Shell-tube-type phase-change energy storage heat exchanger

A phase-change energy storage and heat exchanger technology, applied in the direction of heat exchanger types, indirect heat exchangers, heat storage equipment, etc., can solve the problems of bulky, low heat exchange efficiency, etc. The effect of speeding up the heat exchange rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

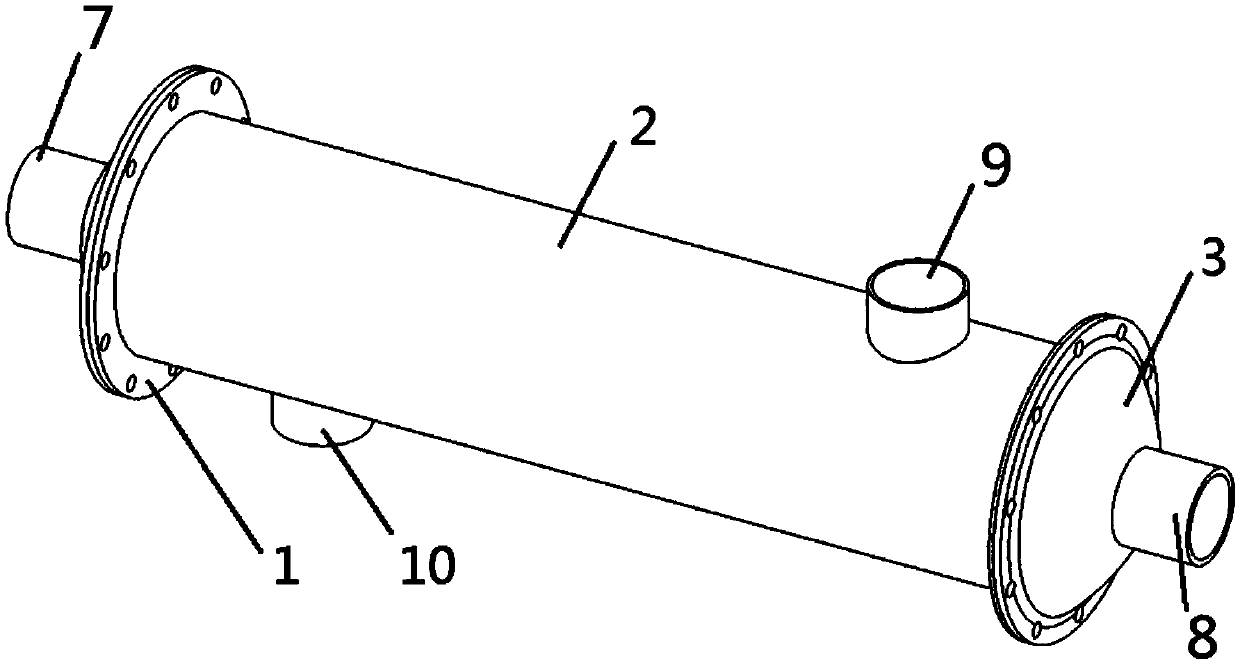

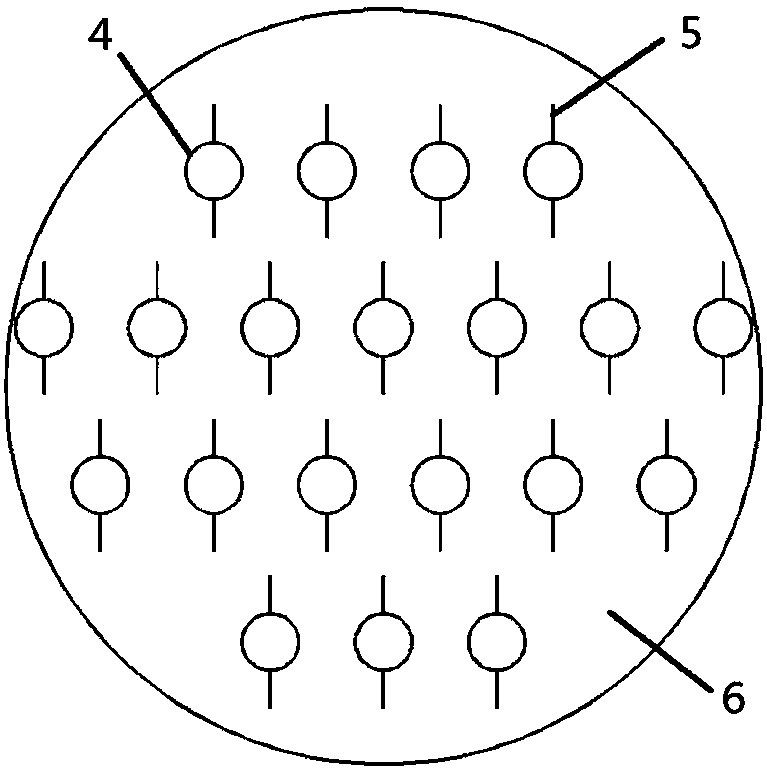

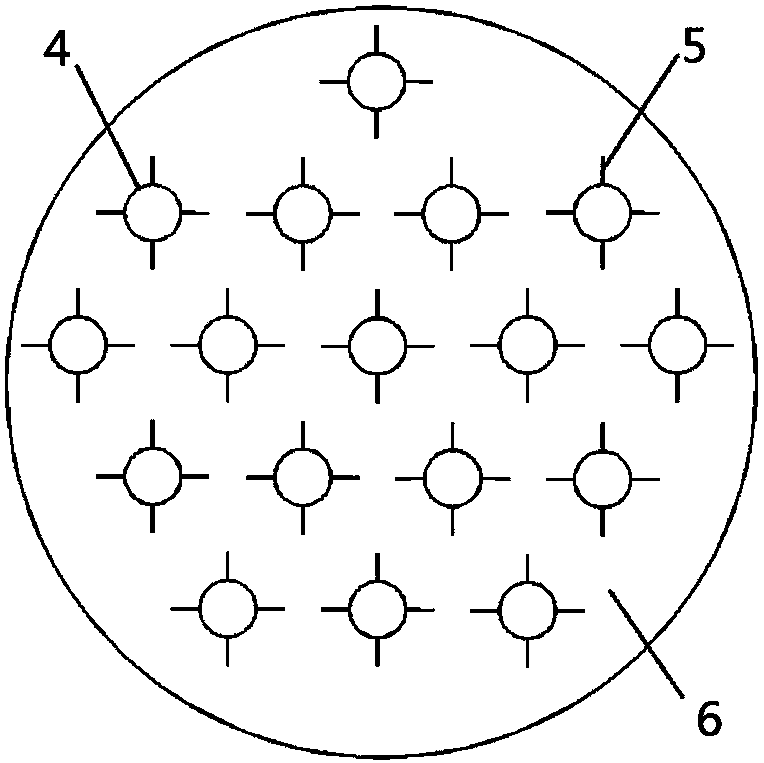

[0024] see figure 1 , 2. The present invention includes two heat exchanger shell tubes 2 equipped with left and right end covers 1, 3, and heat source fluid inlets and outlets 7, 8 are opened on the left and right end covers 1, 3, and heat exchanger shells There are several groups of heat exchange tubes 4 connected to heat source fluid inlets and outlets 7 and 8 on both sides installed in the cylinder 2. Ribs 5 are evenly distributed on the outer wall of the heat exchange tubes 4. Phase change material inlet 9 and phase change material discharge port 10 are respectively opened on the upper and lower side walls of both sides. The heat source fluid flows in the heat exchange circular tube 4, and the phase change heat storage material is poured between the heat exchange circular tube 4.

[0025] When the phase-change thermal storage material is injected into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com