Intercooler of automobile supercharged engine

A supercharged engine and cooler technology, applied to combustion engines, machines/engines, internal combustion piston engines, etc., can solve engine power and poor user use, increase the risk of intercooler freezing, and high-temperature gas heat exchange Inhomogeneity and other problems, to achieve the effect of increasing the effective inflation efficiency, increasing the uniformity of heat transfer, and solving the freezing effect of the intercooler

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

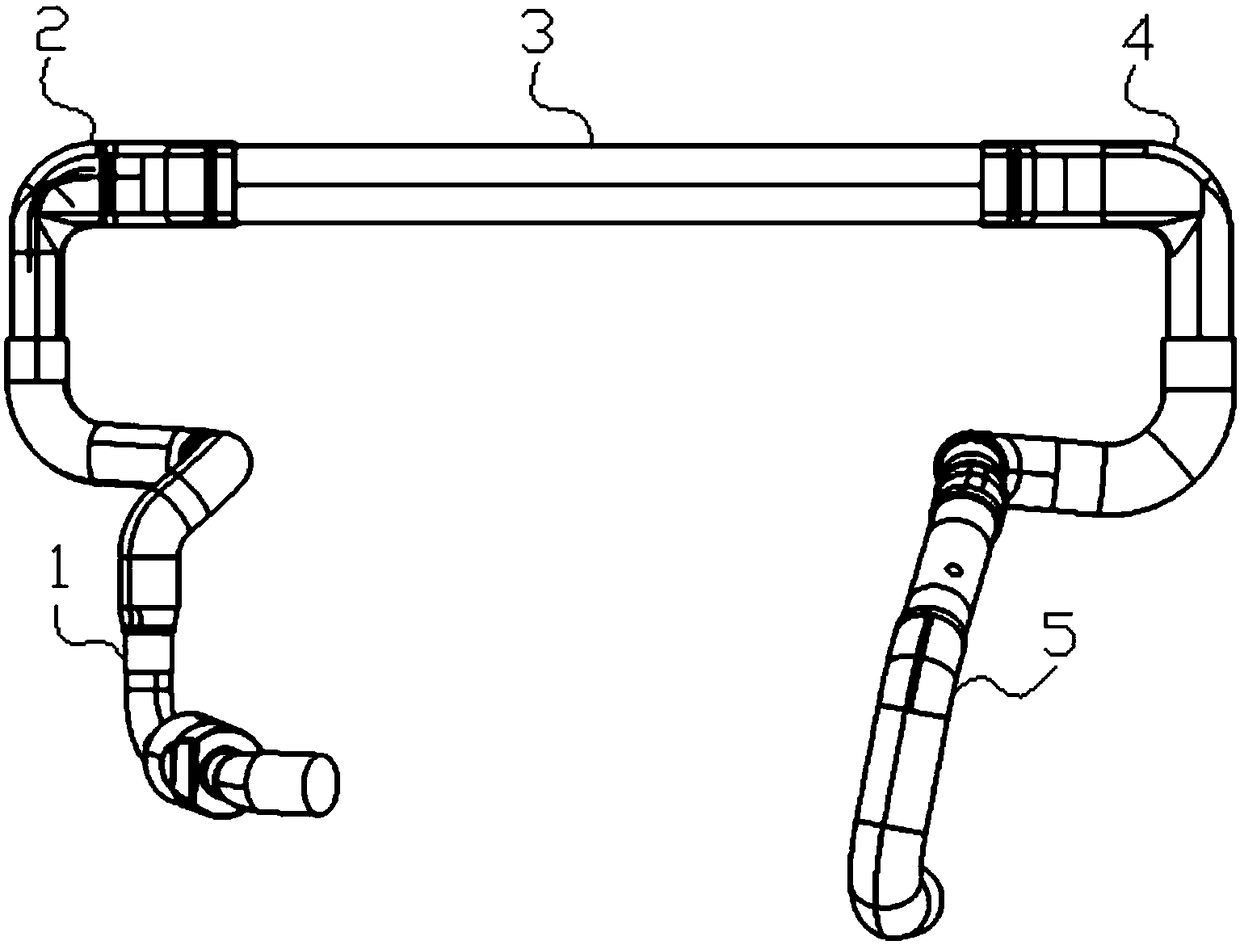

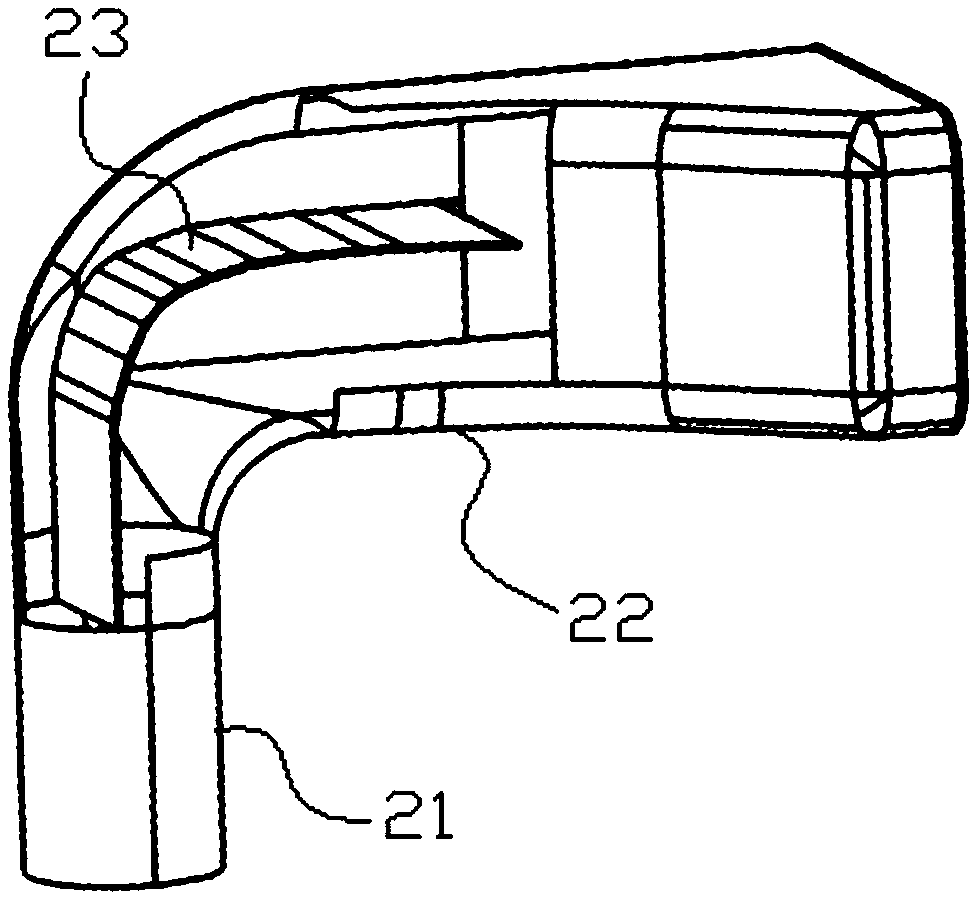

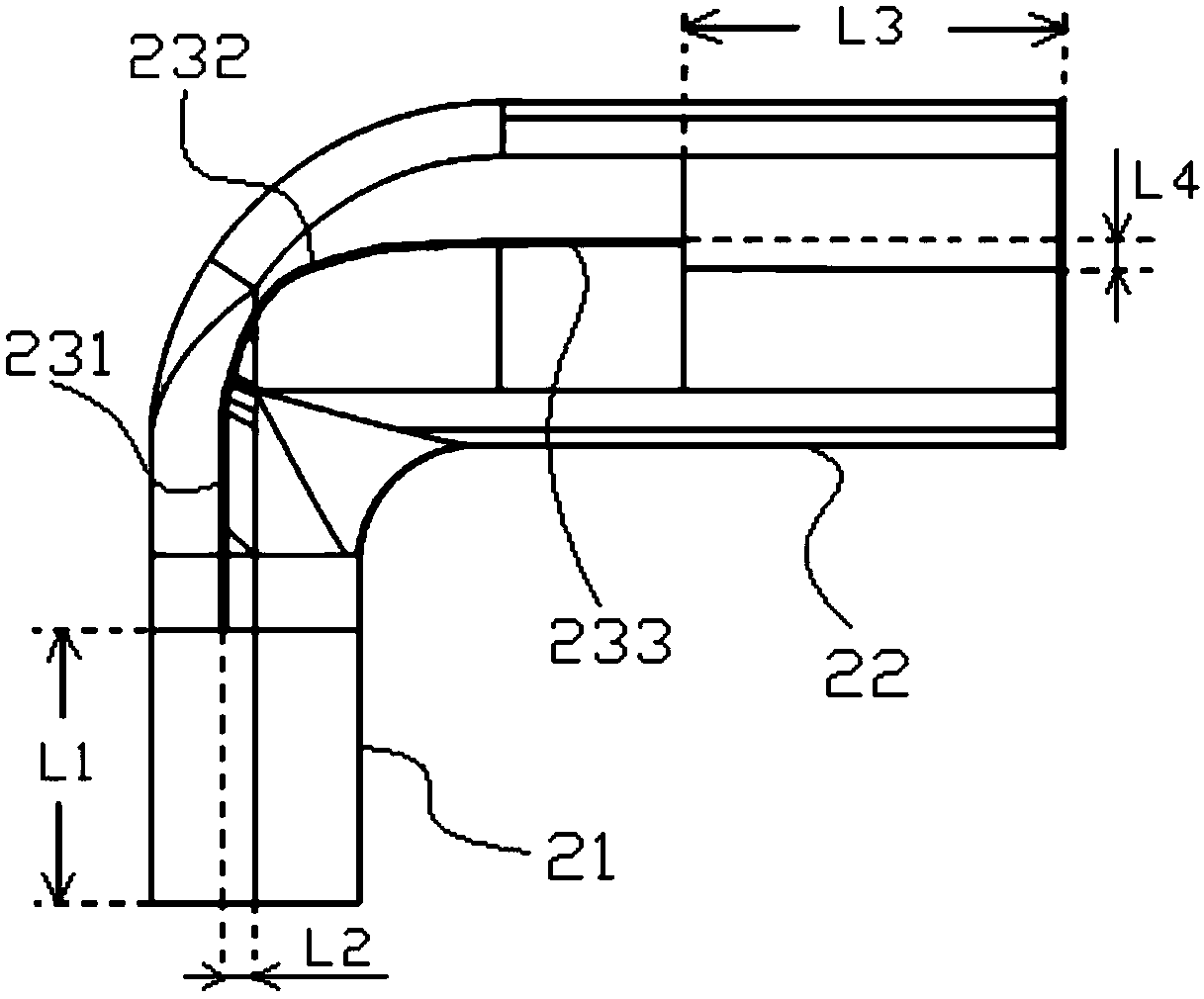

[0018] Embodiment 1: as Figure 1 to Figure 5 The intercooler of the automobile supercharged engine shown includes an air intake structure 2, a core body 3 and an air outlet structure 4. The core body 3 is arranged between the air intake structure 2 and the air outlet structure 4 and is connected to the air intake structure 2 and the air outlet structure. 4 are connected, the intake structure 2 includes an intake pipe 21, an intake chamber 22 and a deflector 23, the intake pipe 21 communicates with the intake chamber 22, a part of the deflector 23 is located in the intake pipe 21, and another part is located In the chamber 22, the inlet pipe 21, the air inlet chamber 22 and the deflector 23 are integrally formed by injection molding, and the material is high-temperature nylon. The deflector 23 is composed of an arc-shaped plate 232 , a vertical straight plate 231 connected to one end of the arc-shaped plate 232 , and a horizontal straight plate 233 connected to the other end o...

Embodiment 2

[0020] Embodiment 2: Most of the structure of the intercooler of the automobile supercharged engine in this embodiment is the same as Embodiment 1, the difference is that: the vertical straight plate 231 is positioned at the right side of the center line of the inlet pipe 21, and is connected with the inlet pipe. The distance between the centerlines of 21 is also 4mm, and the horizontal straight plate 233 is located on the lower side of the centerline of the air inlet chamber 22, and the distance between the centerline of the air inlet chamber 22 is also 4mm.

[0021] The thickness of deflector 23 in above-mentioned embodiment 1,2 also can be 1mm, 4mm, 5mm, the length of vertical straight plate 231 also can be 30mm, 50mm, the length of horizontal straight plate 233 also can be 40mm, 60mm, arc-shaped The central angle of the plate 232 can also be 60°, 75°, 90°, and the arc length can also be 40mm, 50mm, 70mm. The distance between the lower end of the vertical straight plate 231...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com