a centrifugal fan

A centrifugal fan and air outlet technology, which is used in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems such as the decrease of the air speed of the air inlet of the range hood, the decrease of the sound quality of the range hood, and the disturbance of the volute airflow. Eliminate flow dead zone, improve fan performance and reduce airflow turbulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

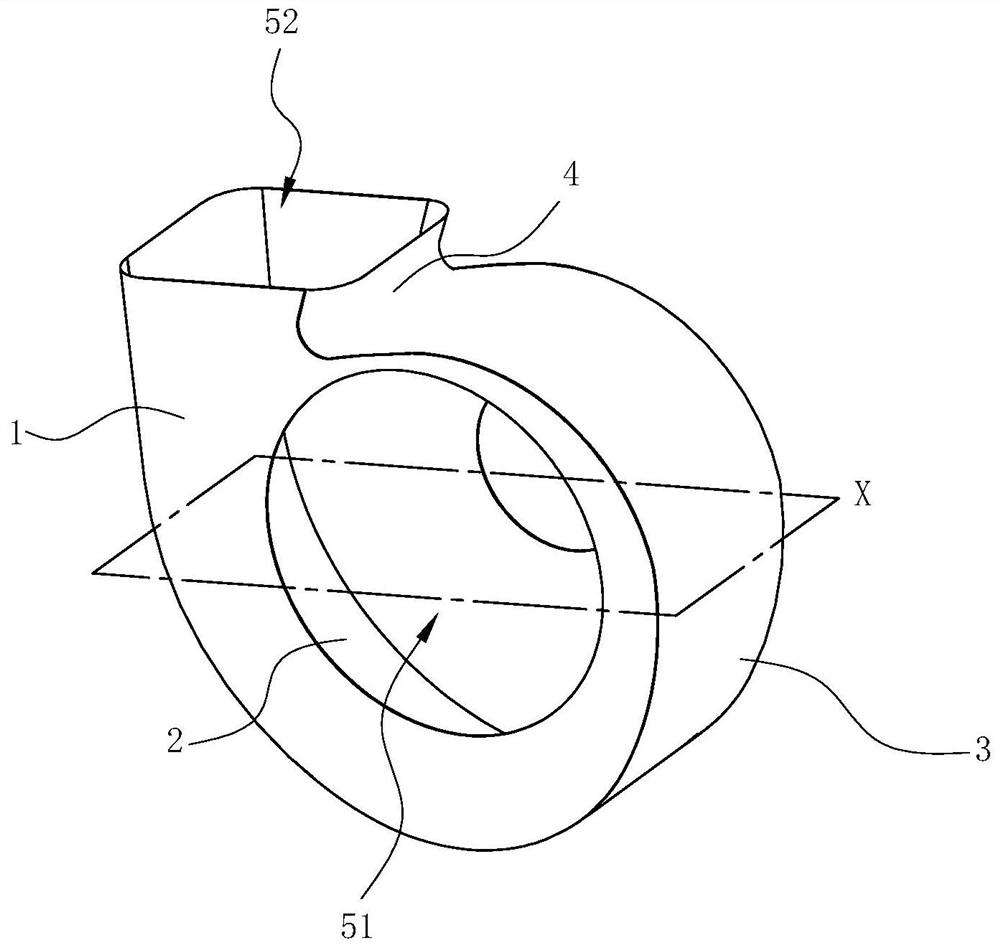

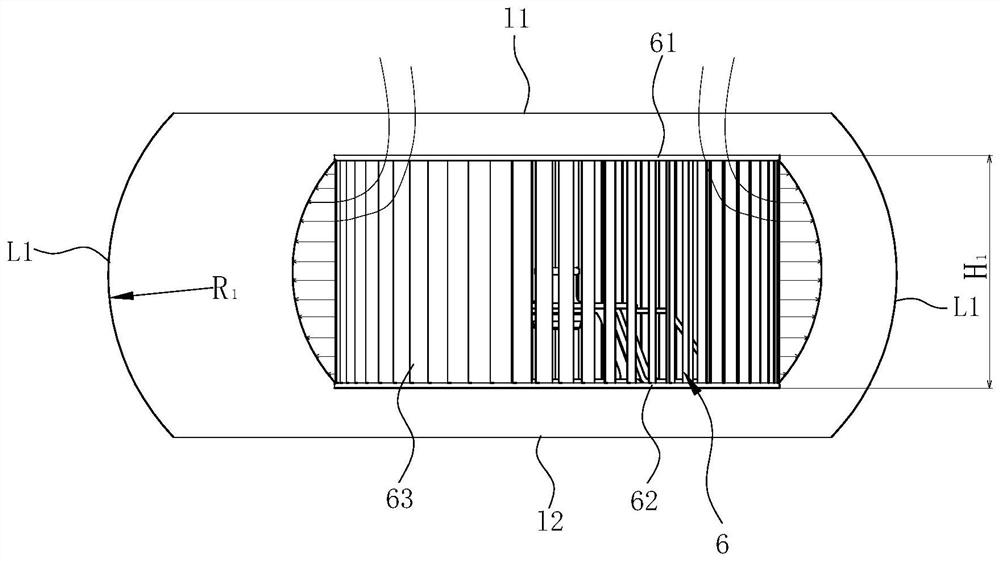

[0019] see figure 1 and figure 2 , a volute for a centrifugal fan, including a front cover 1, a rear cover 2, a ring wall 3 disposed between the front cover 1 and the rear cover 2, and a volute tongue 4. An air inlet 51 and an air outlet 52 are opened on the volute formed by the above components. The centrifugal fan used in the volute further includes an impeller 6 arranged in the volute, and the impeller 6 includes a front disk 61 , a rear disk 62 and a plurality of blades 63 arranged between the front disk 61 and the rear disk 62 .

[0020] The front cover 1 and the rear cover 2 are parallel to each other, and the plane X perpendicular to the front cover 1 and the rear cover 2 and parallel to the air outlet 52 is used as a section (through the ring wall 3, preferably below the volute tongue 4), to obtain For a schematic cross-section of the volute, see figure 2 , on this cross-section X, the profile line of the ring wall 3 is respectively connected to the profile line l...

Embodiment 2

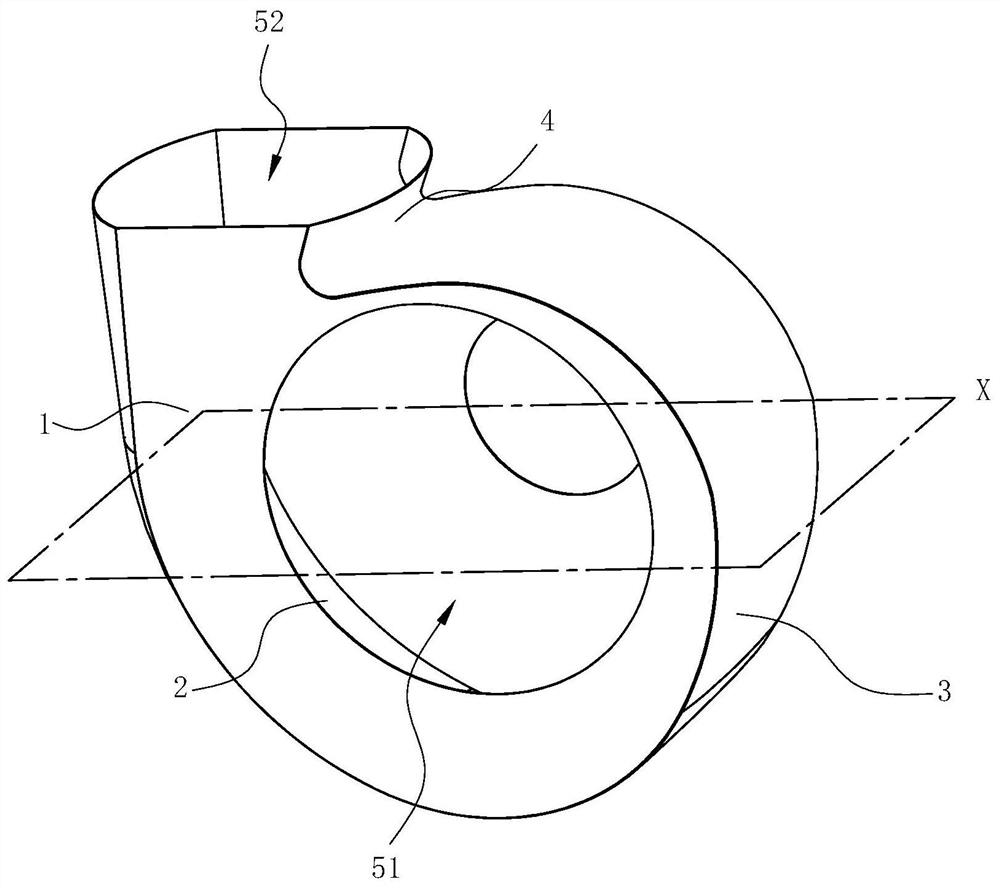

[0024] see image 3 and Figure 4 , in this embodiment, the difference from the first embodiment above is that the profile line of the ring wall 3 on the section X is respectively connected to the corresponding two ends of the profile line l1 of the front cover 1 and the profile line l2 of the rear cover 2 Between the straight line segment L2, the two ends of each straight line segment L2 are respectively connected to the corresponding end of the front cover 1-shaped line l1 through the second circular arc segment L3, and corresponding to the rear cover 2-shaped line l2 through the third circular arc segment L4 The ends are connected, and both the second arc segment L3 and the third arc segment L4 protrude toward the outside of the volute. Preferably, the radii of the second arc segment L3 and the third arc segment L4 are equal, both being R 2 . And preferably, H 2 / 5《R 2 "H 2 / 3, where H 2 is the width of the volute.

[0025] h 2 / 5《R 2 , whose purpose guarantees th...

Embodiment 3

[0027] see Figure 5 and Figure 6 , In this embodiment, the difference from the first embodiment above is that the two ends of each first arc segment L1 are respectively tangent to the corresponding ends of the front cover 1-shaped line l1 and the rear cover 2-shaped line l2.

[0028] In Embodiments 2 and 3, the molded line of the ring wall 3 and the molded line l2 of the front cover 1 and the rear cover 2 are respectively connected by arc segments or tangentially connected, which can effectively eliminate the flow dead zone existing in the volute, Eliminate the vortex at the edge of the volute, effectively improve the aerodynamic efficiency in the volute, increase the air volume, and reduce the aerodynamic noise.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com