Wing-shaped pipe type adsorption column for polycrystalline silicon tail gas recovery system

A tail gas recovery and adsorption column technology, applied in gas treatment, silicon compounds, climate sustainability, etc., can solve the problem of adsorbent heating efficiency, low cooling efficiency, unsatisfactory hydrogen purity, and poor adsorbent regeneration effect. and other problems to achieve the effect of improving the regeneration effect, reducing the regeneration time and saving the production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

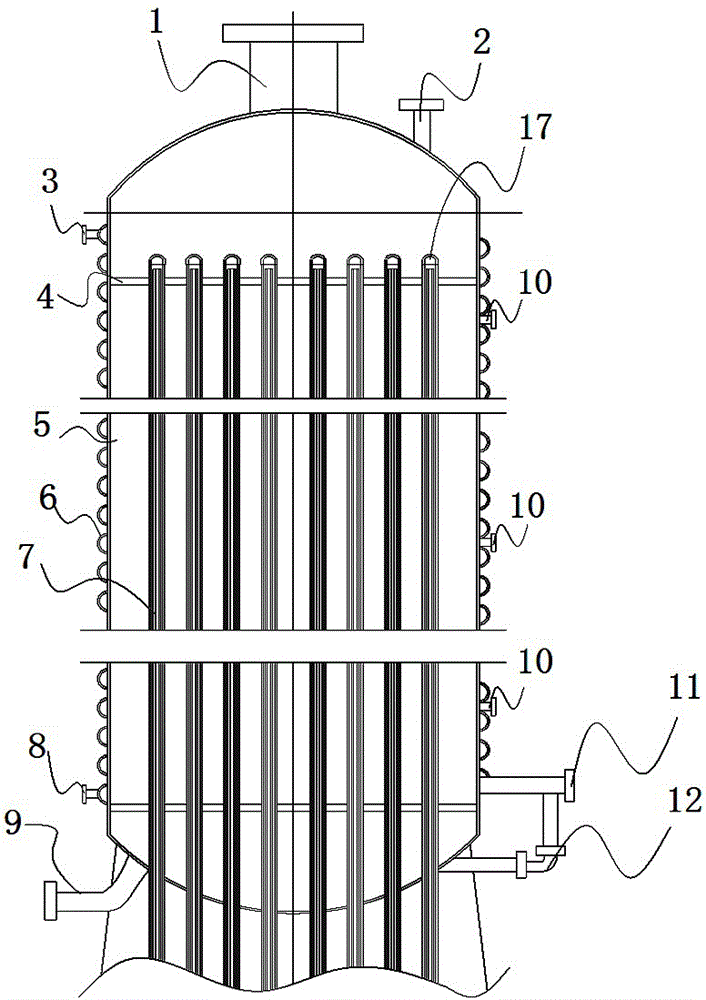

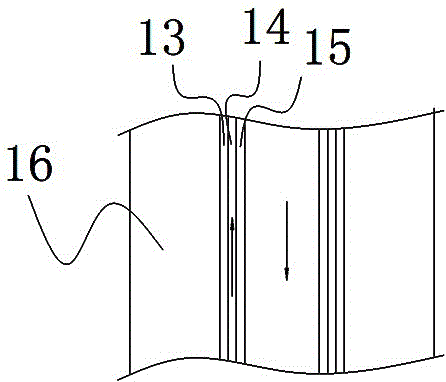

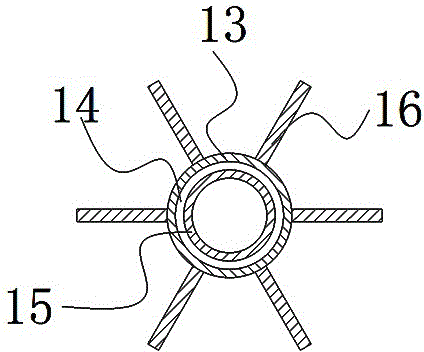

[0018] Such as Figure 1~Figure 4 As shown, the polysilicon tail gas recovery system has a finned sleeve type adsorption column, which includes an adsorption column body 5, a return sleeve 7 and a companion pipe 6, and the companion pipe 6 is spirally installed on the outer tube wall of the adsorption column body 5 , the return sleeve 7 is installed in the adsorption column body 5 through the pipe support plate 4, the return sleeve 7 includes an outer tube 13 and an inner tube 15, in this embodiment, the inner tube 13 and The outer tube 15 is made of metal material, and the metal material is required to have good thermal conductivity, which can quickly realize heat exchange, so as to achieve the purpose of rapid heating or cooling, and also requires high pressure resistance. The inner tube 15 Locate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com