A high-temperature fire-tube waste heat boiler tube plate cooling chamber

A waste heat boiler and cooling chamber technology, applied in the field of tube sheet cooling chamber, can solve the problems of insufficient cooling of synthetic gas pipe flexible tube sheet, unreasonable structure of tube sheet cooling chamber, uneven cooling of flexible tube sheet, etc. Nearby temperature, elimination of flow dead zone, small effect of thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

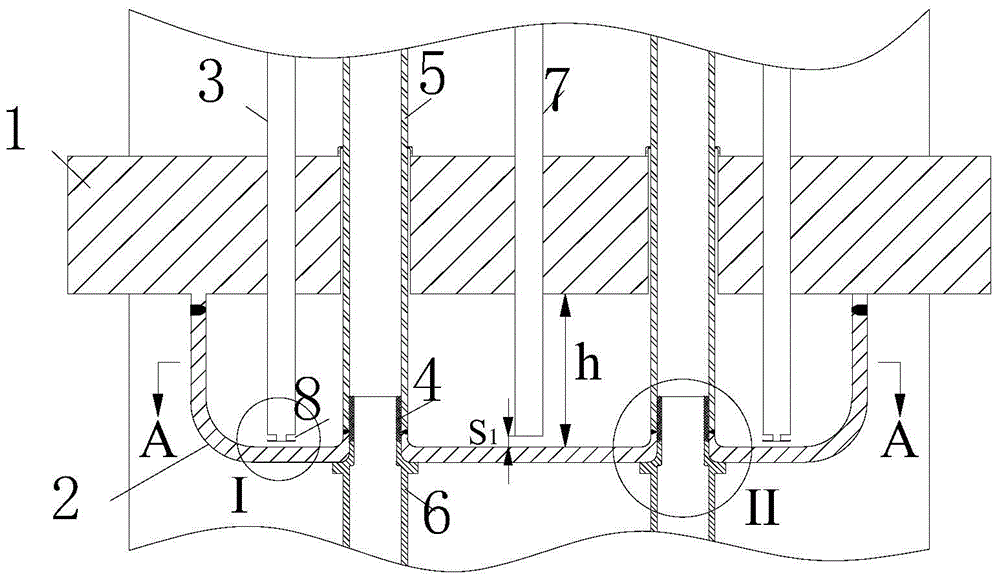

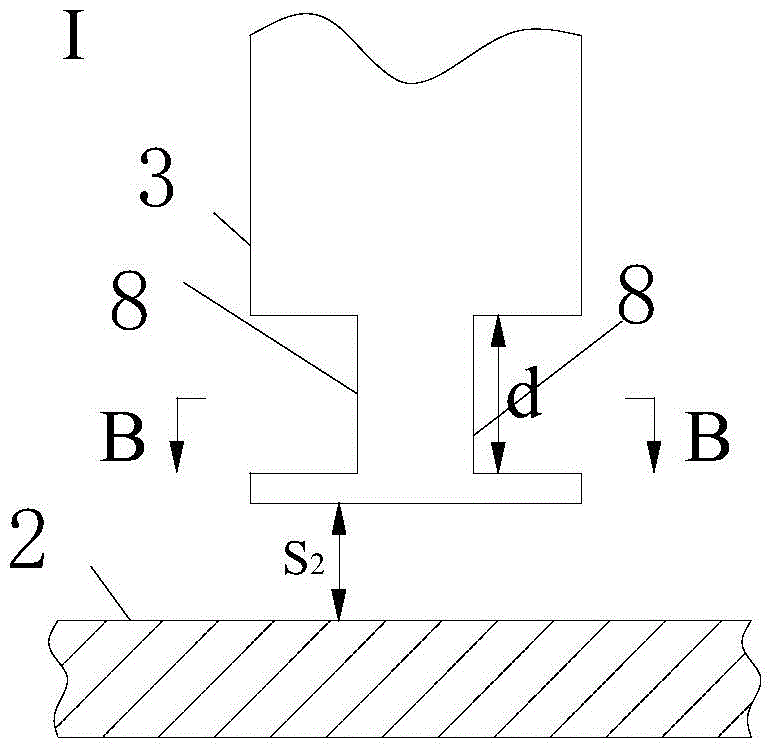

[0036] see figure 1 , The tube plate cooling chamber structure of the high temperature fire tube waste heat boiler includes four parts: the cooling chamber tube plate, the flexible tube plate of the synthesis gas pipe, the synthesis gas pipe and the cooling water pipe. The cooling water pipe includes the cooling water inlet pipe and the central cooling water outlet pipe. The distance S1 between the central cooling water outlet pipe and the flexible tube sheet of the syngas is 5-30 mm. The distance h between the tube sheet of the cooling chamber and the flexible tube sheet of the synthesis gas is 100-600 mm.

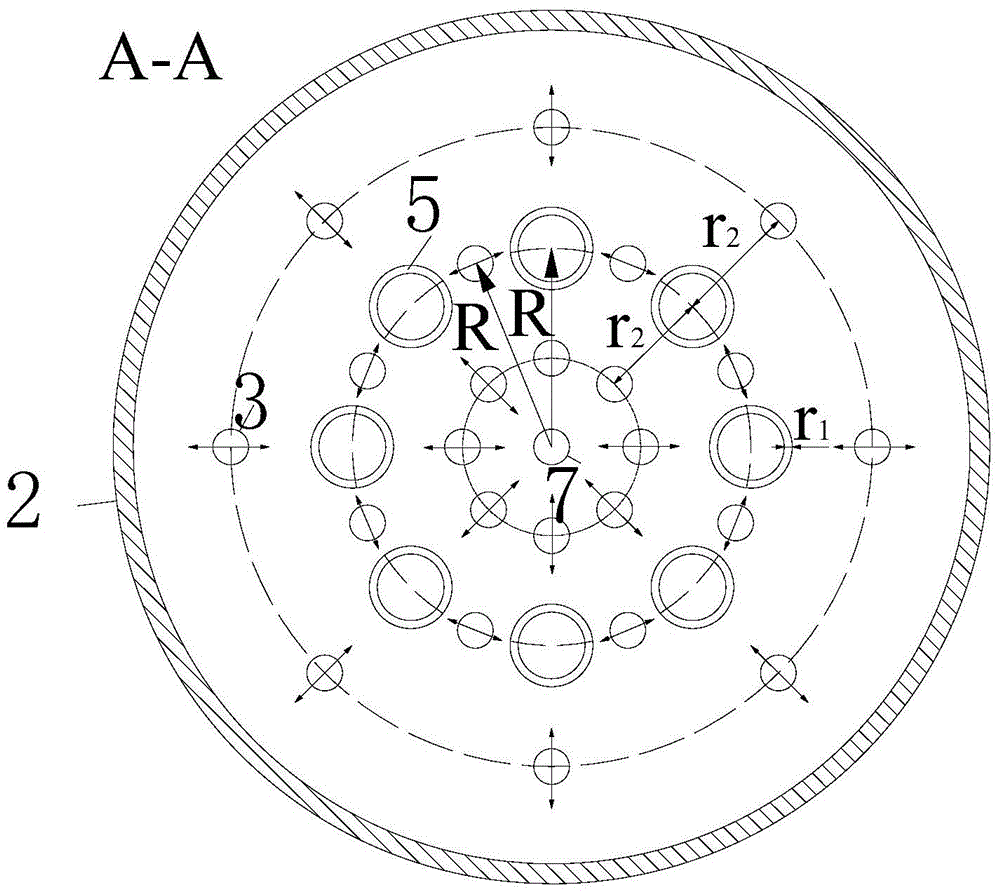

[0037] see figure 2 , there are 8 tube holes on the tube plate of the cooling chamber for the passage of the synthetic gas pipe, which are evenly distributed on the circumference of the radius R centered on the axis of the cooling chamber. The annular gap r1 between the tube sheet of the cooling chamber and the synthesis gas pipe, r1=5-20mm, serves as the outlet of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com