Evaporation source device for evaporator and evaporator

A technology of evaporation machine and evaporation source, which is applied in vacuum evaporation coating, sputtering coating, ion implantation coating and other directions, can solve the problem of reducing the yield of evaporation material, uneven heat transfer, poor thermal conductivity, etc. The problem is to reduce the low thermal conductivity, improve the uniformity of heat transfer, and shorten the heat transfer path.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

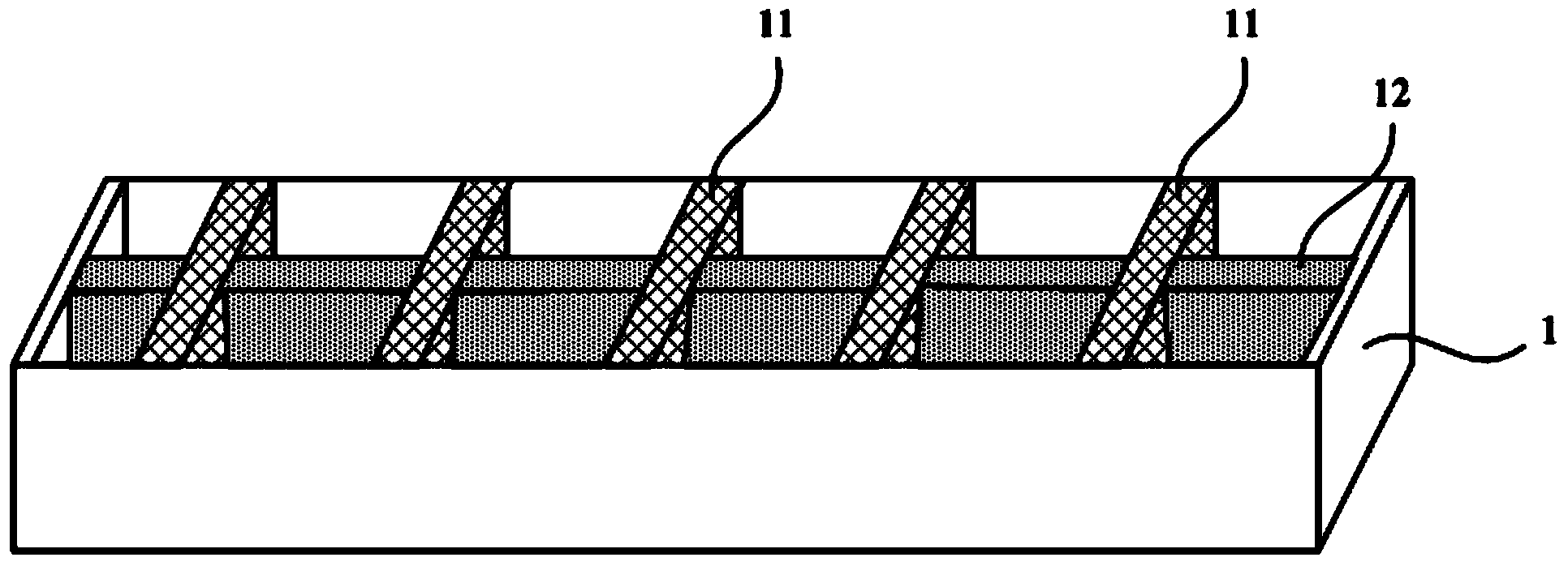

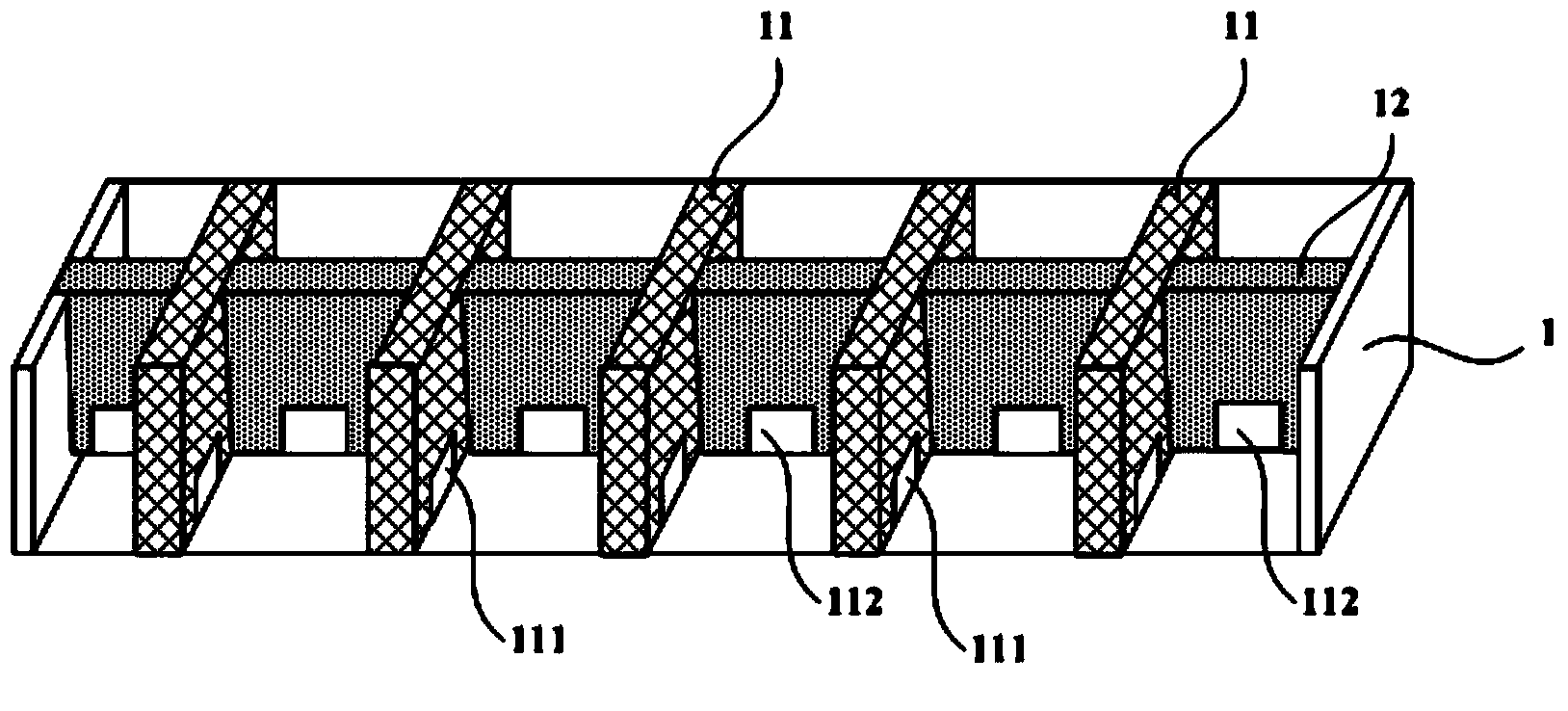

[0028] In order to improve the heat transfer uniformity of the vapor deposition material, an embodiment of the present invention provides an evaporation source device of the vapor deposition machine and an vapor deposition machine. In this technical solution, since a plurality of first thermally conductive partitions along the first direction and a plurality of second thermally conductive partitions along the second direction are used in the crucible groove, the first thermally conductive partitions and the second thermally conductive partitions can separate the crucible The heat of the wall is conducted, therefore, the vapor deposition materials in the multiple storage tanks composed of the first heat conduction partition and the second heat conduction partition are heated evenly, which greatly reduces the influence of the vapor deposition material from its own low thermal conductivity , Therefore, the uniformity of heat transfer can be greatly improved, thereby improving the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com