Herringbone corrugated plate for welding plate type heat exchanger

A technology of heat exchangers and welded plates, applied in the field of herringbone corrugated plate structures, can solve the problems of difficult design of medium inlet and outlet structures, uneven distribution of plate fluid, etc., and achieve simple structure, uniform fluid distribution, and no dead zone Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

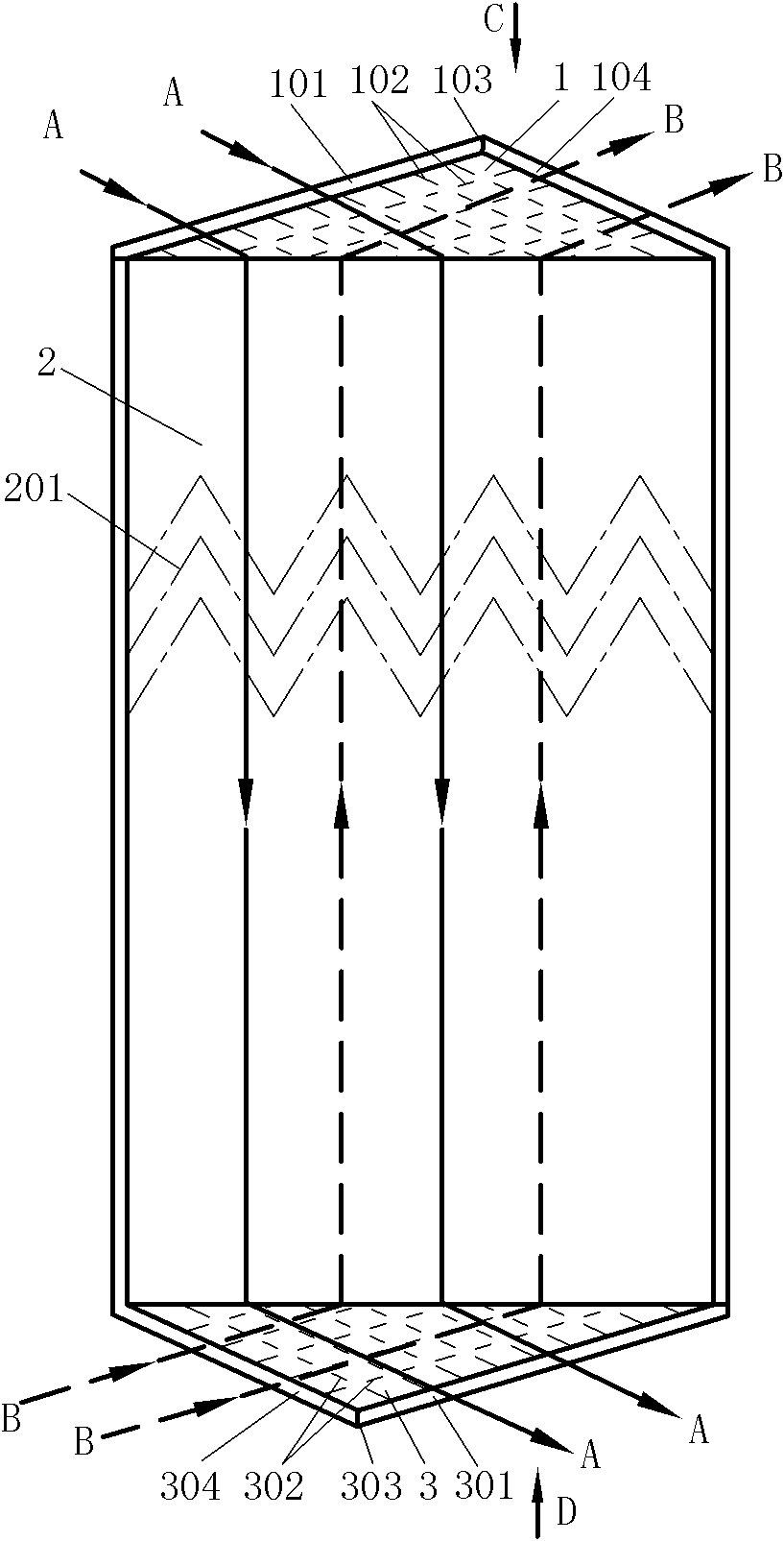

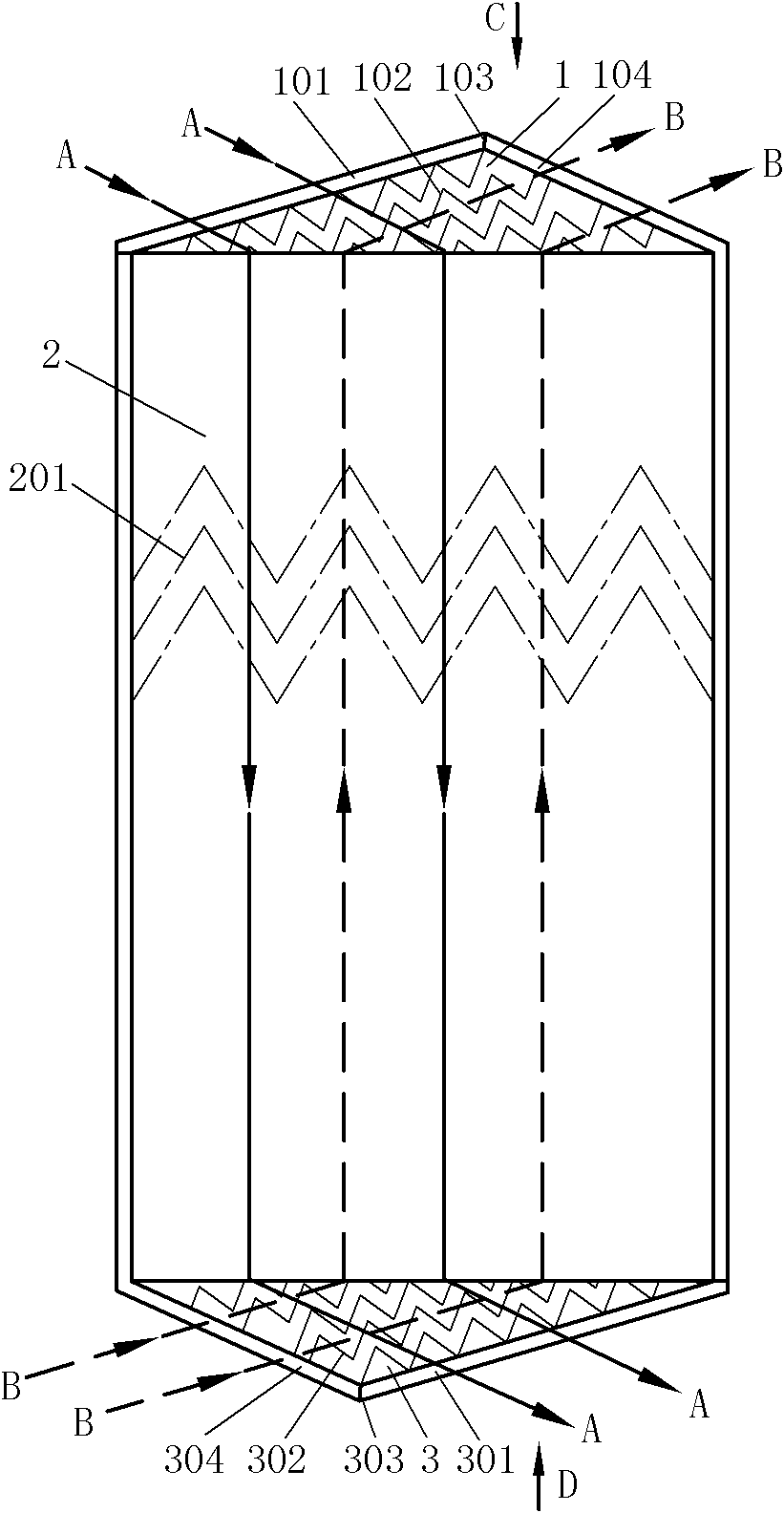

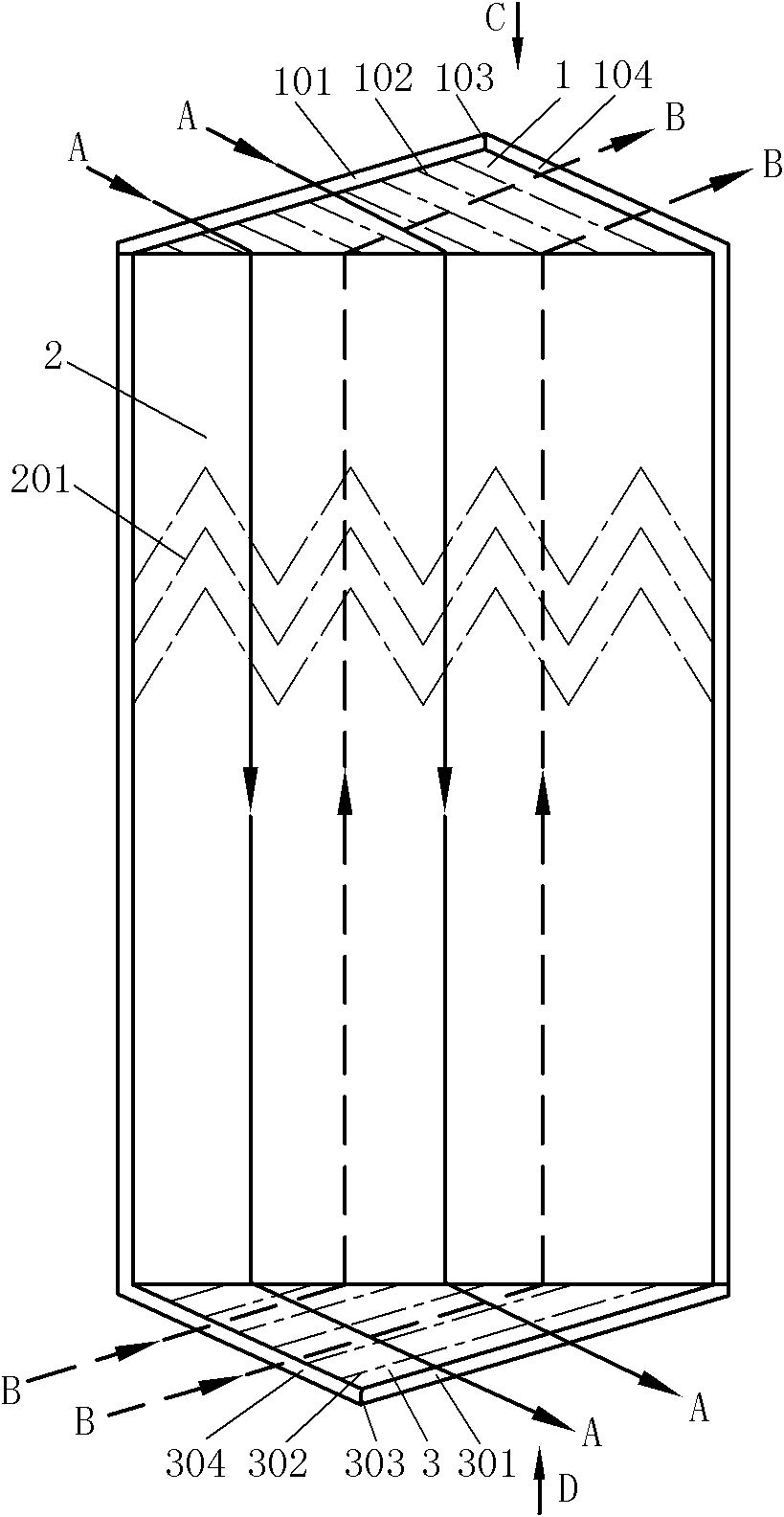

[0022] Concrete structure of the present invention refers to figure 1 , figure 2 , image 3 shown. Numbers in the figure: A. Hot (cold) medium, B. Cold (hot) medium, 1. Upper end distribution diversion area, 101. Medium A inlet hypotenuse, 102. Upper end distribution diversion area corrugation, 103. Hemming, 104. Outlet hypotenuse of medium B, 2. Rectangular heat transfer area, 201. Corrugation of rectangular heat transfer area, 3. Lower end distribution diversion area, 301. Media A outlet hypotenuse, 302. Lower end distribution diversion area corrugation, 303. Hem, 304. Media B inlet bevel.

[0023] figure 1 Shown is a structure in which the triangular distribution area is a checkered corrugation. figure 2 Shown is a structure in which the triangular distribution area is a herringbone corrugation. image 3 Shown is a structure in which the triangular distribution area is a straight oblique corrugation.

[0024] The herringbone corrugated plate is composed of a triang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com