Improved Rotating Disk Column Internals for Solids-Containing Extraction Operations

An improved, rotating disk tower technology, applied in the direction of solid solvent extraction, solvent extraction, chemical instruments and methods, etc., can solve problems such as low solid content, blockage of tower body, and influence on extraction operation, so as to improve processing capacity and prevent solid phase Effect of deposition and elimination of flow dead zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

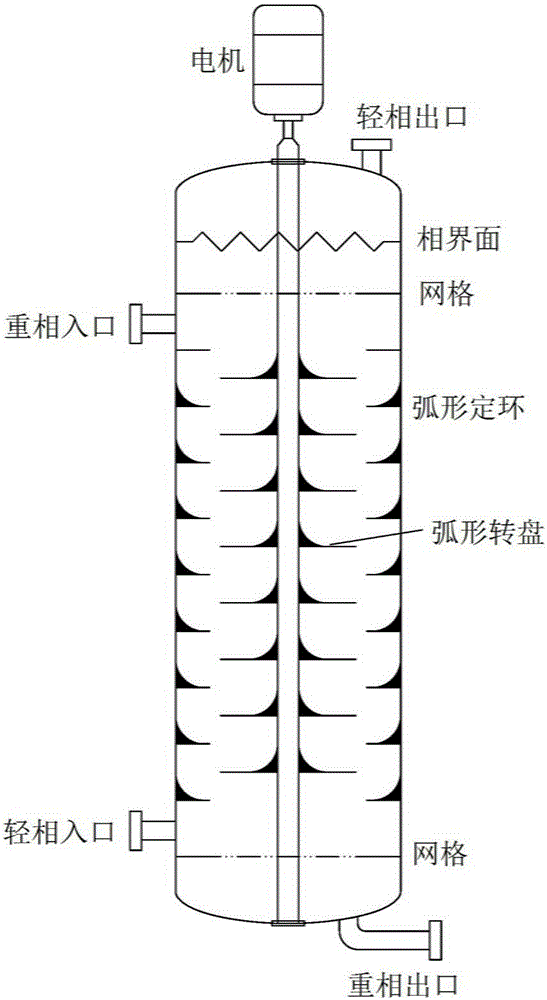

[0021] An improved internal component of a turntable column suitable for solid-containing extraction operations, which includes a turntable and a fixed ring, and is characterized in that the turntable and the fixed ring are designed in an arc shape.

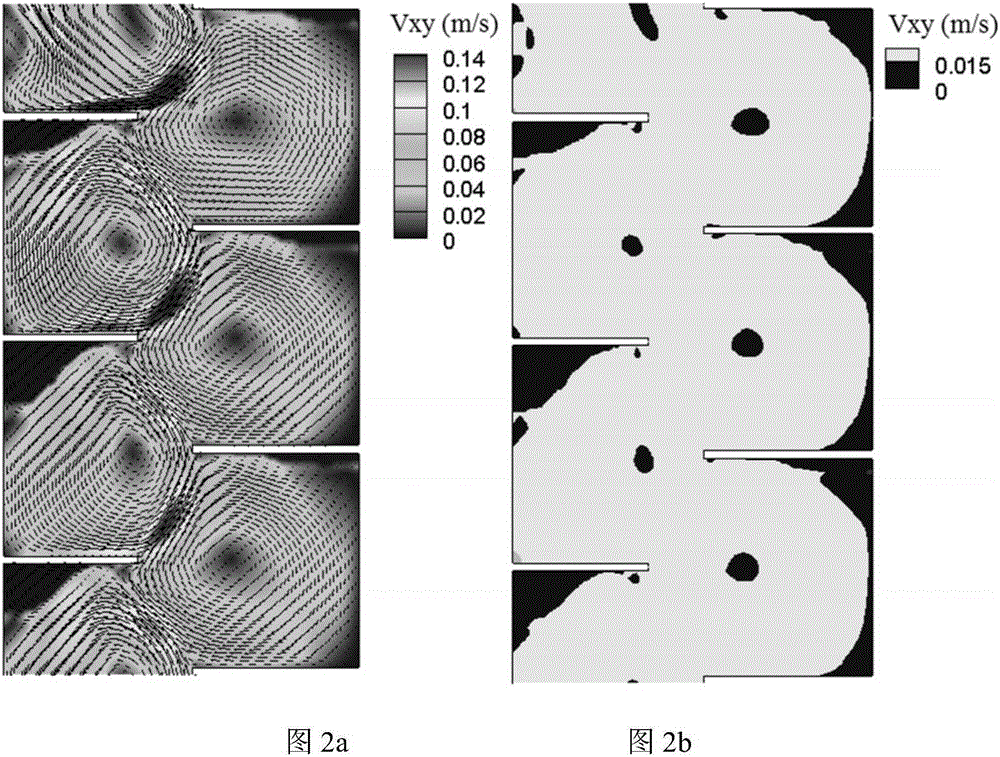

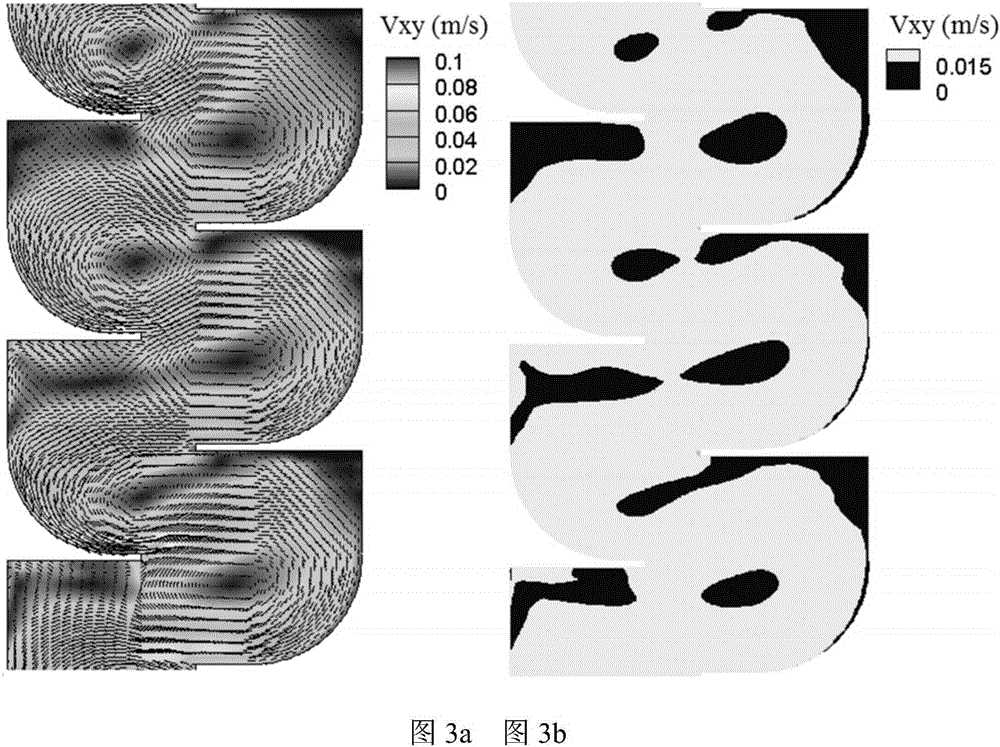

[0022] Technically speaking, the radian on the fixed ring and the turntable matches the vortex formed by the multiphase fluid of the material in the tower to prevent the generation of flow dead zone;

[0023] The upper side of the fixed ring is processed into a streamline arc suitable for the multiphase flow field, or the upper and lower sides of the fixed ring are simultaneously processed into a streamline arc suitable for the multiphase flow field.

[0024] The upper side of the turntable is processed into a streamline arc suitable for the multiphase flow field, or the upper and lower sides of the turntable are simultaneously processed into a streamline arc suitable for the multiphase flow field.

[0025] The diameter of the ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com