Gas and solid radial reactor for moving-bed

A moving bed and reactor technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve problems such as difficult engineering implementation, and achieve the effects of easy implementation, easy manufacturing and assembly, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

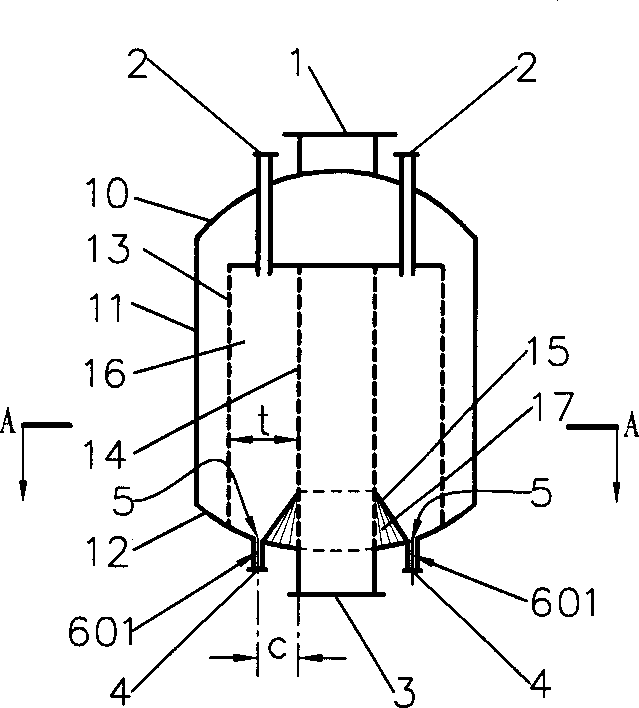

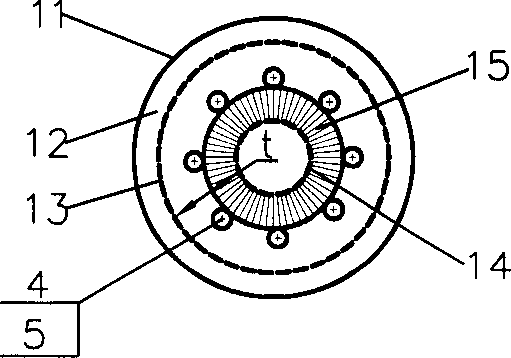

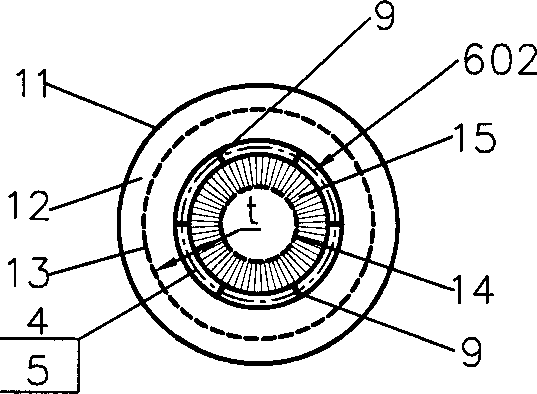

[0018] Such as figure 1 and figure 2 The moving bed gas-solid radial reactor shown includes a shell, which is composed of a cylindrical side wall 11 , an upper seal 10 and a bottom seal 12 . The shell is provided with an inner net 14 and an outer net 13 which are arranged sequentially from the inside to the outside along the axial direction of the shell. An annular space 16 is formed between the inner net 14 and the outer net 13. After the annular space 16 is filled with catalyst, a cylindrical catalyst is formed. bed. A reactant inlet 1 is provided on the top cover 10 of the housing, and a reaction product outlet 3 is provided on the bottom cover 12 . A plurality of (more than one) catalyst introduction pipes 2 are arranged at intervals on the upper head 10 at the top of the reactor for introducing the catalyst into the annular space 16 . A plurality of (more than one) catalyst discharge pipes 4 with a circular cross-section are arranged at intervals on the bottom head 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com