Vertical storage tank leakage monitoring system with dual-layer tank bottom plate structure

A technology for monitoring systems and vertical storage tanks, applied to containers, packaging, transportation and packaging, etc., can solve the problems of large economic losses, failure to find leakage, time-consuming and labor-intensive problems, to avoid leakage accidents, eliminate flow dead zones, reduce The effect of the leak

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Further description will be given below in conjunction with the embodiments shown in the accompanying drawings.

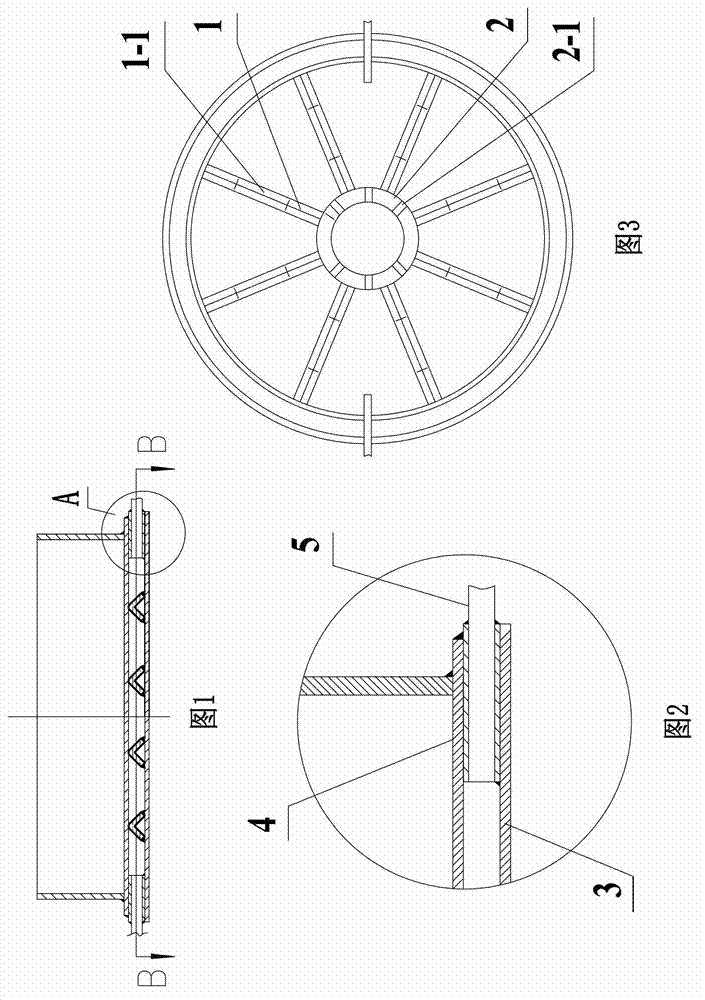

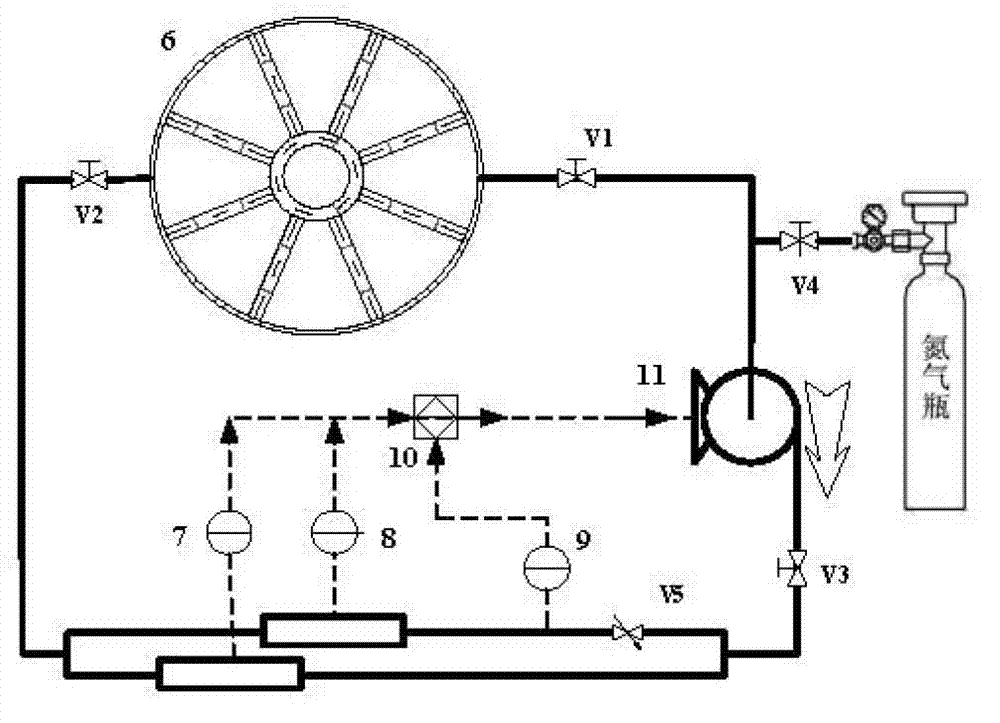

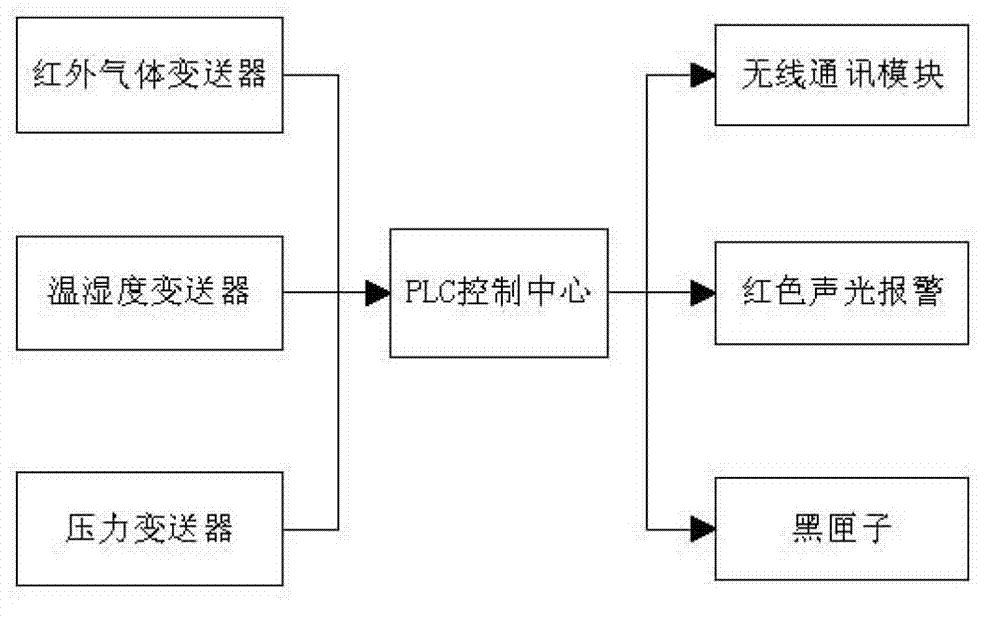

[0023] As shown in the figure, the vertical storage tank leakage monitoring system provided by the present invention has a double-layer tank bottom plate structure. The vertical storage tank (6) bottom structure includes an upper bottom plate (4), a lower bottom plate (3) and a The airtight cavity 8 between the base plate and the lower base plate. The upper and lower bottom plates are spliced by multiple steel plates. The splicing of the bottom plates adopts a butt joint structure. After welding, the internal and external quality of the welds are inspected to ensure the airtightness of the inner cavity of the sandwich formed; and the diameter of the lower bottom plate is slightly smaller than that of the upper bottom plate. Large to facilitate welding around the upper and lower plates. The airtight cavity is formed by setting a support structure between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com