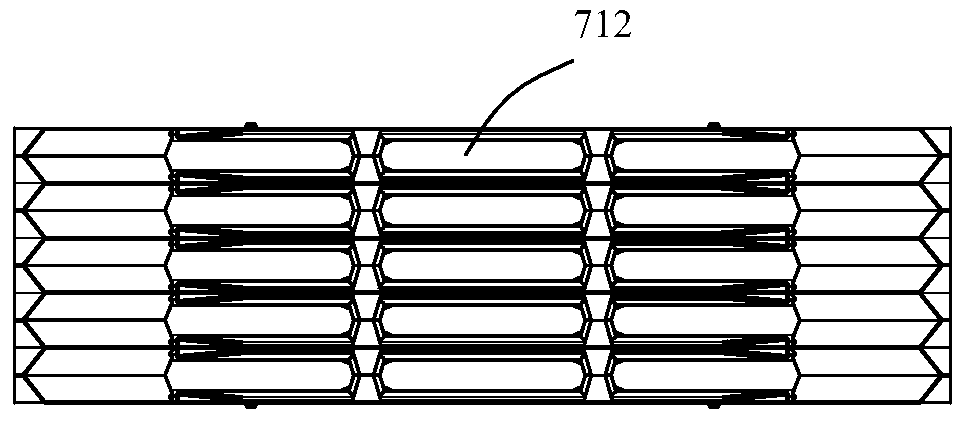

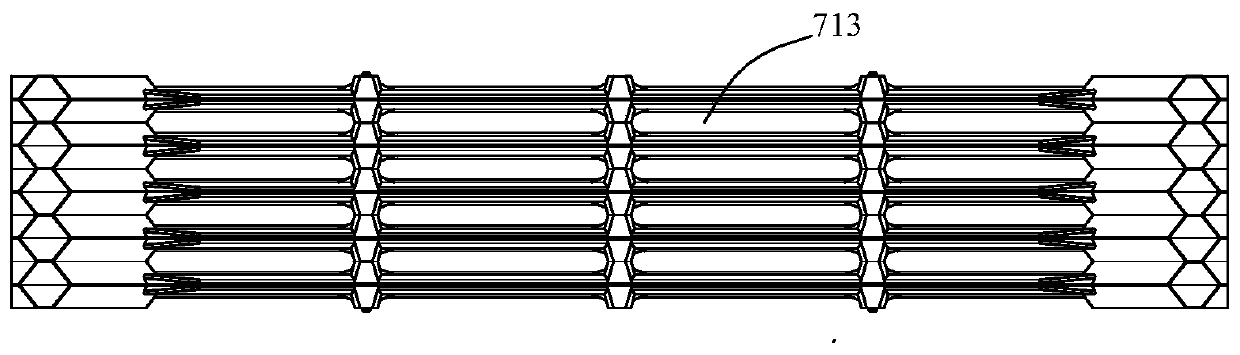

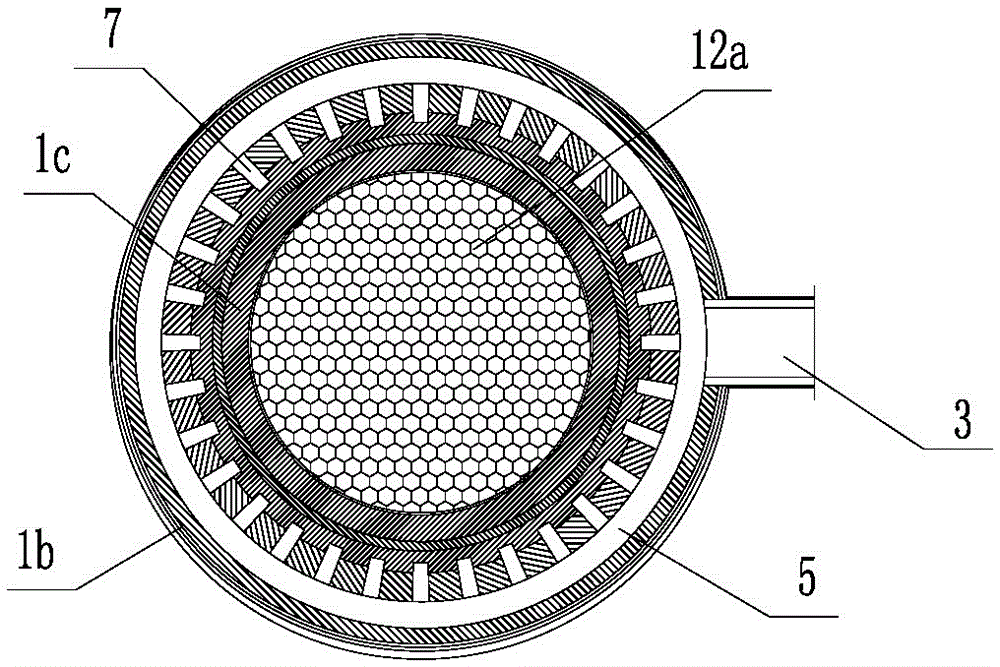

The invention provides a vapor-liquid two-phase flow tube shell type heat exchanger. The heat exchanger comprises a shell, wherein sealing heads are arranged at two ends of the shell respectively; tube plates are arranged in connection positions between the sealing heads and the shell; heat exchange tubes are connected with the tube plates at two ends; vapor phase in vapor-liquid two-phase flow can be condensed into liquid phase in the heat exchange process; the vapor-liquid two-phase flow flows in a tube process; separation devices used for decreasing vibration and reducing noise are arranged in the heat exchange tubes; a plurality of separation devices are arranged in the same heat exchange tube; the length of the separation devices is gradually reduced along the flowing direction of flow in the heat exchange tubes. According to the vapor-liquid two-phase flow tube shell type heat exchanger, the vibration of the tubes can be decreased to a maximum extent due to the length change of the separation devices when the vapor-liquid two-phase flow flows in the tubes; the noise level is reduced; meanwhile, the flowing resistance is reduced; the heat exchange uniformity is improved.

Owner:SHANDONG UNIV

Mold powder capable of effectively controlling peritectic steel thick slab narrow face depression defect

The invention relates to a mold powder capable of effectively controlling peritectic steel thick slab narrow face depression defect. The mold powder comprises the following elements by weight percent: 38.02 to 40.1 percent of Cao, 28.8 to 30.02 percent of SiO2, 9.9 to 10.5 percent of CaF2, 9.06 to 9.5 percent of Na2O, 1.55 to 1.93 percent of MgO, 1.5 to 1.93 percent of AL203, 0.01 to 0.037 percent of Li2O and 0.035 to 0.053 percent of MnO. The mold powder has good lubricating property and spreadability. Because of the high melting speed, the invention can complement the quick consumption of liquid slag in time; because of the high alkalinity, the invention has strong absorbing and mixing capability; and because of the proper viscosity and the reasonable crystallization temperature, the invention plays an important role in uniformity. When the mold powder is applied to the casting of peritectic steel thick slab, the slag entrapment defect caused by crystallizer liquid level fluctuation is reduced greatly, the heat transmission uniformity is improved greatly and the surface quality of casting blank is good.

Owner:SHOUGANG CORPORATION

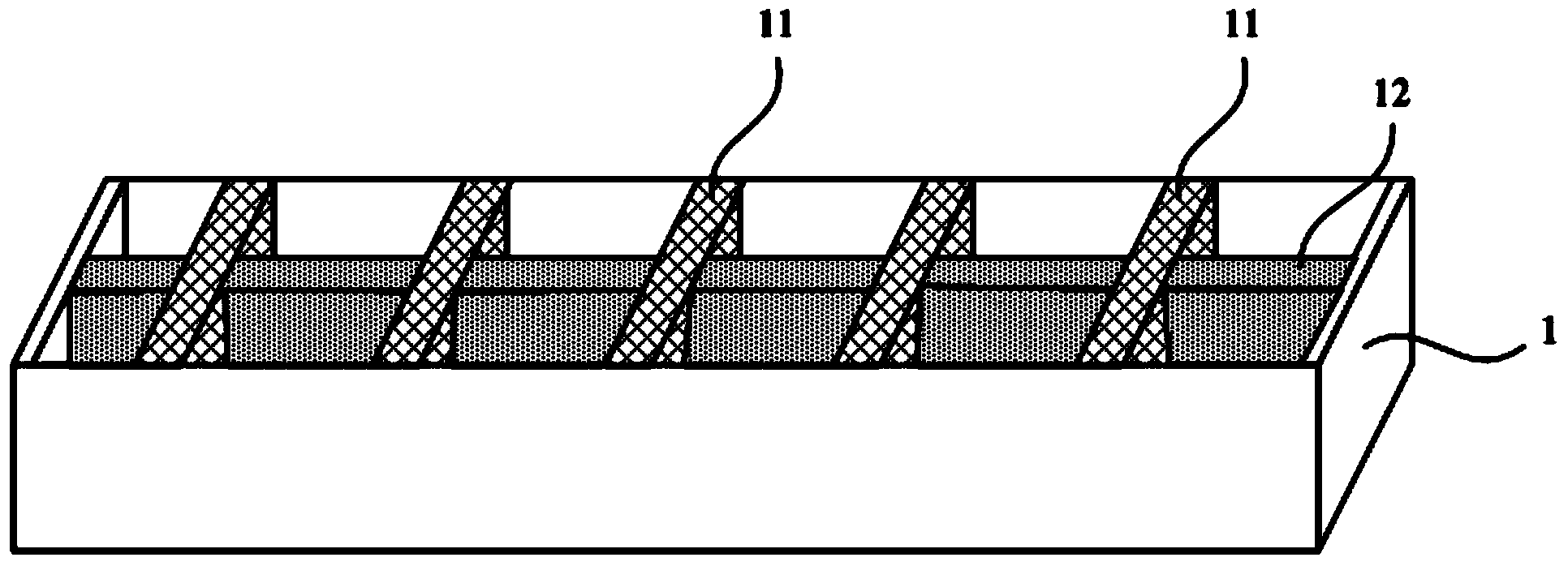

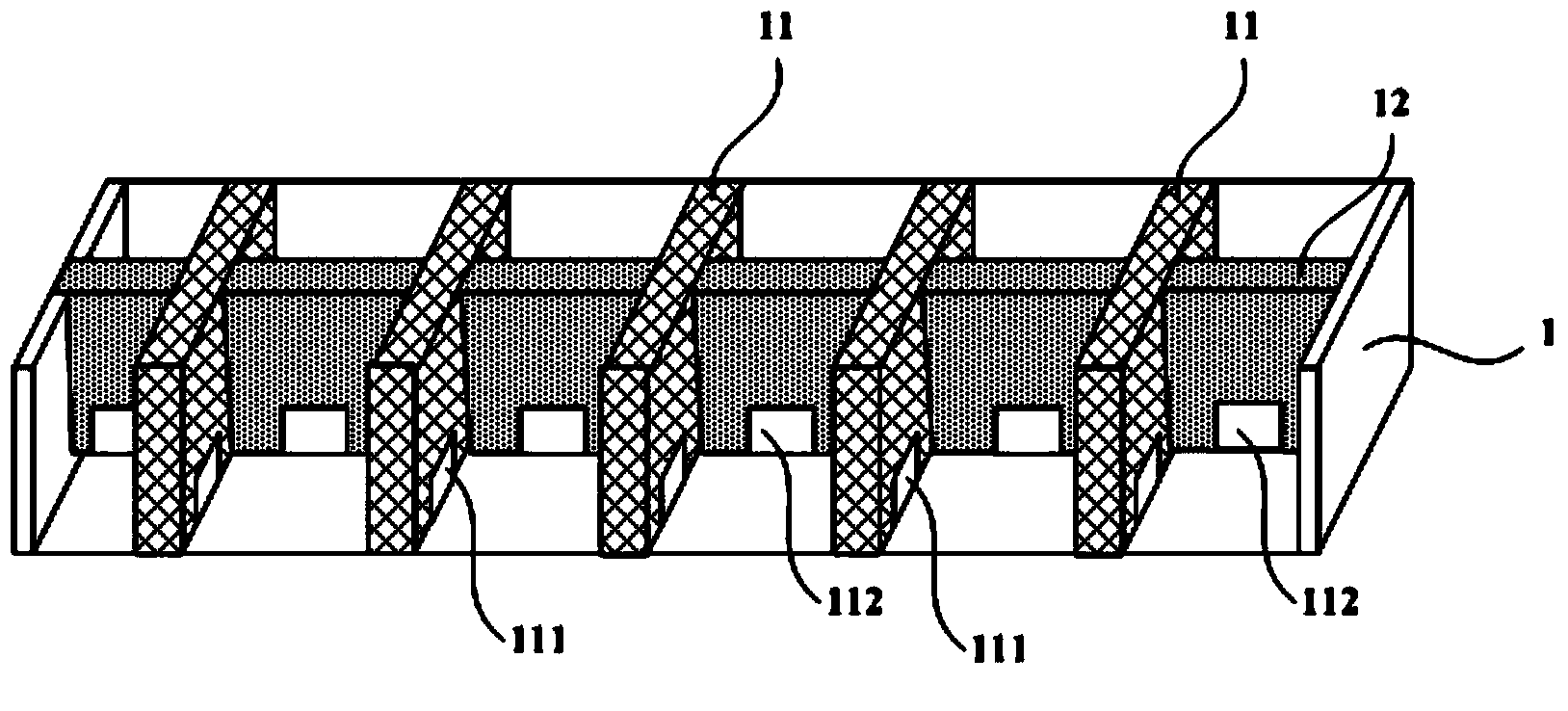

Evaporation source device for evaporator and evaporator

ActiveCN104109834AReduces the effects of lower thermal conductivityImprove uniformityVacuum evaporation coatingSputtering coatingCrucibleEvaporation

The invention relates to the technical field of evaporation equipment, and discloses an evaporation source device for an evaporator and the evaporator. The evaporation source device for evaporator provided by the invention comprises a crucible; the crucible slot of the crucible is provided with at least one first conductive clapboard along a first direction, and each of the first conductive clapboard is connected with the crucible wall; and the crucible slot is provided with at least one second conductive clapboard fixedly connected with the first conductive clapboard along a second direction, and each of the second conductive clapboard is connected with the crucible wall. The technical scheme provided by the invention can shorten the heat transfer path in an evaporation material, realize even transfer of heat in the evaporation material, and further improve the thermal stability of the organic material evaporation, thereby maintaining stability of plating rate and improving the yield rate of the organic material evaporation.

Owner:HEFEI XINSHENG OPTOELECTRONICS TECH CO LTD +1

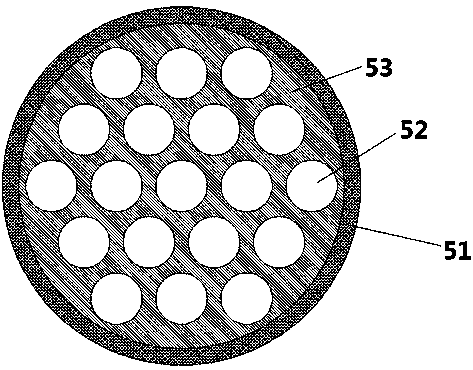

Wing-shaped pipe type adsorption column for polycrystalline silicon tail gas recovery system

InactiveCN105964105AImprove heat transfer efficiencyShorten the timeGas treatmentHydrogen separation using solid contactHydrogenPolycrystalline silicon

The invention discloses a wing-shaped pipe type adsorption column for a polycrystalline silicon tail gas recovery system. The wing-shaped pipe type adsorption column comprises an adsorption column body and a tracing tube, wherein the tracing tube is mounted on the outer casing wall of the adsorption column body; backflow sleeves are mounted in the adsorption column body through supporting plates; each backflow sleeve comprises an outer pipe and an inner pipe; each inner pipe is positioned inside the corresponding outer pipe; a cavity between the outer side wall of each inner pipe and the inner side wall of the corresponding outer pipe serves as a medium passage; a sealing cap for enabling medium to flow back is mounted at the top of each outer pipe; a plurality of fins are mounted on the outer side wall of each outer pipe; an adsorbent filling opening and a hydrogen outlet are also formed in the top of the adsorption column body; an adsorbent discharging opening is formed in the bottom of the adsorption column body; a main hydrogen pipe and a plurality of groups of hydrogen inlet branch pipes are also mounted on the side wall of the bottom of the adsorption column body; the hydrogen inlet branch pipes are connected with the main hydrogen pipe. The wing-shaped pipe type adsorption column has the benefits that the heat exchange efficiency is high; heating is uniform; the production cost is reduced; equipment safety and reliability are improved.

Owner:成都瑞奇智造科技股份有限公司

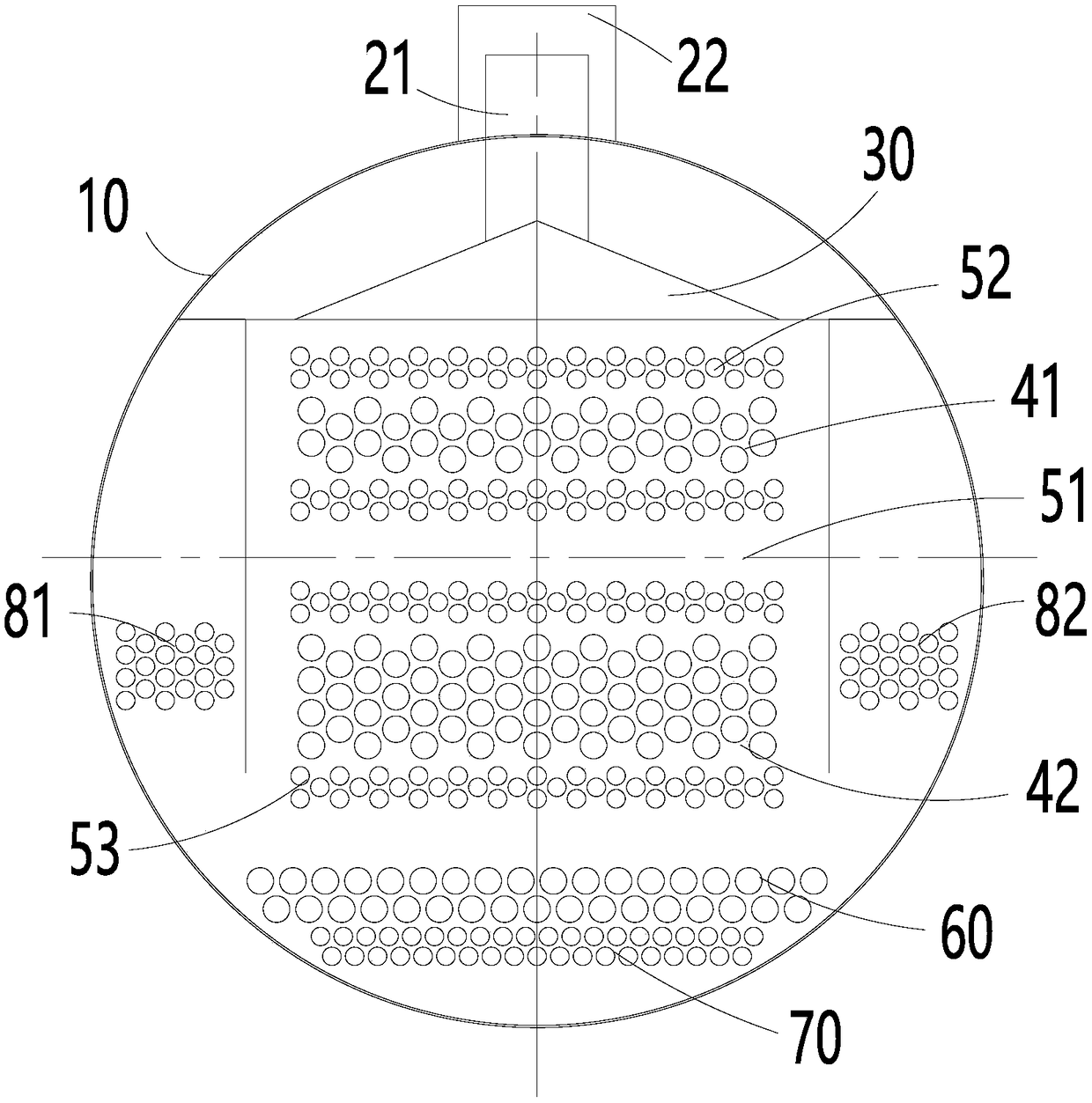

Shell-tube-type phase-change energy storage heat exchanger

InactiveCN107631657AReduce volumePromote mutual disturbanceHeat storage plantsEngineeringPhase change

The invention discloses a shell-tube-type phase-change energy storage heat exchanger. The shell-tube-type phase-change energy storage heat exchanger comprises a heat exchanger shell cylinder, a heat source fluid inlet and a heat source fluid outlet, wherein the heat source fluid inlet and the heat source fluid outlet are formed in the two sides of the heat exchanger shell cylinder; the upper sidewall and the lower side wall of the heat exchanger shell cylinder are provided with a phase-change material filling port and a phase-change material discharging port correspondingly; and a plurality groups of heat exchange round tubes of which the two ends communicate with the heat source fluid inlet and the heat source fluid outlet correspondingly are arranged in the heat exchanger shell cylinder, and fins are evenly distributed on the outer wall of each heat exchange round tube. According to the shell-tube-type phase-change energy storage heat exchanger, by designing arrangement of the heatexchange round tubes, the heat exchanger fully adapts to the flowing and heat exchanging characteristics in the heat exchange process of a phase-change material, a temperature field and a velocity field achieve the synergistic effect, the heat exchange uniformity is improved, and the heat exchange rate is increased; furthermore, by additionally arranging the fins, the heat exchange area of the heat exchanger is effectively increased, the heat exchange coefficient is increased, and convection heat exchange is enhanced; in addition, by designing arrangement of the fins, the flow guiding effect of the fins is fully utilized, mutual disturbance among multiple tube bundles is enhanced, convergency and circulation of a liquid-phase area are promoted, the heat exchange rate is increased, and theheat exchange efficiency is improved.

Owner:XI AN JIAOTONG UNIV

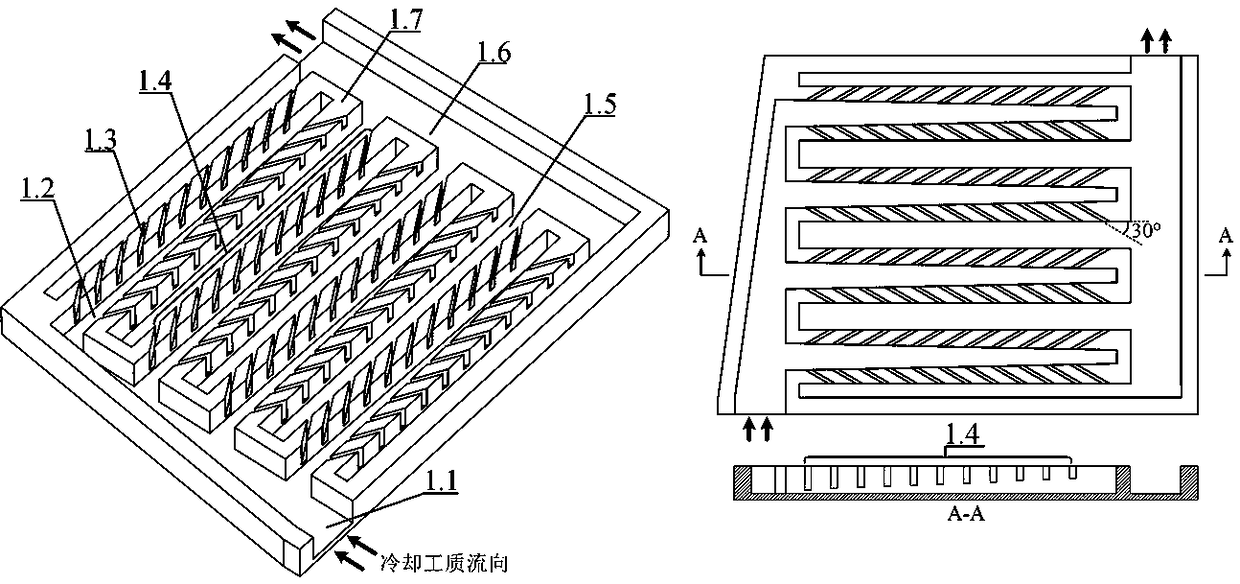

Microchannel heat sink having special shunting structure

ActiveCN108601289AAchieve homogenizationImprove abilitiesCooling/ventilation/heating modificationsHeat sinkStreamflow

The invention discloses a microchannel heat sink having the special shunting structure. The heat sink comprises a shunting module and a uniform heating base plate which is arranged above the shuntingmodule and directly contacts with heat release equipment, wherein the shunting module comprises a main in-flow channel, a shunting sub channel, an overflow channel, an out-flow sub channel and a mainout-flow channel, the cooling working medium enters the heat sink from the main in-flow channel, the main in-flow channel employs the cross section tapered structure, the cooling working medium is guaranteed to distribute to each shunting sub channel, the overflow channel is formed through directly processing on a solid wall surface of the shunting sub channel, through inclination arrangement, theoverflow channel and the shunting sub channel are made to form a relatively small incident flow angle, so flow resistance is reduced. Along the main flow direction in the shunting sub channel, heightof the overflow channel is gradually reduced, the cross section tapered structure is employed at the shunting sub channel, the excessive cooling work medium can be prevented from flowing to the downstream overflow channel of the sub channels, flow distribution in the whole heat sink is made to be uniform, and heat exchange uniformity of the heat sink is guaranteed. The method is advantaged in that through the special shunting structure and the overflow channel structure, the distribution process in the heat sink is made to be uniform, and integral heat exchange efficiency and heat exchange uniformity of the heat sink are improved.

Owner:SICHUAN UNIV

Composition and ceramic atomizing core thereof

The invention relates to a composition and a ceramic atomizing core thereof. The composition comprises the following components: ceramic powder, a sintering aid, a pore-forming agent, a plasticizer, a solvent and a dispersing agent. A porous even heating layer obviously improves the heat transfer uniformity, and effectively avoids the phenomena of uneven heating, local overheating, core pasting and the like.

Owner:SHENZHEN GEEKVAPE TECH CO LTD

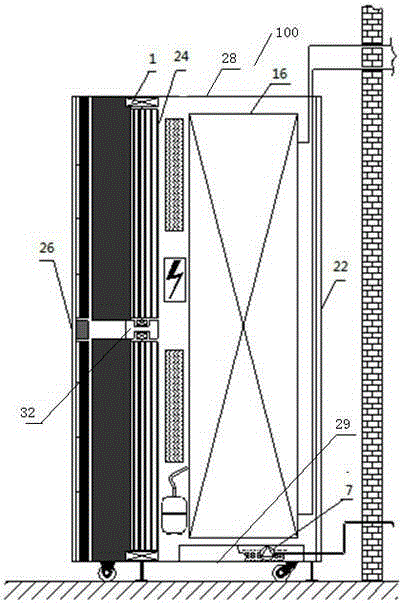

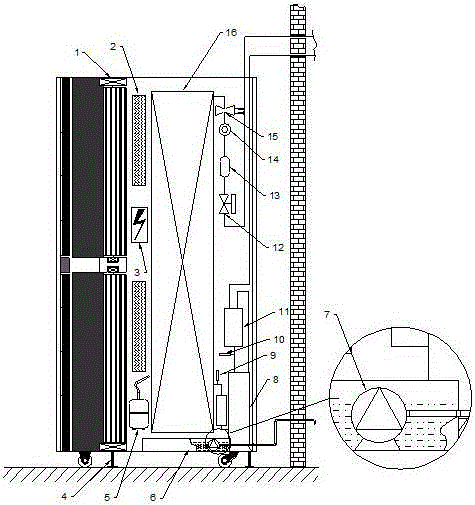

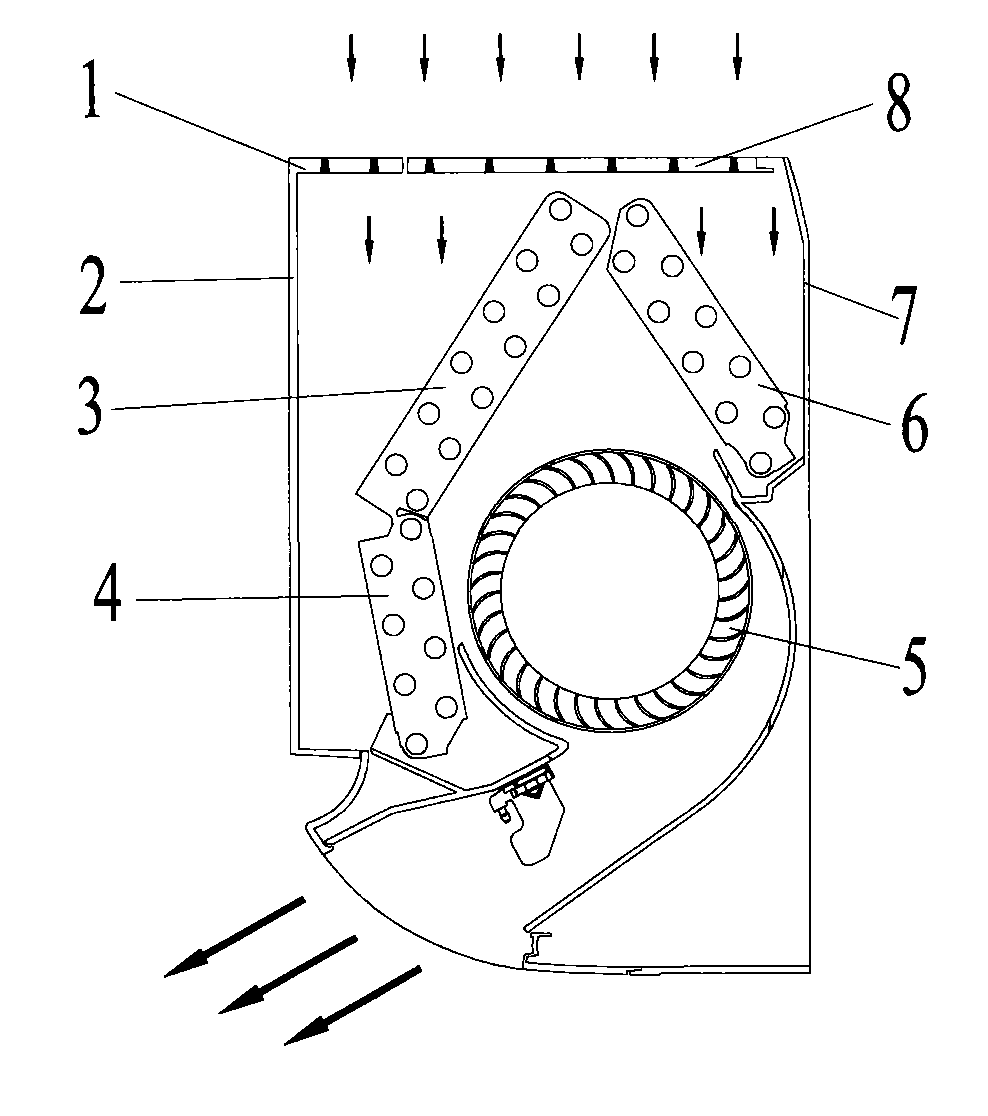

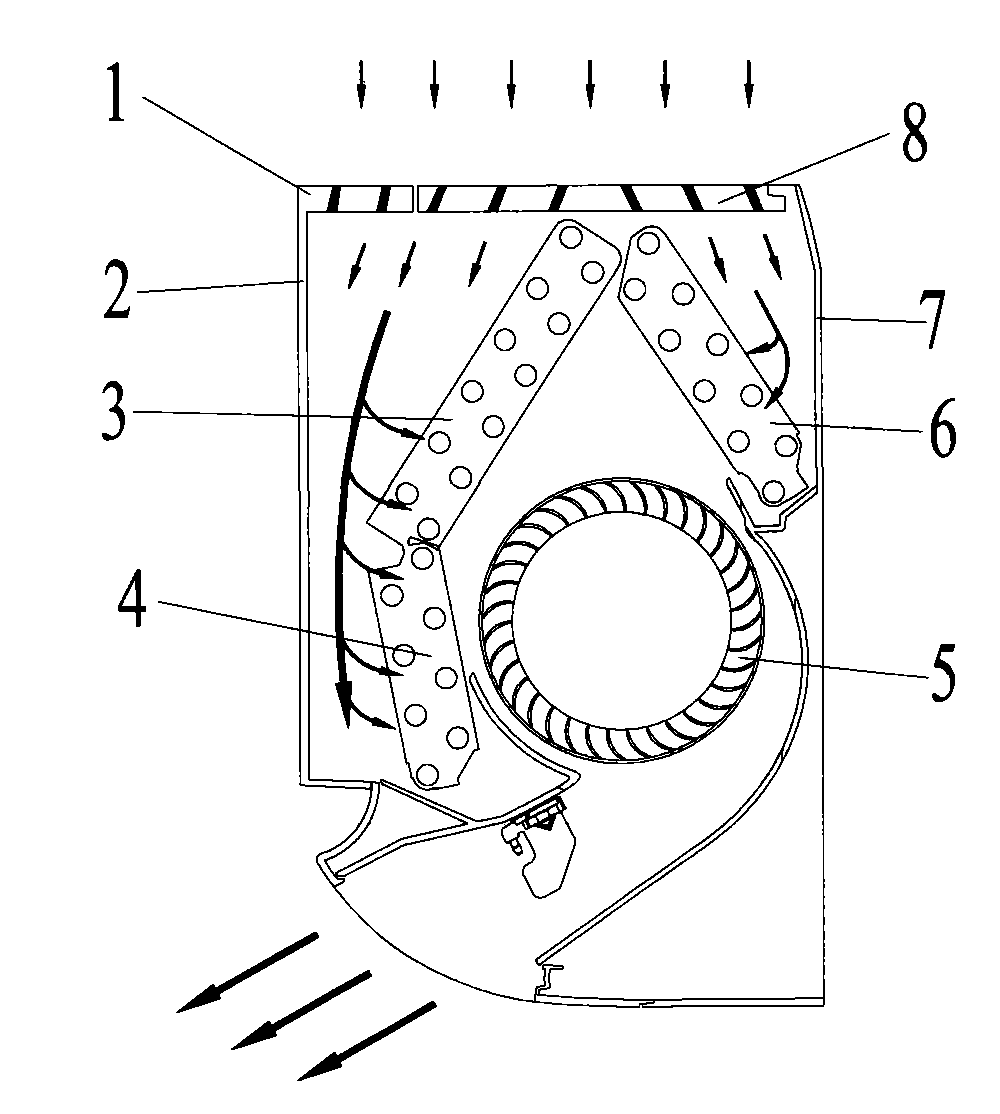

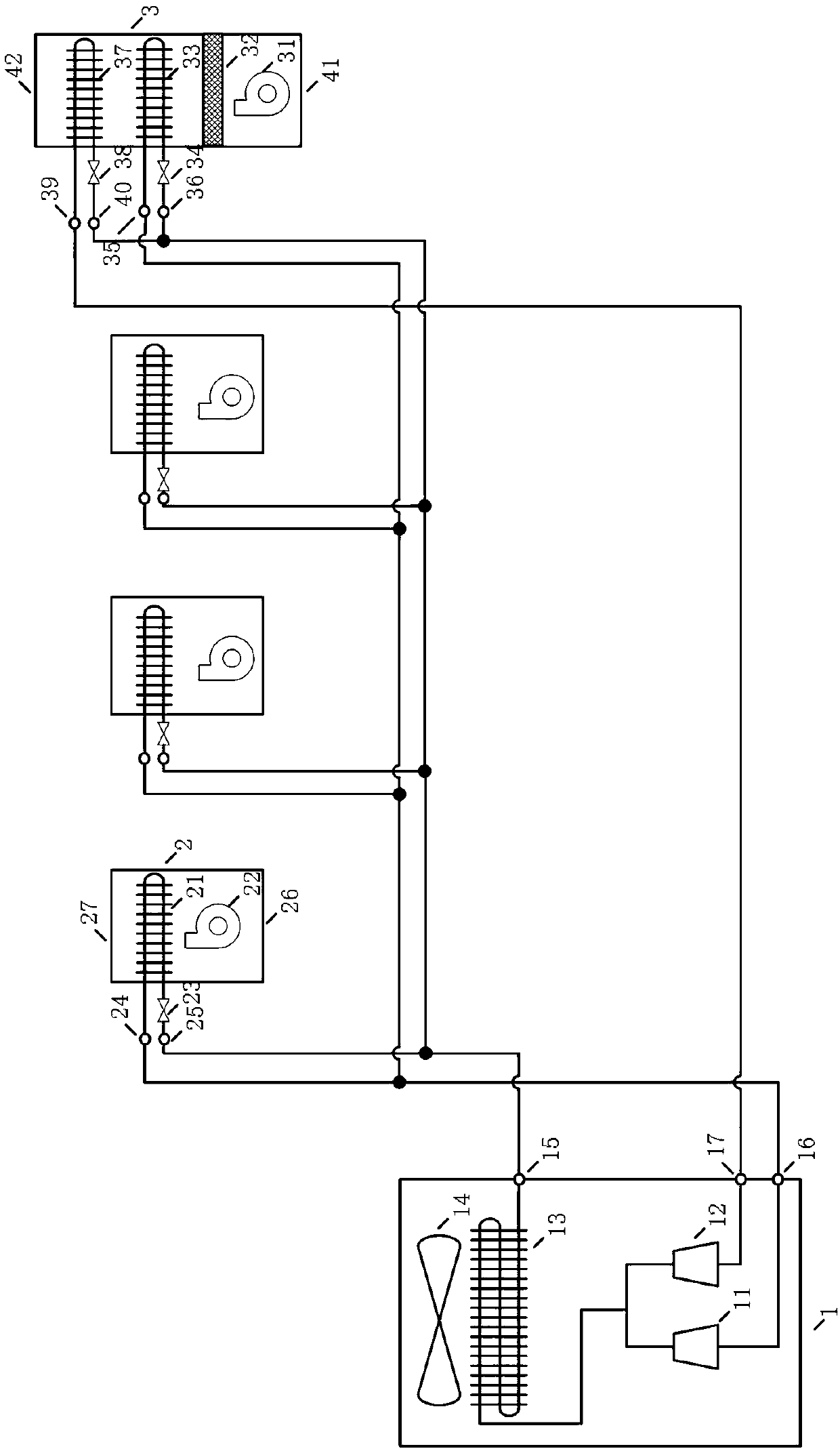

Air conditioning system for computer room

InactiveCN105258212AImprove heat transfer uniformityImprove heat transfer efficiencySpace heating and ventilation safety systemsLighting and heating apparatusElectric machineryEngineering

The invention discloses an air conditioning system for a computer room. The air conditioning system for the computer room comprises an indoor unit and an outdoor unit set placed outside the computer room. The indoor unit is placed in a cabinet chamber and comprises a machine shell. The machine shell comprises a front door plate and a rear door plate, an upper plate and a lower plate, a left side plate and a right side plate which are arranged oppositely respectively. The rear door plate is provided with an air inlet. The front door plate is provided with an air outlet. The indoor unit further comprises a heat exchanger and cross-flow blowers. The heat exchanger is arranged in the machine shell. The cross-flow blowers are located on the side close to the front door plate. The cross-flow blowers comprise cross-flow fans, driving motors, volutes and volute tongues. The driving motors drive the cross-flow fans. Air passages are formed by the volutes and the volute tongues. The driving motors are installed on the upper plate and / or the lower plate. The volutes and the volute tongues are installed on the machine shell. According to the air conditioning system for the computer room, the technical problems that an existing air conditioning system for a computer room is too high in energy consumption and big in noise are solved. The air conditioning system for the computer room is specifically suitable for various large-scale data computer rooms.

Owner:GUANGDONG HIWAVE TECH

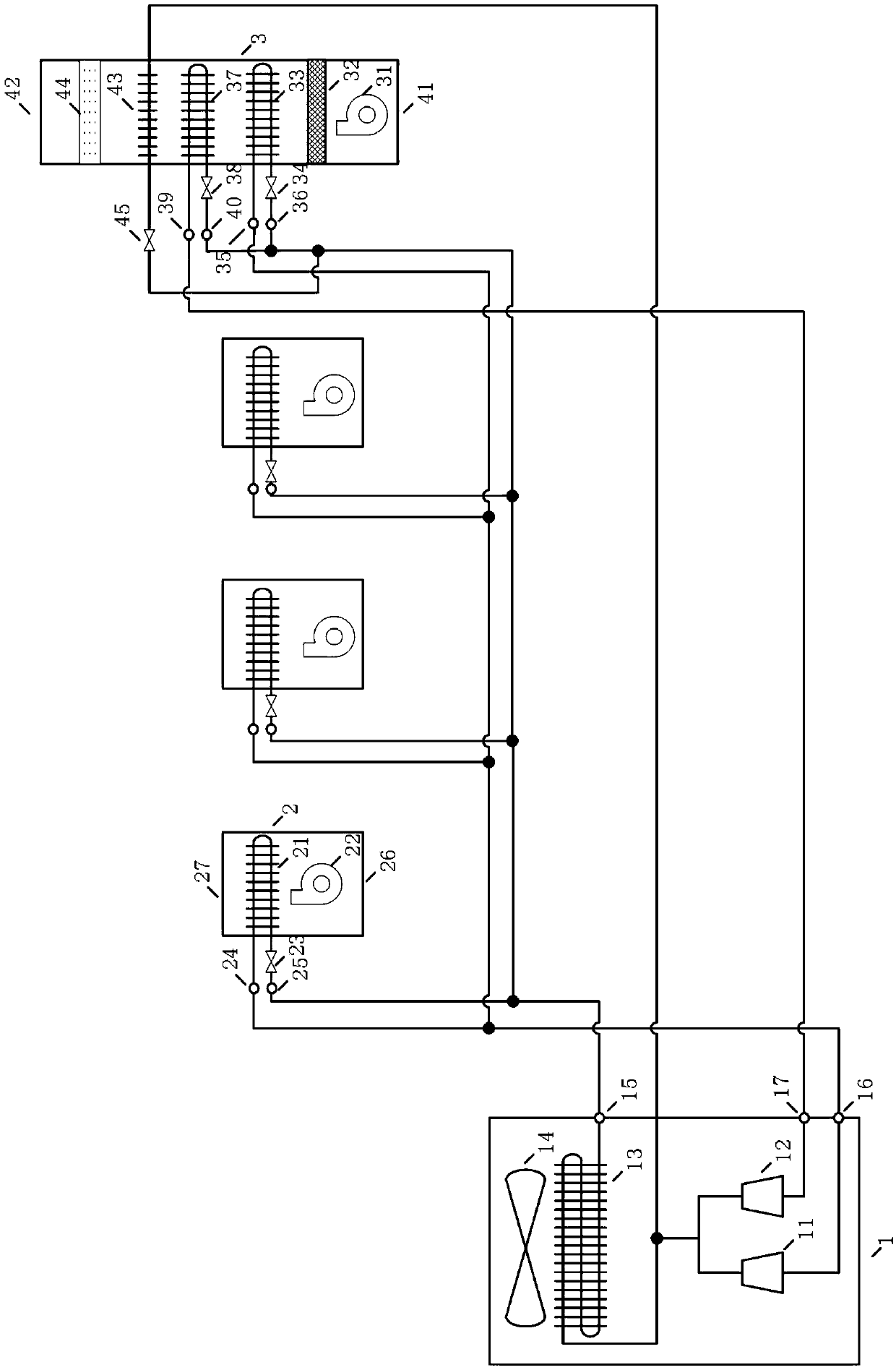

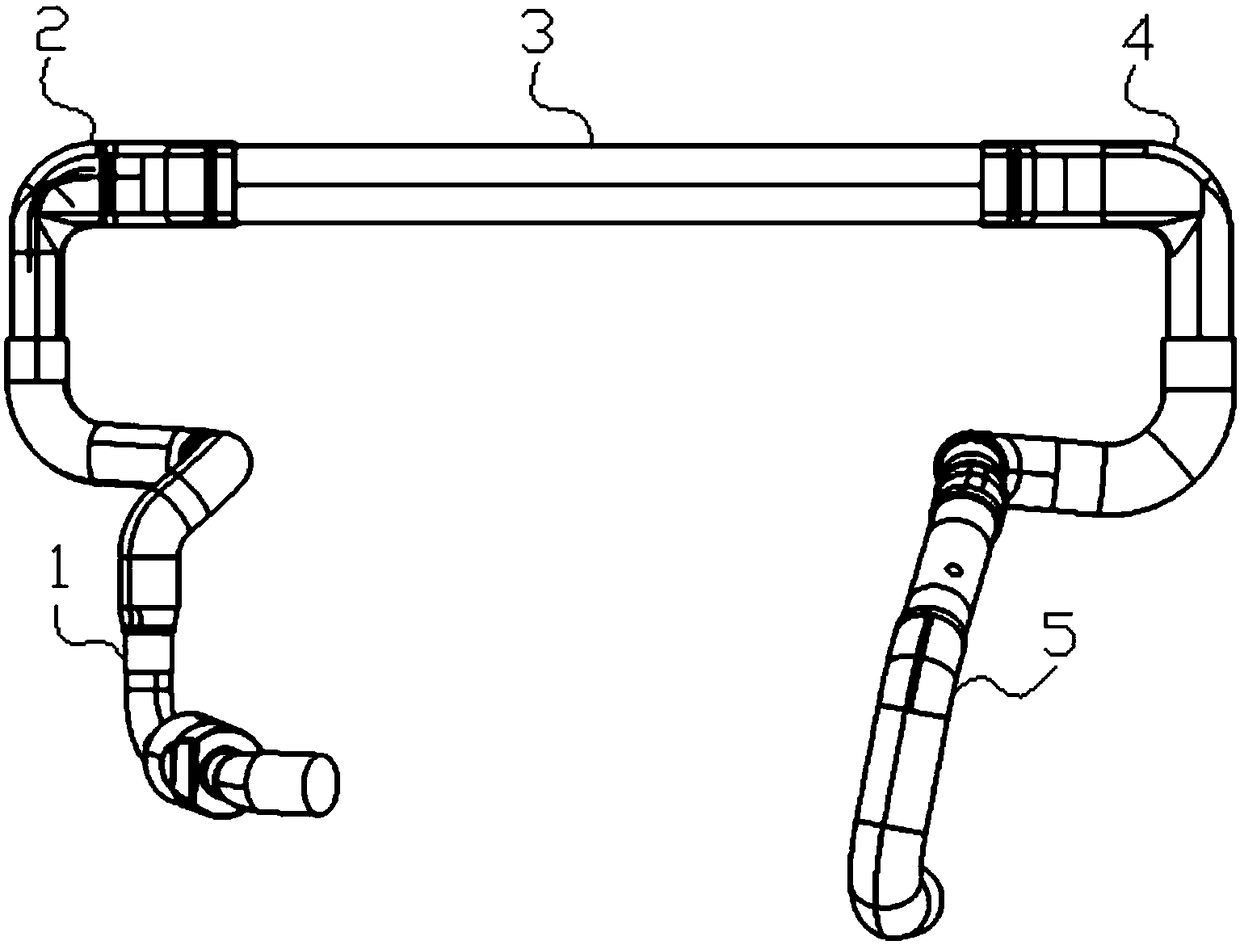

Refrigeration equipment and heat exchange assembly for same

InactiveCN104791910AImprove heat transfer uniformityImprove heat transfer efficiencyLighting and heating apparatusSpace heating and ventilation detailsPlate heat exchangerEngineering

The invention discloses refrigeration equipment and a heat exchange assembly for the refrigeration equipment. The refrigeration equipment comprises a shell and the heat exchange assembly. The heat exchange assembly comprises a flow split heat exchanger, a close-to-ventilation-opening heat exchanger, a away-from-ventilation-opening heat exchanger, a first communication pipe and a second communication pipe, wherein the flow split heat exchanger is provided with a close-to-ventilation-opening portion adjacent to a ventilation opening and a away-from-ventilation-opening portion away from the ventilation opening; the close-to-ventilation-opening heat exchanger is provided with a close-to-ventilation-opening heat exchanger inlet and a close-to-ventilation-opening heat exchanger outlet; the away-from-ventilation-opening heat exchanger is provided with a away-from-ventilation-opening heat exchanger inlet and a away-from-ventilation-opening heat exchanger outlet; the two ends of the first communication pipe are communicated with a away-from-ventilation-opening portion outlet and a close-to-ventilation-opening heat exchanger inlet to lead refrigerants flowing out of the away-from-ventilation-opening portion outlet into the close-to-ventilation-opening heat exchanger; the two ends of the second communication pipe are communicated with a close-to-ventilation-opening portion outlet and the away-from-ventilation-opening heat exchanger inlet to lead refrigerants flowing out of the close-to-ventilation-opening portion outlet into the away-from-ventilation-opening heat exchanger. The heat exchange assembly of the refrigeration equipment is even in heat exchange.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

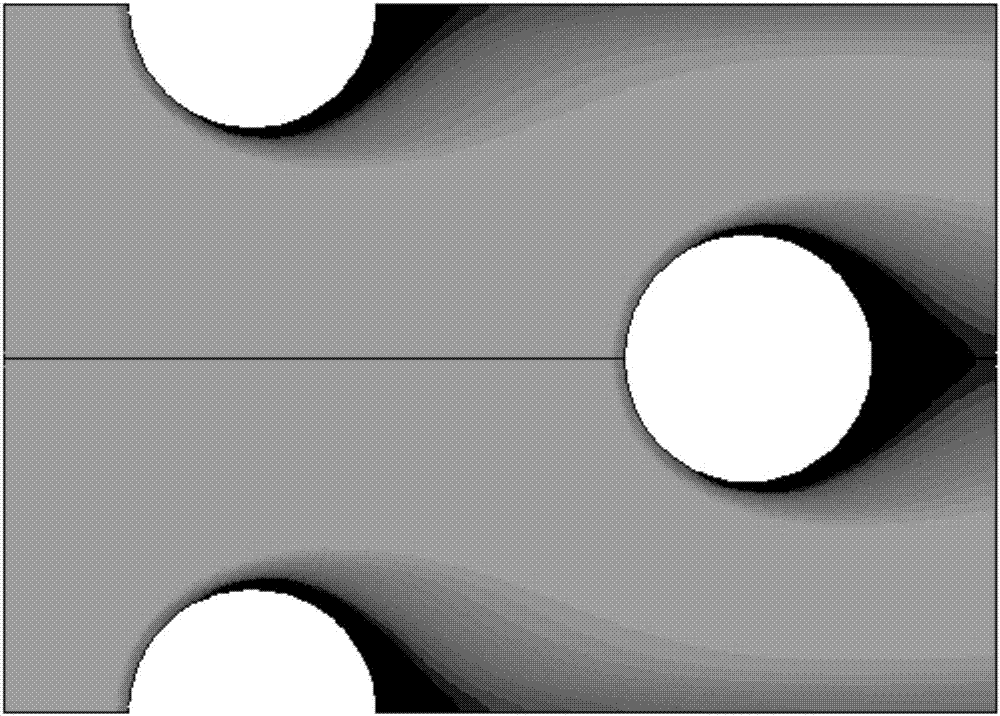

Heat exchange device and air-conditioning equipment

InactiveCN108006941AGuaranteed heat transfer efficiencyFull play of heat exchange effectLighting and heating apparatusSpace heating and ventilation detailsBusiness efficiencyBlind zone

The invention provides a heat exchange device and air-conditioning equipment. The heat exchange device comprises at least two subsidiary heat exchangers arranged in the wind direction; each subsidiaryheat exchanger comprises at least one row of refrigerant pipes and fins mounted on the refrigerant pipes in a sleeving manner; and the transverse pipe center distance of the refrigerant pipes betweenany two adjacent subsidiary heat exchangers ranges from 8 mm to 35 mm. According to the heat exchange device provided in the scheme, an air flow can extend fully and smoothly when flowing among the refrigerant pipes of the adjacent subsidiary heat exchangers, air flow blind zones and weak wind zones on the leeward sides of the refrigerant pipes can be reduced, all the refrigerant pipes in the subsidiary heat exchangers in the upstream and downstream positions of the wind direction can make full contact with the air flow, the problem that the refrigerant pipes in the subsidiary heat exchangersin the downstream position of the wind direction cannot exchange heat effectively due to the fact that the refrigerant pipes are located in the air flow blind zones or the weak wind zones is avoided,the problem that the wind force on the subsidiary heat exchangers in the downstream position of the wind direction is greatly reduced due to the excessively large transverse pipe center distances ofthe refrigerant pipes between among any subsidiary heat exchangers can also be avoided with the design, and the overall energy efficiency ratio of the air-conditioning equipment is increased.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

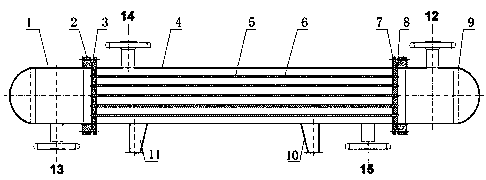

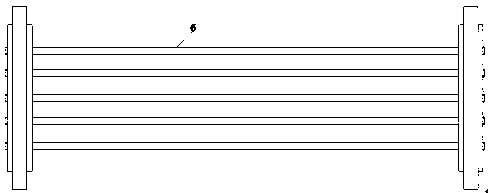

Wound tube heat exchanger with baffle plates

PendingCN110455098AEffective installationEasy to installHeat exchanger casingsStationary tubular conduit assembliesPlate heat exchangerStraight tube

The invention discloses a wound tube heat exchanger with baffle plates. The wound tube heat exchanger comprises a shell, wherein a multi-section spiral wound heat exchange tube is arranged in the shell, and the multi-section spiral wound heat exchange tube is formed by winding a plurality of spiral wound tube sections and a plurality of straight tube sections alternately; a plurality of combined baffle plates are respectively arranged between the straight tube sections and the shell and are vertically arranged along the axis of the shell; and the two ends of the shell are further respectivelyprovided with tube sheets, and the shell is divided into a tube-side heat exchange area and a shell-side heat exchange area. By means of the wound tube heat exchanger with the baffle plates, through the improvement of the structure, the baffle plates can be effectively and conveniently installed on the multi-section spiral wound heat exchange tube, so that a dead zone of shell-side flow is effectively eliminated, the disturbance of shell-side fluid is enhanced, the fluid heat exchange process is prolonged, the shell-side heat transfer is finally enhanced, consumables and energy sources are saved, the integral heat exchange uniformity of the heat exchanger is improved, and the practicability is high.

Owner:ZHONGKAI UNIV OF AGRI & ENG

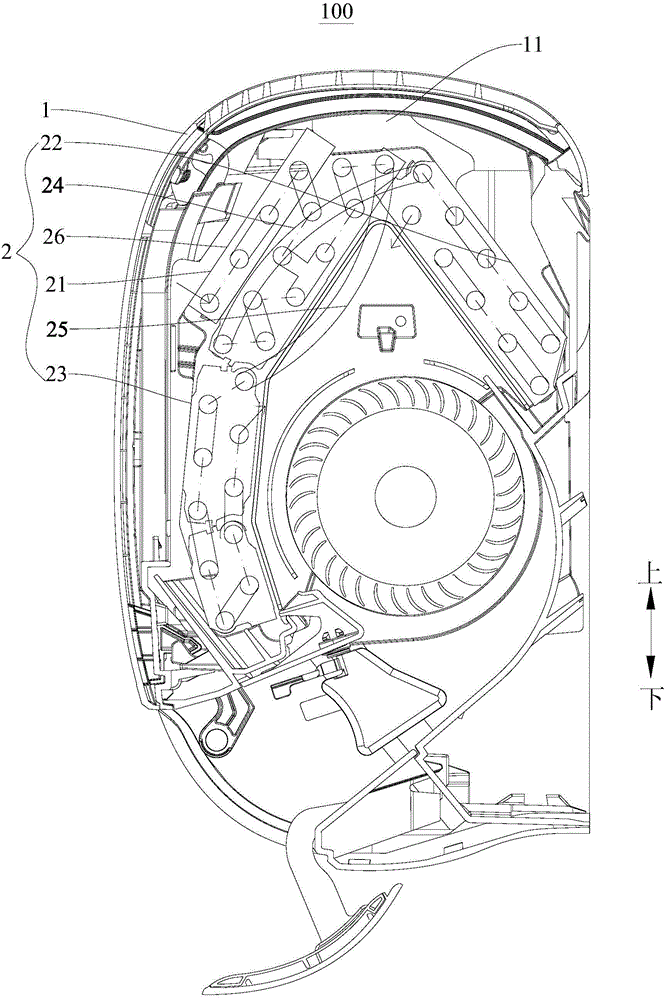

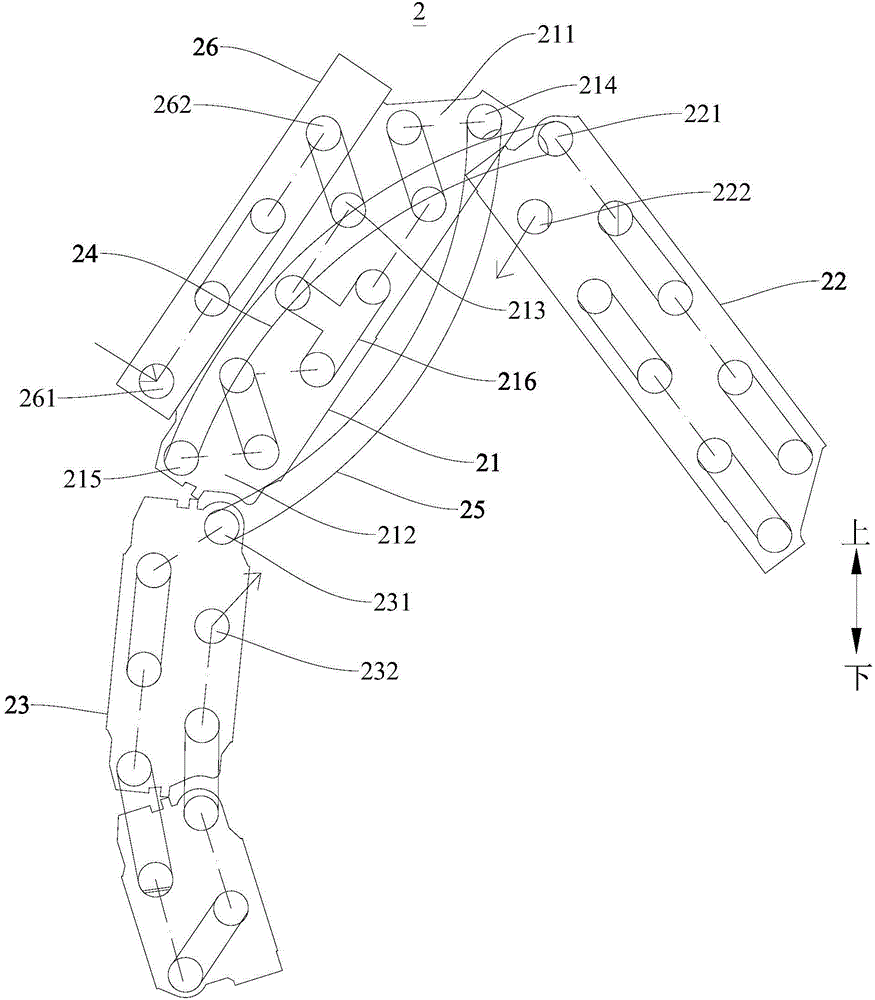

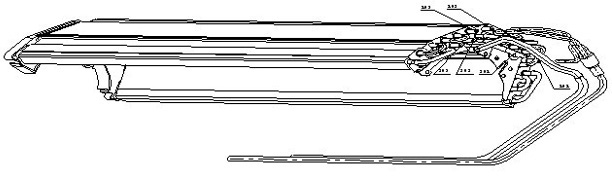

Wall mounted air conditioning indoor unit

InactiveCN101608816AImprove heat transfer uniformityGood heat transfer capacityLighting and heating apparatusSpace heating and ventilation detailsEvaporatorEngineering

The invention discloses a wall mounted air conditioning indoor unit, comprising a shell, as well as an evaporator and a tangential fan that are arranged in the shell. The evaporator comprises at least two folds, wherein an angle is formed between a first fold evaporator and a second fold evaporator. The shell is provided with a grating part thereon, and the grating part is provided with a plurality of air inlets which are respectively inclined to the middle part of the grating part. The wall mounted air conditioning indoor unit can balance the air velocity of the evaporator and overcomes the problem that the heat exchange uniformity of the evaporator is poor, thus improving the heat exchange capacity of the evaporator as well as the overall heat exchange effect of the evaporator.

Owner:GUANGDONG CHIGO AIR CONDITIONING

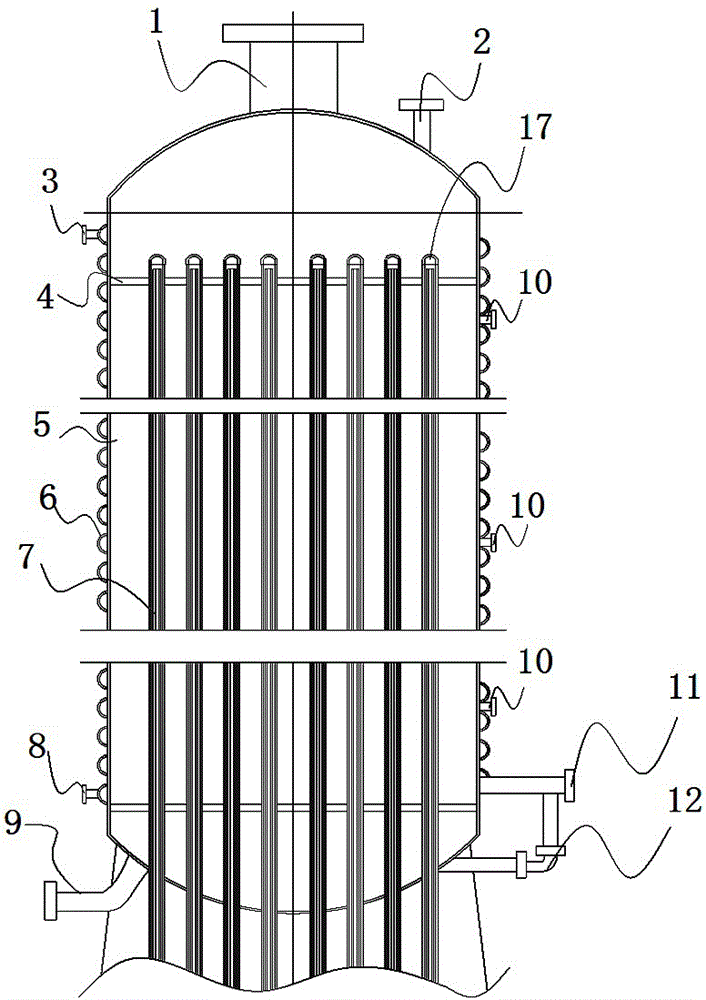

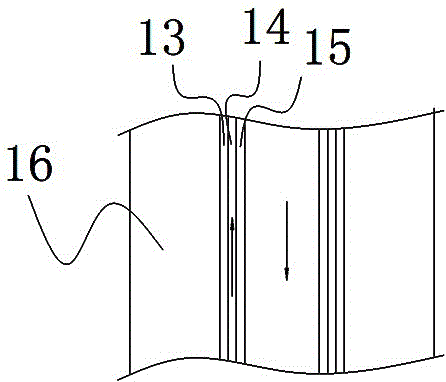

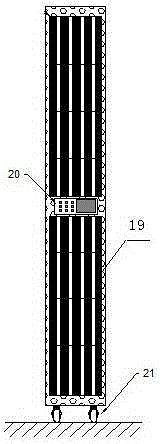

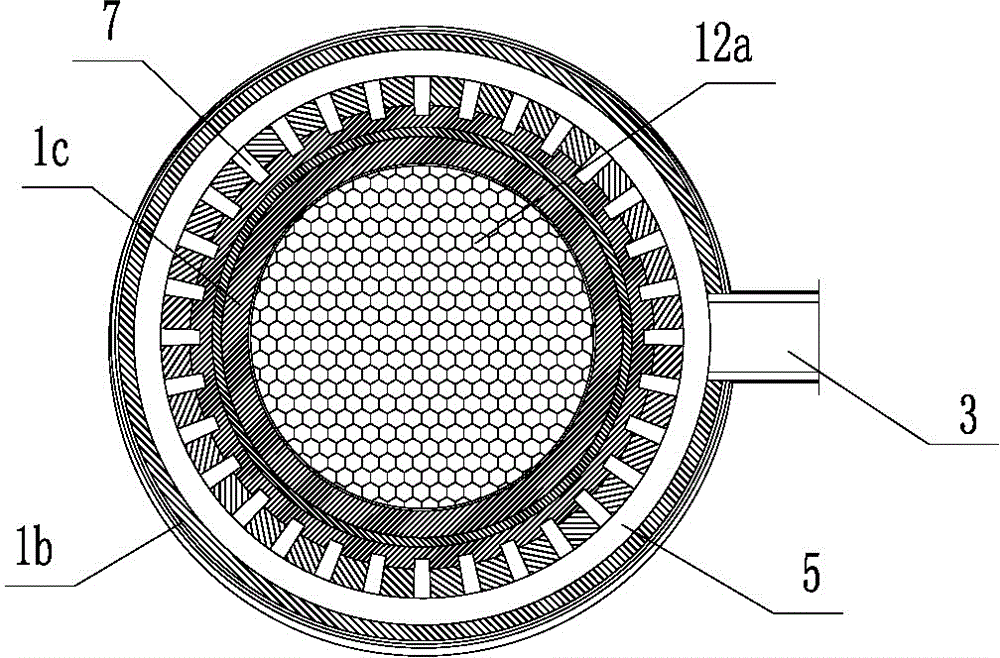

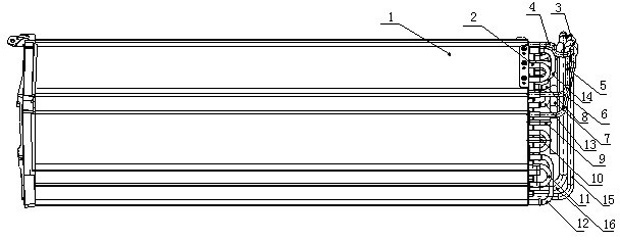

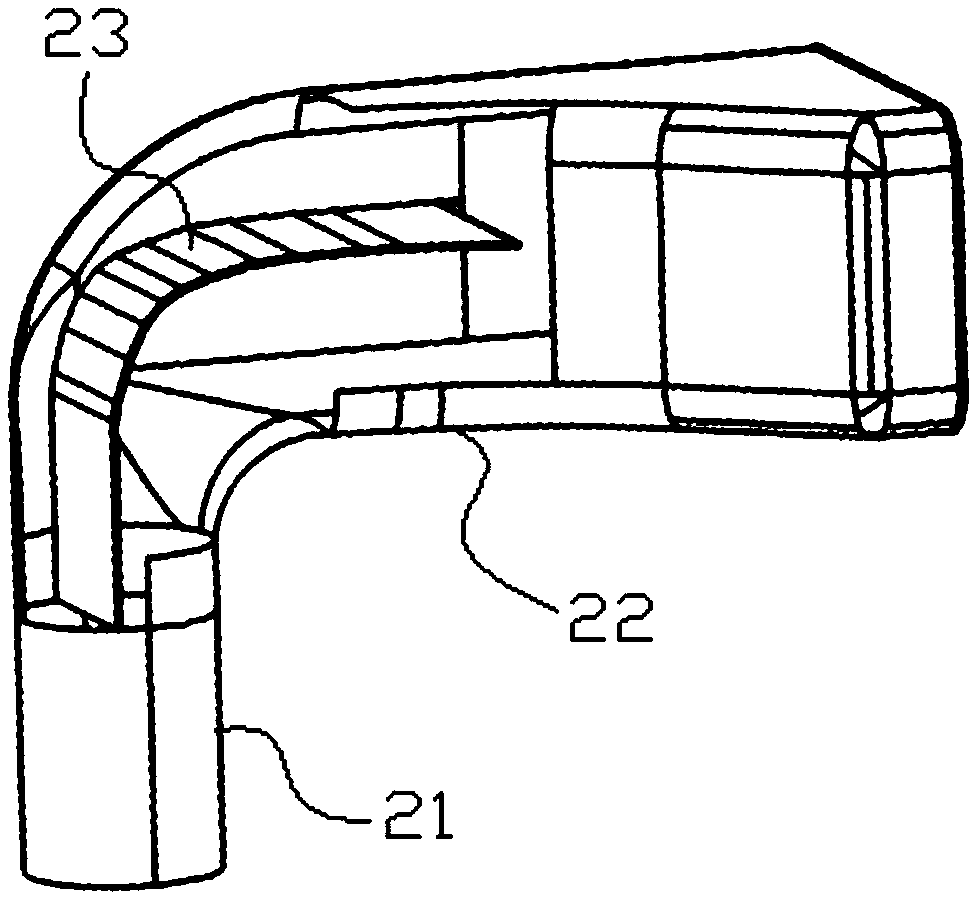

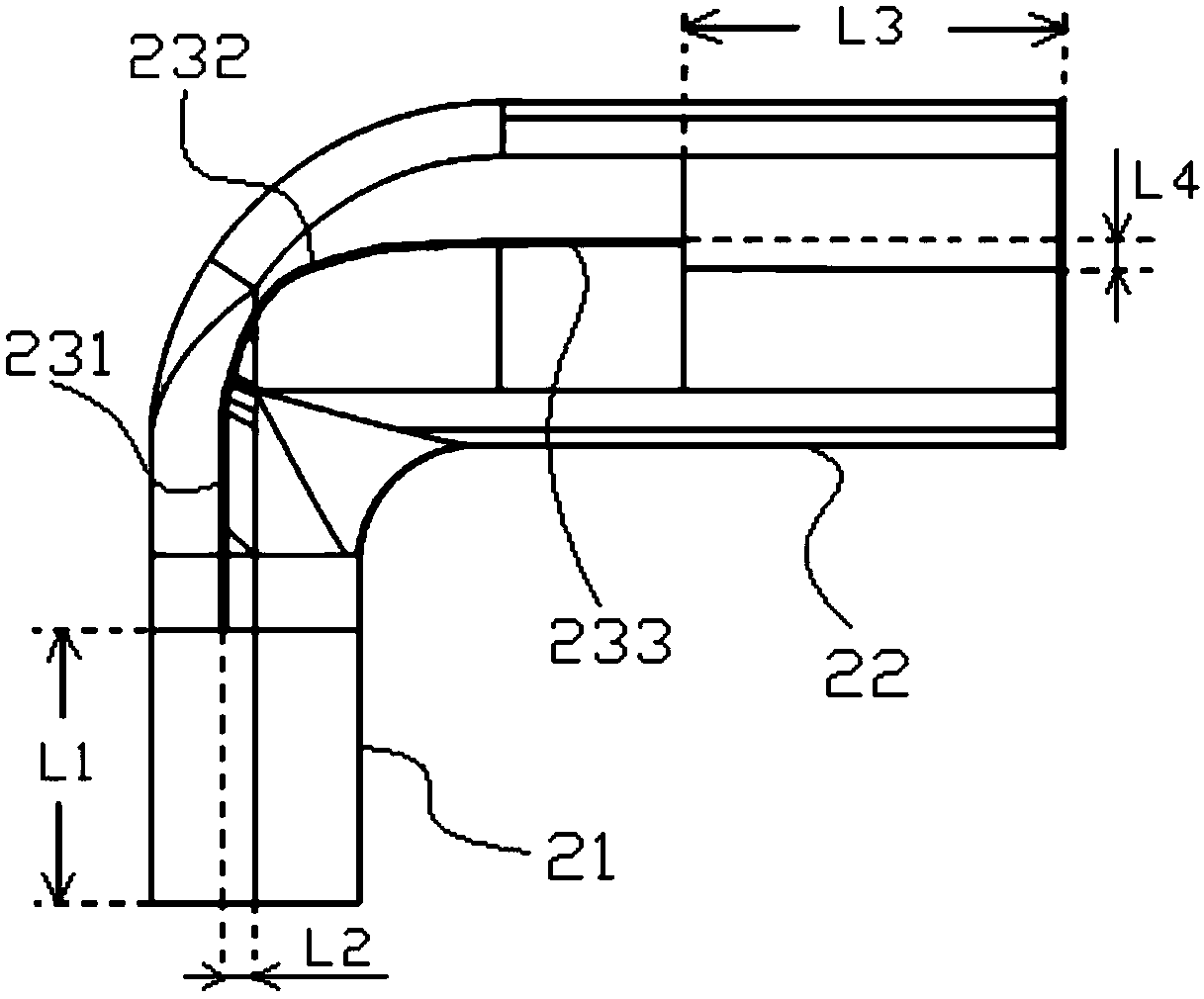

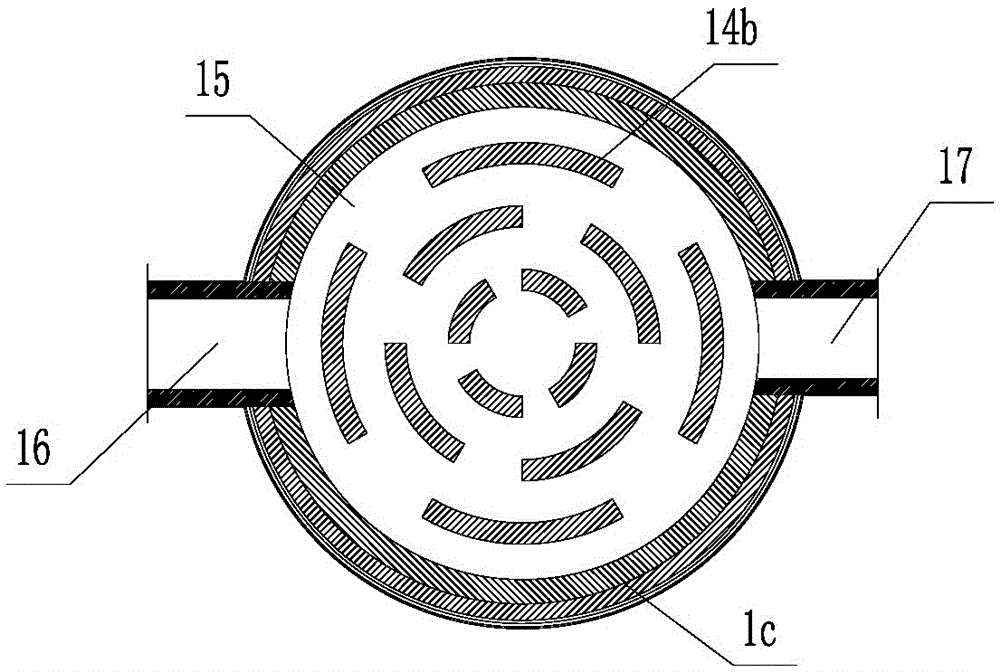

Flow stabilizer distance enlarging condensable gas heat exchanger

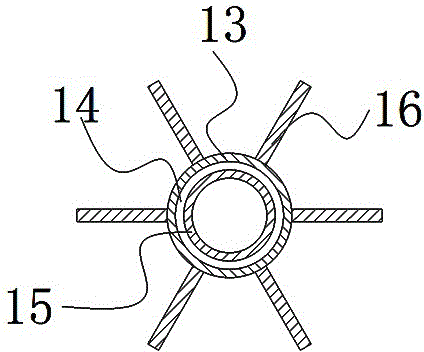

InactiveCN107894178AReduce vibrationReduce noise levelStationary tubular conduit assembliesHeat transfer modificationPlate heat exchangerGas phase

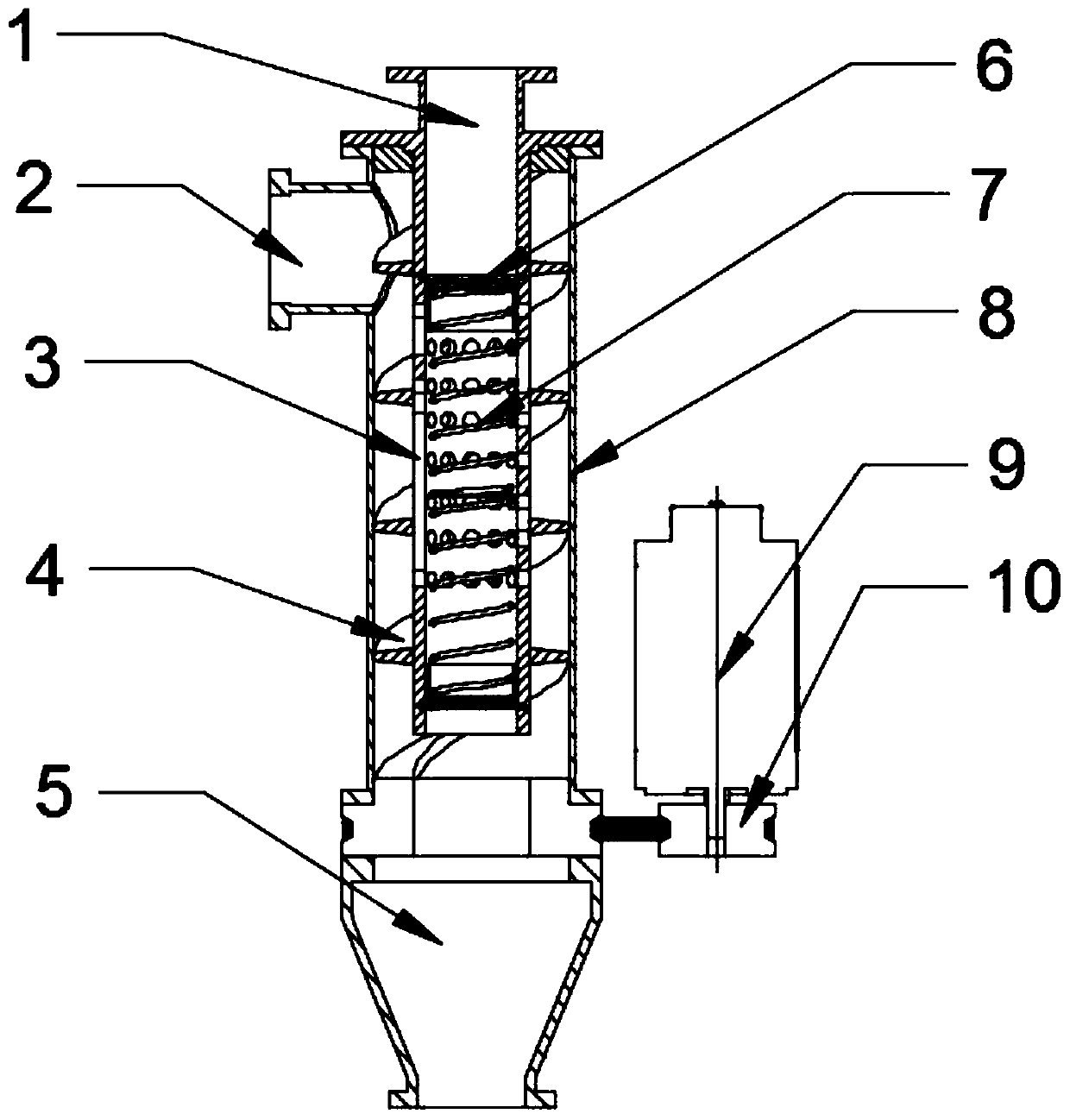

The invention provides a gas-liquid two-phase flow multi-tube type shell-tube heat exchanger. The gas-liquid two-phase flow multi-tube type shell-tube heat exchanger comprises a shell. Sealing heads are arranged at the two ends of the shell correspondingly. Tube plates are arranged at the connecting positions of the sealing heads and the shell. Heat exchange tubes are connected with the tube plates at the two ends, and a gas phase in gas-liquid two-phase flow can be condensed into a liquid phase in the heat exchange process. Each heat exchange tube is internally provided with flow stabilizersfor damping and noise lowering. The same heat exchange tube is internally provided with the multiple flow stabilizers. In the flowing direction of fluid in the heat exchange tubes, the distance between the adjacent flow stabilizers is gradually increased. According to the provided gas-liquid two-phase flow multi-tube type shell-tube heat exchanger, through the length changes of the flow stabilizers, when gas-liquid two-phase flow exists in a pipeline, pipeline vibration is weakened to the maximum degree, the noise level is reduced, meanwhile, flowing resistance is reduced, and the heat exchange uniformity is improved.

Owner:SHANDONG UNIV

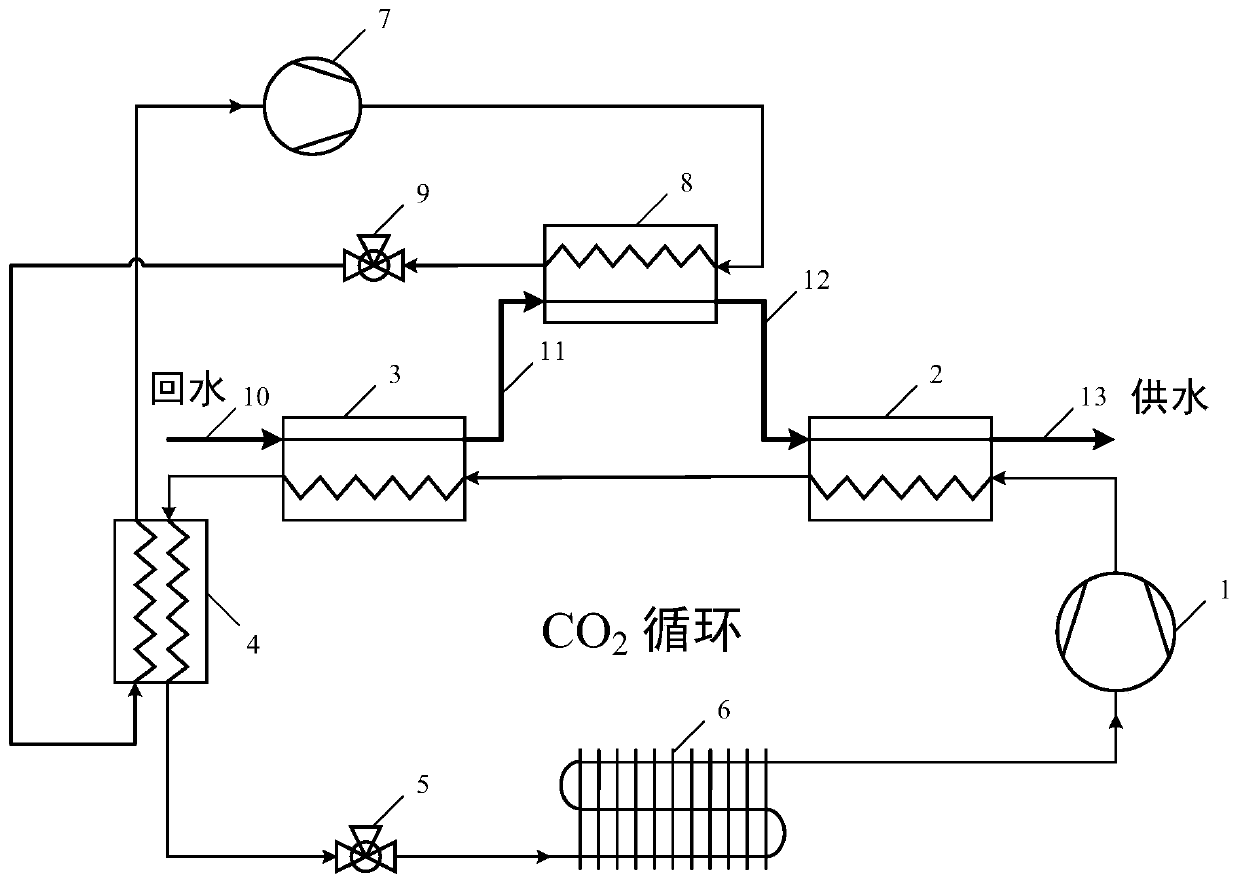

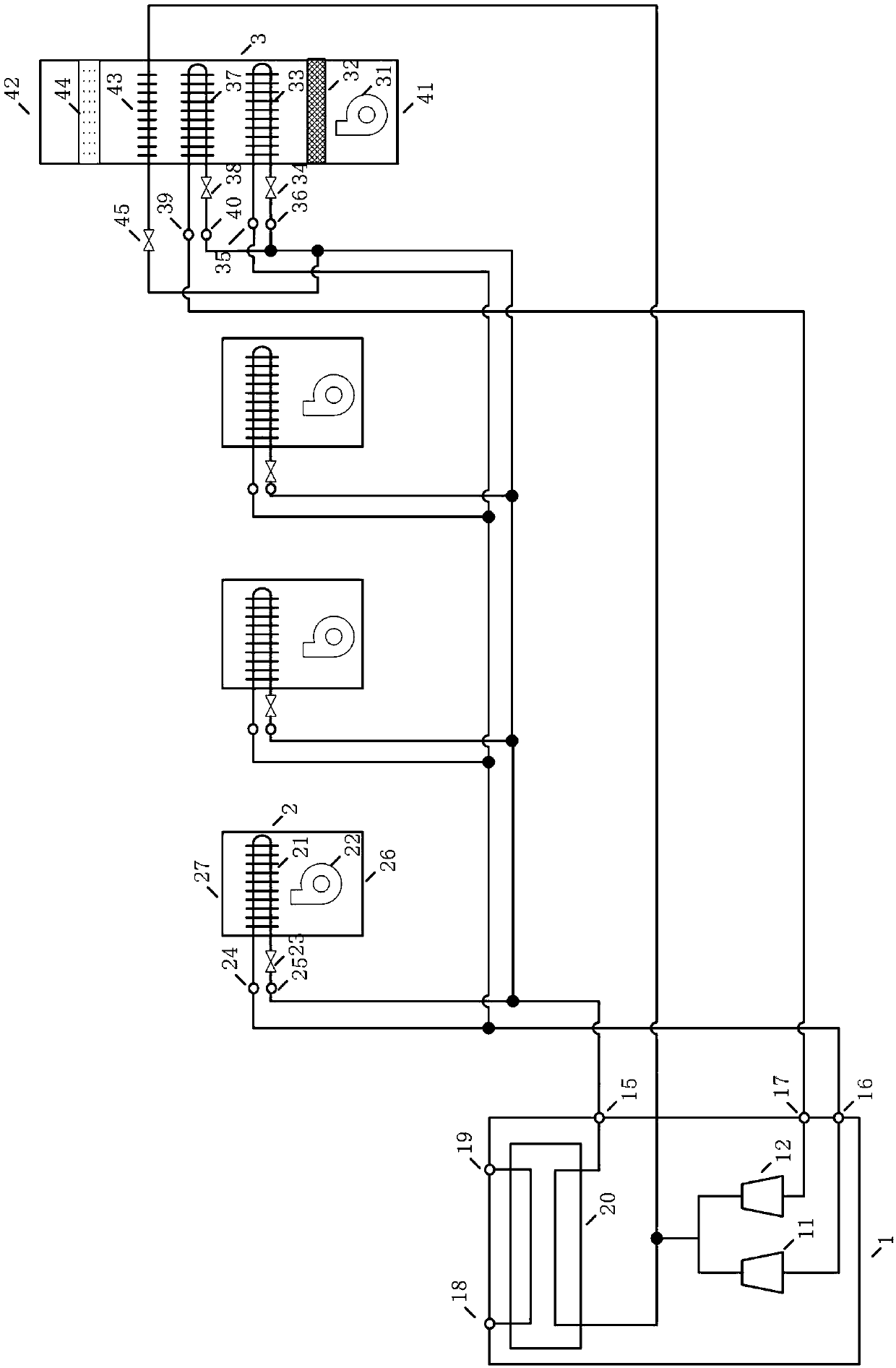

Multi-heat exchanger series transcritical CO2 heat pump heating system

InactiveCN111271752AImprove cycle efficiencyReduce the temperatureHeating fuelMechanical apparatusTranscritical cycleWater flow

The invention relates to a multi-heat exchanger series transcritical CO2 heat pump heating system which comprises a first compressor, a first air cooler, a second air cooler, a cooling evaporator, a first throttling device, a low-temperature evaporator, a second compressor, a condenser and a second throttling device. The first compressor, a refrigerant channel of the first air cooler, a refrigerant channel of the second air cooler, one refrigerant channel of the cooling evaporator, the first throttling device and a refrigerant channel of the low-temperature evaporator are sequentially connected through a pipeline to form CO2 transcritical circulation loop. The second compressor, a refrigerant channel of the condenser, the second throttling device and the other refrigerant channel of the cooling evaporator are sequentially connected through a pipeline to form an auxiliary circulation loop. A secondary refrigerant channel of the second air cooler, a secondary refrigerant channel of the condenser and a secondary refrigerant channel of the first air cooler are connected through a pipeline form a water supply flow path. According to the system, the heat exchange uniformity can be improved, and the overall energy efficiency of the CO2 heat pump heating system is improved.

Owner:TONGJI UNIV

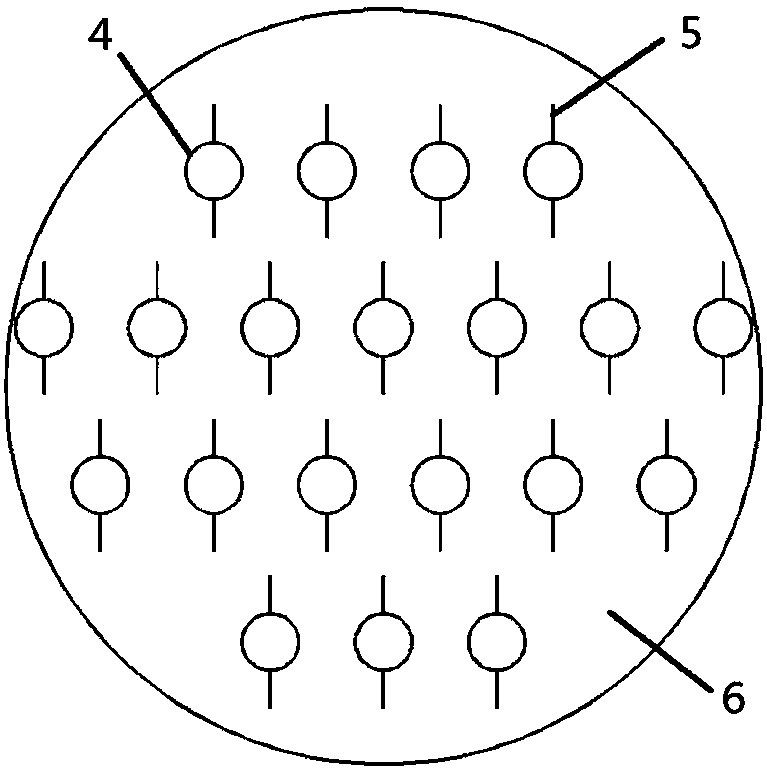

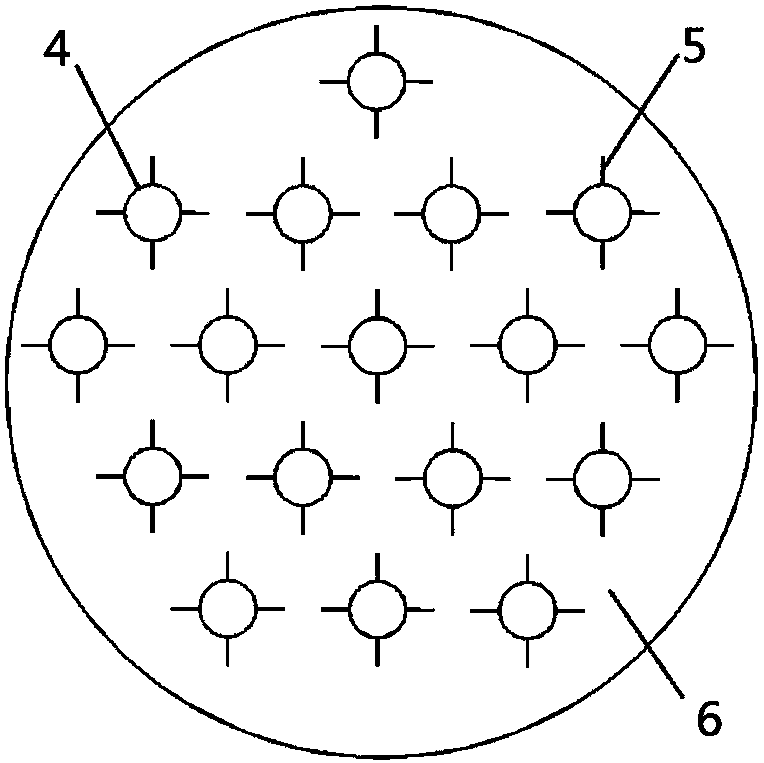

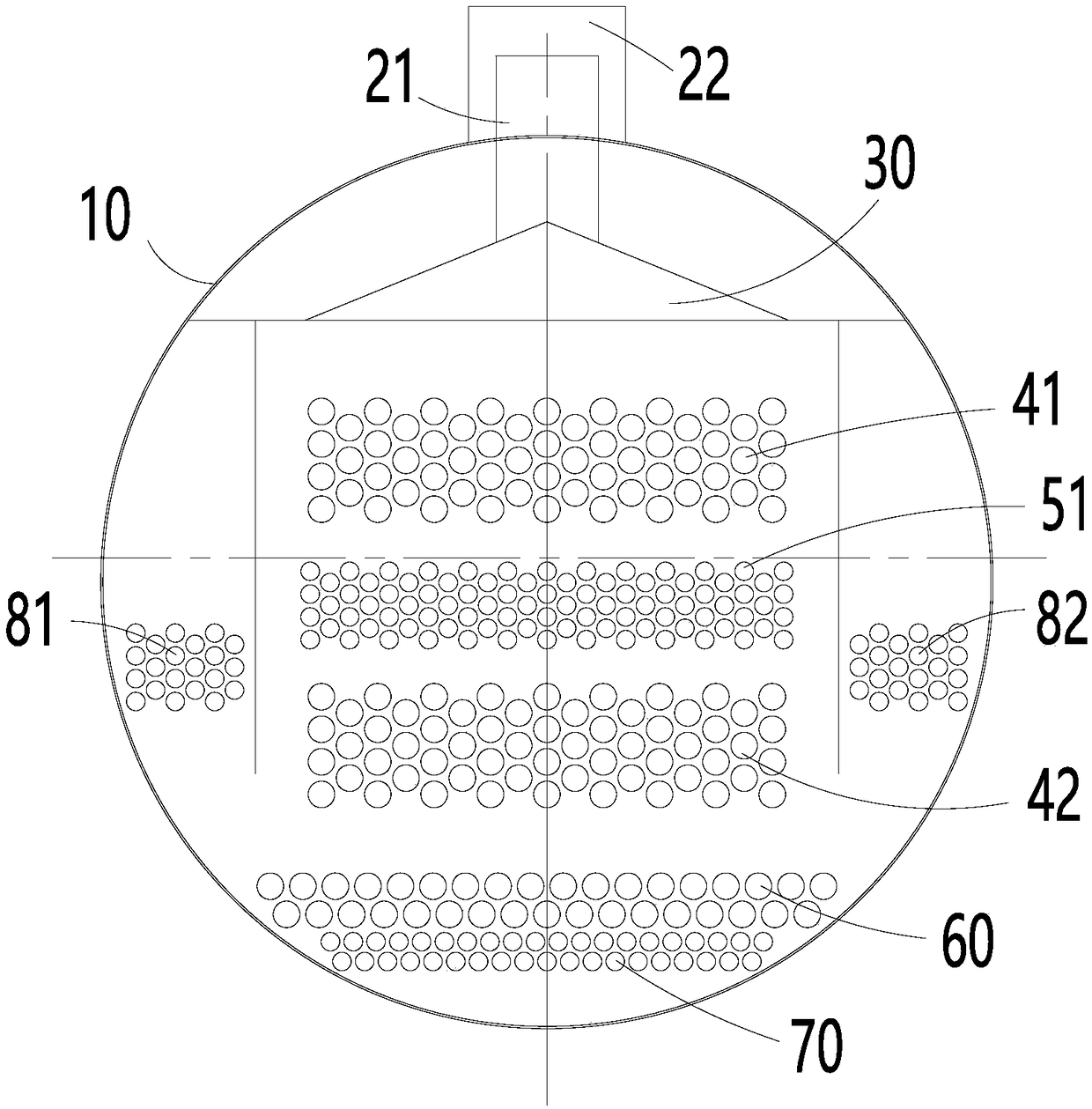

Evaporator and an air conditioning unit

ActiveCN108844258AImprove heat transfer uniformityEvenly distributedEvaporators/condensersStationary conduit assembliesEngineeringAir conditioning

The application provides an evaporator and an air conditioning unit. According to the evaporator, a first heat exchange tube set and a second heat exchange tube set are arranged in a casing; the second heat exchange tube set is located below a liquid distributor; a first liquid uniformizing tube set is arranged in the casing and is located between the first heat exchange tube set and the second heat exchange tube set; the tube diameter of heat exchange tubes of the first liquid uniformizing tube set is smaller than that of heat exchange tubes of the first heat exchange tube set; and the distribution density of the heat exchange tubes of the first liquid uniformizing tube set is larger than that of the heat exchange tubes of the first heat exchange tube set. By applying the technical scheme, after a refrigerant flows through the first heat exchange tube set, the refrigerant will fall on the first liquid uniformizing tube set. When the refrigerant flows through the first liquid uniformizing tube set, the refrigerant is randomly distributed uniformly through the heat exchange tubes of the first liquid uniformizing tube set, thus, the refrigerant can be re-uniformized again, and the refrigerant can uniformly fall on the second heat exchange tube set. In this way, heat exchange uniformity is of the evaporator is improved, and the overall heat exchange efficiency is improved.

Owner:GREE ELECTRIC APPLIANCES INC

Flow equalizing hot blast heater with premix air flow nozzle interconnection and air supply flow curved flowing

ActiveCN104805246AEvenly distributedStable combustionBlast furnace detailsHeating stovesCold airCombustor

The invention relates to a flow equalizing hot blast heater with premix air flow nozzle interconnection and air supply flow curved flowing. A combustor wall body is connected with a burner wall body; the burner wall body is supported on a regenerative chamber wall body; the upper part and the middle part of the regenerative chamber wall body are inserted into a burner; a gas inlet pipe and an air inlet pipe on the burner wall body are connected to a gas distribution circuit and an air distribution circuit; a gas main nozzle and an air main nozzle on the gas distribution circuit and the air distribution circuit are communicated with an air flow premixing nozzle passage; a premixing air adjusting nozzle is arranged at the top of the air flow premixing nozzle passage; a communication passage is arranged on the air flow premixing nozzle passage; a hot air outlet pipe is arranged on the combustor wall body; the lower part of the regenerative chamber is built on the hot blast heater bottom in a masonry manner; a casting grate is arranged on support columns at the hot blast heater bottom; a heat accumulator is arranged on the casting grate; a flue gas outlet pipe and a cold air inlet pipe are arranged on the regenerative chamber wall body at the lower part of the casting grate. The flow equalizing hot blast heater has the advantages of high efficiency, high heat strength and high air supply temperature, saves fuel, and reduces waste gas temperature and the emission of harmful gas.

Owner:陈维汉

Heat storage body gas and air swirl entrainment pre-mixing combustion hot-blast stove

ActiveCN104962677AIncrease temperatureImprove heat utilizationBlast furnace detailsHeating stovesCombustion chamberEngineering

The invention relates to a heat storage body gas and air swirl entrainment pre-mixing combustion hot-blast stove. The hot-blast stove solves the problems of low mixing rate, non-uniform mixing effects, and low intensity, low temperature and incomplete combustion. A sleeve-type heat storage block is arranged in the wall of a combustion chamber, a gas inlet pipe at the lower part is connected to a gas distribution circuit, a gas main nozzle of the gas distribution circuit is communicated with a gas adjustment nozzle, the gas adjustment nozzle is connected to the bottom of a gas mixing circuit, the top of the gas mixing circuit is provided with an annular adjustment baffle plate, an air inlet pipe of the wall of an air mixing chamber at the top is connected to an air distribution circuit, the air distribution circuit is provided with an air distribution nozzle, the bottom of the air mixing chamber is provided with an air nozzle, the wall is provided with a hot air outlet pipe, the wall of a heat storage chamber is sleeved by the wall of the combustion chamber and is built on the stove bottom, support columns on the stove bottom are provided with a grate, the heat storage block is arranged on the grate, and the lower part of the grate is provided with a flue gas outlet pipe and a cold air inlet pipe. The hot-blast stove has the advantages of uniform mixing, high combustion intensity, uniform air-flow distribution, good heat transfer uniformity and high heat utilization rate.

Owner:陈维汉

Vertical type rapid heating device for euphausia superba

InactiveCN110583961AAvoid stickingImprove heat transfer uniformityAnimal feeding stuffFood scienceFrequency conversionShort duration

The invention relates to a vertical type rapid heating device for euphausia superba. The vertical type rapid heating device for euphausia superba comprises a porous steam inlet tube, wherein a springis disposed in the porous steam inlet tube. The lower end of the spring is fixed inside the porous steam inlet tube, and the upper end of the spring can be compressed downward, and is fixedly connected with a steam volume control cap. A snap spring for a hole is disposed on the upper end of the steam volume control cap to limit a highest position of the steam volume control cap. Multiple sets of through-holes are disposed at different heights in the side wall of the porous steam inlet tube. Vertical type spiral scrapers are disposed in a shell. The upper end of the porous steam inlet tube protrudes out of the shell and serves as a steam inlet. The space between the upper end of the shell and the porous steam inlet tube is closed, and the lower end of the shell is a euphausia discharge port. The vertical type spiral scrapers are connected to the output shaft of a frequency conversion motor through a transmission mechanism, and the vertical type spiral scrapers are driven to rotate by the frequency conversion motor. The device has the advantages of fast heating speed, instantaneous killing of microorganisms in euphausia superba at high temperature, short duration of high temperature,less damage to nutrients in materials, and high nutrient retention rate. The device has a simple structure, occupies a small space, and is easy to implement.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

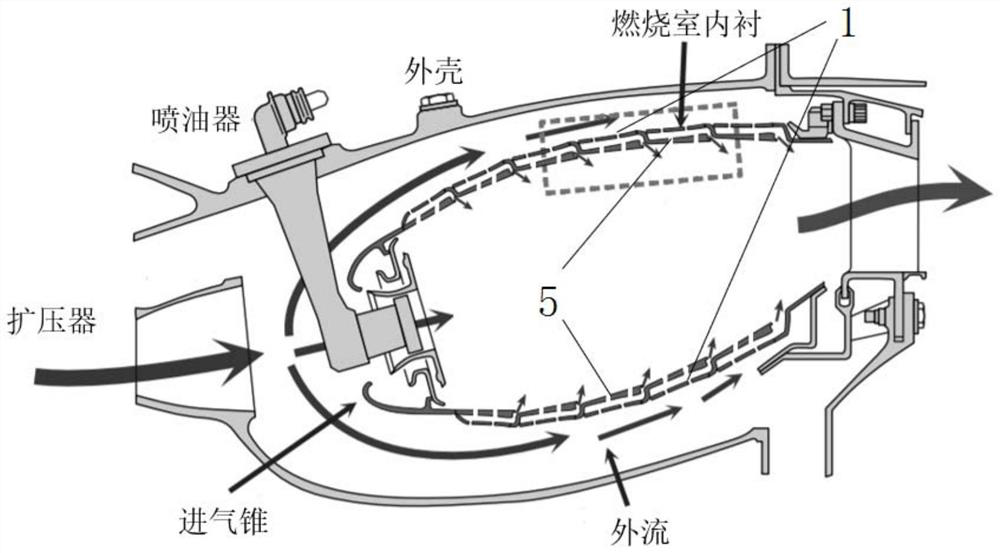

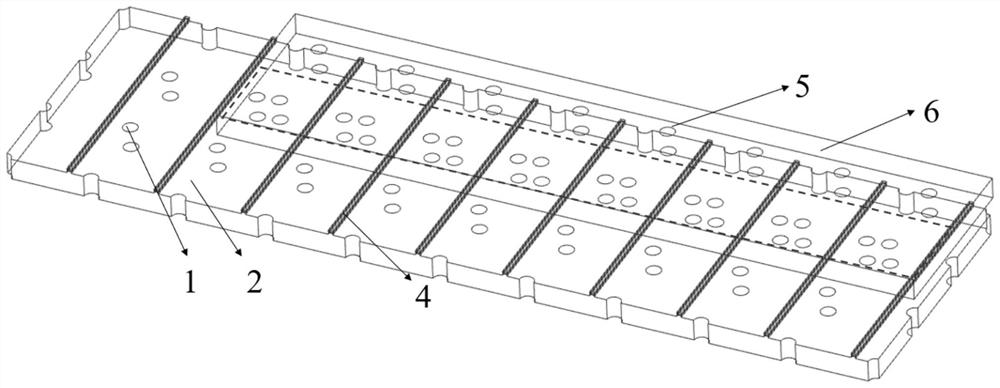

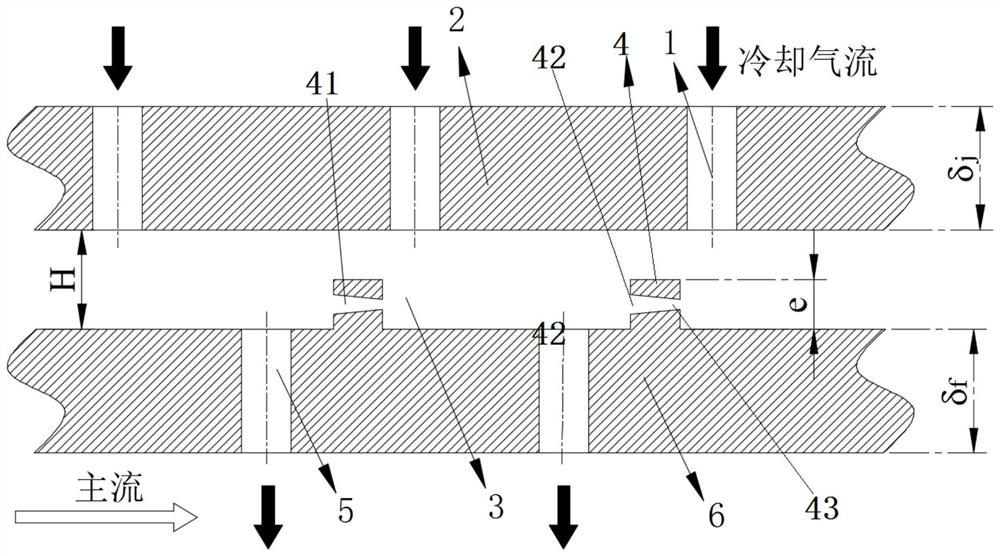

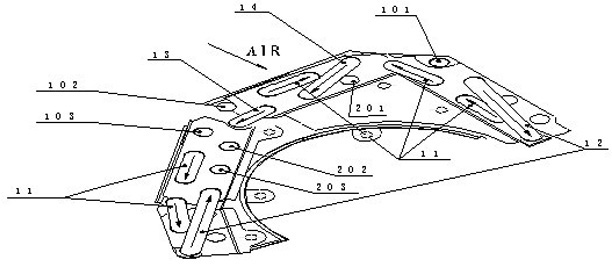

Cooling structure with slit rib laminates for turbofan engine combustion chamber and cooling method

ActiveCN114412645AImprove heat transfer uniformityImprove cooling efficiencyTurbine/propulsion engine coolingCombustion chamberJet flow

The invention relates to a rib layer plate cooling structure with slits for a combustion chamber of a turbofan engine, which is characterized in that a plurality of high-blockage-ratio annular ribs are arranged on the surface, positioned in an impact airflow cooling channel, of an air film pore plate along the airflow direction, and the plurality of high-blockage-ratio annular ribs are parallel to one another; at least two contraction or expansion slits used for improving heat exchange uniformity are formed in the high-blocking-ratio annular fin in the cooling airflow direction, and the at least two contraction or expansion slits are formed in the high-blocking-ratio annular fin at intervals. After the contraction / expansion type slit ribs are arranged on the wall surface of the impact target plate, the heat transfer performance of a low heat transfer area between impact jet flow areas on the impact target plate in traditional impact cooling is improved, so that the heat transfer uniformity of the wall surface of the impact target plate is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

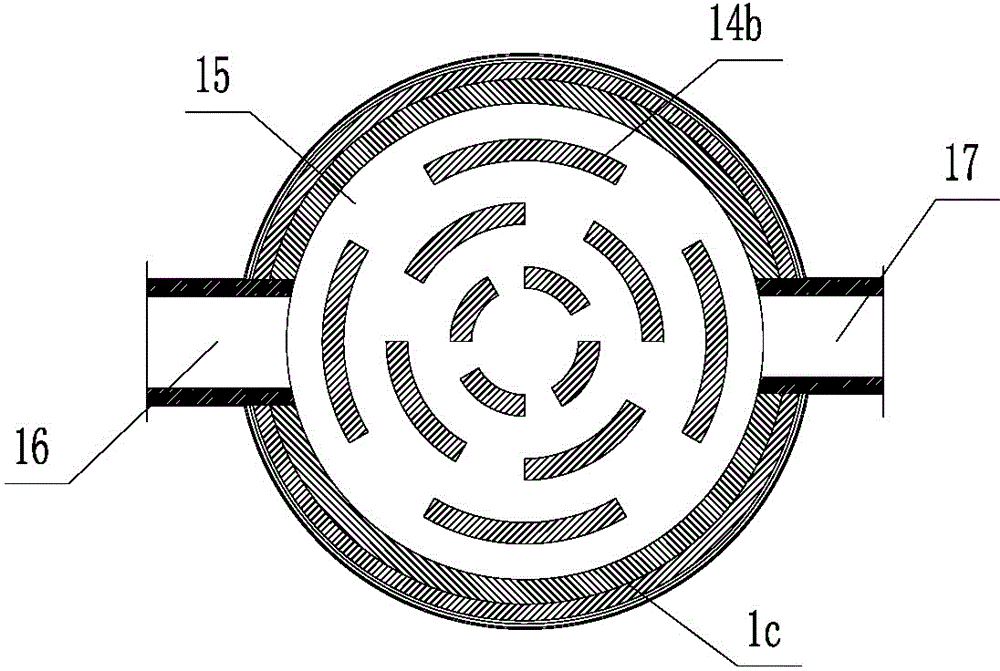

Efficient continuous falling film melt crystallizer

PendingCN114191843AImprove heat transfer uniformityImprove uniformitySolution crystallizationHeat exchange cooling cystallizationEngineeringMechanical engineering

The invention provides an efficient continuous falling film melt crystallizer. The falling film melt crystallizer comprises a barrel, a feeding port and a discharging port are formed in the top and the bottom of the barrel respectively, a plurality of layers of crystallization areas are sequentially arranged in the barrel from top to bottom, each crystallization area is provided with a plurality of vertically-arranged crystallization pipes, and the crystallization pipes are sleeved with heat exchange pipes. The crystallization pipe heat exchange pipes of the adjacent crystallization areas are in one-to-one correspondence and are communicated with each other; the crystallization pipe positioned on the uppermost layer and the crystallization pipe positioned on the lowermost layer are respectively communicated with the feed port and the discharge port; a cold and hot medium inlet and outlet communicated with the top end of the heat exchange tube in each layer of crystallization area is formed in the cylinder body; and a cold and hot medium inlet and outlet communicated with the bottom end of the heat exchange tube on the lowest layer is formed in the lower part of the cylinder body. The cold and hot medium inlet and outlet is additionally formed in the middle of the barrel, so that the heat exchange uniformity between to-be-purified materials at the upper part and the lower part of the barrel and a cold medium can be improved, and the uniformity of crystallization at the upper part and the lower part of the barrel is further improved.

Owner:SHANGHAI DONGGENG CHEM TECH CO LTD

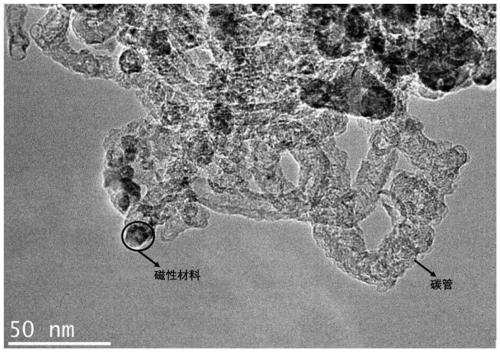

Preparation method of carbon tube coated magnetic material and magnetic oriented heat conduction material

InactiveCN109824092AHigh magnetic stabilityGood magnetic responseCarbon preparation/purificationCobalt oxides/hydroxidesAir atmosphereHeat transfer efficiency

The invention discloses a preparation method of a carbon tube coated magnetic material and a magnetic oriented heat conduction material. The preparation method of the carbon tube coated magnetic material comprises the following steps: S1, respectively dissolving a cobalt source and 2-methylimidazole in methanol for mixing, then enabling them to react to obtain a mixed solution C, carrying out solid-liquid separation on the mixed solution C to obtain a precipitate, and drying the precipitate to obtain a framework material; S2, calcining the framework material for the first time under a hydrogenand argon mixed atmosphere to obtain an intermediate material; S3, calcining the intermediate material for the second time under an air atmosphere to prepare the carbon tube coated magnetic material.The carbon tube coated magnetic material prepared by the preparation method has higher magnetic stability, good magnetic response effect, better heat transfer uniformity and higher heat transfer speed. In addition, under the action of an external magnetic field, a heat conduction channel consistent with the heat conduction direction can be formed, so that the heat transfer efficiency of the heatconduction material is improved.

Owner:ANHUI UNIVERSITY

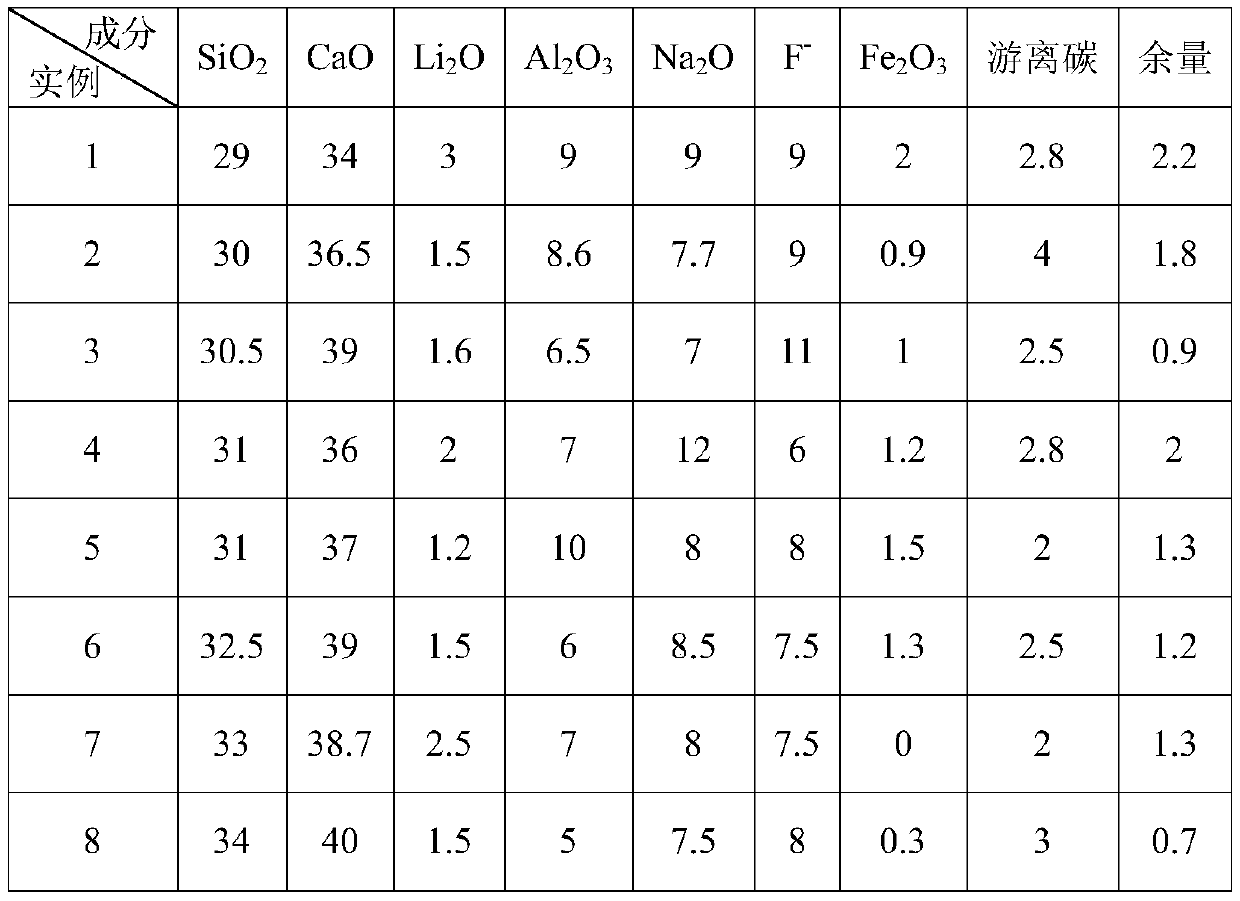

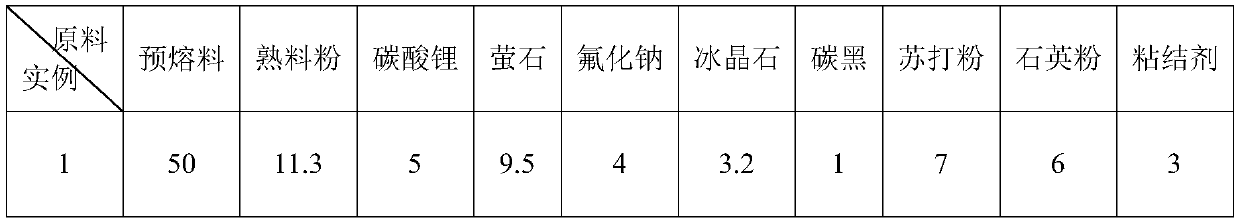

Continuous casting crystallizer casting powder for 310S stainless steel

InactiveCN109954852AImprove heat transfer uniformityImprove performanceChemical compositionTrace element

The invention discloses continuous casting crystallizer casting powder for 310S stainless steel. The continuous casting crystallizer casting powder is prepared from the chemical components in percentage by weight: 29%-34% of SiO2, 34%-40% of CaO, 1.2%-3% of Li2O, 5%-10% of Al2O3, 7%-12% of Na2O, 7.5%-11% of F<->, 0-2% of Fe2O3, 2%-4% of free carbon and the balance of trace elements. The casting powder is high in heat transfer uniformity, good in lubrication effect, stable in slag layer and uniform in melting, the non-clearing rate of the surfaces of cast 310S stainless steel casting blanks is99% or above, and the subsurface and interior quality of the casting blanks is good.

Owner:西峡县西保冶金材料有限公司

Air-conditioning heat exchanger

InactiveCN102052804AReduce weightUniform heat exchangeEvaporators/condensersSpace heating and ventilation detailsFluteBusiness efficiency

The invention discloses an air-conditioning heat exchanger. The air-conditioning heat exchanger comprises a fin, a U-shaped pipe which passes through an inner cavity of the fin, a copper bridging bend which is fixed at the tail end of the U-shaped pipe, a liquid inlet pipe and an air outlet pipe which are connected with an outdoor unit, a distributor, an inlet branch pipe, an outlet summary flute-shaped pipe and an outlet branch pipe, wherein the inlet branch pipe comprises a first inlet branch pipe, a second inlet branch pipe and a third inlet branch pipe; and the outlet branch pipe comprises a first outlet branch pipe communicated with the first inlet branch pipe, a second outlet branch pipe communicated with the second inlet branch pipe, and a third outlet branch pipe communicated with the third inlet branch pipe. The air-conditioning heat exchanger keeps heat exchange quantity equivalent to that of the conventional phi7 pipe heat exchanger on the premise of reducing pipe diameter and saving pipes; and the cooling energy efficiency ratio (EER) and heating coefficient of performance (COP) of the whole machine are equal to those of the conventional machine.

Owner:HISENSE HOME APPLIANCES GRP CO LTD +1

Integrated multi-connected high-temperature air conditioning unit with fresh air handling function

PendingCN110822567AEasy to installFlexible controlMechanical apparatusLighting and heating apparatusFresh airProcess engineering

The invention discloses an integrated multi-connected high-temperature air conditioning unit with a fresh air handling function. The whole unit is composed of a refrigeration system, and comprises anoutdoor unit, one or more indoor units and an outdoor fresh air handler, an air pipe connecting port and a liquid pipe connecting port are formed in each of cases of the outdoor unit, the indoor unitsand the outdoor fresh air handler, the air pipe connecting port of the outdoor unit, the air pipe connecting port of the outdoor fresh air handler and the air pipe connecting ports of the plurality of indoor units communicate with one another, and the liquid pipe connecting port of the outdoor unit, the liquid pipe connecting port of the outdoor fresh air handler and the liquid pipe connecting ports of the plurality of indoor units communicate with one another. According to the integrated multi-connected high-temperature air conditioning unit with the fresh air handling function, both returnair and fresh air can be handled at the same time, additional fresh air handling units are not needed for cooperation, and the advantages of flexible installation and small occupied area of a multi-connected air conditioning unit are reserved.

Owner:苏州贵鸣新能源科技有限公司

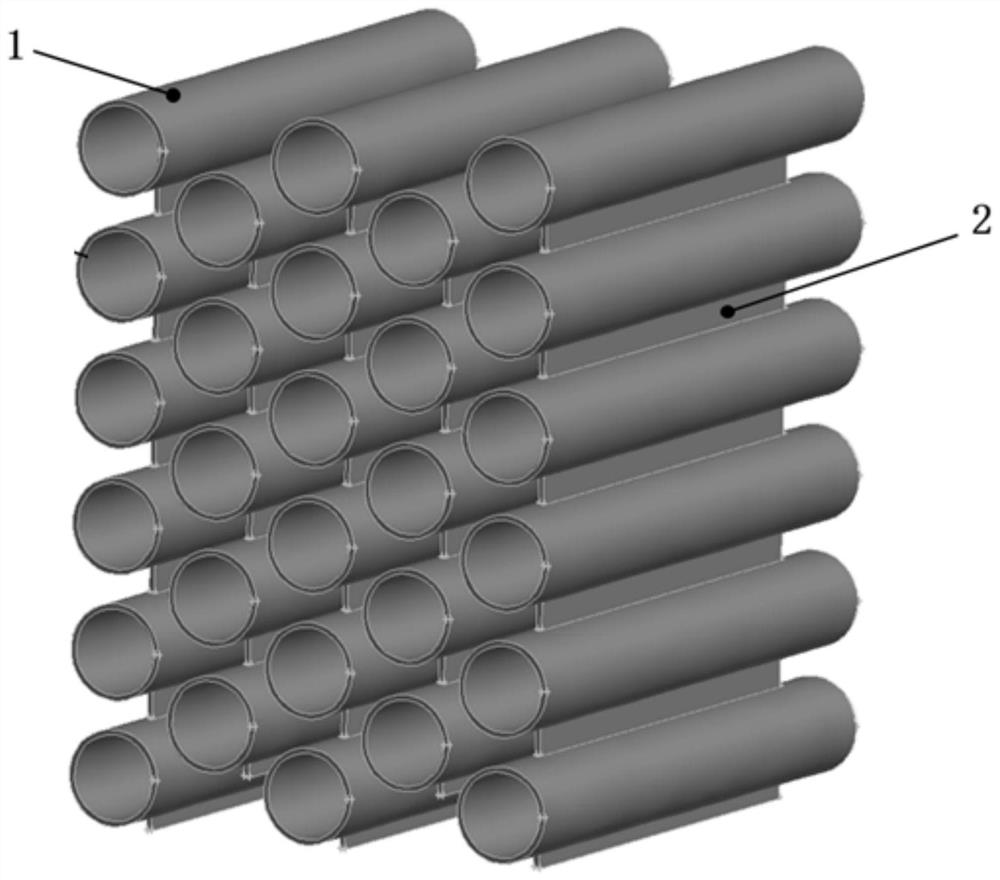

Film type tube row falling film evaporation tube bundle

PendingCN113137786AAvoid gatheringAvoid drippingEvaporators/condensersHeat exchanger casingsThermodynamicsEngineering

The invention discloses a film type tube row falling film evaporation tube bundle. The film type tube row falling film evaporation tube bundle comprises a plurality of heat exchange tubes and flow guide plates; the heat exchange pipes are horizontally arranged; the plurality of heat exchange pipes are arranged in a row in parallel; the top faces and the bottom faces of the adjacent heat exchange pipes are connected through the flow guide plates; the long edges of the flow guide plates make contact with the heat exchange pipes; the short edges of the flow guide plates are vertically arranged; the flow guide plates are arranged at the bottom of the lowest heat exchange pipe; and the flow guide plates and the heat exchange pipes are made of the same material. The liquid film can completely cover the surfaces of the heat exchange tubes, and drying is avoided.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

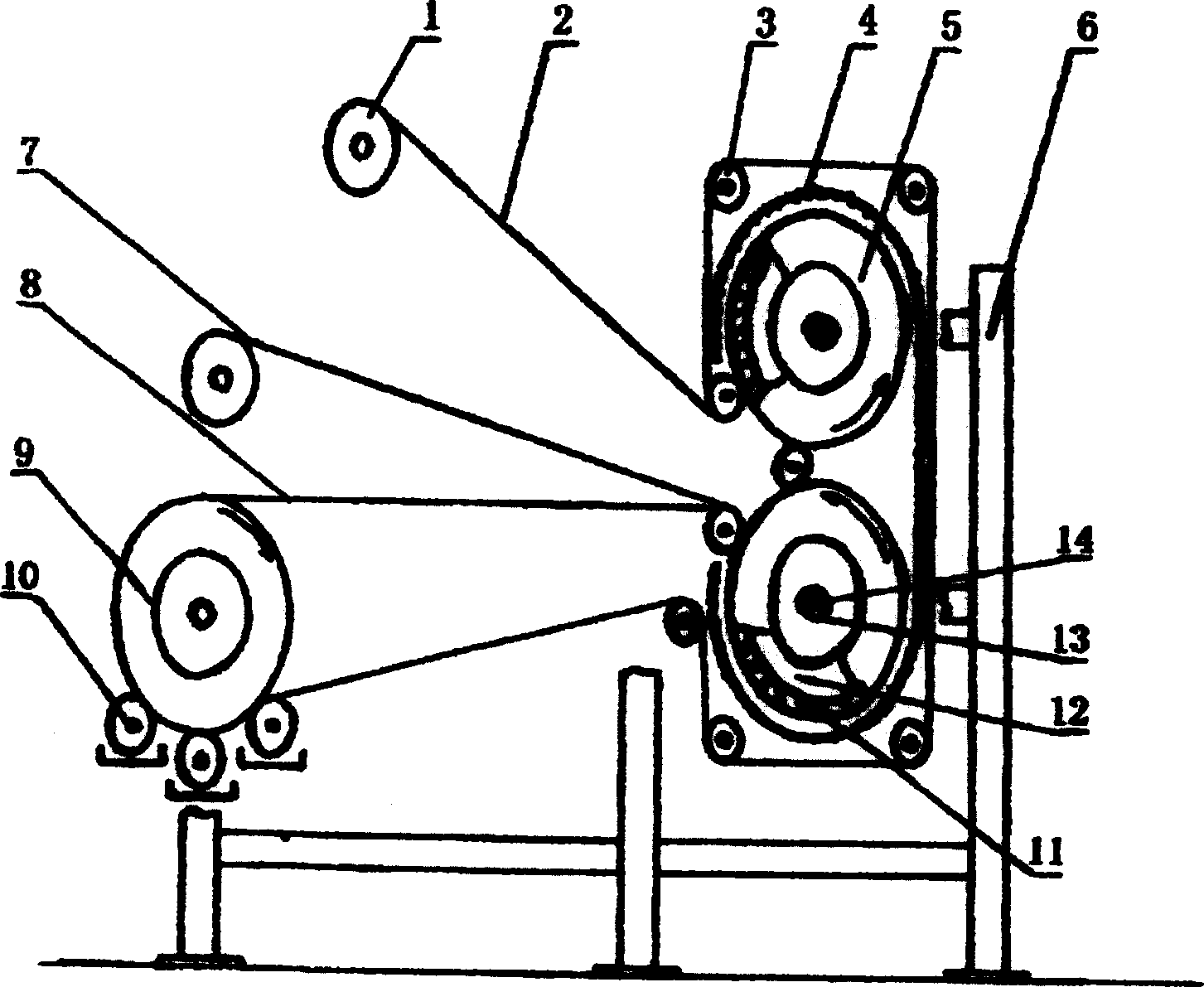

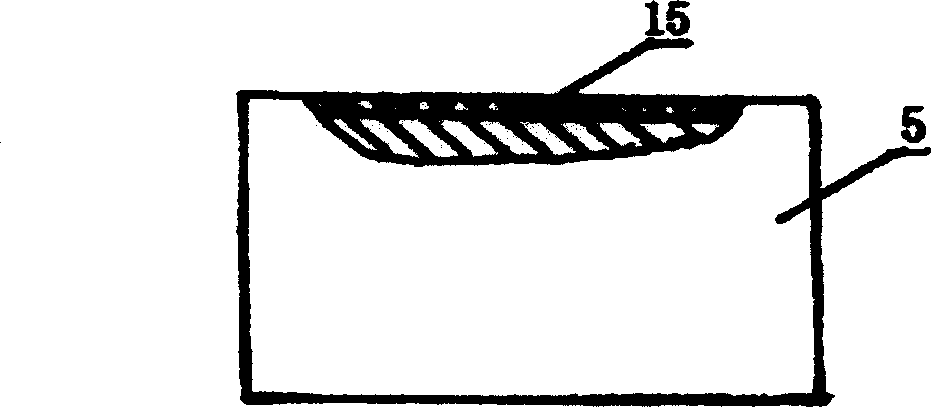

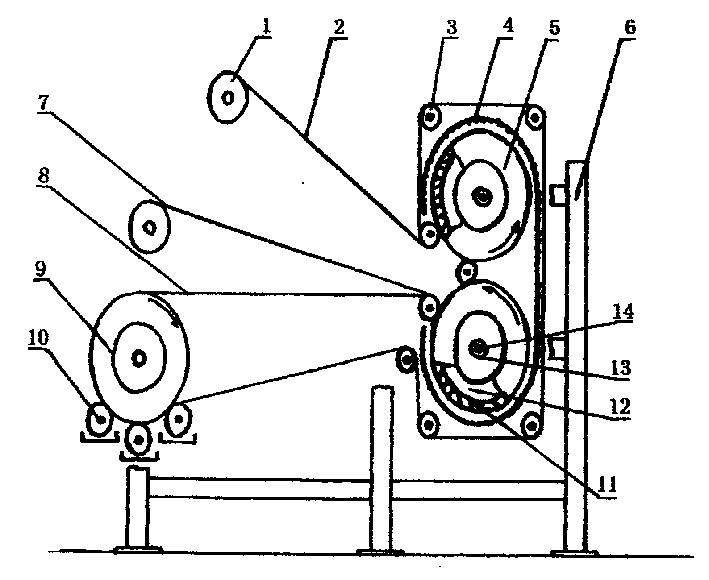

Adsorbing paper-free hot transferring printing and dyeing machine

Owner:BEIJING INST OF CLOTHING TECH

Intercooler of automobile supercharged engine

InactiveCN108869005AEliminate vortexSolve the icingInternal combustion piston enginesIntercoolerEngineering

The invention discloses an intercooler of an automobile supercharged engine. The intercooler comprises an air inlet structure, a core body and an air outlet structure, the core body is arranged between the air inlet structure and the air outlet structure and communicates with the air inlet structure and the air outlet structure, the air inlet structure comprises an inlet pipe and an air inlet chamber which communicate with each other, and a flow guide plate is arranged in the air inlet structure. One part of the flow guide plate is located in the inlet pipe, the other part of the flow guide plate is located in the air inlet chamber, and the flow guide plate is of an integrally formed structure and comprises an arc-shaped plate, a vertical straight plate connected with one end of the arc-shaped plate and a horizontal straight plate connected with the other end of the arc-shaped plate. According to the intercooler, the heat exchange effect of the core body can be improved, and the phenomenon that the intercooler is frozen is avoided.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Anti-freezing saturated wet tail gas condensation dehumidification device and method

PendingCN111530242AEliminate smoke and white mist phenomenonIncrease intake air temperatureGas treatmentDispersed particle separationHeat flowFlue gas

The invention discloses an anti-freezing saturated wet tail gas condensation dehumidification device and method. The device comprises a dehumidification tower and an anti-freezing assembly. The dehumidification tower comprises a tower body, a moisture inlet is formed in the bottom or side wall of the tower body, an exhaust port is formed in the top, dehumidification layers are arranged in the tower body and located above the moisture inlet layer by layer in the smoke flow direction, a plurality of heat exchange modules are arranged in each dehumidification layer, each heat exchange module comprises a plurality of heat exchange membranes which are bonded in sequence, a hot flow channel and a cold flow channel which are distributed by the heat exchange membranes at intervals and are vertically communicated with each other are formed in the heat exchange module, the anti-freezing assembly comprises a preheating air collecting cover and a preheating fan, the preheating air collecting coveris located in the space above the top dehumidification layer, an air inlet of the preheating fan is connected with the preheating air collecting cover through a pipeline, and an air outlet of the preheating fan is connected to the position below a cold flow channel inlet of the heat exchange module in the bottom dehumidification layer through a pipeline. Water resources in the high-humidity fluegas can be effectively recycled, the phenomenon that the high-humidity flue gas discharges white mist is eliminated, and the operation stability of the dehumidification system in winter can be improved.

Owner:新疆天富环保科技有限公司

A uniform flow hot blast stove in which premixed air nozzles communicate with each other and the supply air flow flows in a labyrinth

ActiveCN104805246BEvenly distributedStable combustionBlast furnace detailsHeating stovesCold airCombustor

The invention relates to a flow equalizing hot blast heater with premix air flow nozzle interconnection and air supply flow curved flowing. A combustor wall body is connected with a burner wall body; the burner wall body is supported on a regenerative chamber wall body; the upper part and the middle part of the regenerative chamber wall body are inserted into a burner; a gas inlet pipe and an air inlet pipe on the burner wall body are connected to a gas distribution circuit and an air distribution circuit; a gas main nozzle and an air main nozzle on the gas distribution circuit and the air distribution circuit are communicated with an air flow premixing nozzle passage; a premixing air adjusting nozzle is arranged at the top of the air flow premixing nozzle passage; a communication passage is arranged on the air flow premixing nozzle passage; a hot air outlet pipe is arranged on the combustor wall body; the lower part of the regenerative chamber is built on the hot blast heater bottom in a masonry manner; a casting grate is arranged on support columns at the hot blast heater bottom; a heat accumulator is arranged on the casting grate; a flue gas outlet pipe and a cold air inlet pipe are arranged on the regenerative chamber wall body at the lower part of the casting grate. The flow equalizing hot blast heater has the advantages of high efficiency, high heat strength and high air supply temperature, saves fuel, and reduces waste gas temperature and the emission of harmful gas.

Owner:陈维汉

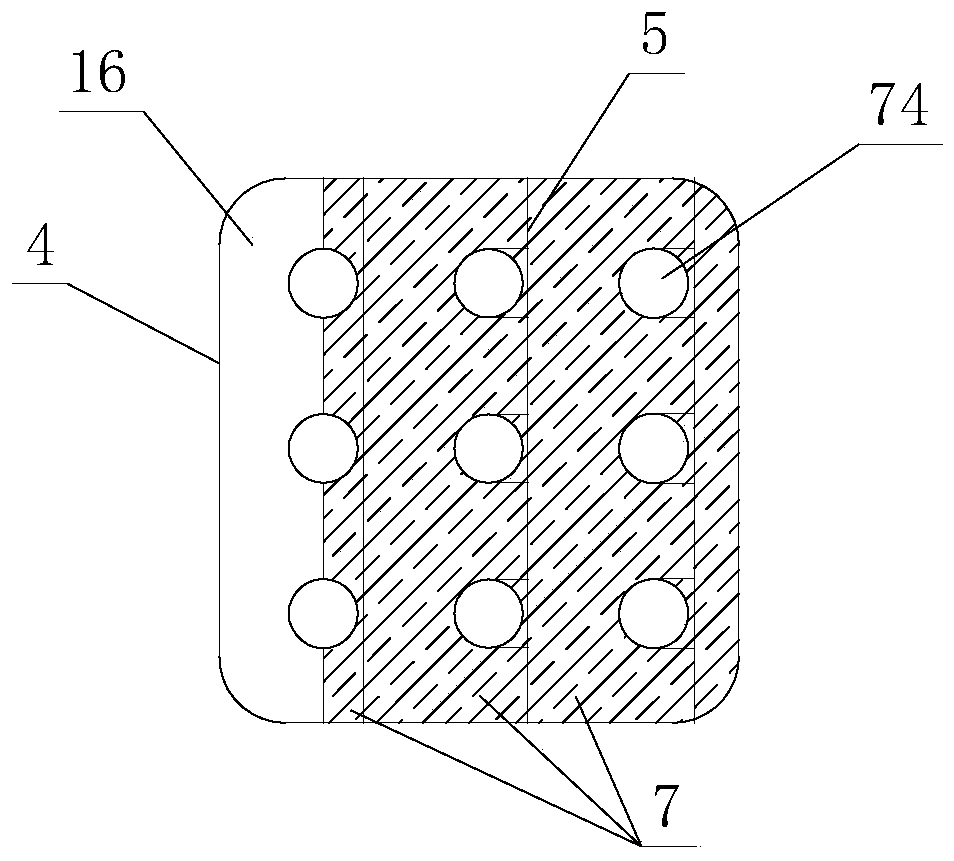

A Condensable Porous Steady Flow Device Heat Exchanger with Varying Spacing

ActiveCN107966051BReduce vibrationReduce noise levelSafety devices for heat exchange apparatusStationary tubular conduit assembliesVapor liquidEngineering

The invention provides a spacing variable condensable porous current stabilizer heat exchanger. The heat exchanger comprises a shell. The two ends of the shell are provided with end sockets correspondingly. Tube plates are arranged at the junctions between the end sockets and the shell. Heat exchange tubes are connected with the tube plates at the two ends. A vapor phase in vapor-liquid two-phaseflow can be condensed into a liquid phase in the heat exchange process. Current stabilizers used for vibration reduction and noise reduction are arranged in the heat exchange tubes. The multiple current stabilizers are arranged in the same heat exchange tube. The distance between the adjacent current stabilizers increases gradually in the flowing direction of fluid in the heat exchange tubes. According to the heat exchanger provided by the invention, vibration of a pipeline is weakened to the maximum extent according to change of the spacing between the current stabilizers when vapor-liquid two phases flow in the pipeline, and noise is lowered; meanwhile, flow resistance is reduced, and the heat exchange uniformity is improved.

Owner:河南盛宏丰化工有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com