Air-conditioning heat exchanger

A technology of heat exchangers and air conditioners, which is applied in space heating and ventilation details, household heating, heating methods, etc., to achieve the effects of improving heat transfer uniformity, improving heat transfer coefficient, and increasing heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

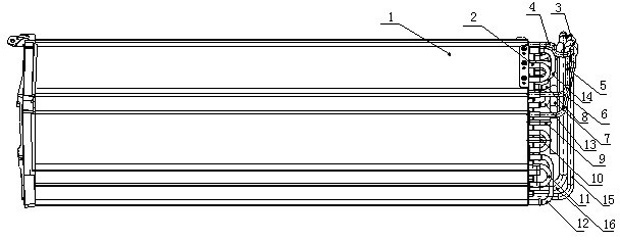

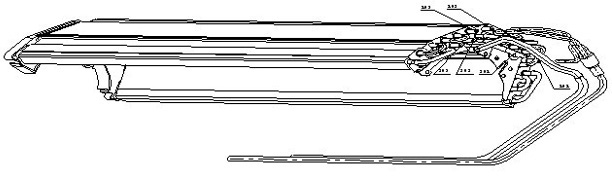

[0023] Such as figure 1 , figure 2 As shown, the air-conditioning heat exchanger of the present invention includes fins 1 and double-row U-shaped tubes 2 passing through the inner cavity of the fins 1, a distributor 3, a first inlet branch pipe 4, a second inlet branch pipe 5, and a second inlet branch pipe 5. Three inlet branch pipes 6, outlet summarizing flute pipe 7, first outlet branch pipe 8, second outlet branch pipe 9, third outlet branch pipe 10, copper jumpers welded at both ends of the U-shaped pipe according to the flow path distribution Elbow 11, bridging elbow 12, bridging elbow 13, bridging elbow 14, liquid inlet pipe 15, air outlet pipe 16.

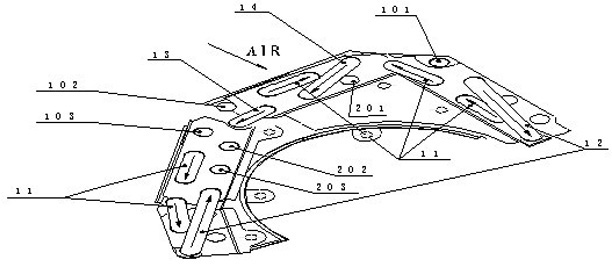

[0024] Such as image 3 As shown, when the air conditioner is cooling, the refrigerant flowing out from the outdoor unit enters the distributor 3 through the liquid inlet pipe 15 and is divided i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com