A slurry bed internal circulation reaction device and its application and method for producing hydrogen peroxide

A reaction device and slurry bed technology, applied in the field of slurry bed loop reactors, can solve the problems of uneven temperature distribution in the bed, low catalyst utilization efficiency, large catalyst liquid holding capacity, etc. Reduced operational burden, uniform gas distribution and temperature distribution

Active Publication Date: 2017-05-24

CHINA PETROLEUM & CHEM CORP +1

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the most commonly used in the anthraquinone hydrogenation process in China is the downflow fixed bed reactor, that is, the trickle bed reactor, but the fixed bed reactor has low catalyst utilization efficiency, low reaction selectivity, uneven temperature distribution in the bed, The problem of large local liquid holding capacity of the catalyst and serious degradation of the working fluid

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0072] Embodiment 1 illustrates the effect of synthesizing hydrogen peroxide by the circulating flow reactor in the slurry bed.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Login to View More

Abstract

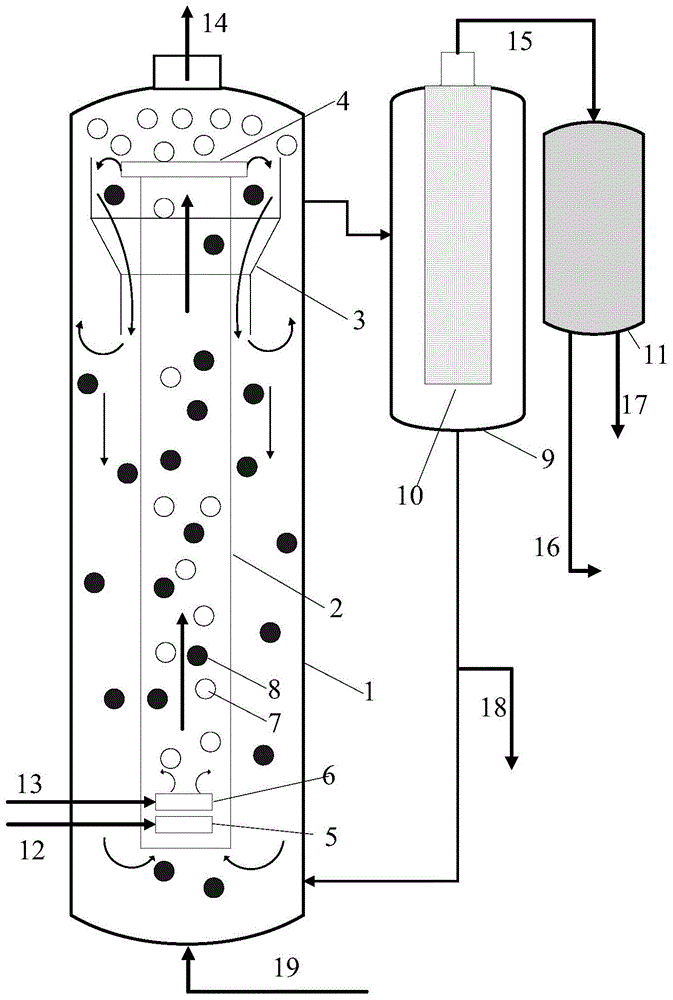

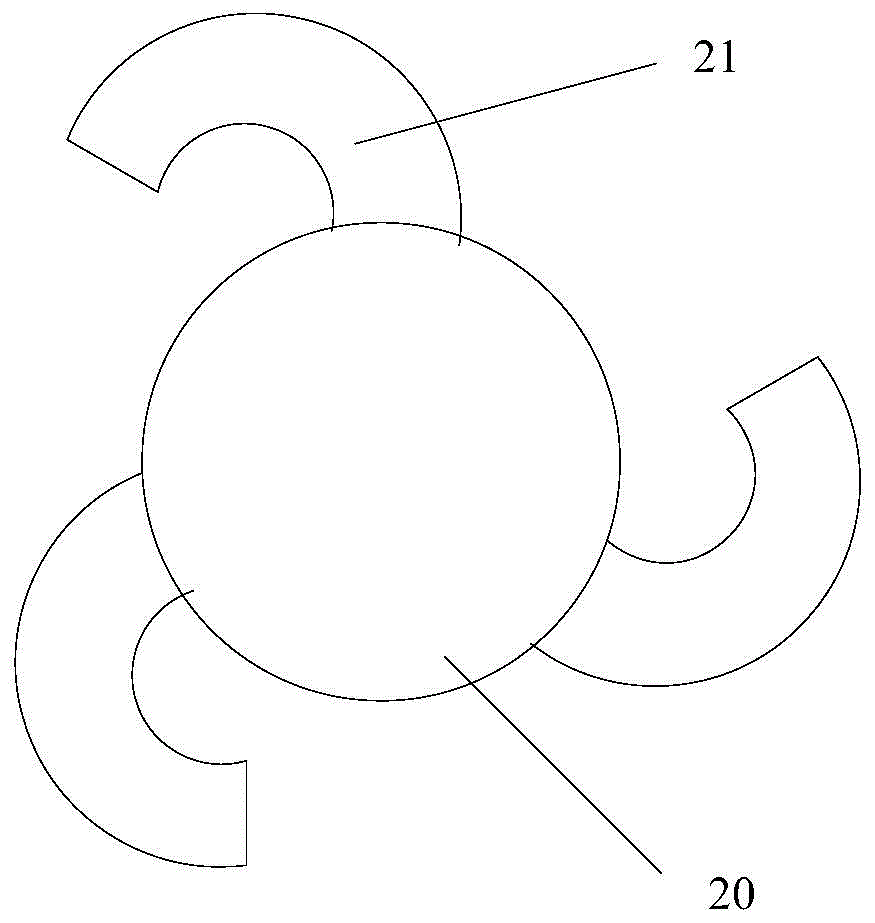

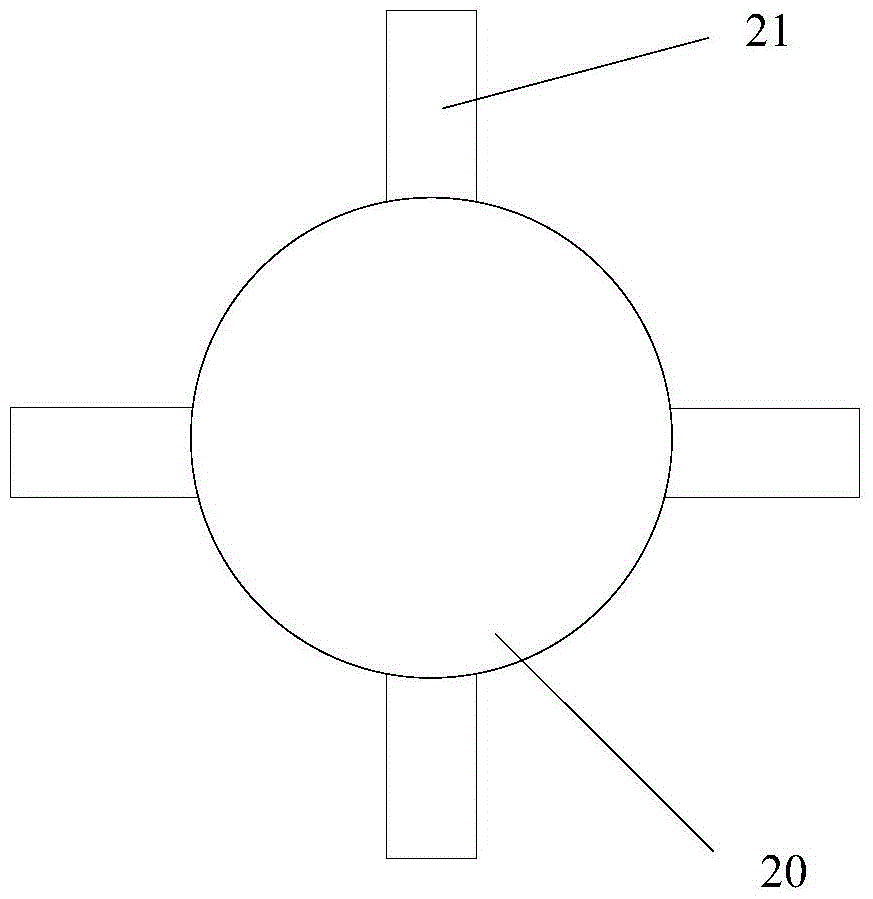

The invention relates to a loop reaction device in a slurry bed, application and a method for producing hydrogen peroxide. The loop reaction device comprises a slurry bed reactor and a solid-liquid separator, wherein the upper part of the slurry bed reactor is communicated with the upper part of the solid-liquid separator, and the bottom of the slurry bed reactor is communicated with the bottom of the solid-liquid separator; and a coaxial inner sleeve is arranged in the slurry bed reactor, an outer sleeve is arranged between the inner sleeve and the outer wall of the slurry bed reactor at the upper part of the slurry bed reactor, a raw material inlet and a fluid distributor are arranged in the inner sleeve and at the bottom, a gas outlet is formed in the top of the slurry bed reactor, a filtration component is arranged in the solid-liquid separator, and a clear liquid outlet is formed in the wall of the solid-liquid separator via the filtration component. According to a hydrogenation method for producing hydrogen peroxide by an anthraquinone method with the adoption of the slurry bed loop reactor, the gas-liquid-solid three-phase separation efficiency is high, the excess local liquid holdup of a catalyst is avoided, the possibility of excessive hydrogenation is reduced, the hydrogenation efficiency is further effectively improved and a hydrogen peroxide product with relatively high concentration can be obtained.

Description

technical field [0001] The present invention relates to a slurry bed loop reactor and its application method, more specifically, to a slurry bed reactor suitable for the hydrogenation process in the process of producing hydrogen peroxide by anthraquinone method and a method for producing hydrogen peroxide Methods. Background technique [0002] Hydrogen peroxide is an important inorganic chemical raw material, which is widely used in papermaking, textile, chemical synthesis, military industry, electronics, food processing, medicine, cosmetics, environmental protection, metallurgy and many other fields. Hydrogen peroxide decomposes to produce water and oxygen, which has no secondary pollution to the environment and is a green chemical. At present, the anthraquinone method is widely used in the production of hydrogen peroxide at home and abroad. The anthraquinone method to produce hydrogen peroxide uses anthraquinone derivatives as the working carrier. Under the action of a c...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B01J8/22C01B15/023

CPCB01J8/008B01J8/22B01J2208/00796C01B15/023

Inventor 朱振兴侯栓弟郑博唐晓津胡立峰吕庐峰李学锋

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com