Patents

Literature

117results about How to "Reduce heat flux" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Radiation shield

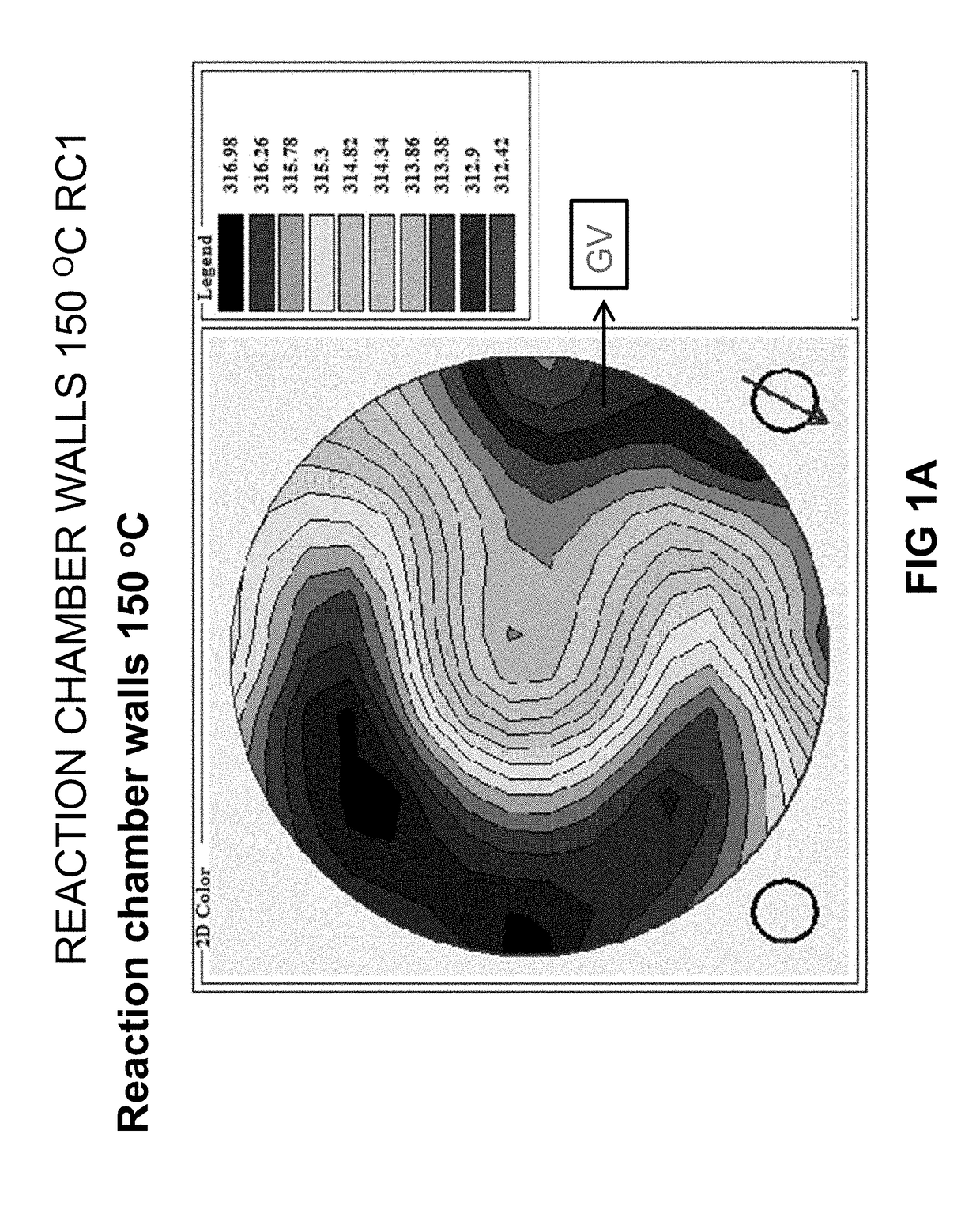

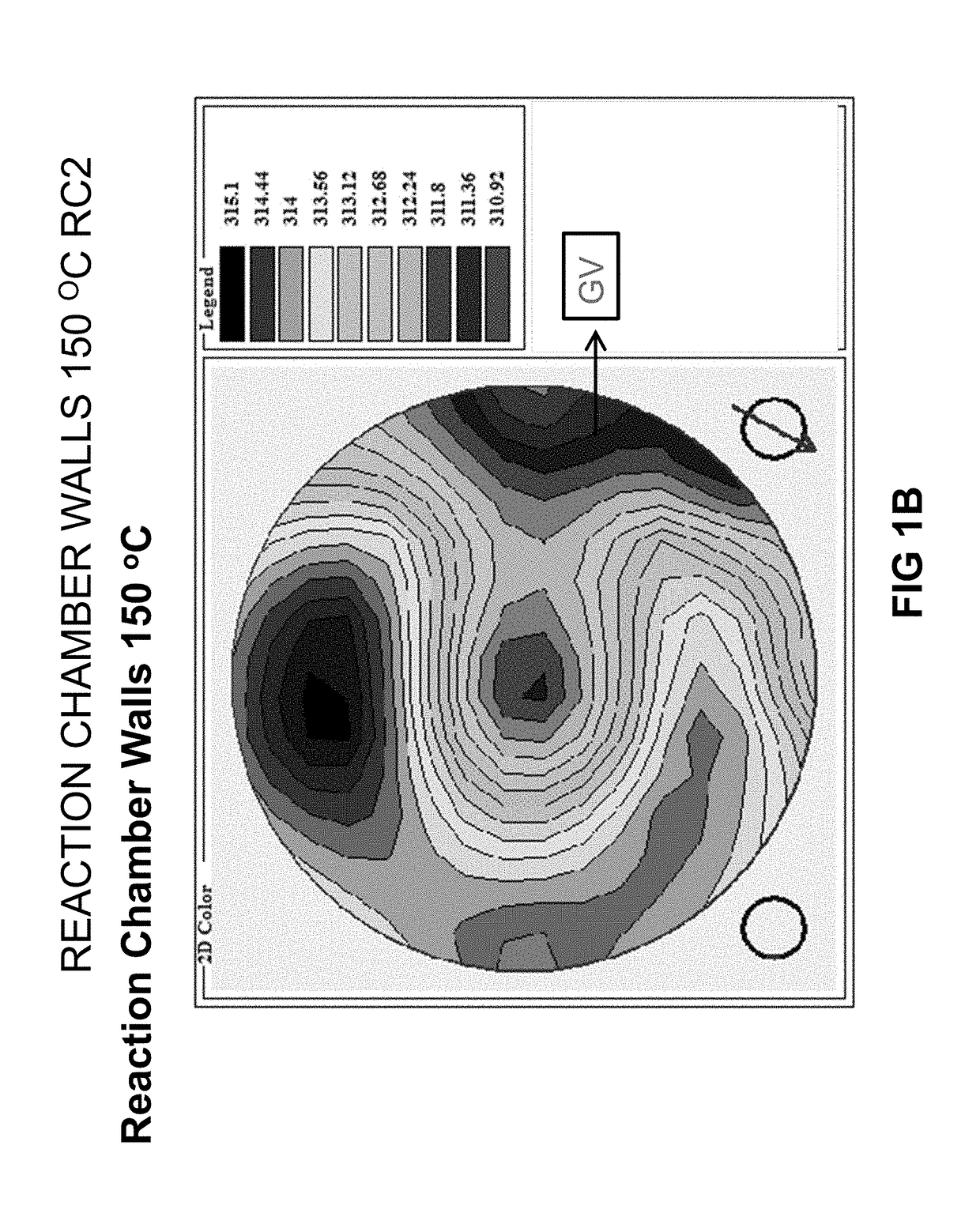

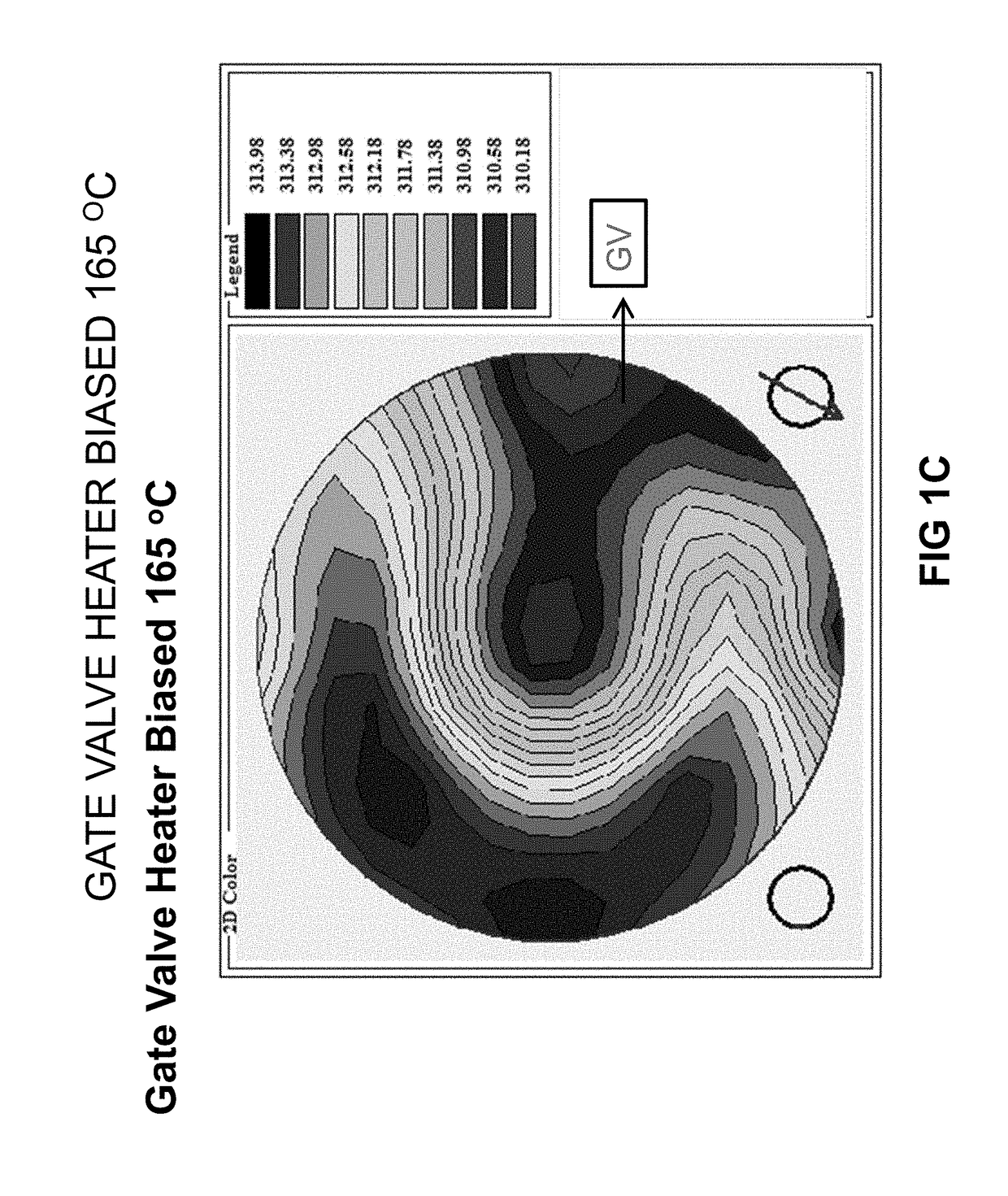

ActiveUS20190051544A1Reduce heat fluxQuality improvementGaseous chemical processesElectric discharge tubesSusceptorHeat flux

A radiation shield and an assembly and a reactor including the radiation shield are disclosed. The radiation shield can be used to control heat flux from a susceptor heater assembly and thereby enable better control of temperatures across a surface of a substrate placed on a surface of the susceptor heater assembly.

Owner:ASM IP HLDG BV

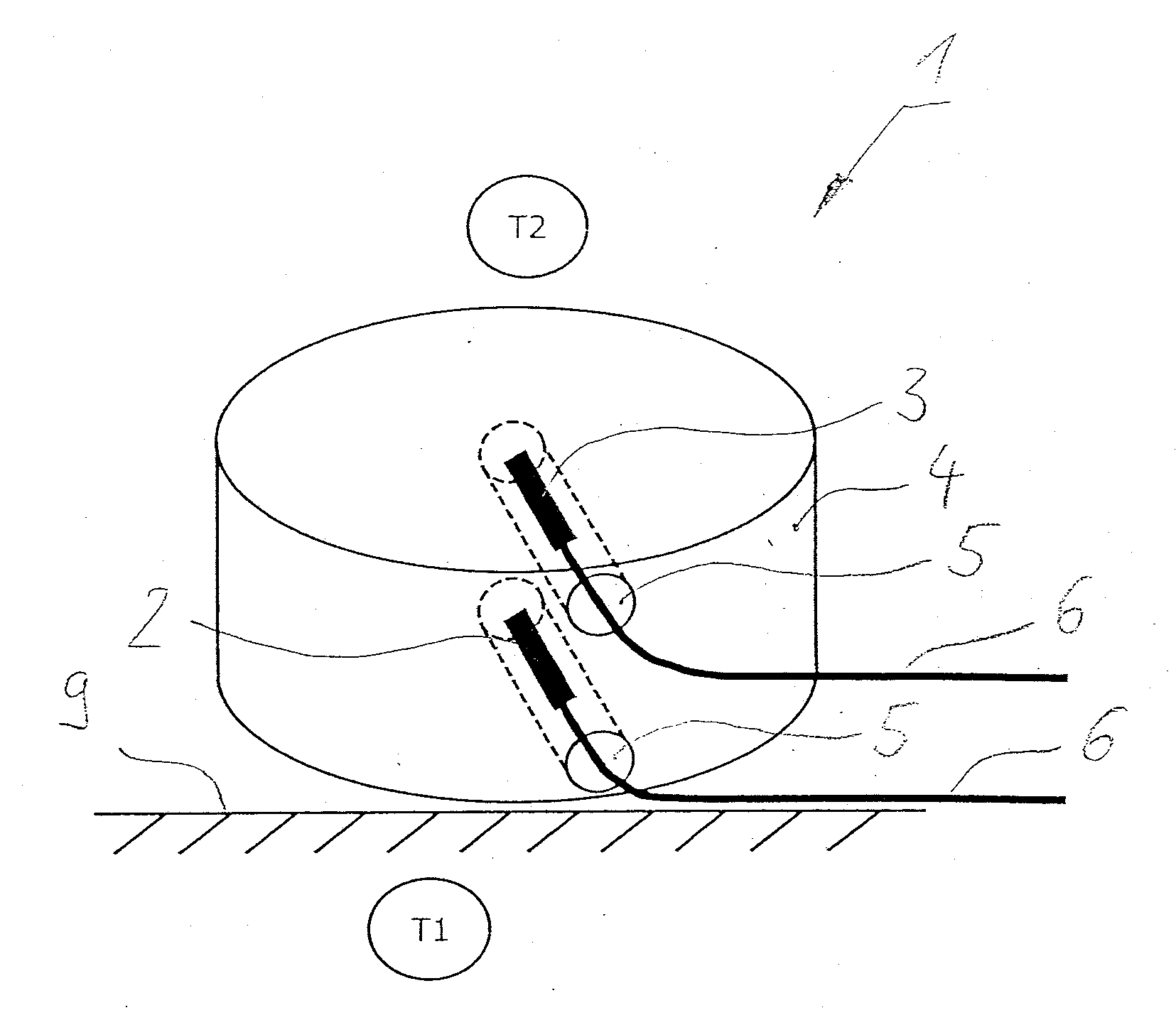

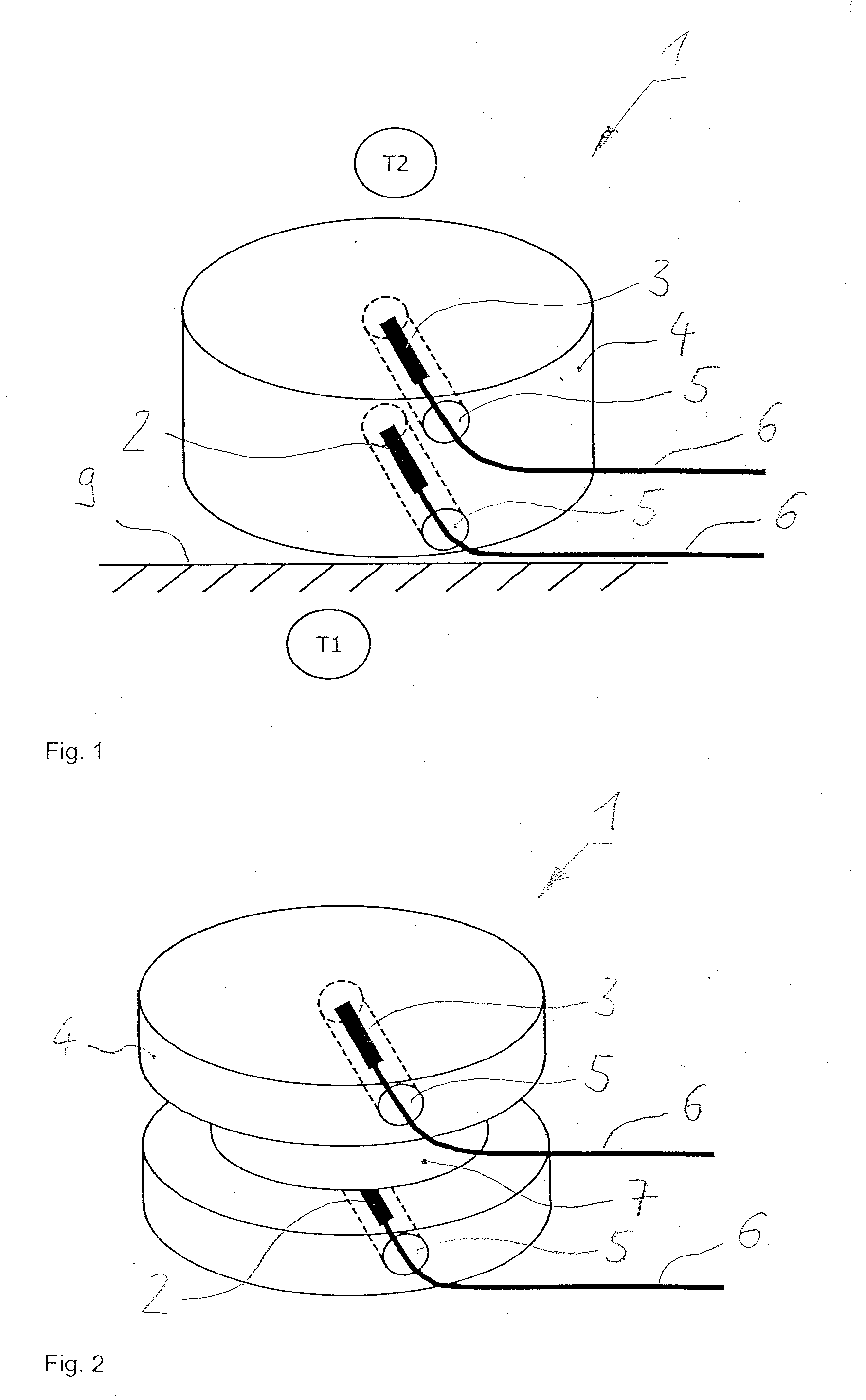

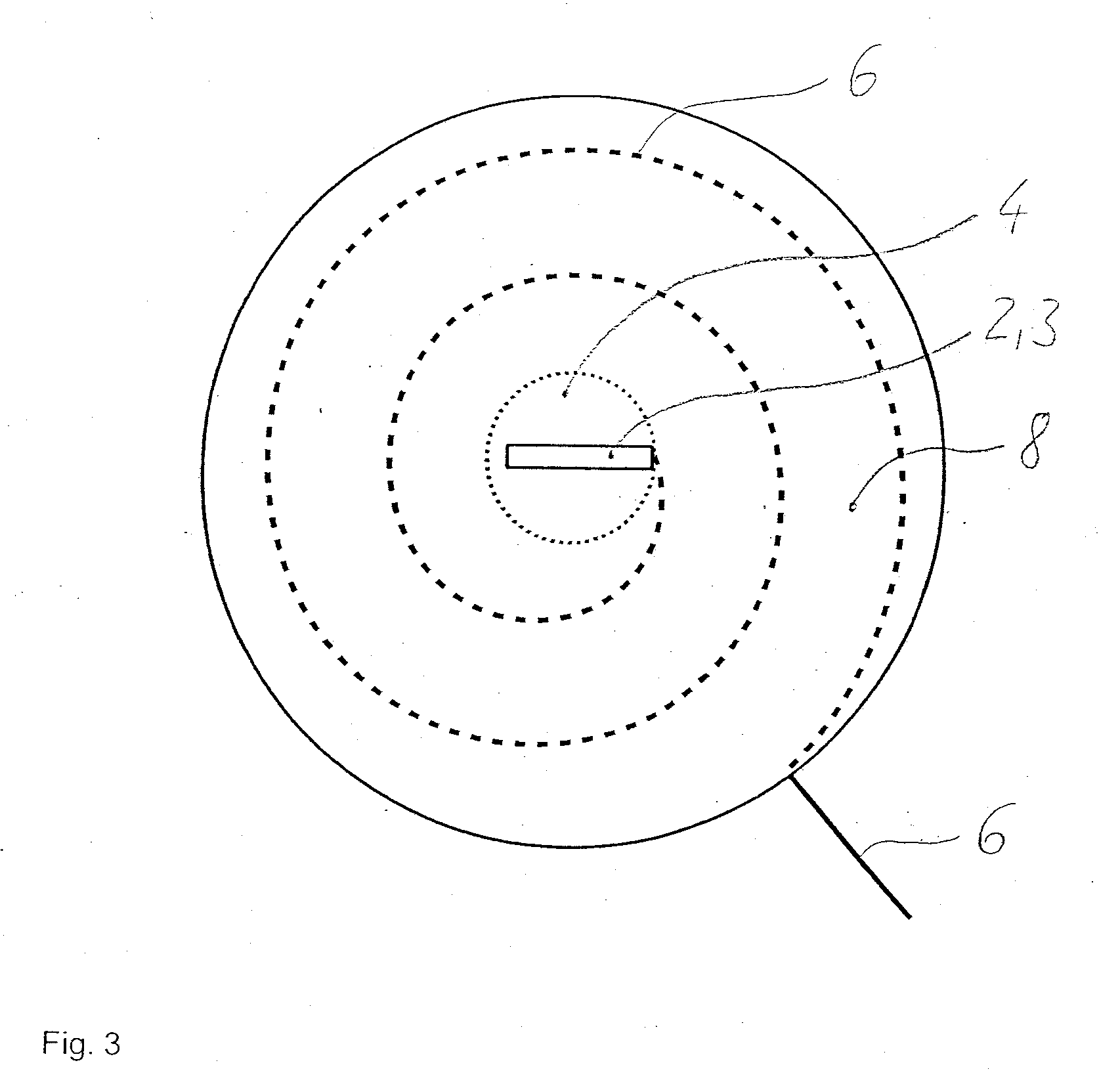

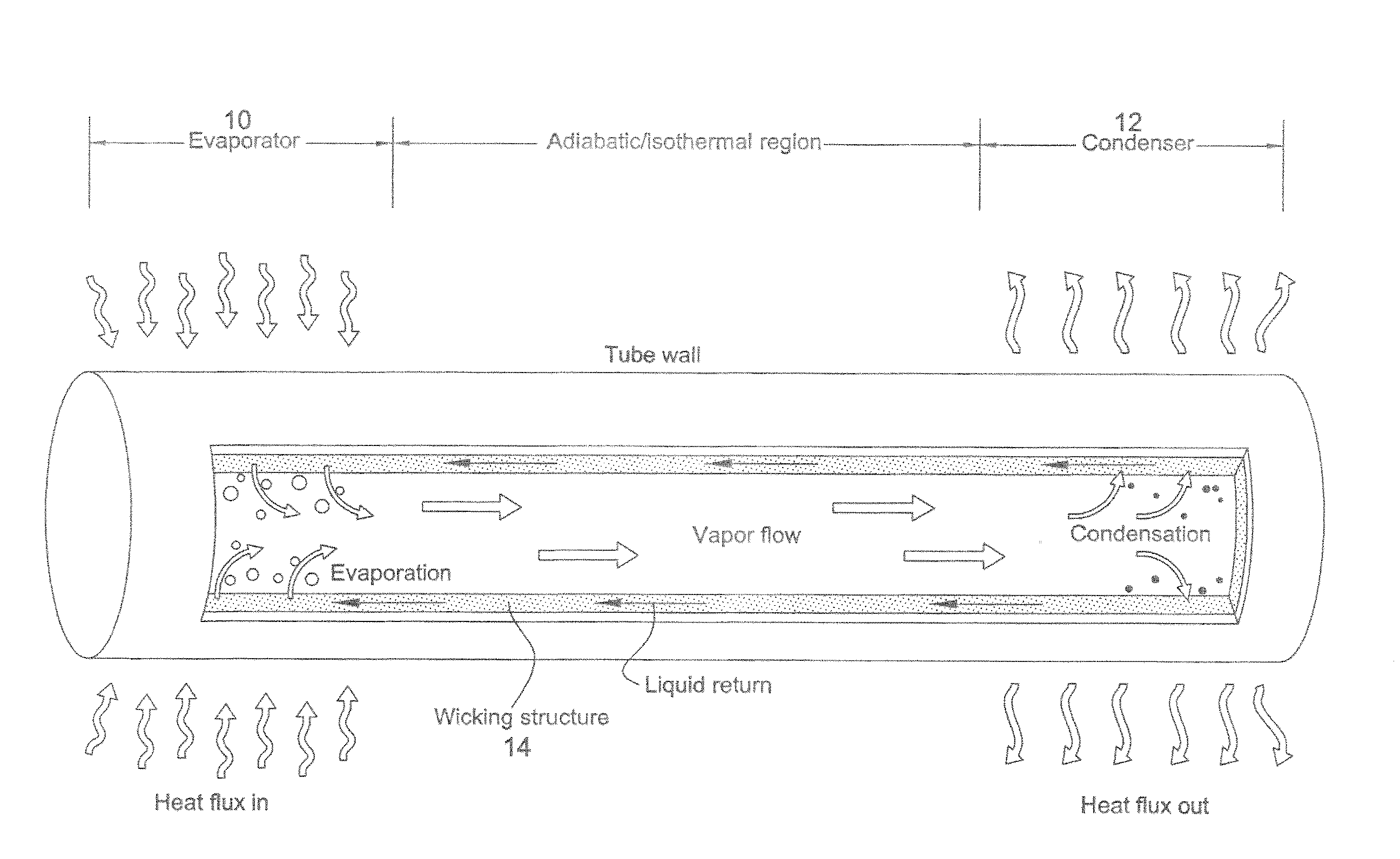

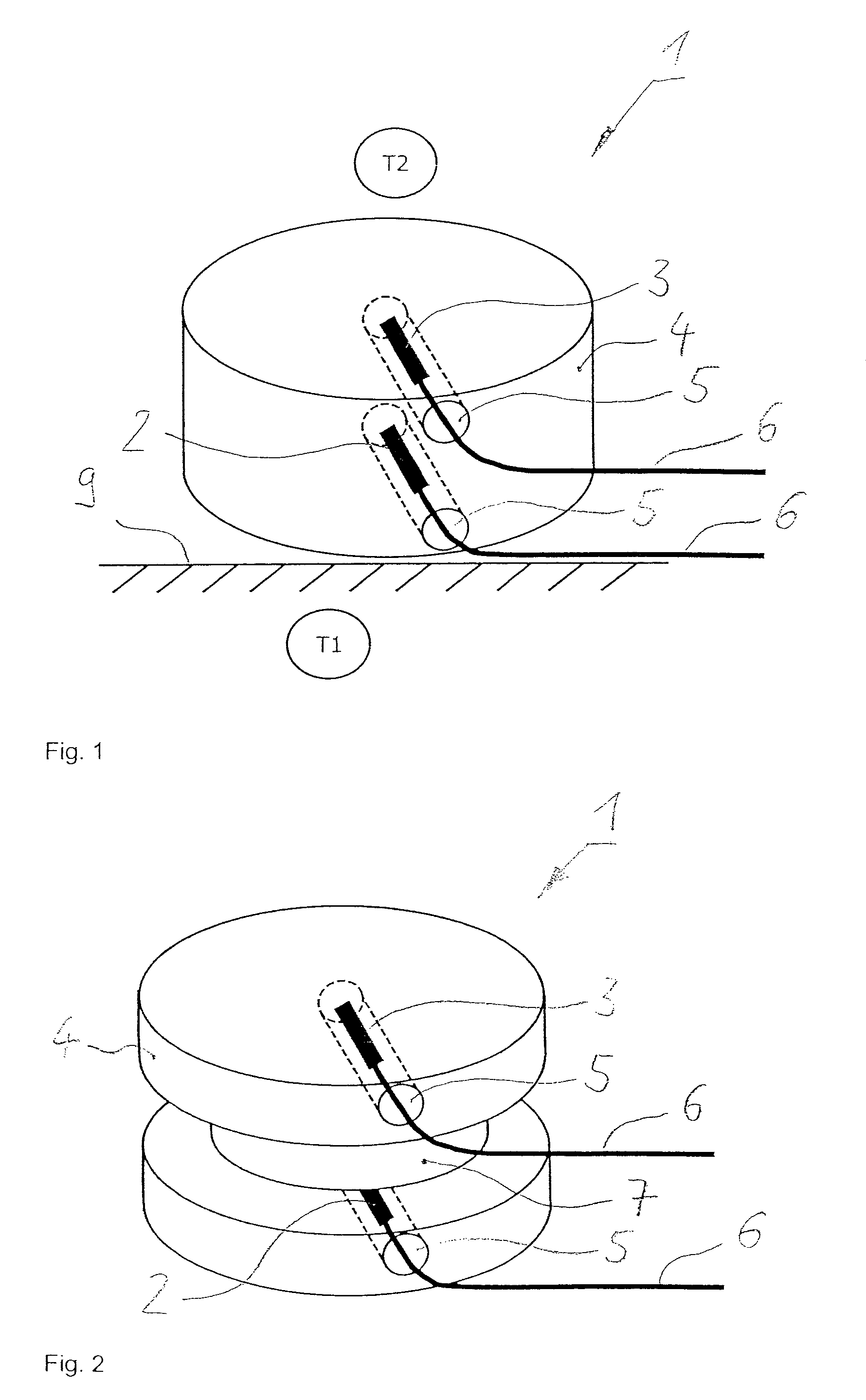

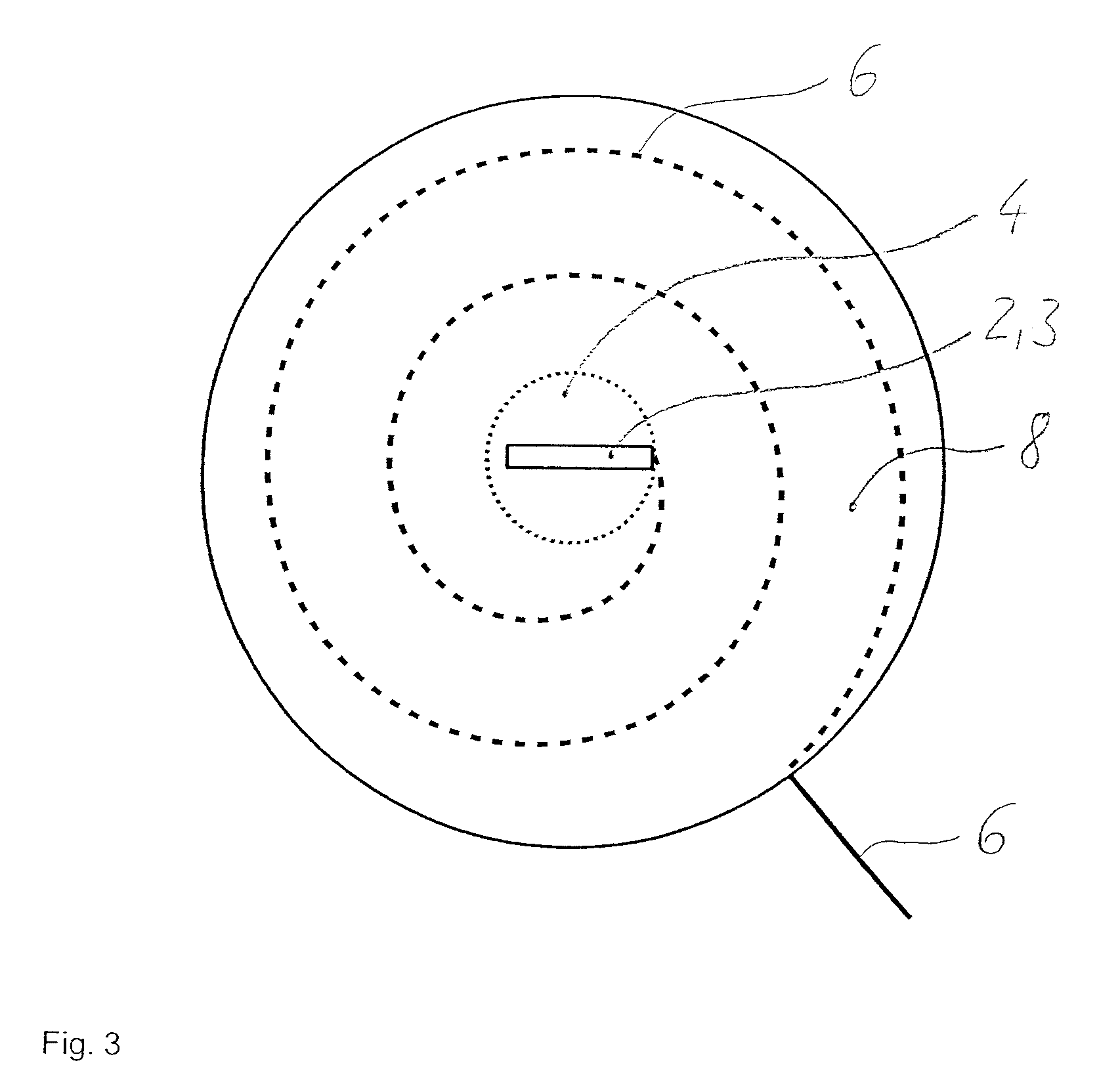

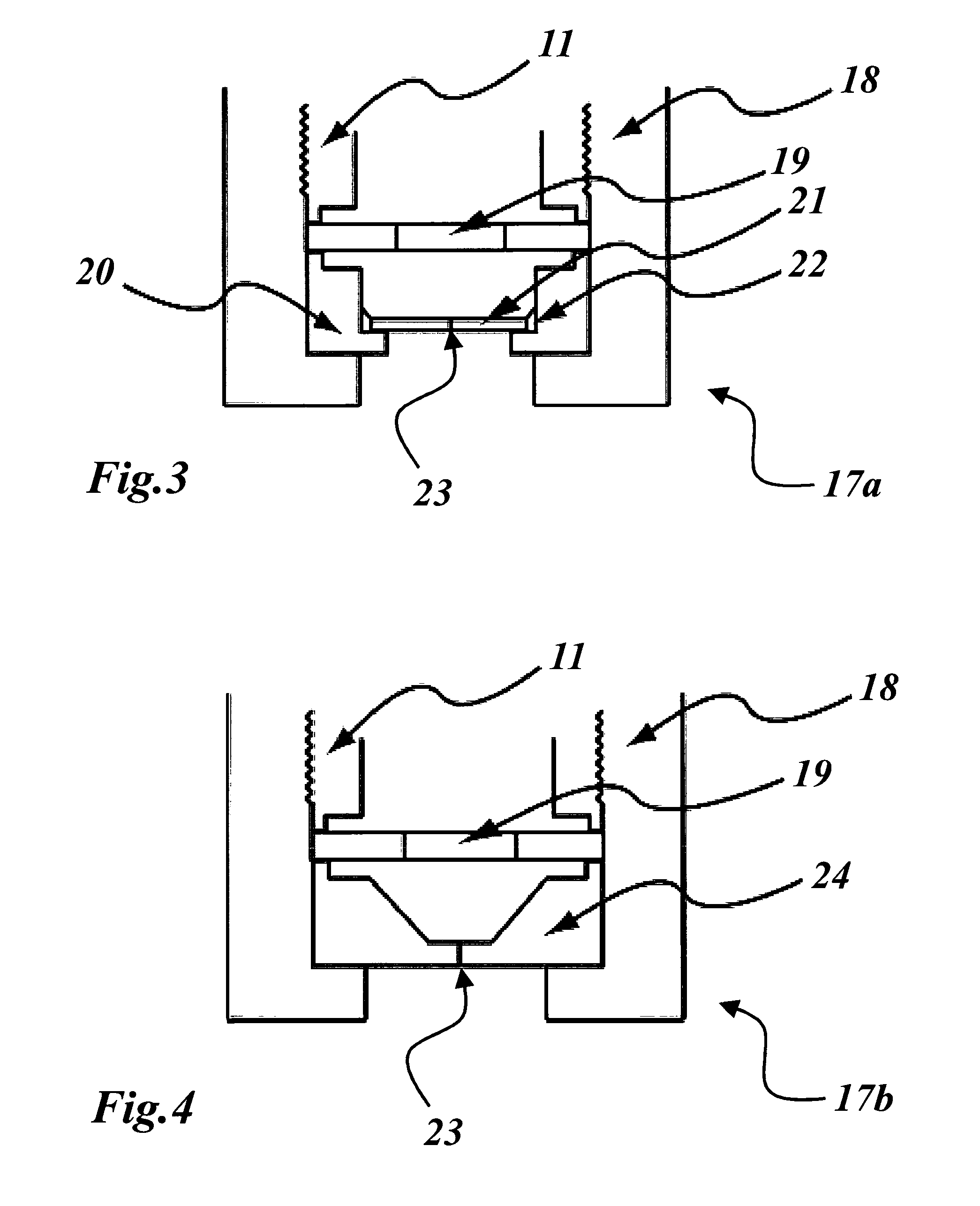

Double temperature sensor

ActiveUS20080170600A1Easy to manufactureTolerances of the heat transfer coefficient can be minimizedThermometer detailsThermometers using electric/magnetic elementsElectricityHeat flux

A double temperature sensor is provided for measuring a near-surface temperature of the ambient air and the temperature of the skin surface (9). A heat flux insulation block (4) is made of an insulation material in one piece as a housing. Two temperature sensor elements (2, 3) with respective electric connections (6) belonging to them are arranged in the heat flux insulation block (4) one on top of another at spaced locations from one another and near the surface.

Owner:DRAGERWERK AG

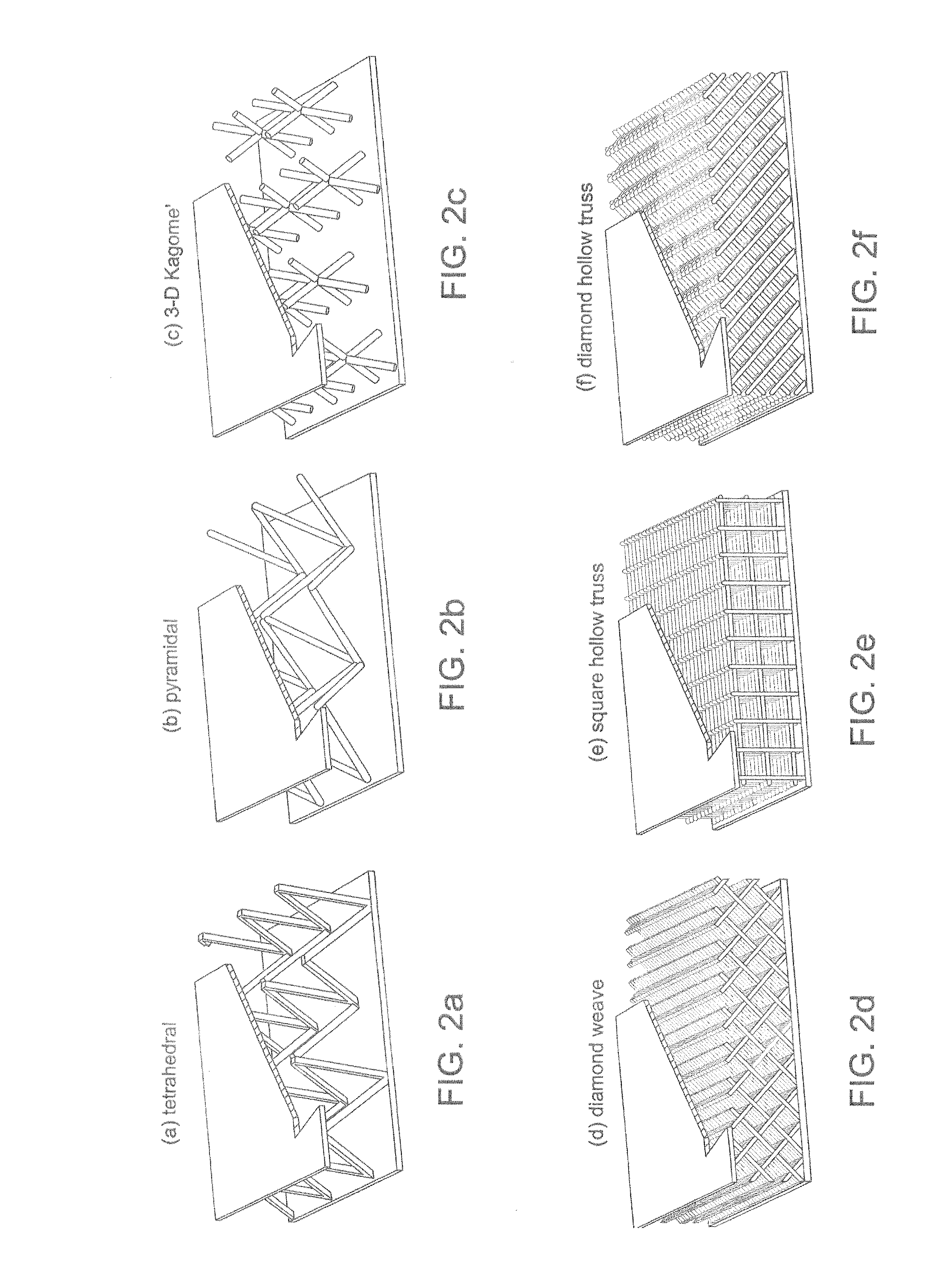

Heat-Managing Composite Structures

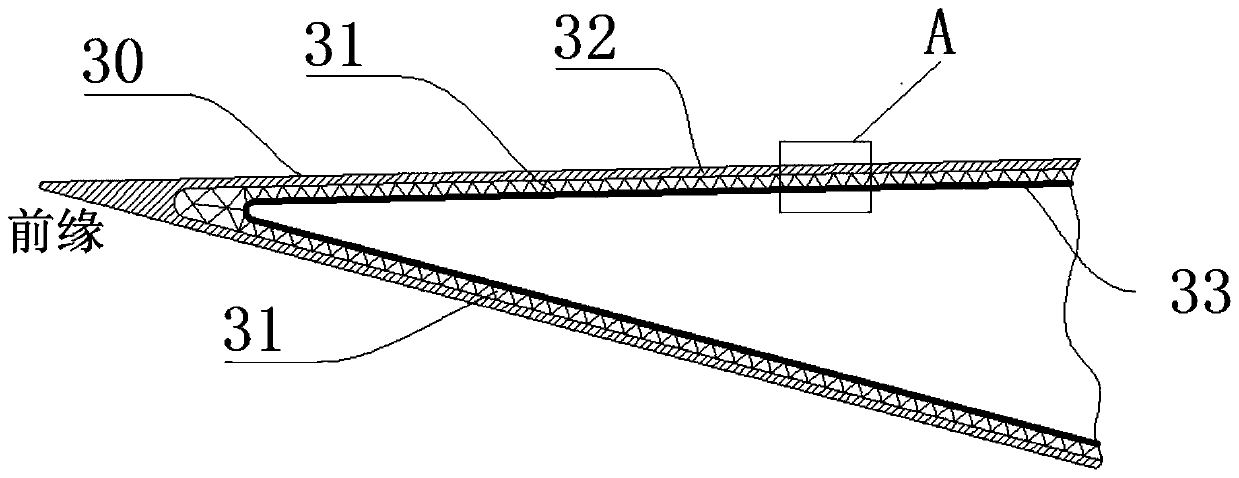

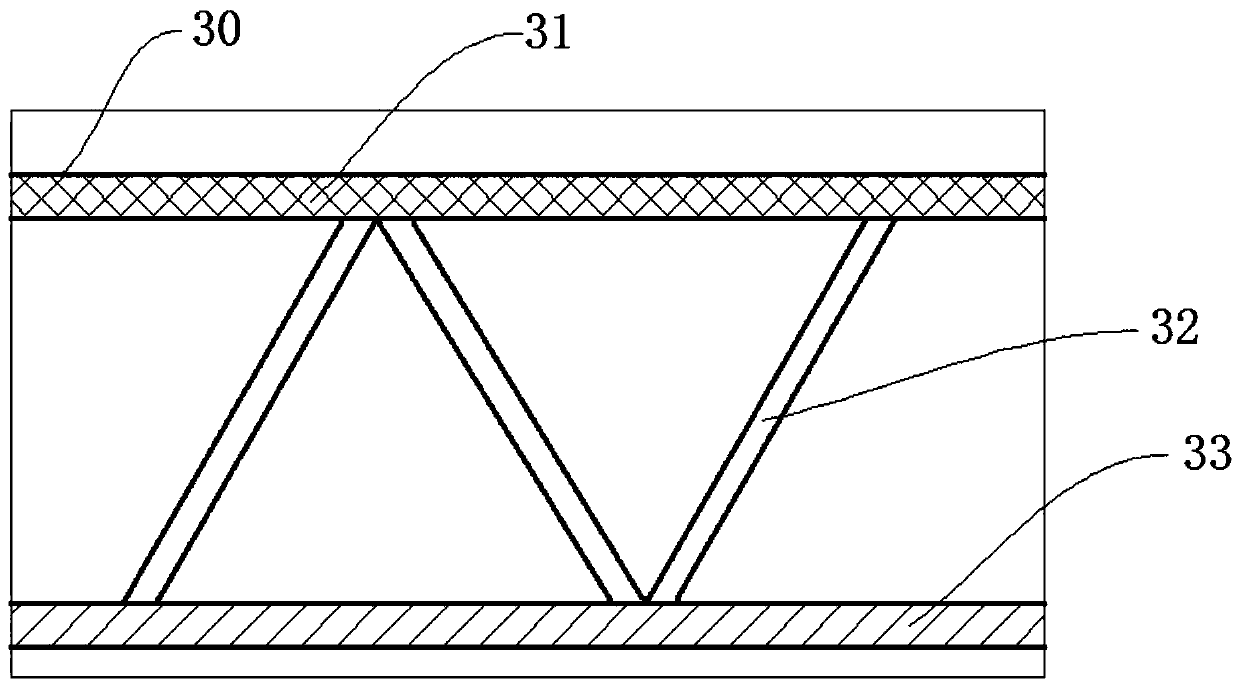

ActiveUS20100236759A1Improve spraying effectHigh dynamic strengthCorrosion preventionBuilding componentsHigh stressRocket

Light-weight, heat-managing structures feature open-cell lattice, honeycomb, and / or corrugated (prismatic) arrangements in their substructures, combined with heat pipe / heat plate arrangements for managing heat to which the structures are subjected. The structures are well suited to aerospace applications and may be employed in the leading edge of wings or other airfoil-shaped components; gas turbine engine components; rocket nozzles; and other high-heat, high-stress environments.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

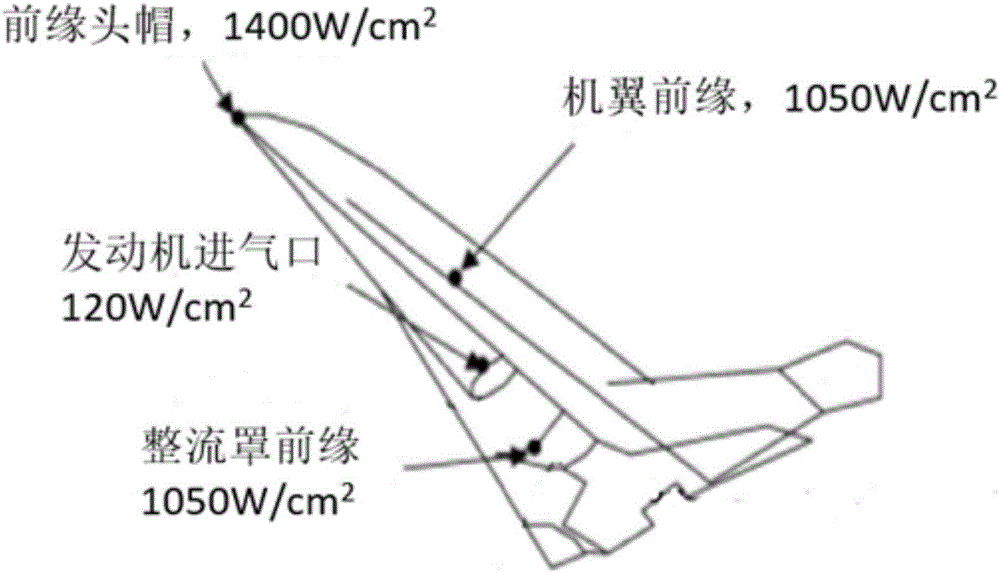

Thermal protection structure for leading edge of hypersonic vehicle

The invention relates to a thermal protection structure for the leading edge of a hypersonic vehicle. The thermal protection structure is sequentially composed of a shell layer and an inner wall layer from outside to inside. The shell layer comprises a first head cap located at the top end of the leading edge and a leading edge side wall shell fixedly connected with the first head cap. The first head cap is made from high temperature resistant materials, and the leading edge side wall shell is made from steel-based porous materials. The inner wall layer comprises a second head cap arranged corresponding to the first head cap, and a metal shell fixedly connected with the second head cap and arranged corresponding to the leading edge side wall shell. The second head cap is made from steel-based porous materials. A cooling channel is formed between the inner wall layer and the shell layer which are connected through a plurality of supporting ribs. A water storage capsule used for storing coolants is arranged inside the inner wall layer and connected with the second head cap through a tree-shaped capillary fractal structure and provides the coolants needed for transpiration cooling for the second head cap.

Owner:TSINGHUA UNIV

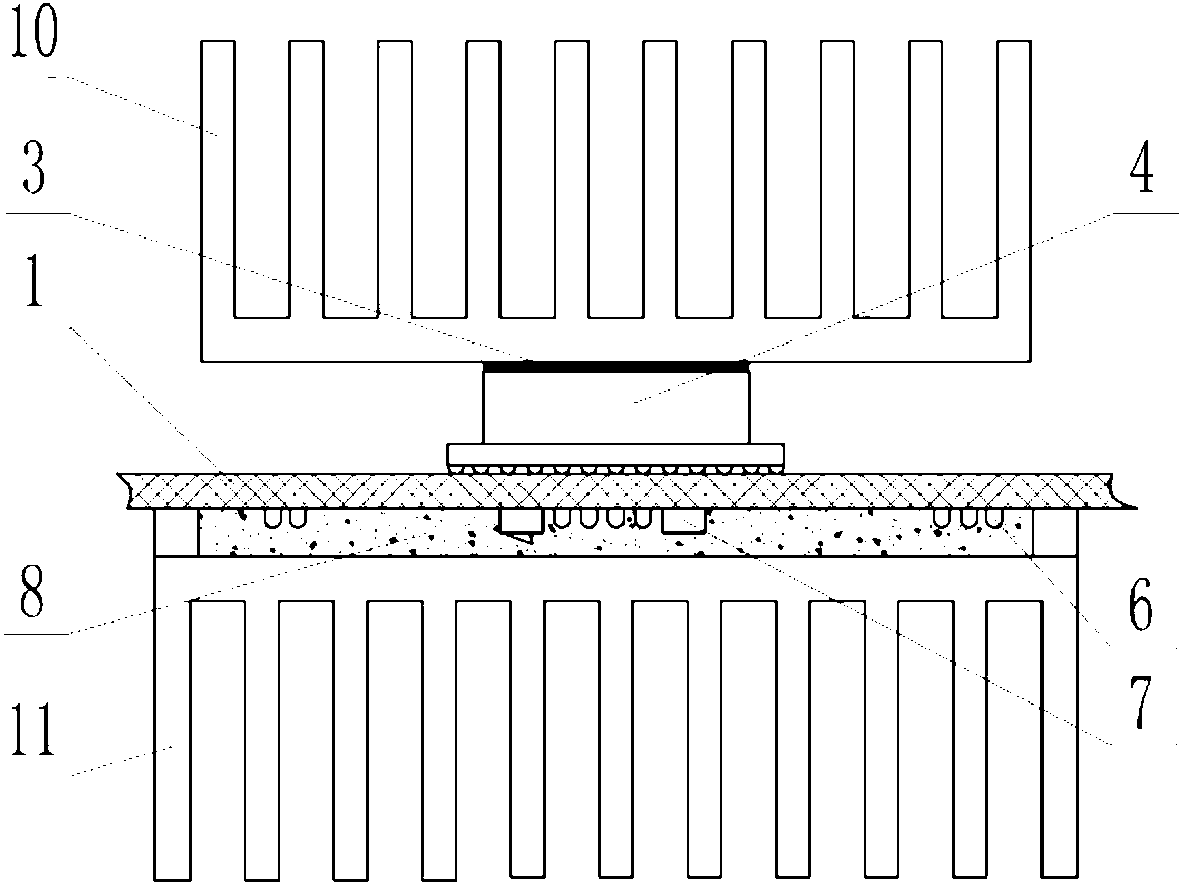

High-density chip radiating method by dual-path heat transfer

ActiveCN103021877AImprove heat transfer performanceSolve heat buildupDigital data processing detailsSemiconductor/solid-state device detailsHigh densityCore temperature

Disclosed is a high-density chip radiating method by dual-path heat transfer. Each heat transfer path comprises a chip, a printed board, thermally conductive and insulating media and radiators. The high-density chip radiating method is characterized by including the steps: firstly, welding the chips on the printed boards; secondly, mounting the radiators on the surfaces of the chips and bottom surfaces of the printed boards; and finally, filling the thermally conductive and insulating media among the chips and the radiators and among the printed boards and the radiators. The high-density chip radiating method has the advantages that heat on the heat transfer paths of the chips is distributed by setting up two parallel heat transfer paths, the thermal flux density on the heat transfer paths is reduced, the radiating capacity of the chips can be improved, the problem of thermal accumulation of the high-density chips is solved, and the core temperature of the chips is reduced.

Owner:NO 709 RES INST OF CHINA SHIPBUILDING IND CORP

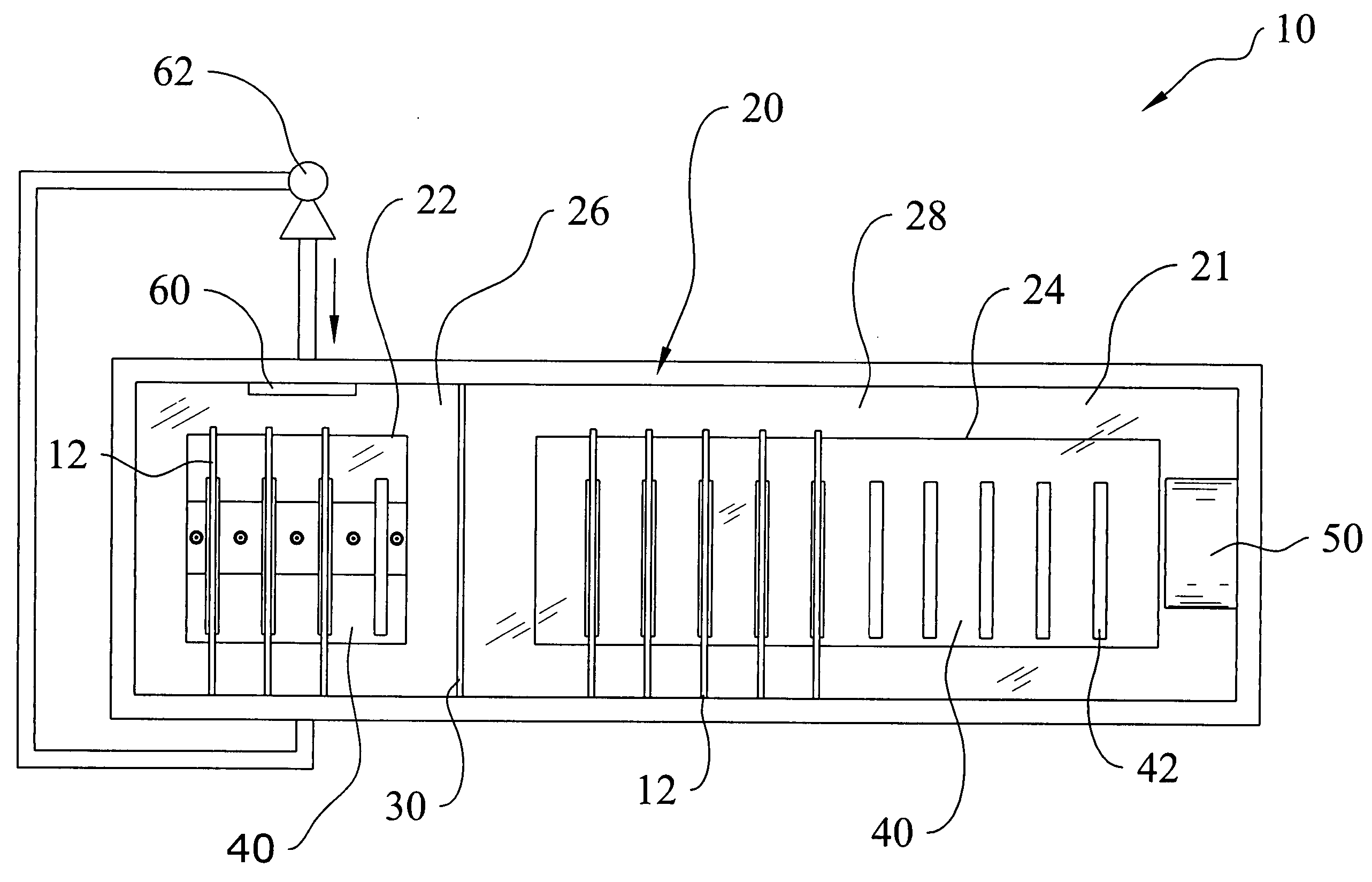

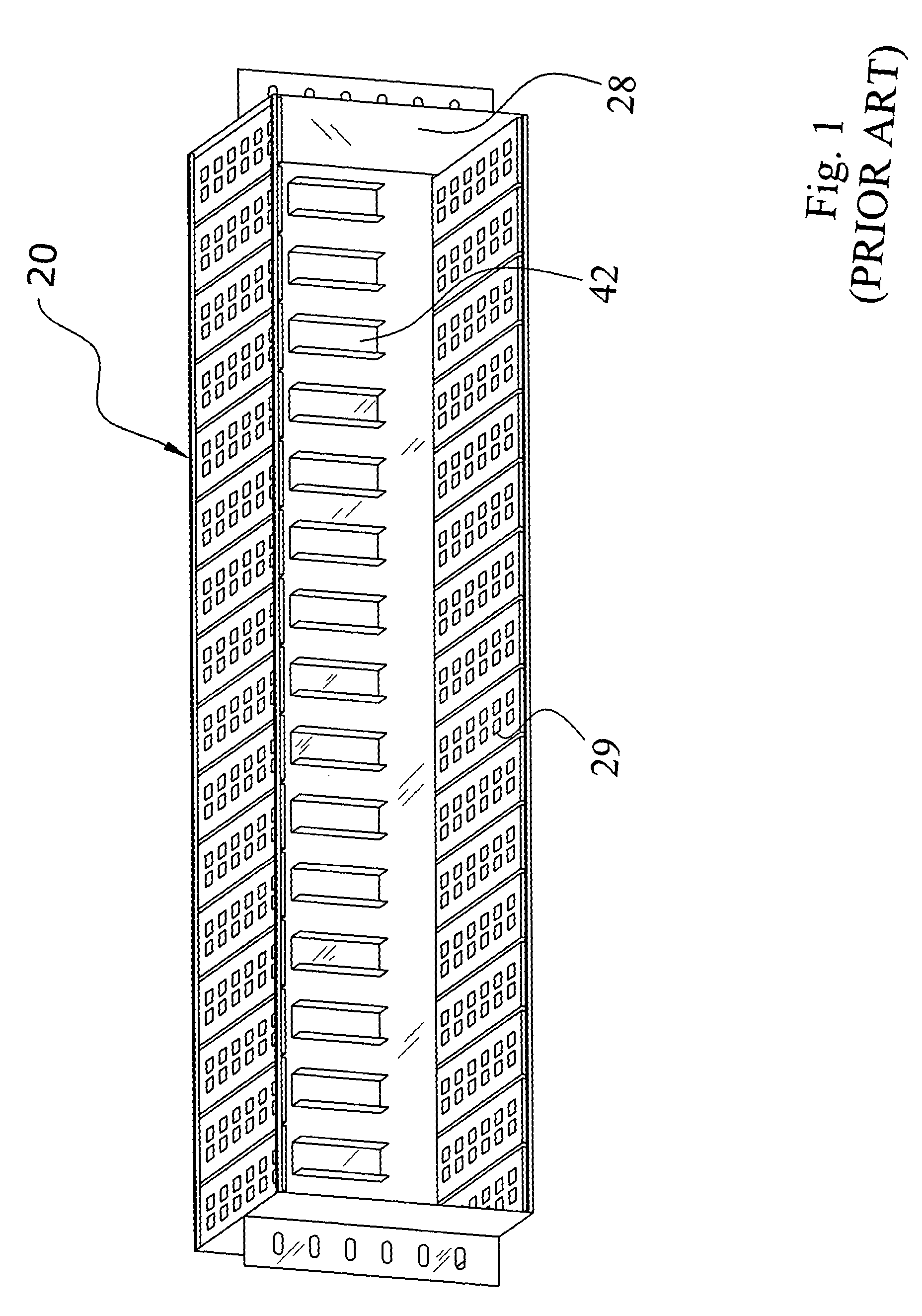

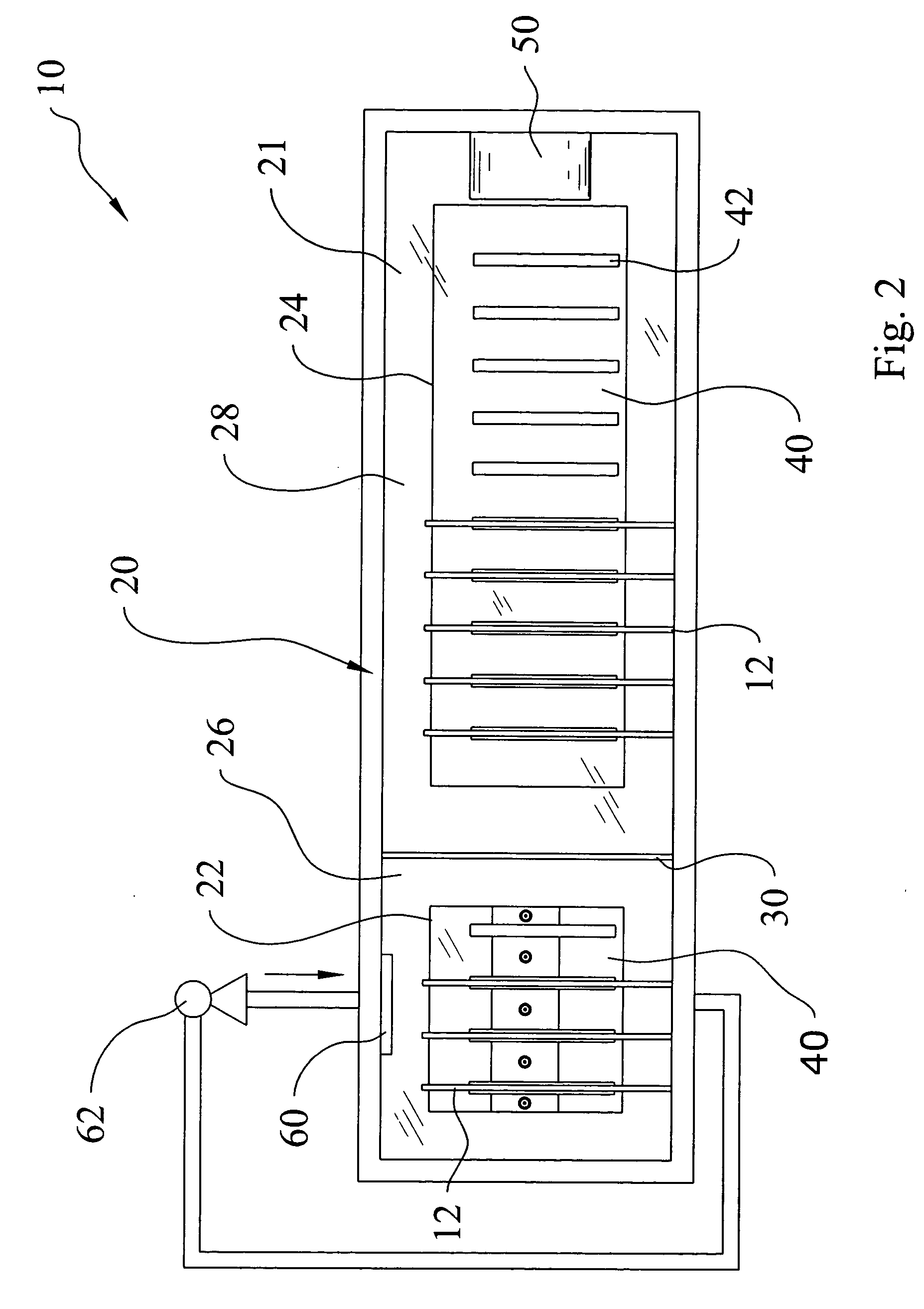

Dry-wet thermal management system

InactiveUS20050138833A1Efficient and cost-effectiveReduce weight and sizeDrying using combination processesSubstation/switching arrangement cooling/ventilationElectricityHeat flux

A dry-wet thermal management system for providing simultaneous spray cooling and dry cooling for a plurality of cards. The dry-wet thermal management system includes a chassis having a dry chamber and a spray chamber, a first opening within a rear portion of the chassis extending into the spray chamber, a second opening within the rear portion of the chassis extending into the dry chamber, and a main backplane secured and sealed to the rear portion of the chassis. Electronic cards may be electrically coupled within sockets of the main backplane within both the dry chamber and the spray chamber. The cards within the spray chamber are typically high heat flux components with increased cooling requirements and the cards within the dry chamber are typically low heat flux components with reduced cooling requirements. A spray cool system is within the spray chamber and a dry cool system is within the dry chamber.

Owner:PARKER INTANGIBLES LLC

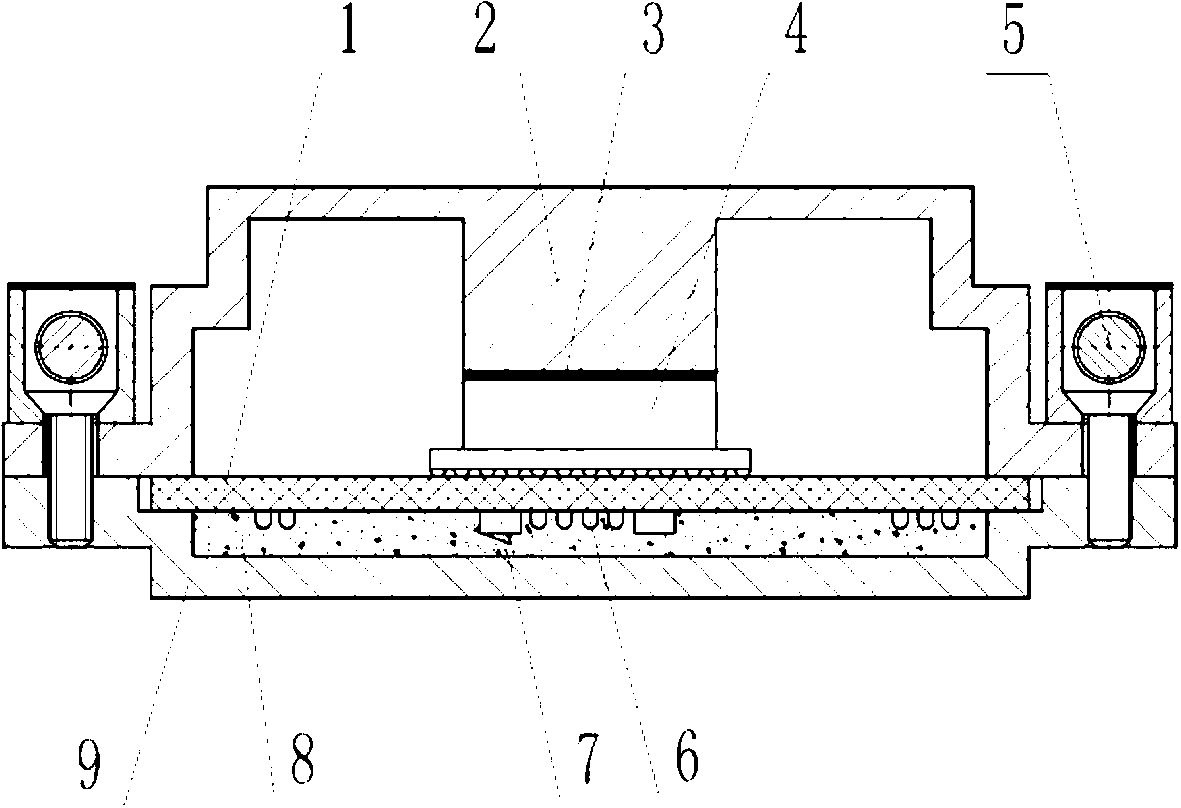

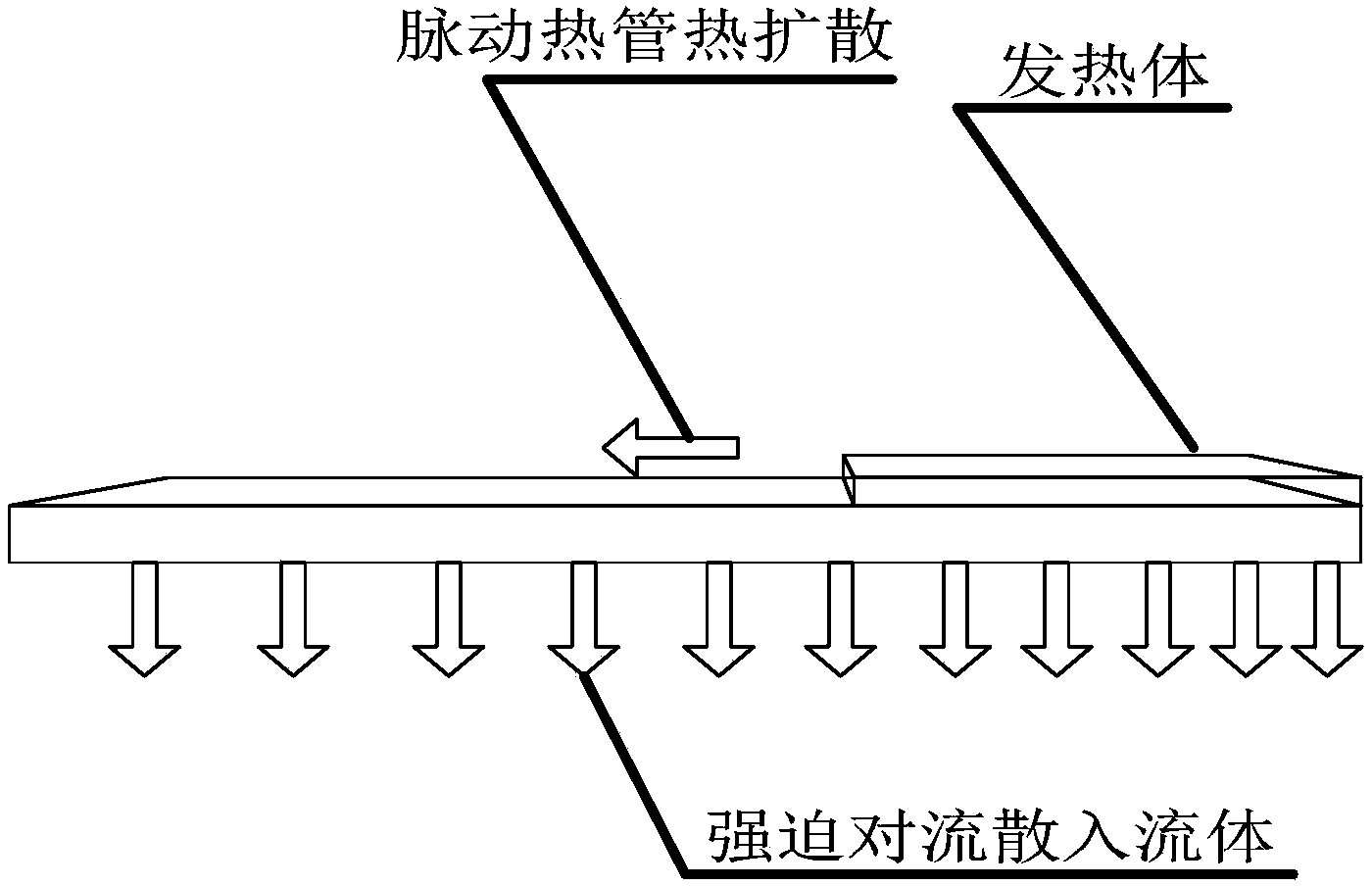

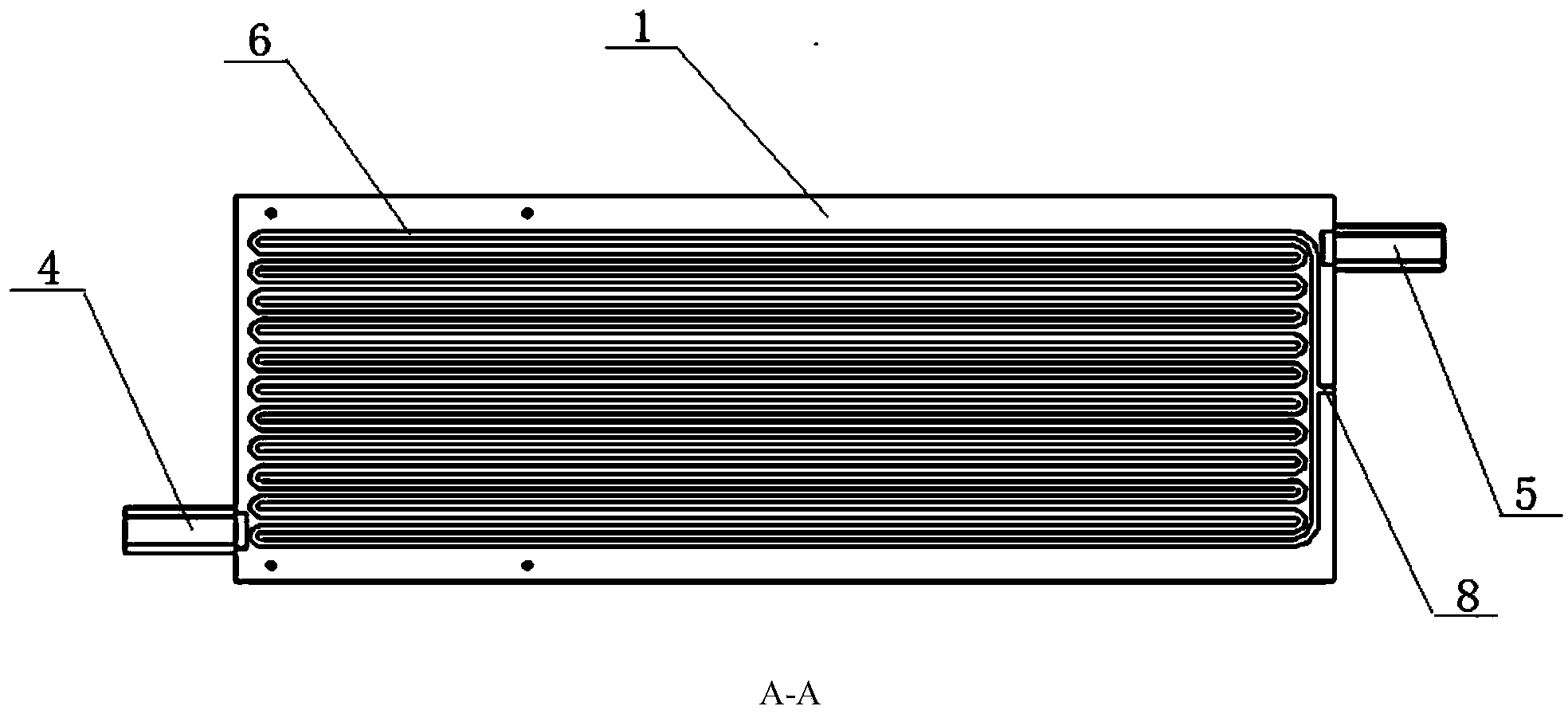

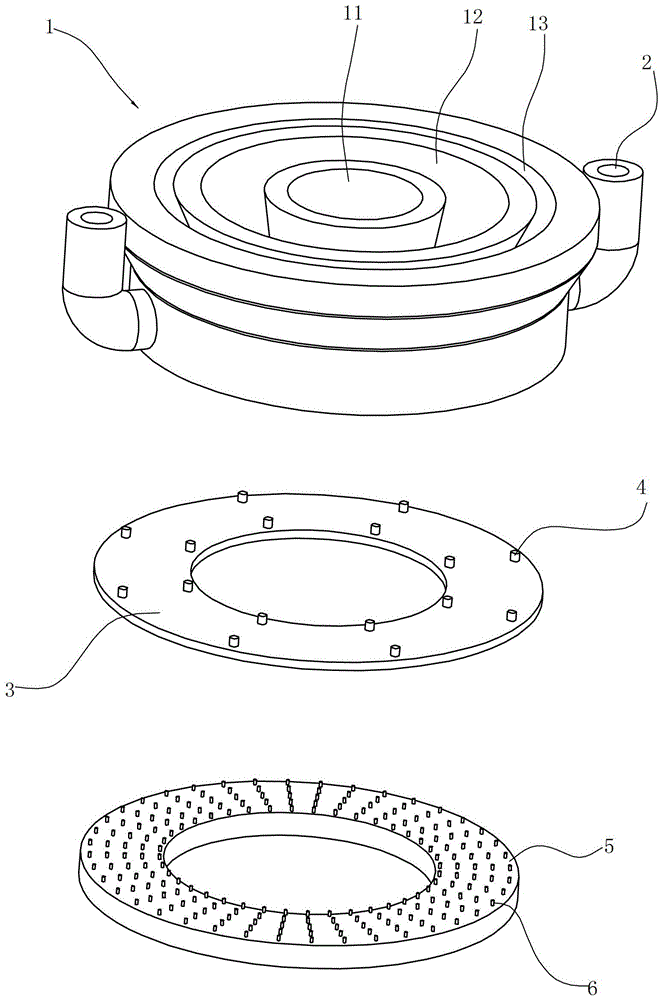

Composite water cooling plate

InactiveCN104244680ASolve the cooling problemReduce surface temperatureIndirect heat exchangersCooling/ventilation/heating modificationsEngineeringElectric equipment

The invention provides a composite water cooling plate which is made of aluminum and comprises a cover plate, a water cooling plate body and a bottom plate. The cover plate, the water cooling plate body and the bottom plate are sequentially arranged from top to bottom. The composite water cooling plate is characterized in that a first S-shaped flow channel and a second S-shaped flow channel which are sunken towards the inside of the water cooling plate body are respectively arranged on the upper surface and the lower surface of the water cooling plate body, the first flow channel is of a closed circuit structure, and the second flow channel is connected with an inlet and an outlet which are formed in two sides of the water cooling plate body. Compared with the prior art, the composite water cooling plate has the advantages that a pulse heat pipe and the water cooling plate are organically combined with each other, so that heat of electric equipment with high heat flow density can be effectively dissipated, the technical difficult problem of ultrahigh surface temperatures of electronic devices due to the difficulty in dissipating heat with high heat flow density can be solved, and the surface temperature of the cooling plate can be reduced by 5-10 DEG C as compared with a heat exchange technology implemented by a single cooling plate under identical conditions.

Owner:CHINA NORTH VEHICLE RES INST

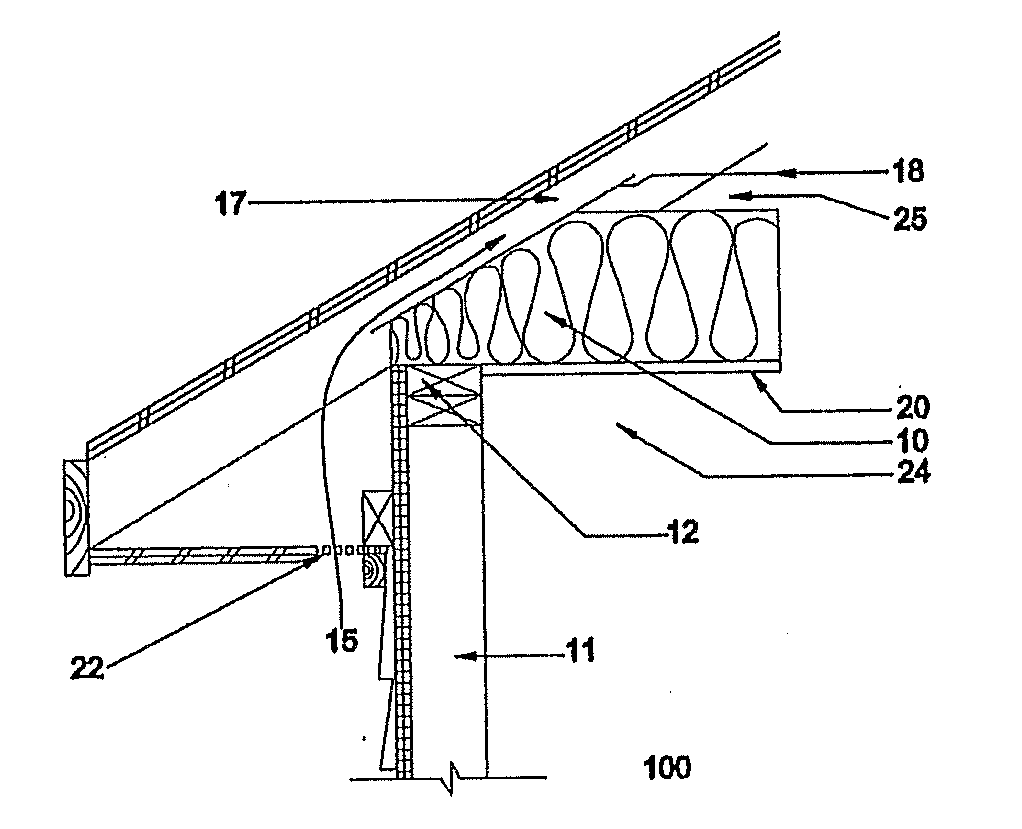

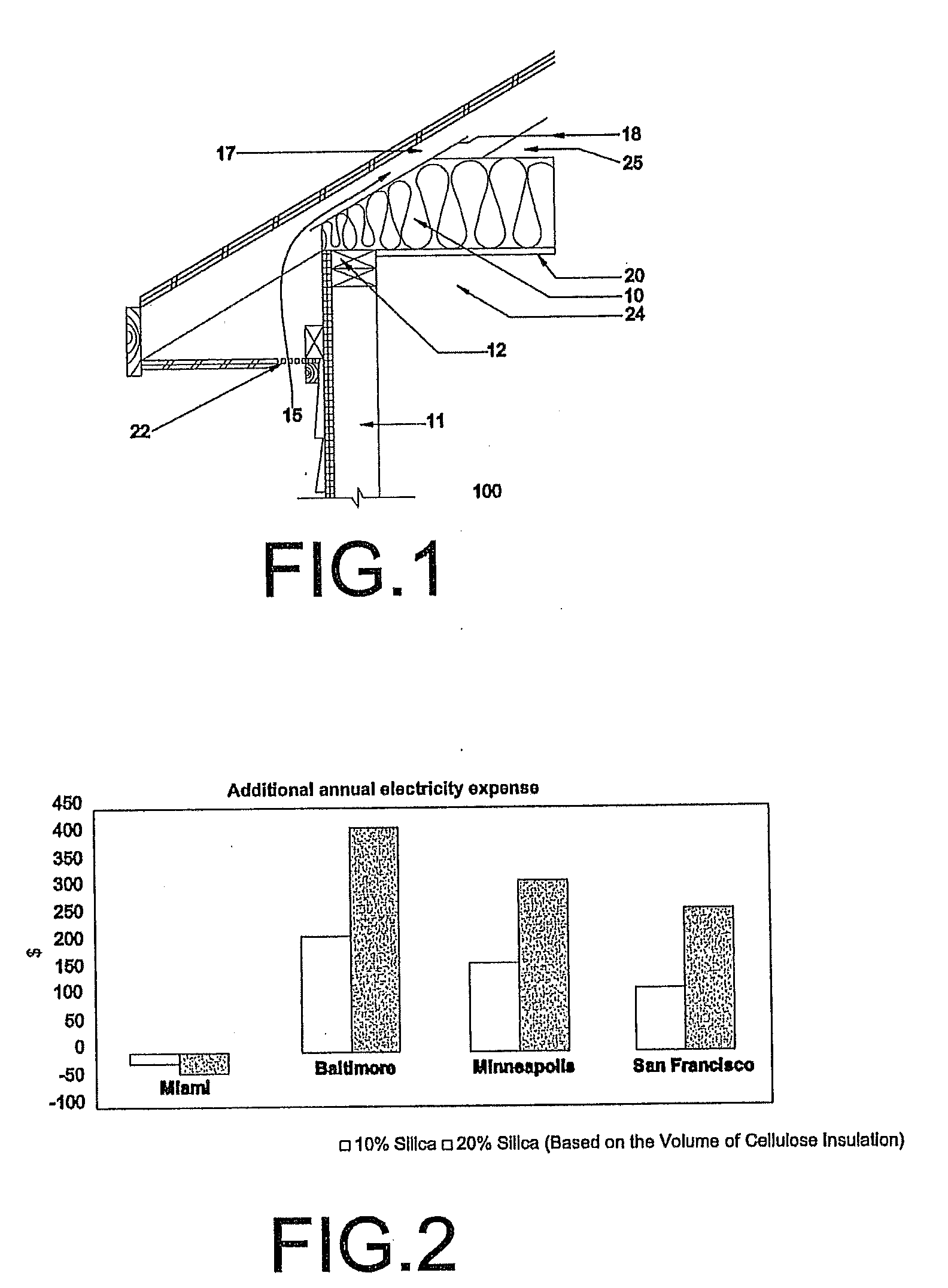

Attic and wall insulation with desiccant

InactiveUS20100107550A1Reduce the amount requiredReduce the temperatureRoof coveringClimate change adaptationDesiccantAttic

A method of reducing the amount of cooling energy required to heat and cool a building is provided. The method includes disposing a porous insulating material in the exterior walls and substantially covering the ceiling in the attic space of the building to a substantial depth. The porous insulating material includes a desiccant. The method further includes permitting the desiccant—bearing porous insulating material to adsorb water moisture from the attic space and then permitting the adsorbed water moisture to desorb from the desiccant—bearing porous insulating material into the enclosed room of the building, resulting in a reduction in the amount of energy required to heat and cool the building.

Owner:CERTAINTEED CORP

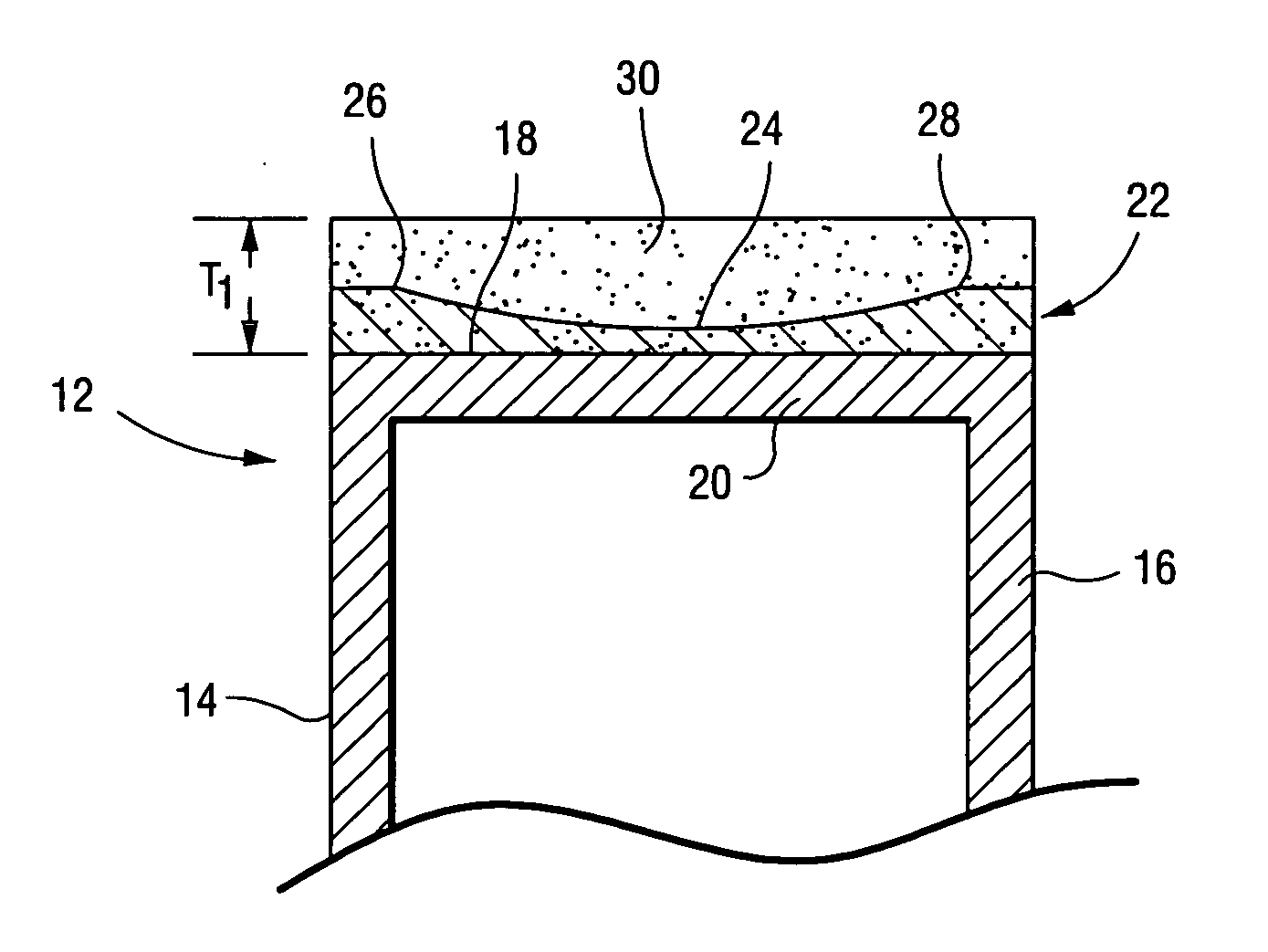

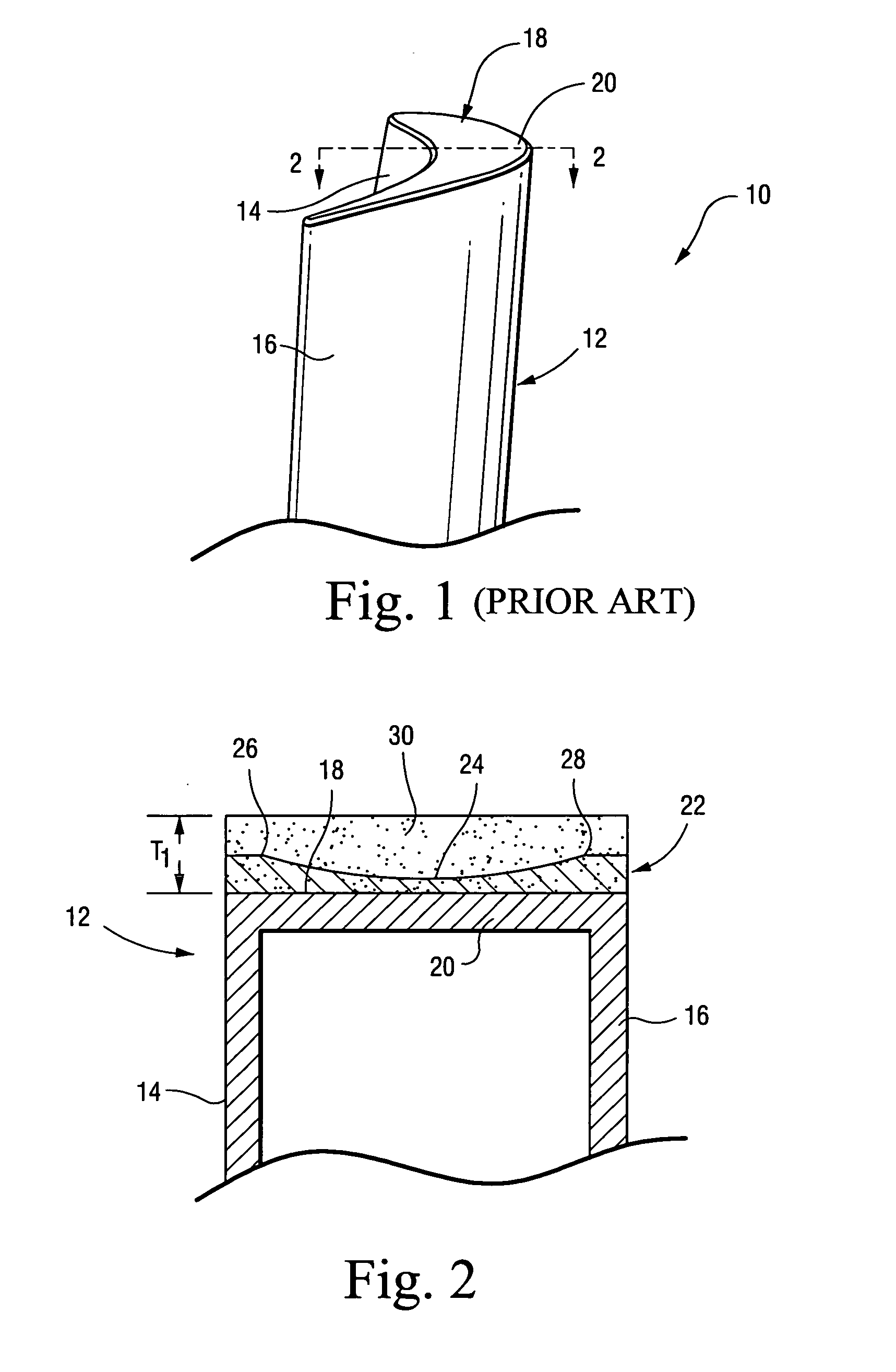

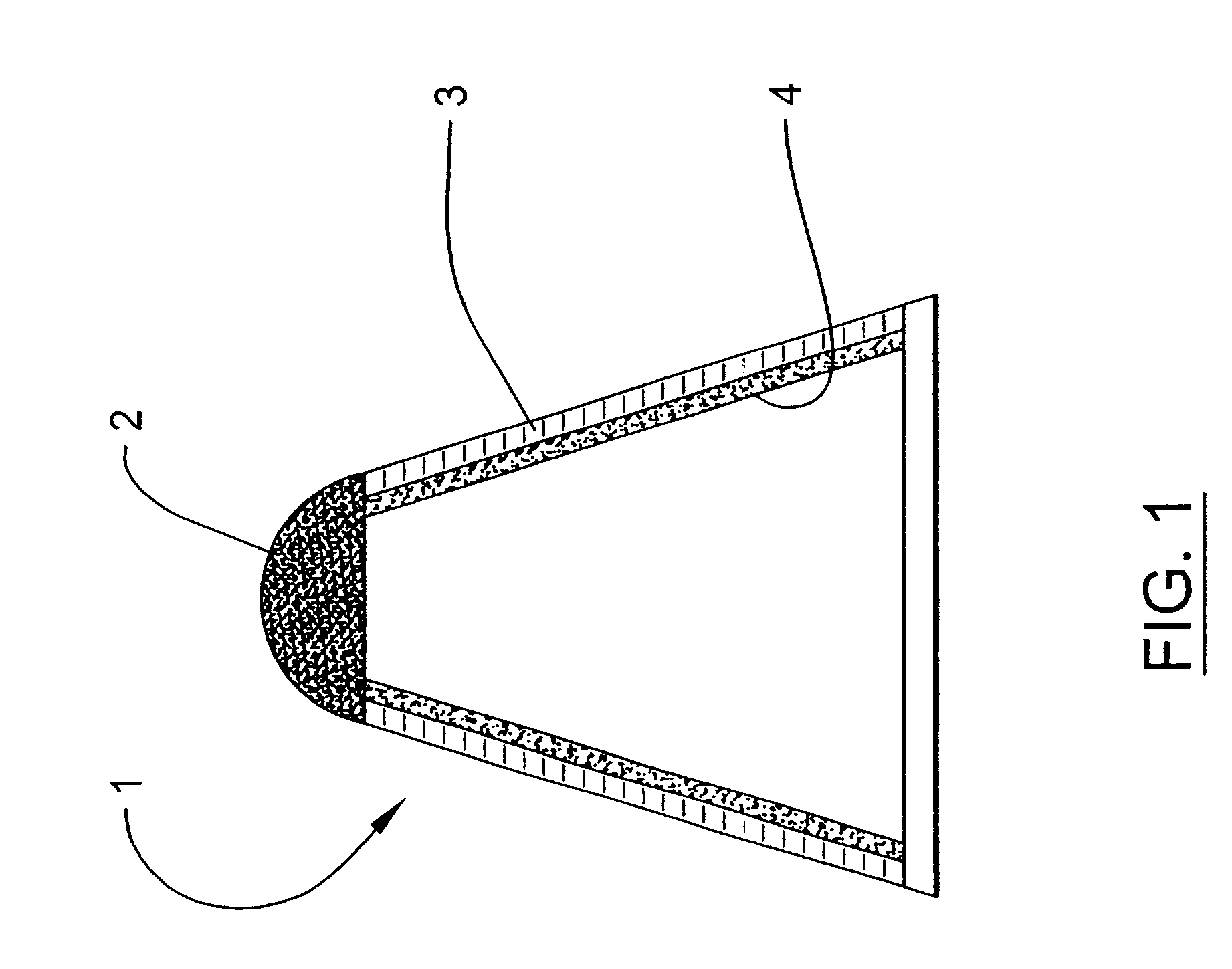

Horizontal continuous casting of metals

A mould for horizontal casting of molten metal comprising a mould body forming an open-ended mould cavity having an inlet end and an outlet end. An annular permeable wall member is mounted in the mould body adjacent the inlet end of the mould cavity with an inner face thereof forming an interior face of the mould. A refractory transition plate is mounted at the inlet end of the mould cavity, this transition plate providing a mould inlet opening having a cross-section less than that of the mould cavity. This provides an annular shoulder at the inlet end of the cavity. Means are provided for feeding molten aluminum through the inlet opening. Separate conduits are also provided for feeding a gas into the shoulder and via the permeable wall means for providing a layer of gas between the metal and the inner face of the mould. A gas that is more reactive with molten aluminum is fed into the shoulder and a less reactive gas is fed via the permeable wall. The reactions with the molten aluminum create a skin or shell on the aluminum which provides smooth passage through the mould and allows for more rapid secondary cooling of the emerging ingot.

Owner:NOVELIS INC

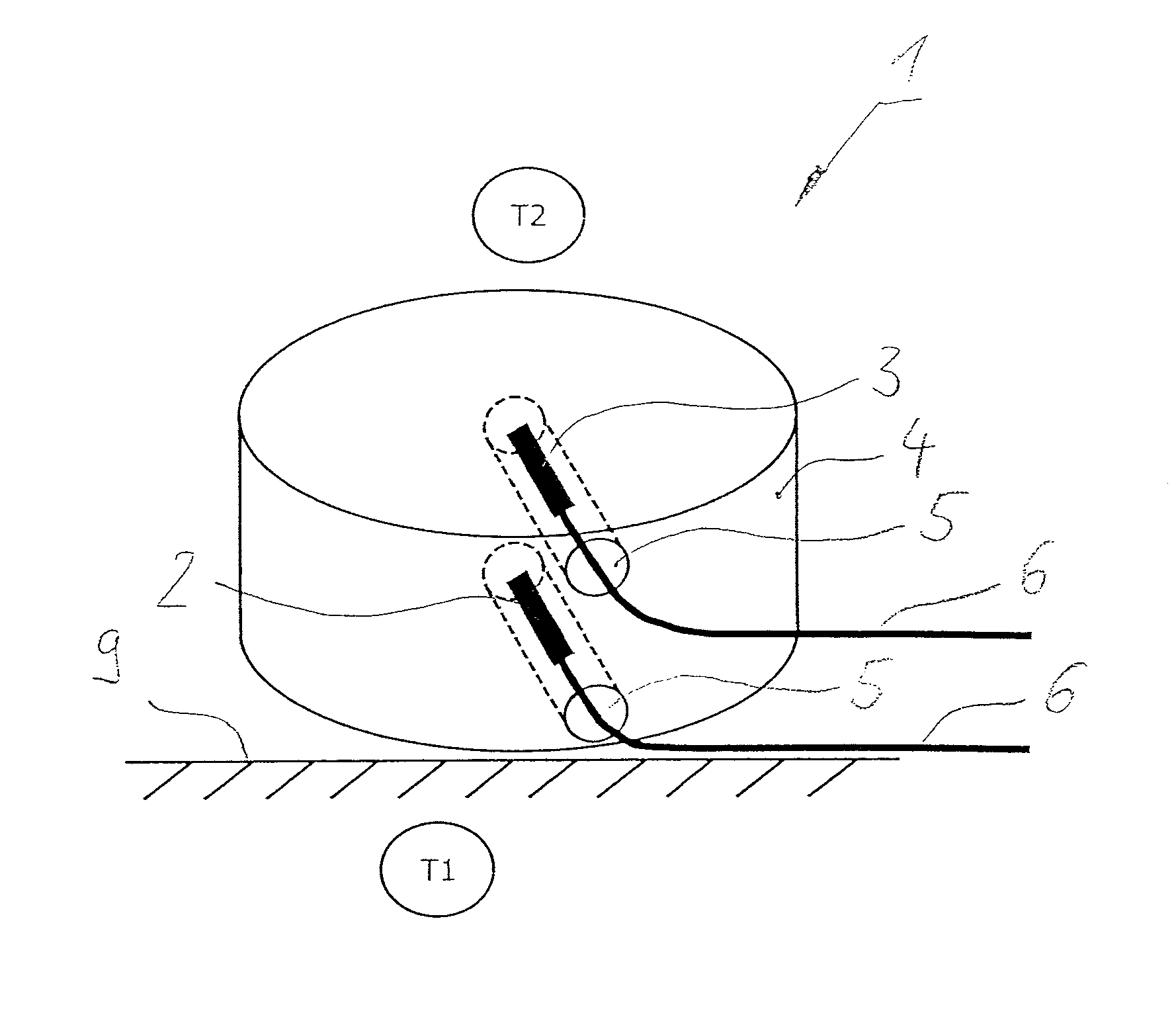

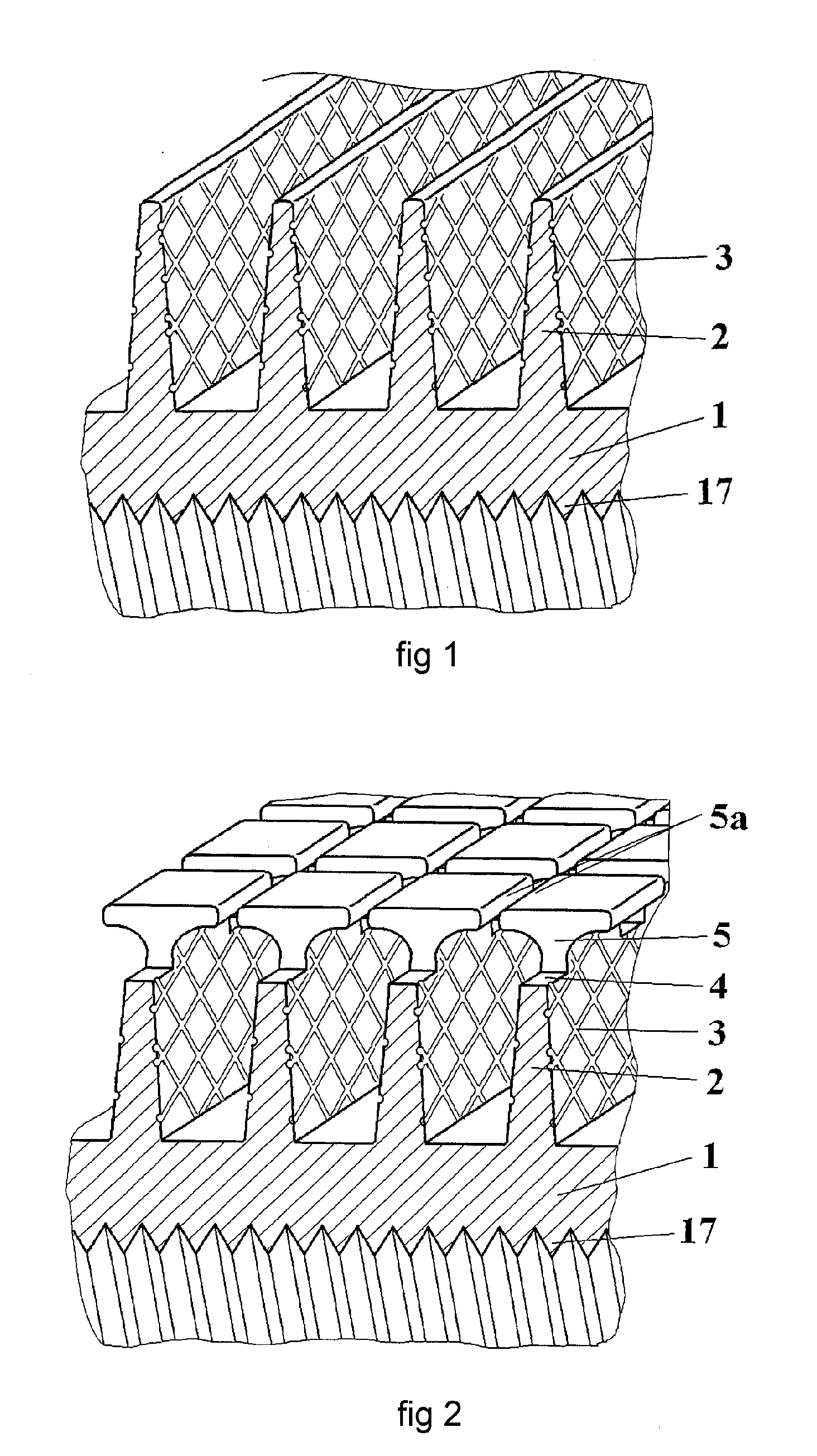

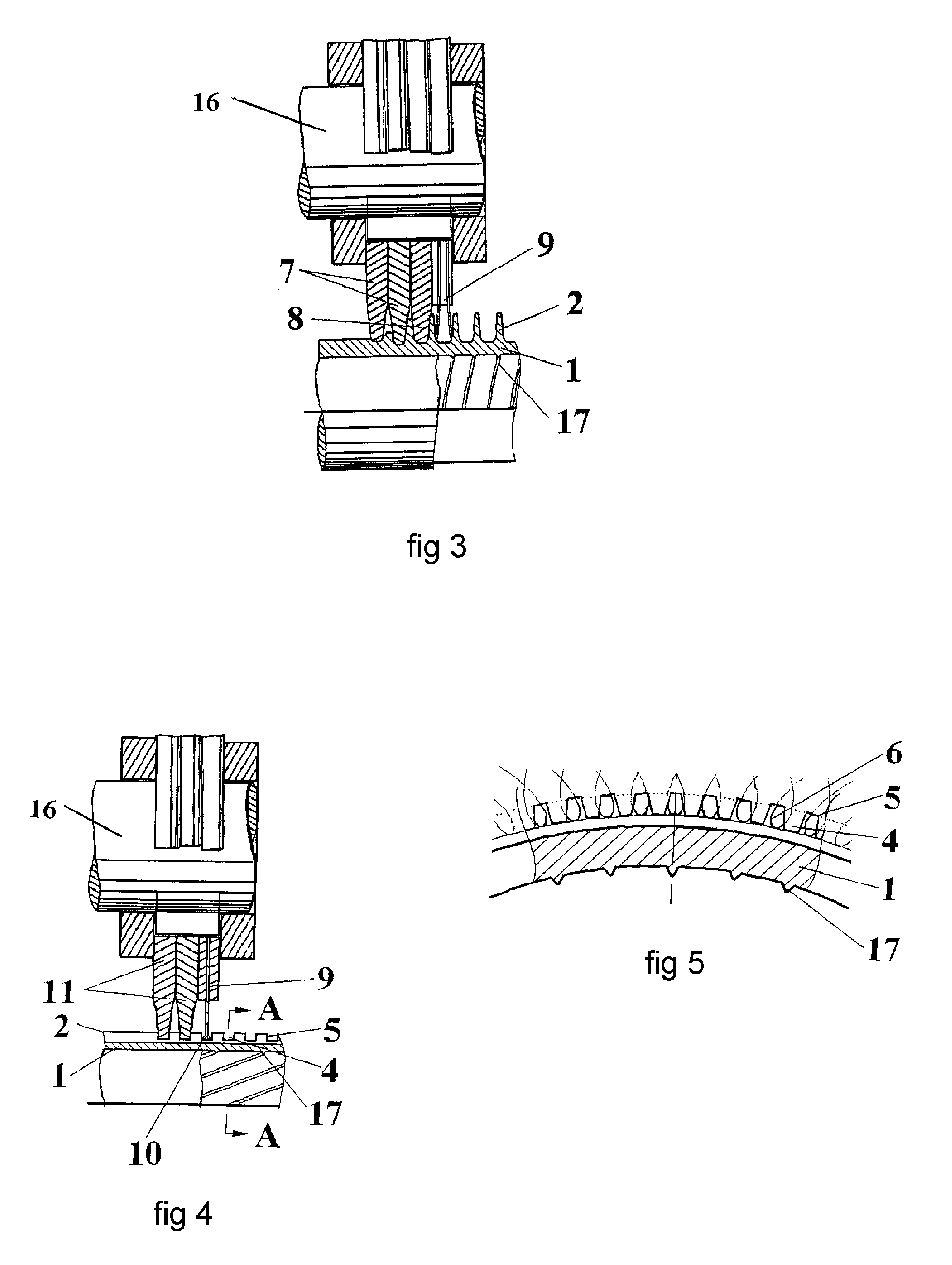

Double temperature sensor

ActiveUS7789554B2Easy to manufactureTolerances of the heat transfer coefficient can be minimizedThermometer detailsThermometers using electric/magnetic elementsElectricityHeat flux

A double temperature sensor is provided for measuring a near-surface temperature of the ambient air and the temperature of the skin surface (9). A heat flux insulation block (4) is made of an insulation material in one piece as a housing. Two temperature sensor elements (2, 3) with respective electric connections (6) belonging to them are arranged in the heat flux insulation block (4) one on top of another at spaced locations from one another and near the surface.

Owner:DRAGERWERK AG

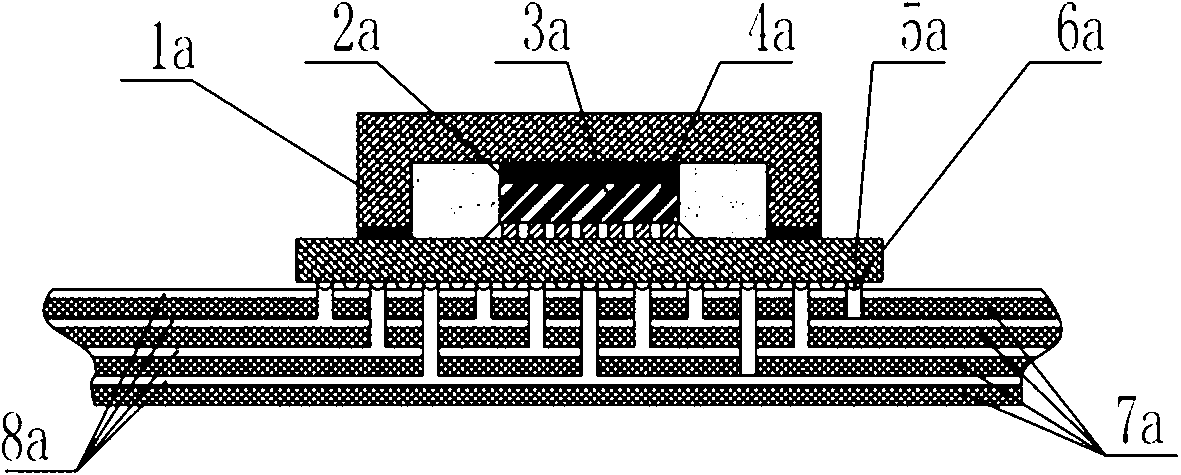

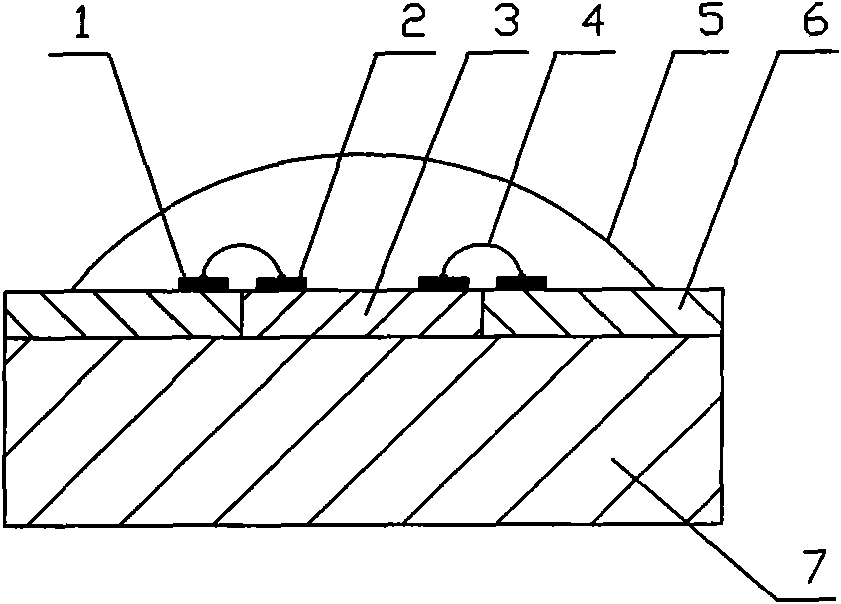

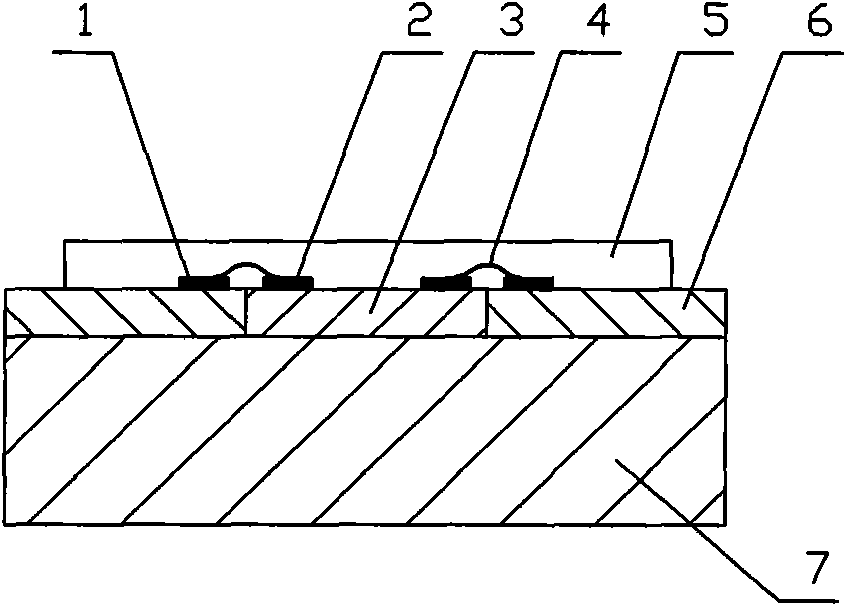

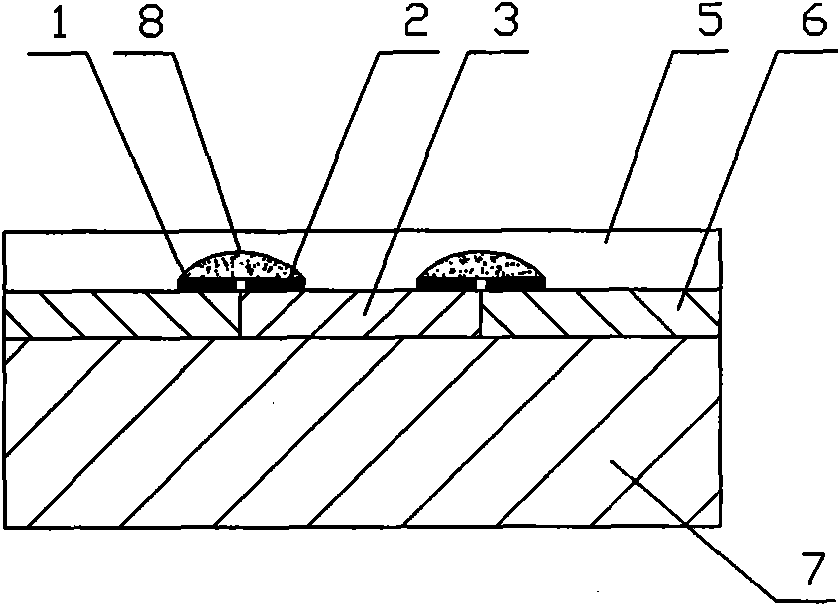

Light emitting diode (LED) chip and LED wafer, and chip manufacturing method thereof

ActiveCN101984511AAll-in-one packagingReduce the problem of internal thermal resistanceSolid-state devicesSemiconductor devicesHeat flowAdhesive

Aiming at reducing thermal resistance, lowering cost and improving efficiency, the invention provides a light emitting diode (LED) chip encapsulation structure, an LED wafer structure and a chip manufacturing method. The wafer in the LED chip is embedded in a locating plate (6), and the wafer and the locating plate are attached to a thermal diffusion piece (7) through welding or adhesion. The thermal diffusion piece is made of copper, aluminum or copper-aluminum composite material, and the heat-flow density is effectively reduced after high heat-flow density on the wafer passes by the thermal diffusion piece, thus being beneficial to reducing the thermal resistance. A wire welding method, a solder welding method or a conductive adhesive is used to communicate the lead wire pad (1) on the locating plate with an electrode pad (2) on the front or side wall of the wafer. A solid wafer protective layer (5) is arranged on the front of the wafer, thus enabling the chip package production to be efficient and simple.

Owner:秦彪

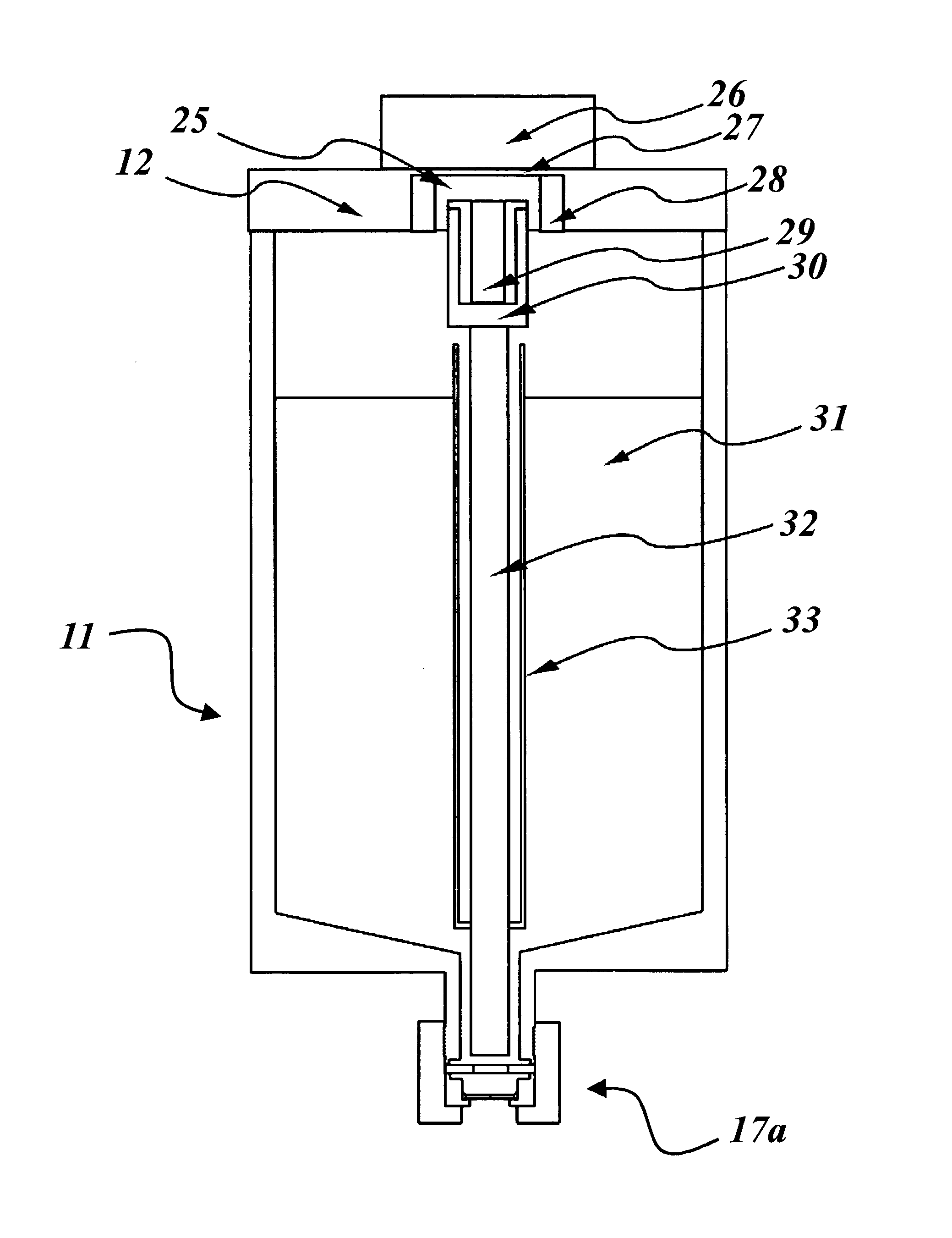

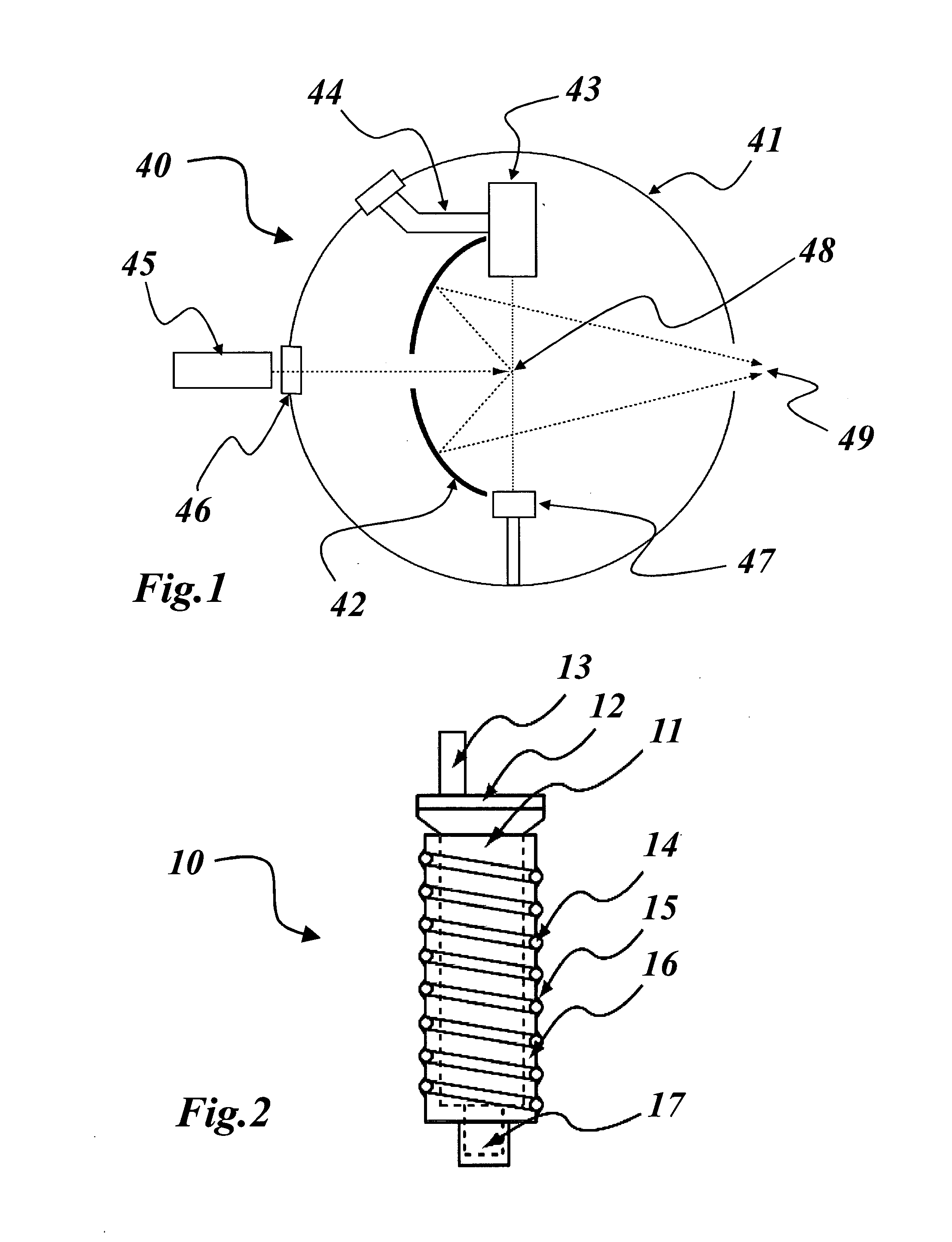

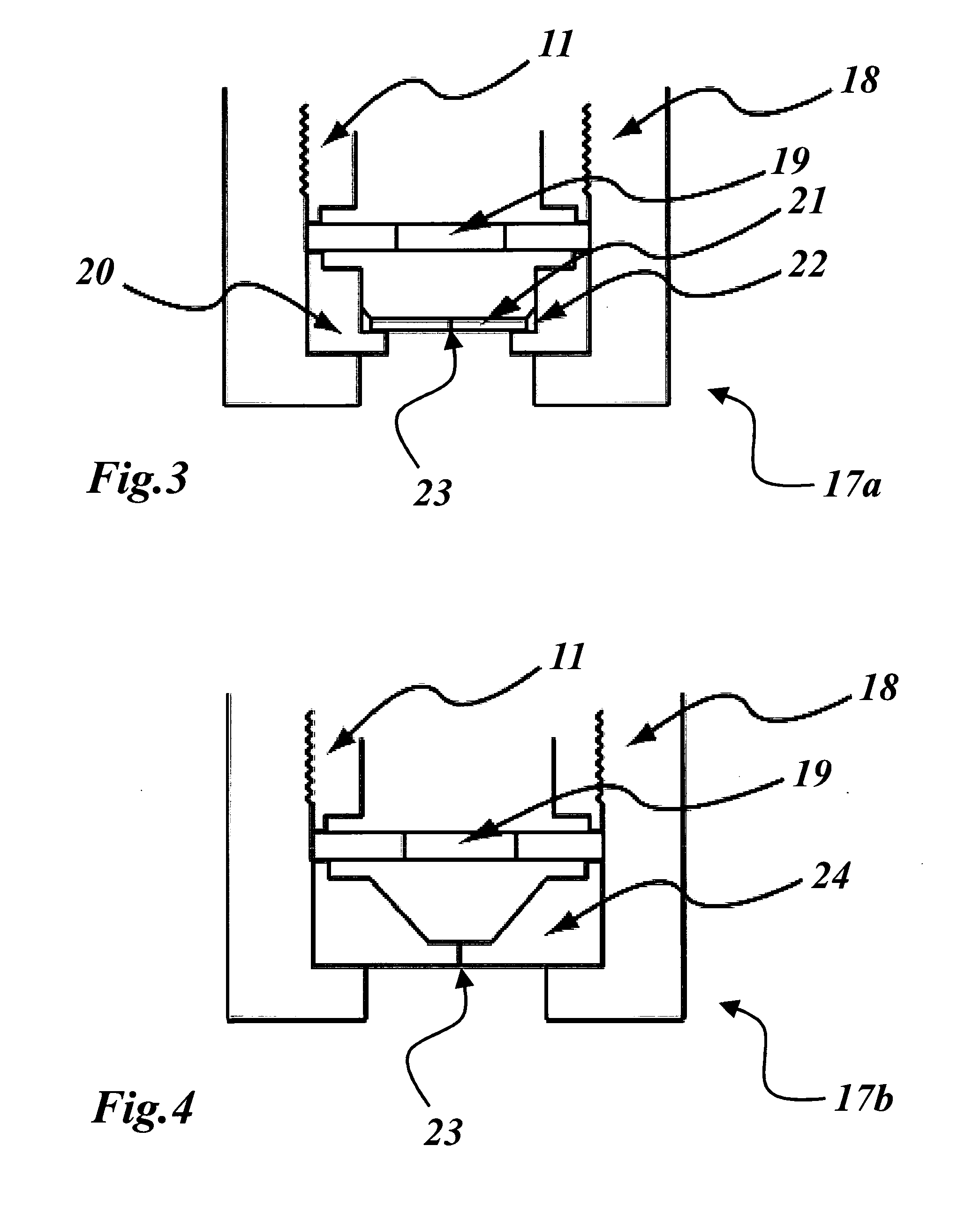

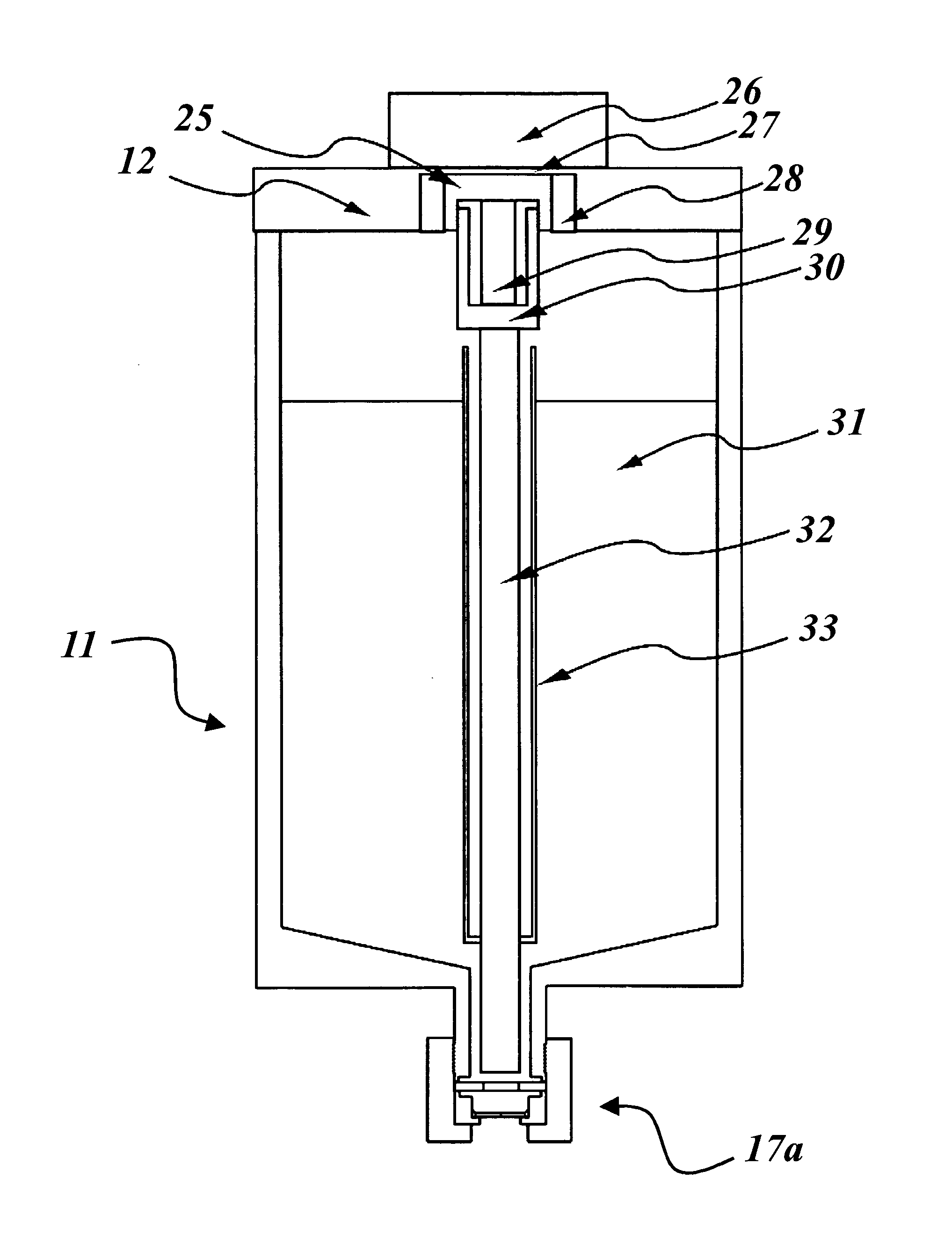

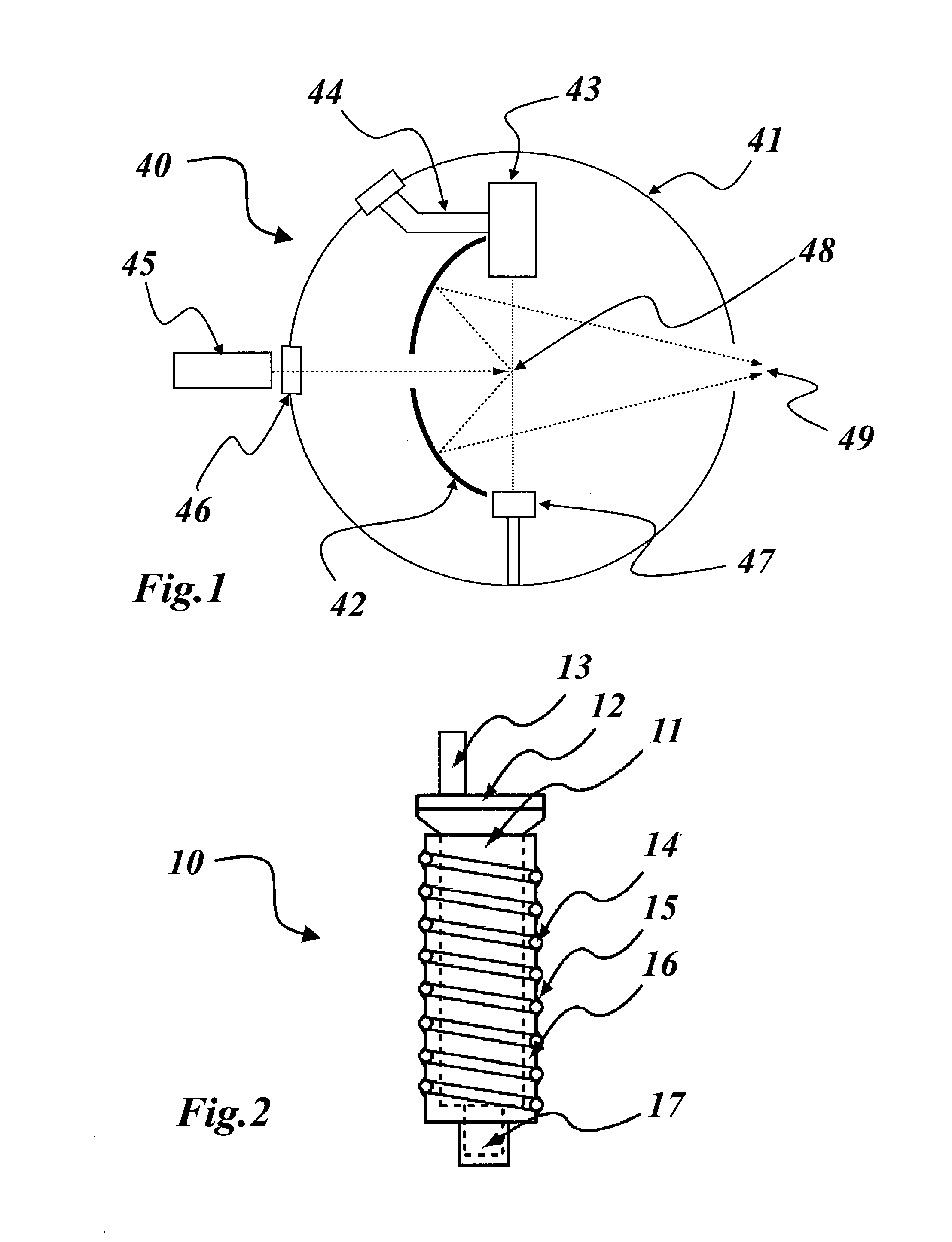

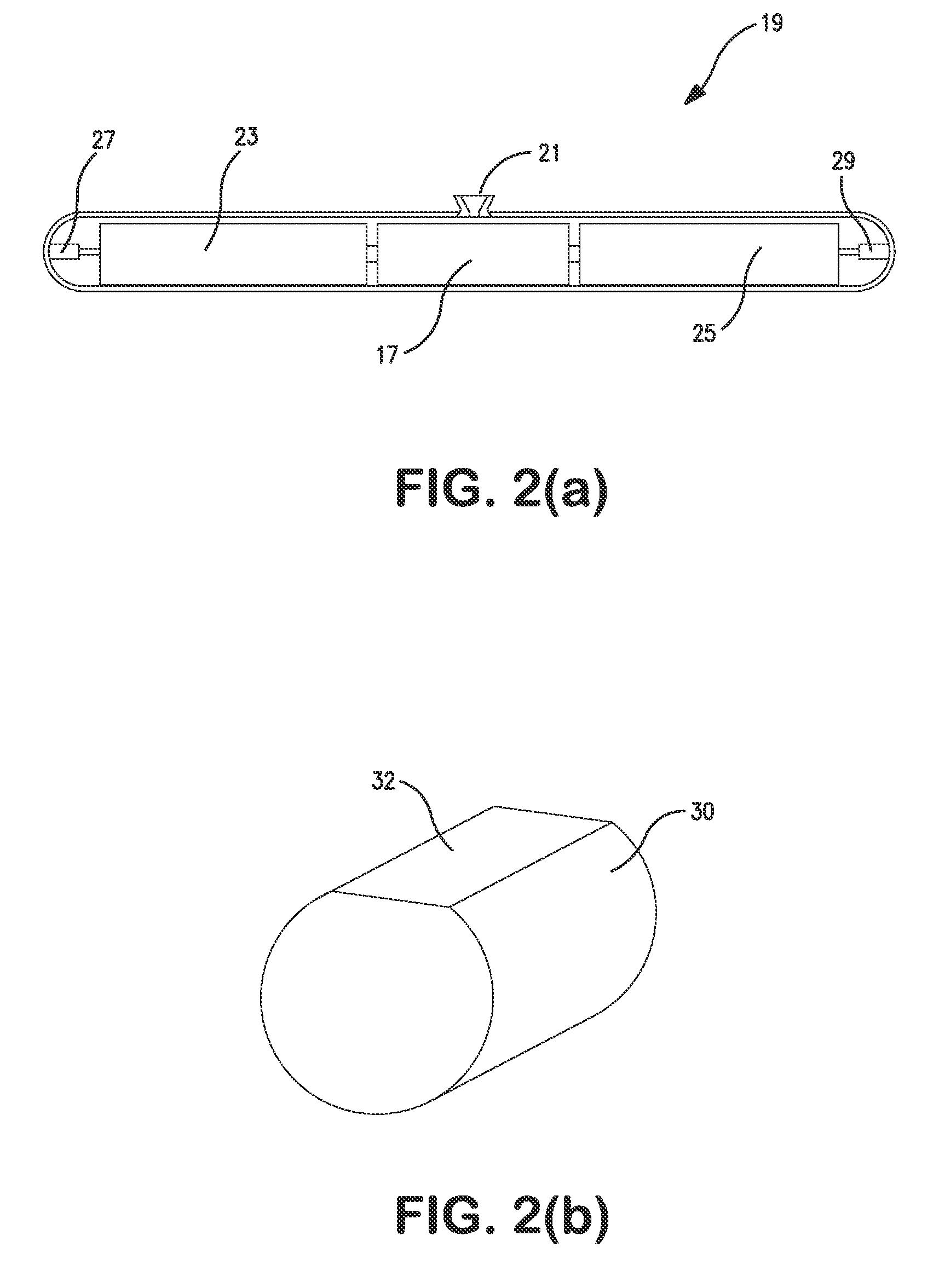

Droplet Dispensing Device and Light Source Comprising Such a Droplet Dispensing Device

ActiveUS20140151582A1High precisionImprove efficiencyRadiation pyrometryMovable spraying apparatusPiezoelectric actuatorsEngineering

A droplet dispensing device includes a reservoir for receiving a liquid material, an outlet nozzle in fluid communication with the reservoir and a piezoelectric actuating means acting on the liquid material at the outlet nozzle to exit the outlet nozzle in a sequence of droplets. A piezoelectric actuating means that includes a piston, which is actuated by a piezoelectric actuator at one end and dips the other, free end into the liquid material is provided just upstream of the outlet nozzle.

Owner:ETH ZZURICH

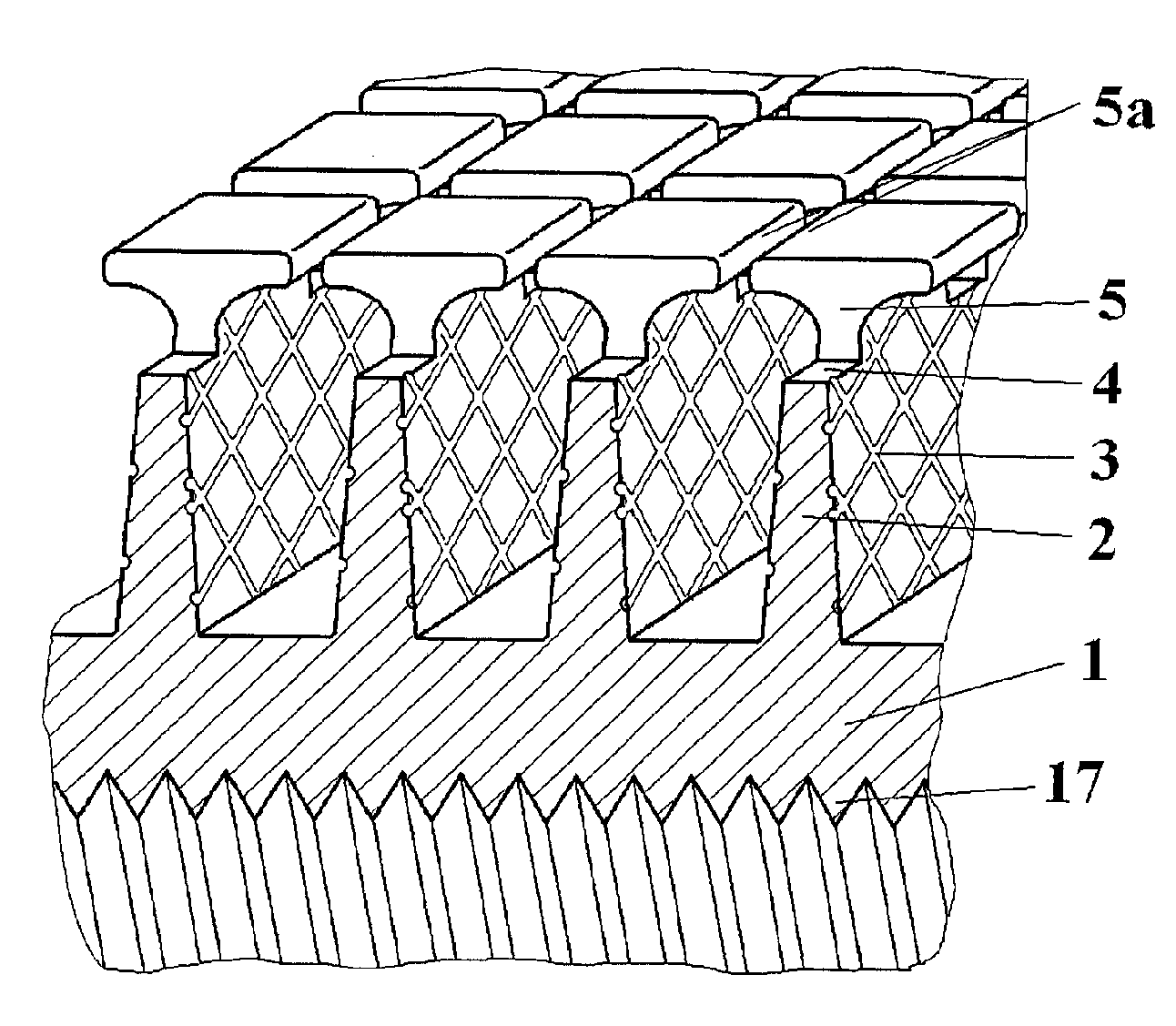

Enhanced Heat Transfer Tube and Manufacture Method Thereof

ActiveUS20090229806A1Increase the heat exchange areaSpeed up heat exchangeCorrosion preventionPlaning/slotting machinesHeat fluxEnhanced heat transfer

A heat transfer tube can comprise a tube body, and outer fins integrated with the tube body which are formed by allowing material on the tube body to extend along radial direction of the tube body and wind and extend around the tube outer surface in helical manner, wherein microscale channels are formed on at least one lateral surface of the outer fin. The invention has the advantage that the microscale channel is formed on at least one lateral surface of the outer fin to help increase the heat exchange area of the outer fin surface, improve the fluid disturbance, enhance the forced convention heat exchange out of tube, and significantly improve the heat transfer coefficient; when the enhanced heat transfer tube in the present invention is applied on an evaporator, the microscale channel can greatly increase the number of the nucleation sites, so as to enhance boiling heat exchange in condition of low heat flux density; when the enhanced heat transfer tube in the present invention is applied on a condenser, the microscale channel can improve distribution of liquid membrane thickness on outer fin surface to enhance condensing heat exchange.

Owner:JIANGSU CUILONG PRECISION COPPER TUBE CORP

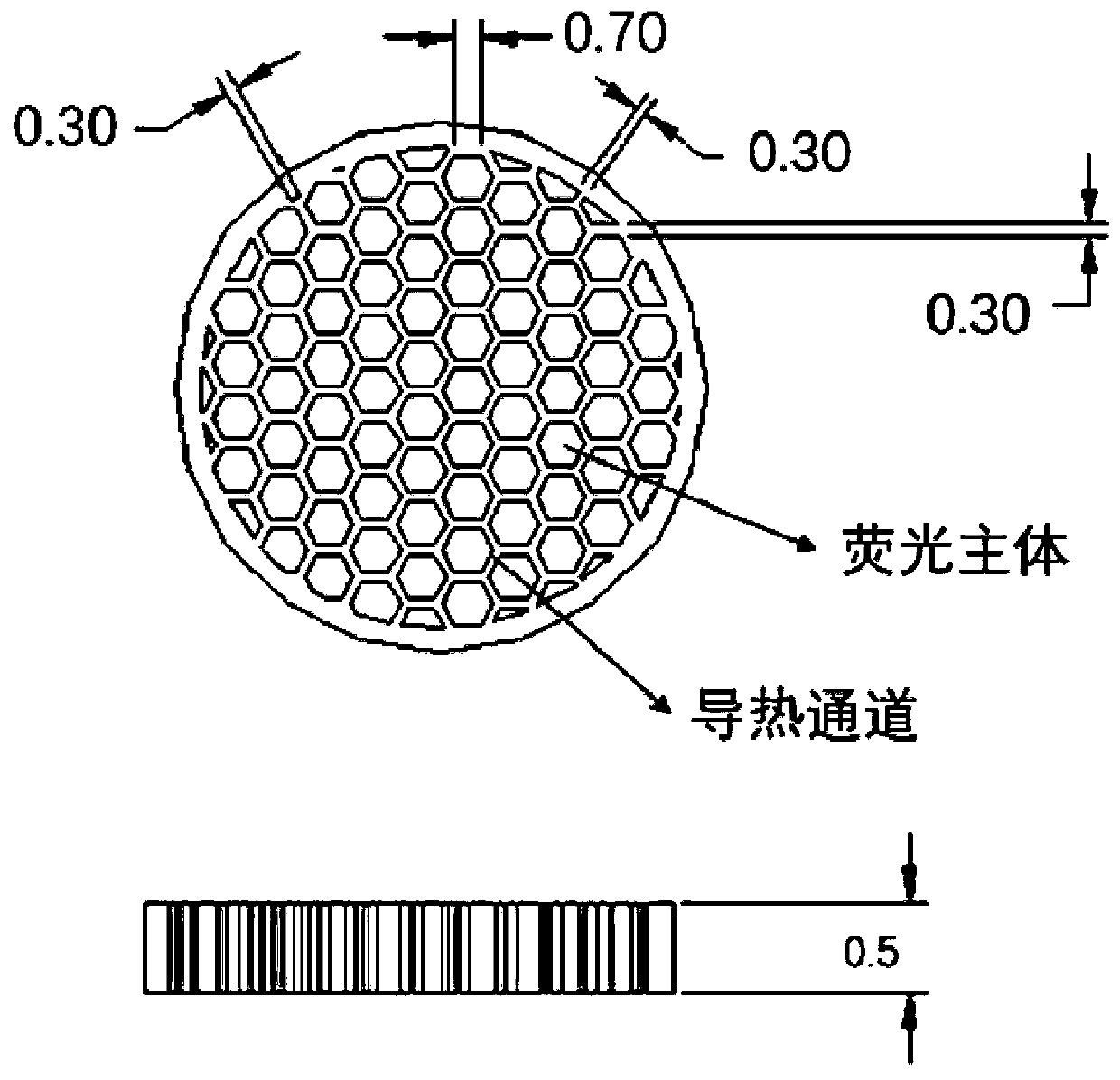

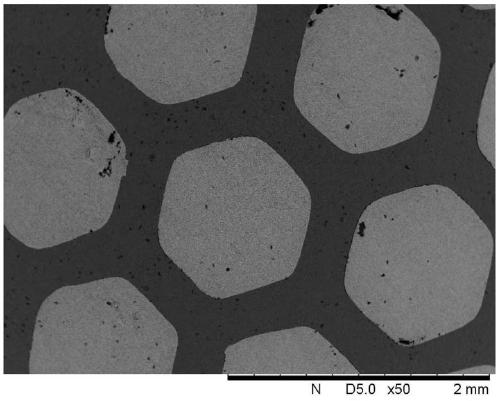

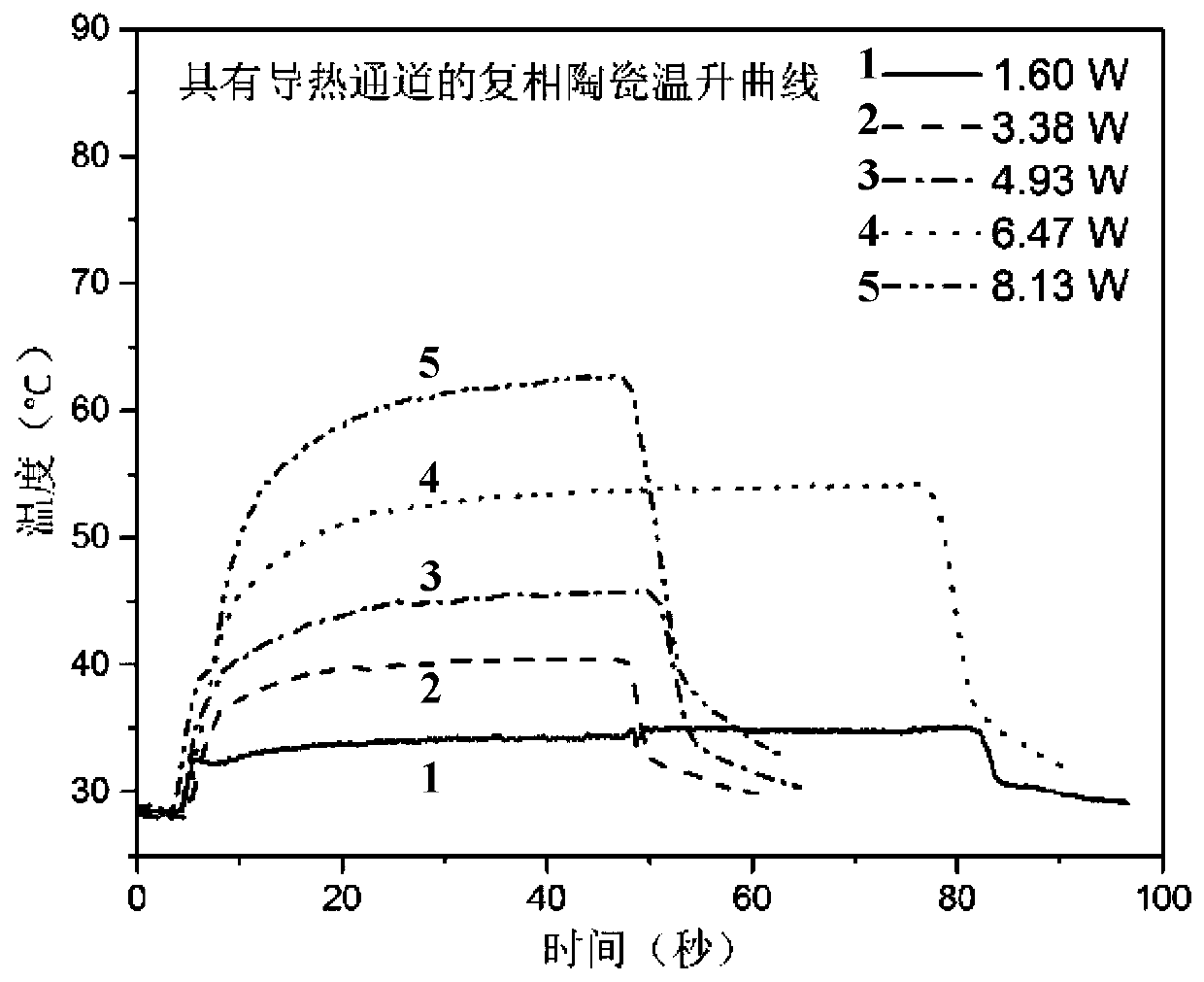

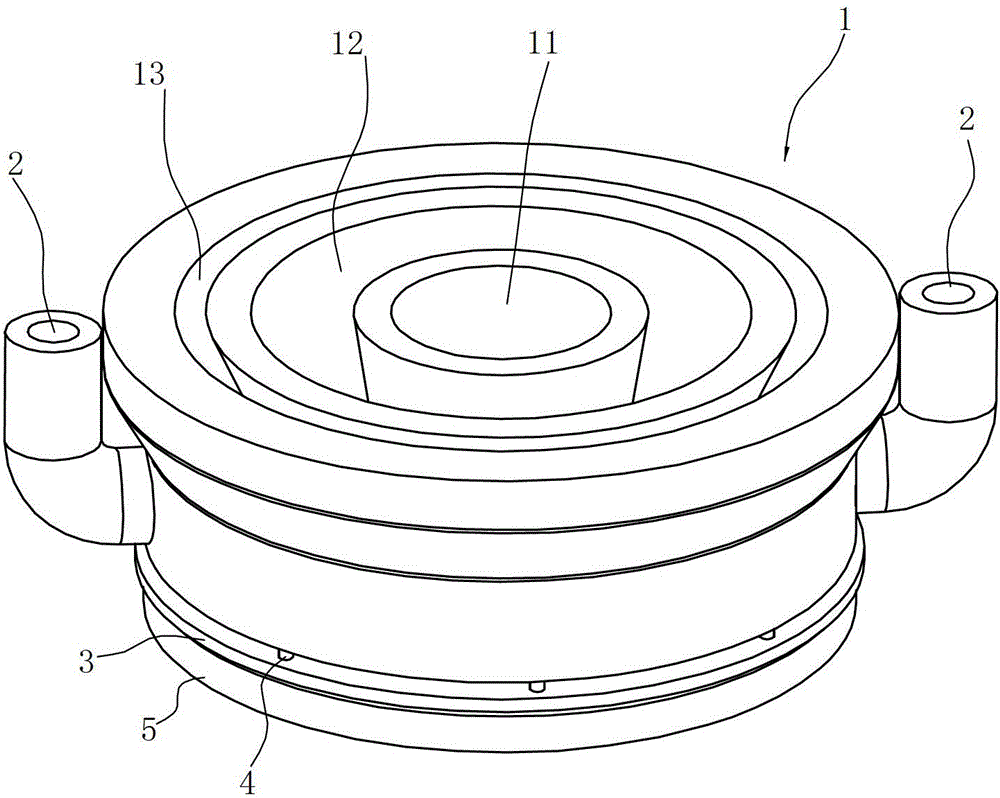

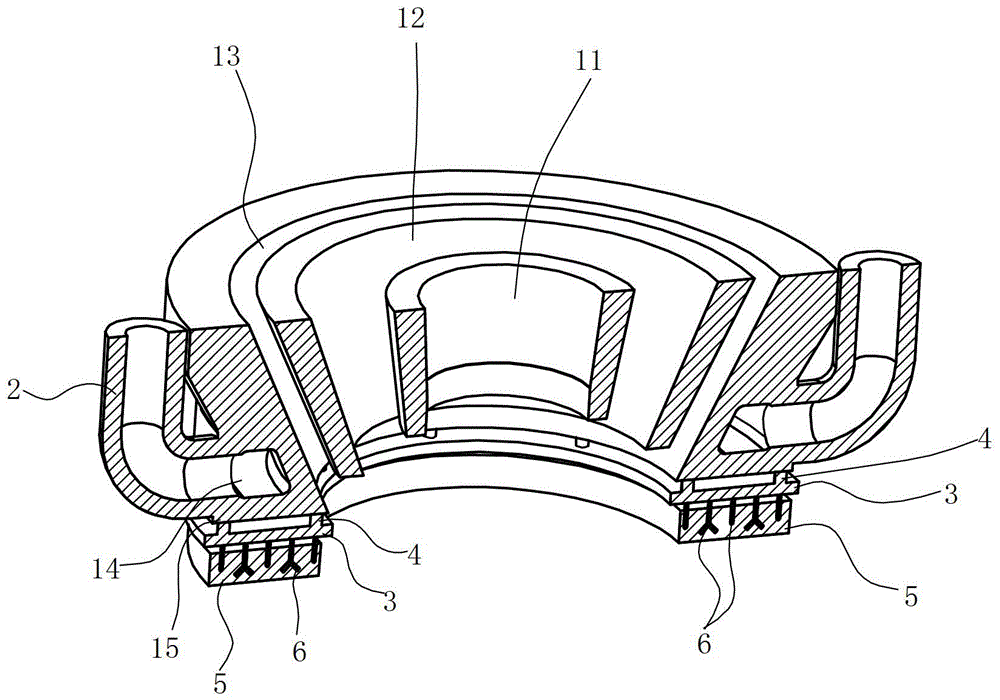

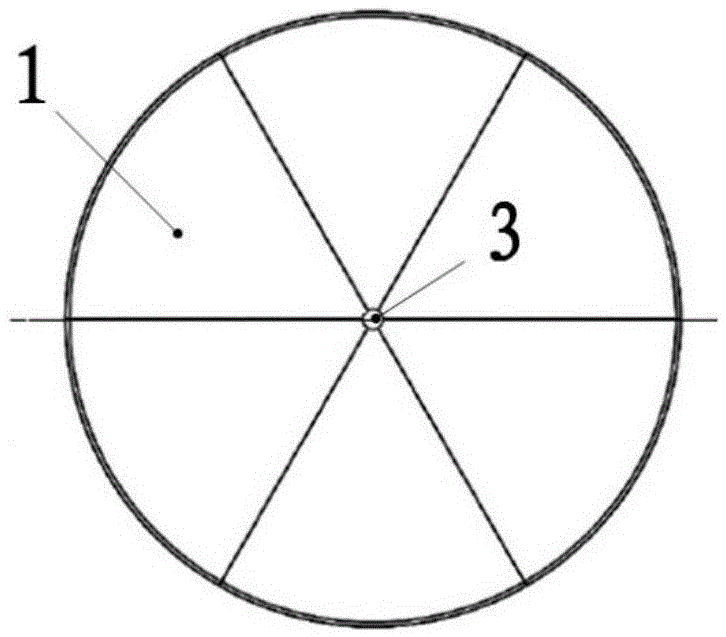

Multiphase fluorescent ceramic and preparation method thereof

ActiveCN111377713AImprove stabilityRaise the thresholdAdditive manufacturing apparatusLuminescent compositionsDielectricTransparent ceramics

The invention relates to a multiphase fluorescent ceramic and a preparation method thereof. The multiphase fluorescent ceramic comprises a high-thermal-conductivity dielectric ceramic matrix and fluorescent ceramic main bodies which are distributed in the high-thermal-conductivity dielectric ceramic matrix and are periodically arranged; the shortest distance L between the adjacent fluorescent ceramic main bodies is 200-1000 microns, and the volume fraction delta of the high-thermal-conductivity dielectric ceramic matrix in the multiphase fluorescent ceramic is 5-60%; the fluorescent ceramic main body is rare earth doped transparent ceramic; and the material of the high-thermal-conductivity dielectric ceramic matrix is selected from at least one of Al2O3, AlN, BeO, Sc2O3, Si3N4, BN, SiC andMgO.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

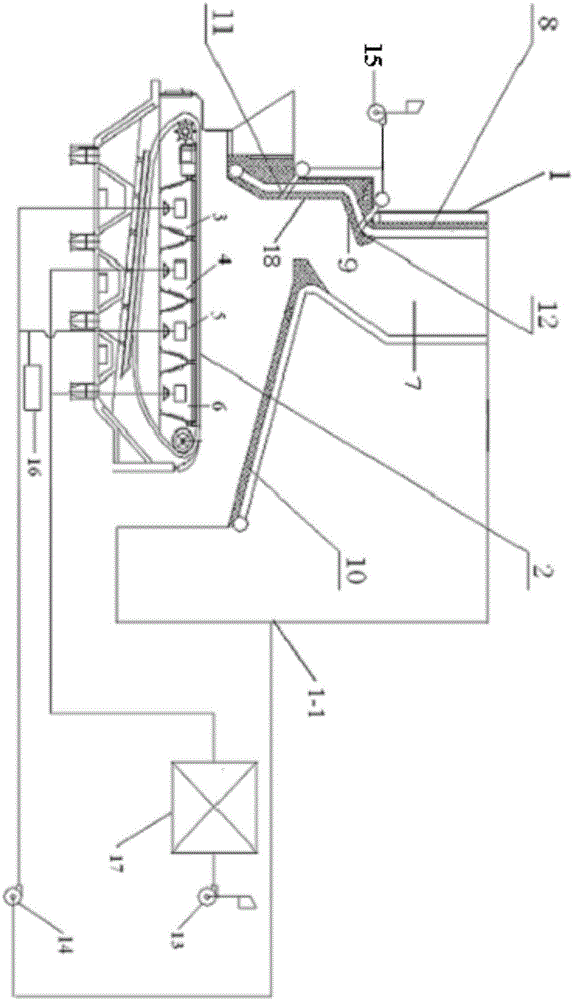

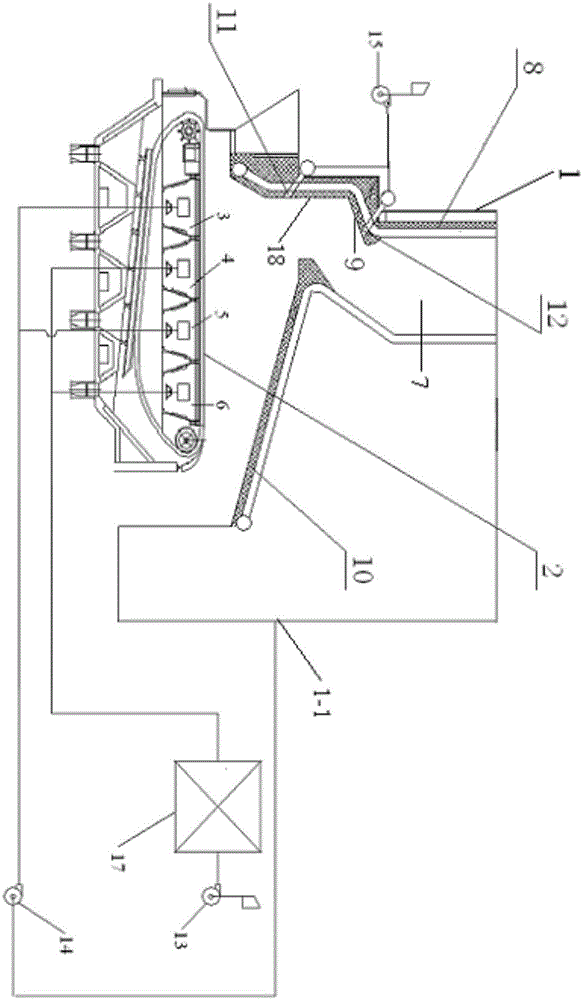

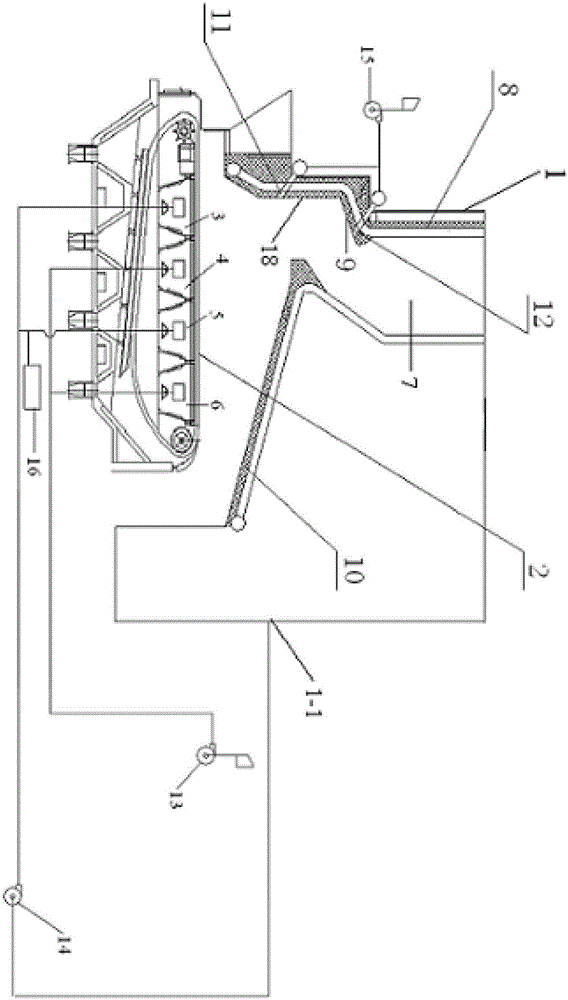

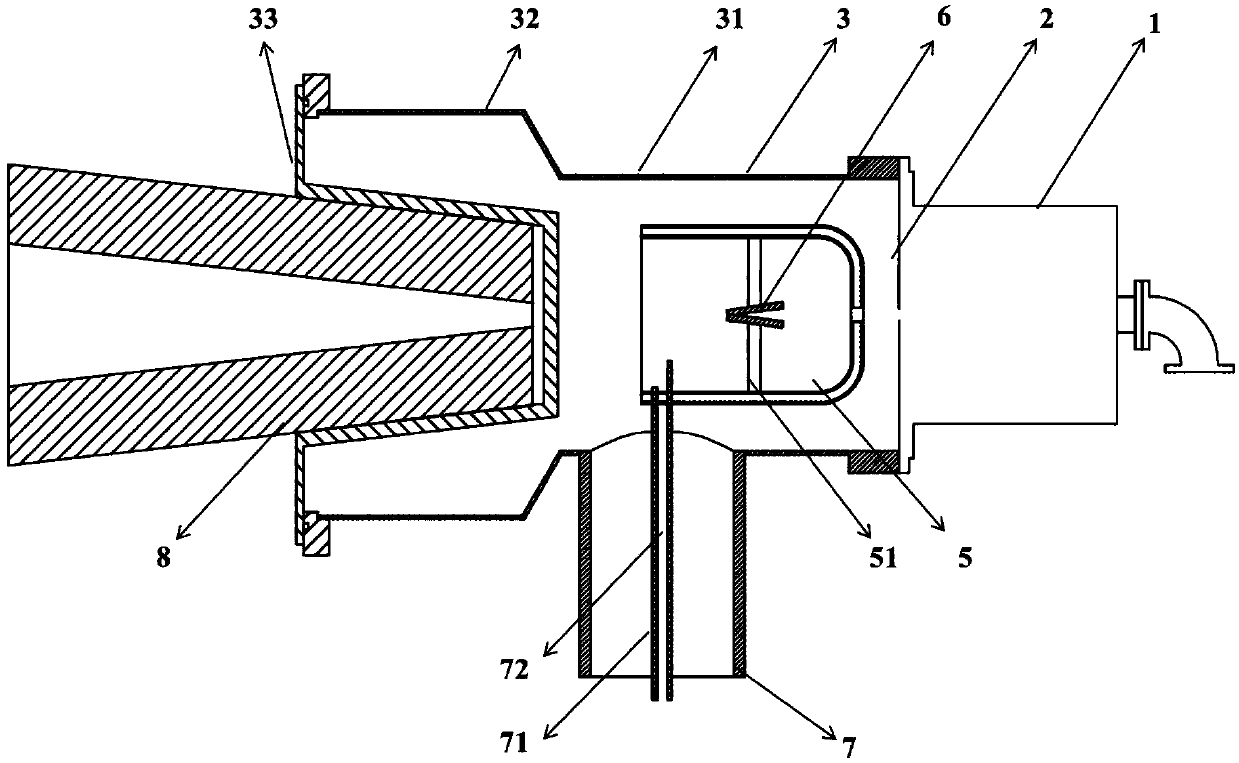

Process burner structure of gasification furnace

ActiveCN103333717AExtended service lifeReduce heat fluxGranular/pulverulent flues gasificationHeat flowSlag

The invention relates to a process burner structure of a gasification furnace. The process burner structure comprises a burner body, wherein a plurality of material channels and cooling water cavities are orderly arranged on the body from inside to outside. The process burner structure is characterized in that a thermal insulating layer, which is matched with the front end face of the burner, and of which the refractoriness is greater than or equal to 1770 DEG C, is arranged at the front end face of the burner; the thermal insulating layer is parallel to the front end face of the burner and connected with the front end face of the burner through a plurality of slag nails which are arranged at intervals. Compared with the prior art, conventional ideas of prolonging the service life of the burner in the field and providing the operating cycle are avoided; the density of heat flow through the front end face of the burner body is greatly reduced by providing the thermal insulating layer to prevent high-temperature radiation inside the gasification furnace. Thus, thermal stress caused by temperature gradient near the front end face is greatly reduced; meanwhile, the temperature of the front end face of the burner can be reduced; the allowable stress of the burner is increased; the operating cycle of the process burner of the gasification furnace is effectively prolonged.

Owner:SINOPEC NINGBO ENG +2

Steam-cooled gas turbine bucket for reduced tip leakage loss

InactiveUS7922455B2Avoid leakage lossReduce gapPump componentsBlade accessoriesEngineeringThermal barrier coating

A bucket for a steam turbine includes an airfoil portion having a radially outer tip, the radially outer tip having a thermal barrier coating applied thereto, and wherein the thermal barrier coating is resurfaced to form at least one ridge along the radially outer tip.

Owner:GENERAL ELECTRIC CO

Anti-slagging biomass cascade conversion combustion device

ActiveCN106594713APrevent slaggingThermochemical conversion achievedSolid fuel combustionIndirect carbon-dioxide mitigationAir preheaterWater vapor

The invention provides an anti-slagging biomass cascade conversion combustion device and relates to a biomass combustion device. The anti-slagging biomass cascade conversion combustion device aims at solving the technical problem that slagging happens easily when straw is combusted through an existing chain furnace. The anti-slagging biomass cascade conversion combustion device is composed of a chain furnace, a steam generator, an air blower, a high-temperature induced draft fan and an air preheater. A secondary air nozzle is arranged on the front wall below a front arch. An overfire air nozzle is arranged on the front arch. A circulating flue gas chamber communicates with a flue opening in the tail of the chain furnace through the high-temperature induced draft fan. A weak primary air chamber communicates with the air blower through the air preheater. A steam-circulating flue gas chamber communicates with the steam generator and the high-temperature induced draft fan. A strong primary air chamber communicates with the air blower through the air preheater. The secondary air nozzle communicates with the air blower. The overfire air nozzle communicates with the air blower. The anti-slagging biomass cascade conversion combustion device effectively solves the problem of slagging of biomass combustion chain grates.

Owner:HARBIN INST OF TECH

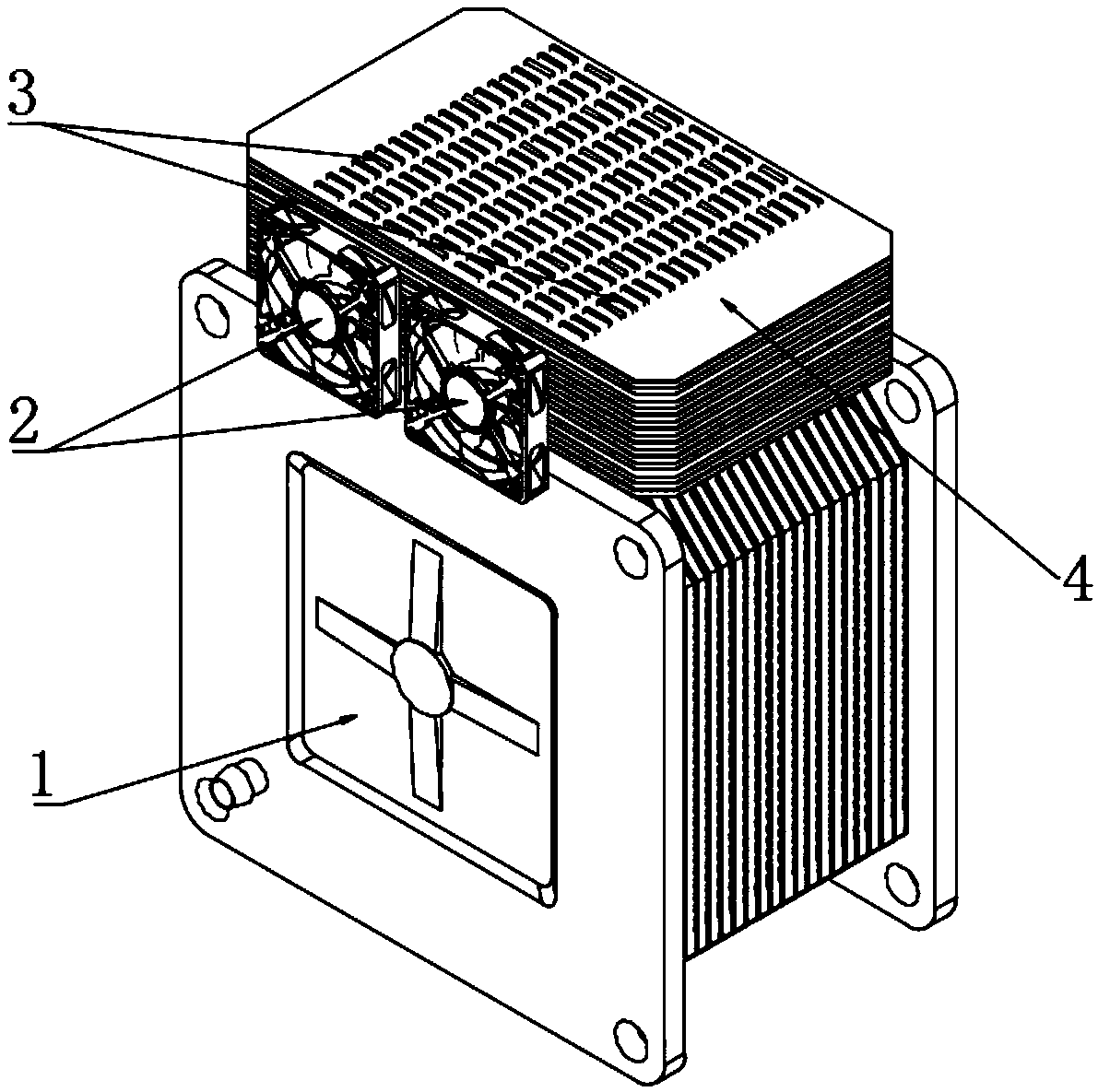

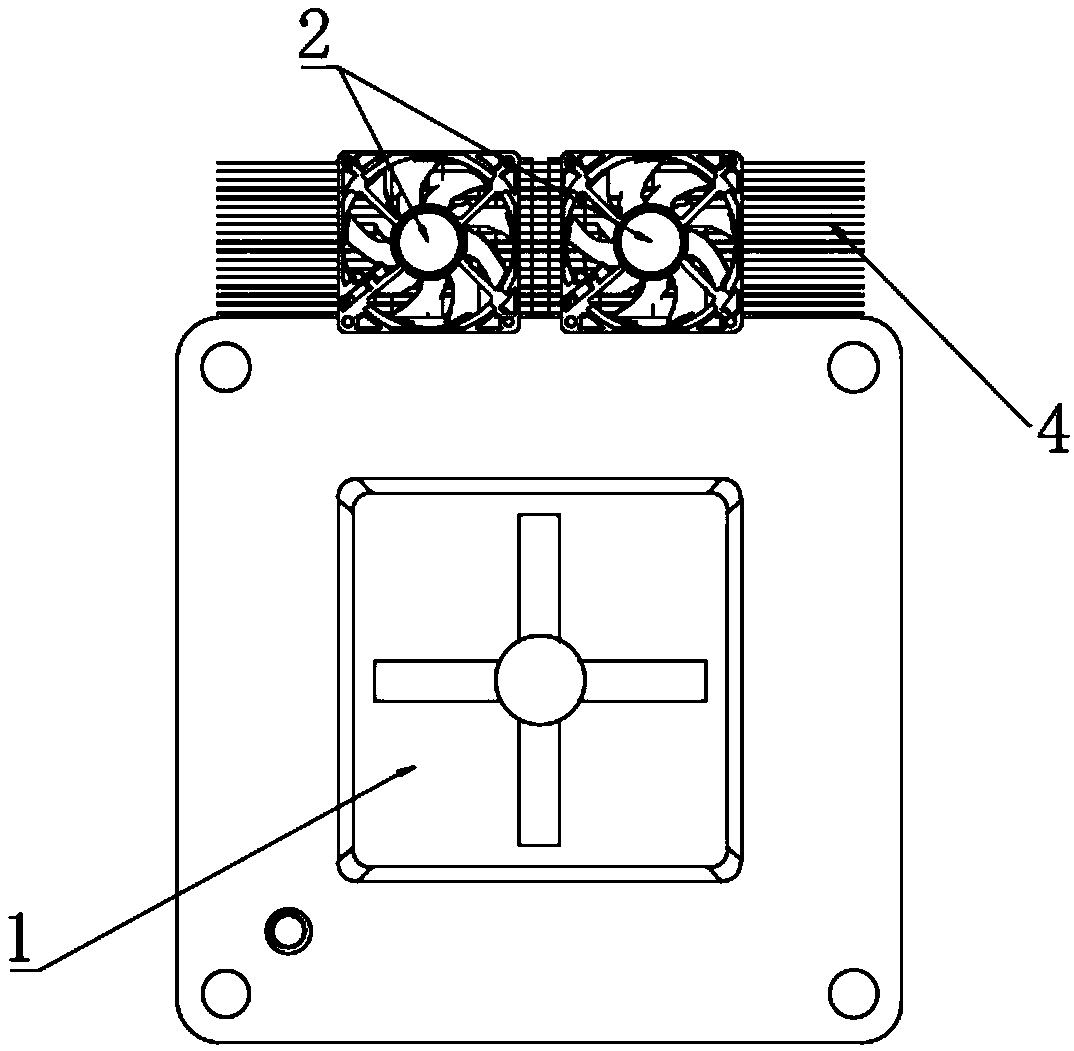

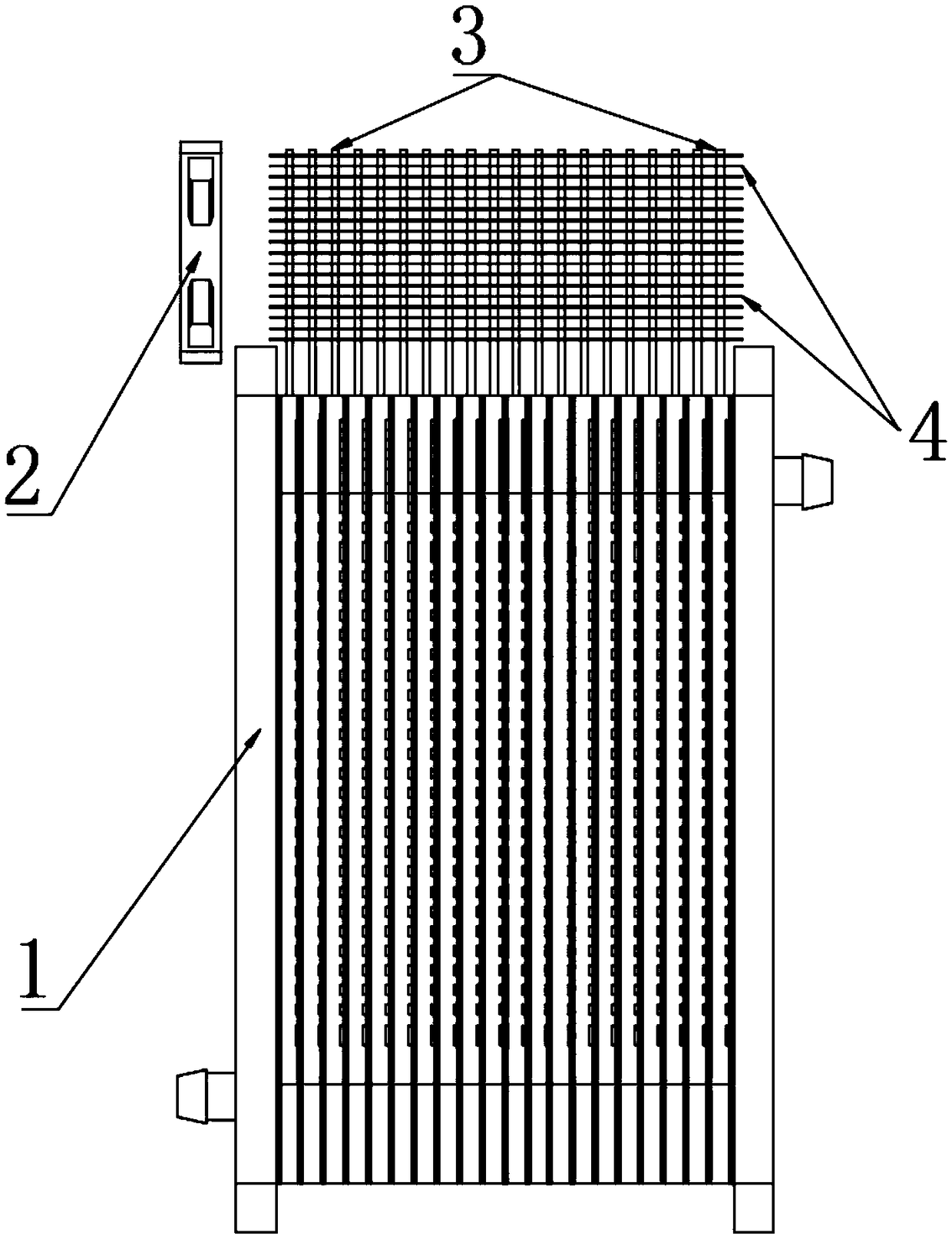

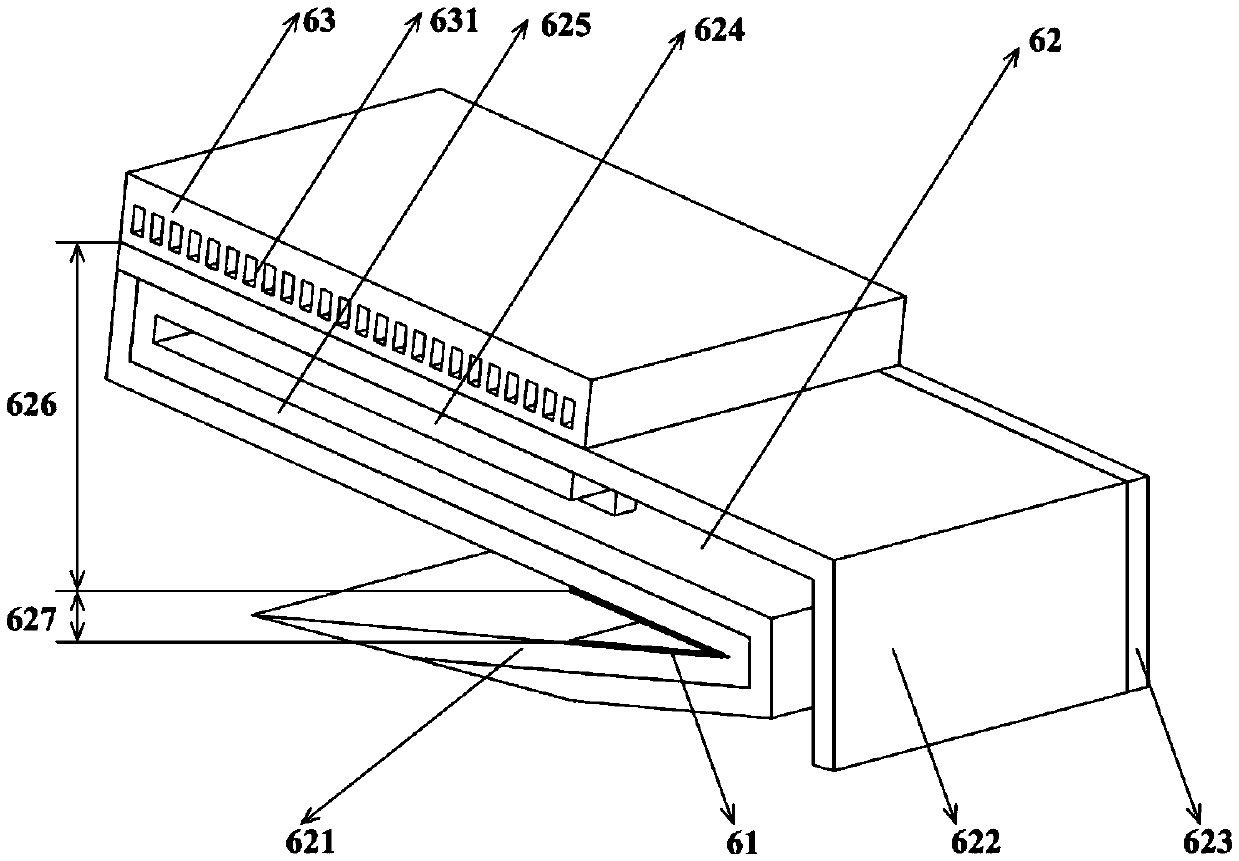

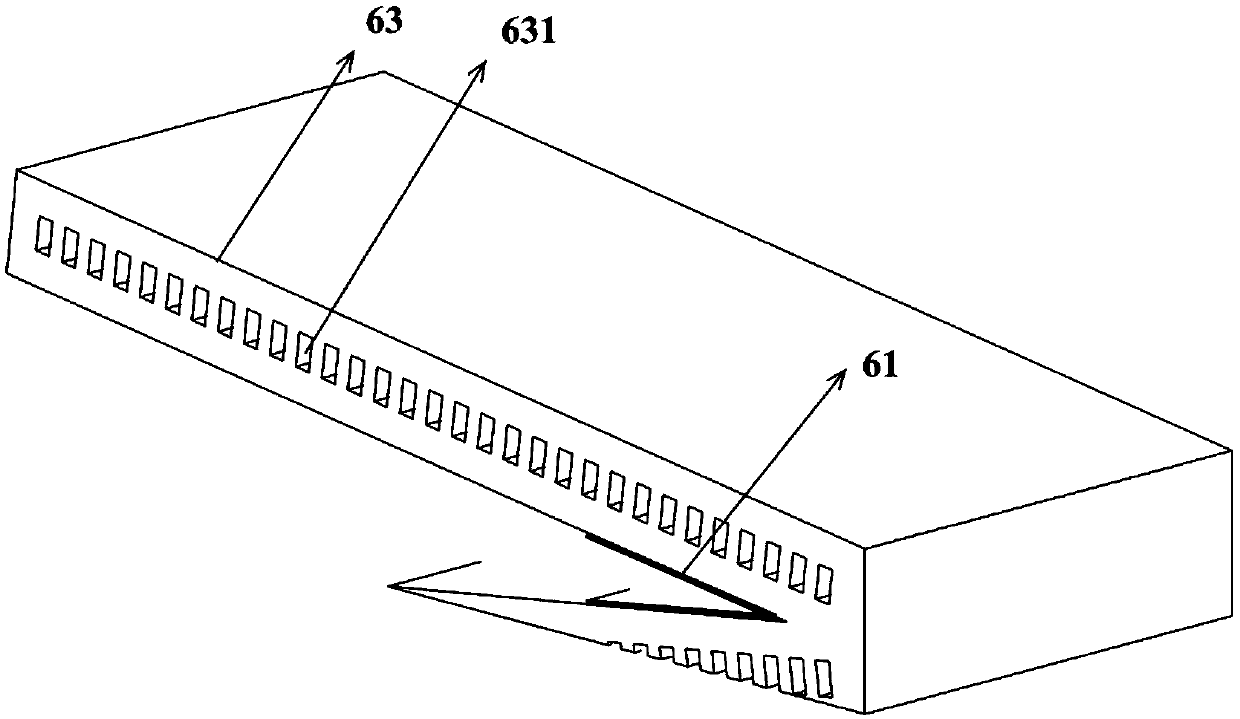

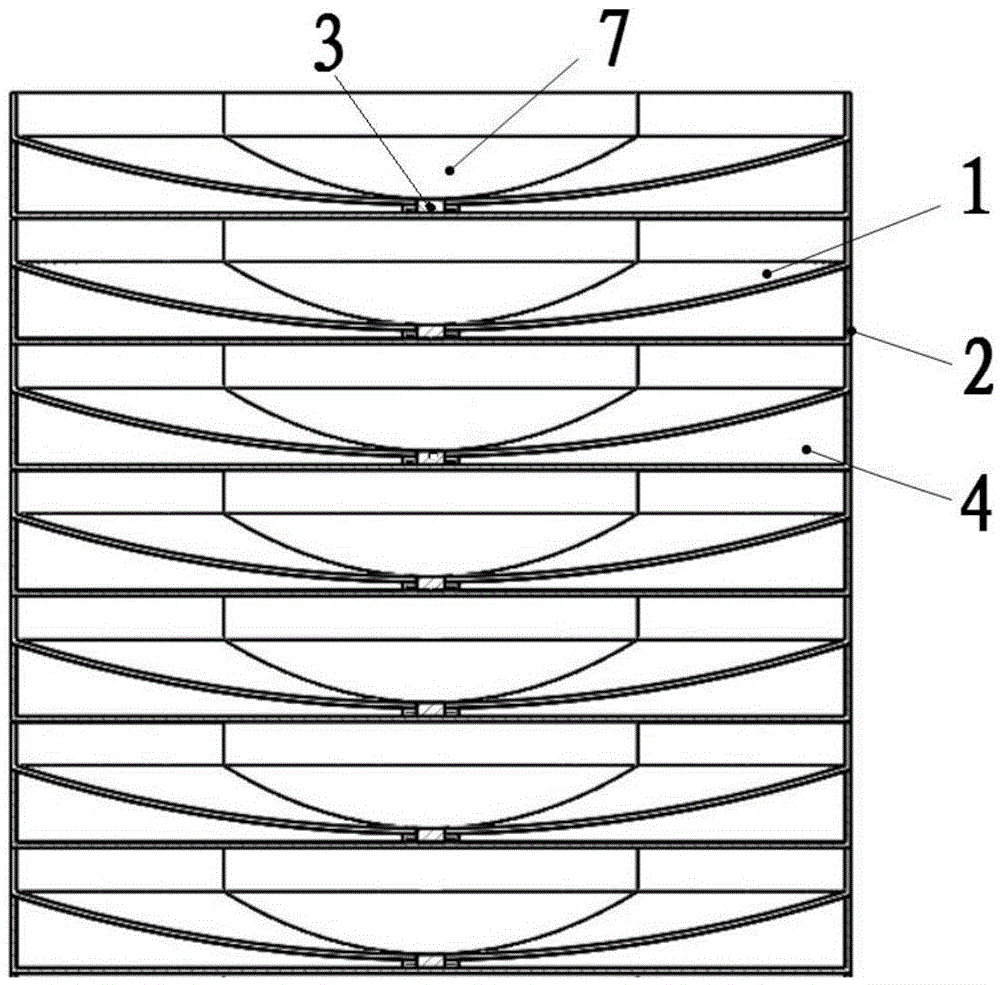

An air-cooled module for heat transfer temperature uniformization of a fuel cell

The invention discloses an air-cooled module for heat transfer temperature uniformization of a fuel cell. The air-cooled module mainly consists of a fuel cell module, fins and a fan system; the fuel cell module comprises an end cap, a membrane electrode, an ultra-thin temperature uniformization plate, a plurality of membrane electrodes and a plurality of ultra-thin uniform temperature plates are alternately arranged, the two sides of each membrane electrode are respectively provided with an ultra-thin uniform temperature plate, and the ultra-thin uniform temperature plate comprises a shell, acavity, a liquid suction core and a working medium; The hollow cavity is arranged in the housing, the hollow cavity is at least protruded from one end of the housing, and the hollow cavity is providedwith a liquid suction core and a working medium; The upper surface or the lower surface of the shell is respectively provided with an air flow channel or a hydrogen flow channel; The overall thickness of the ultra-thin homogeneous temperature plate shall not exceed 3mm; A plurality of fins are installed on the condensing end of the ultra-thin uniform temperature plate. The evaporation end of theultra-thin uniform temperature plate of the invention can separate the reaction gas, collect and conduct the electric current; The heat flux concentrated on the surface of the bipolar plate is rapidlytransferred and diffused to the large area of the condensation surface, which has the effect of uniform temperature and heat dissipation.

Owner:SOUTH CHINA UNIV OF TECH

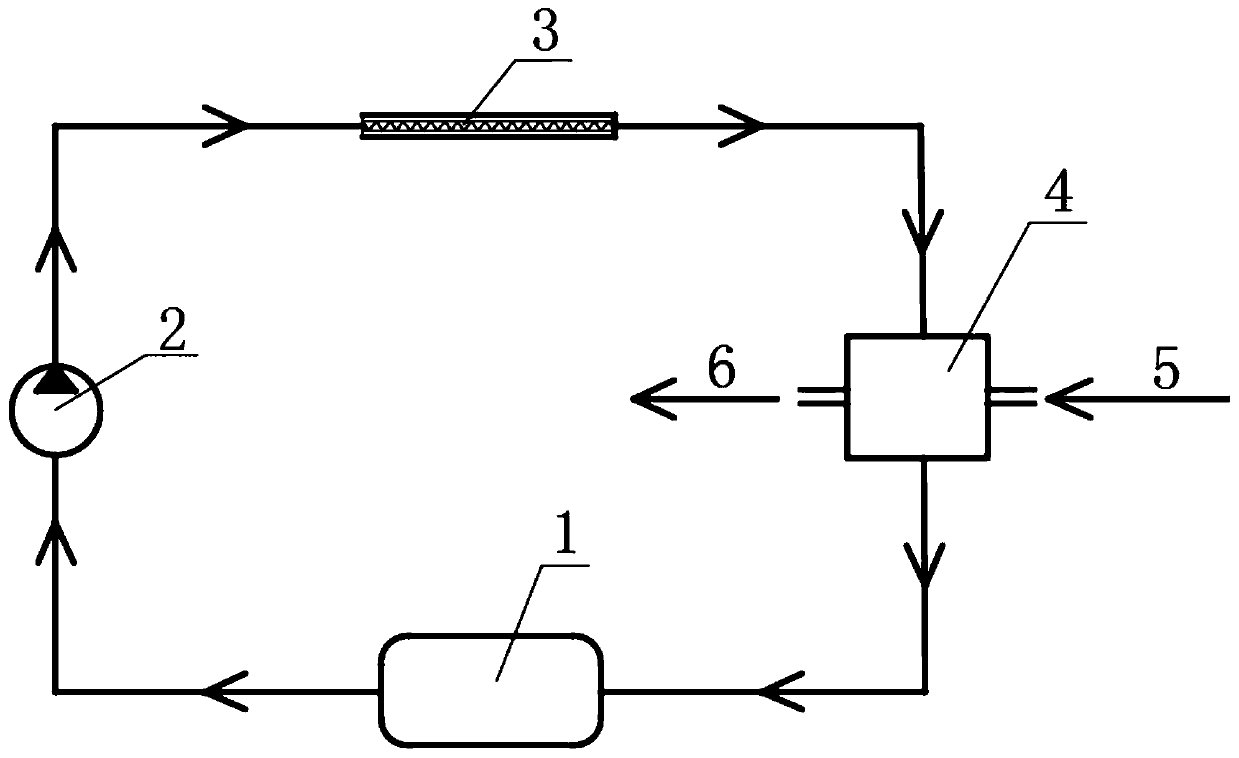

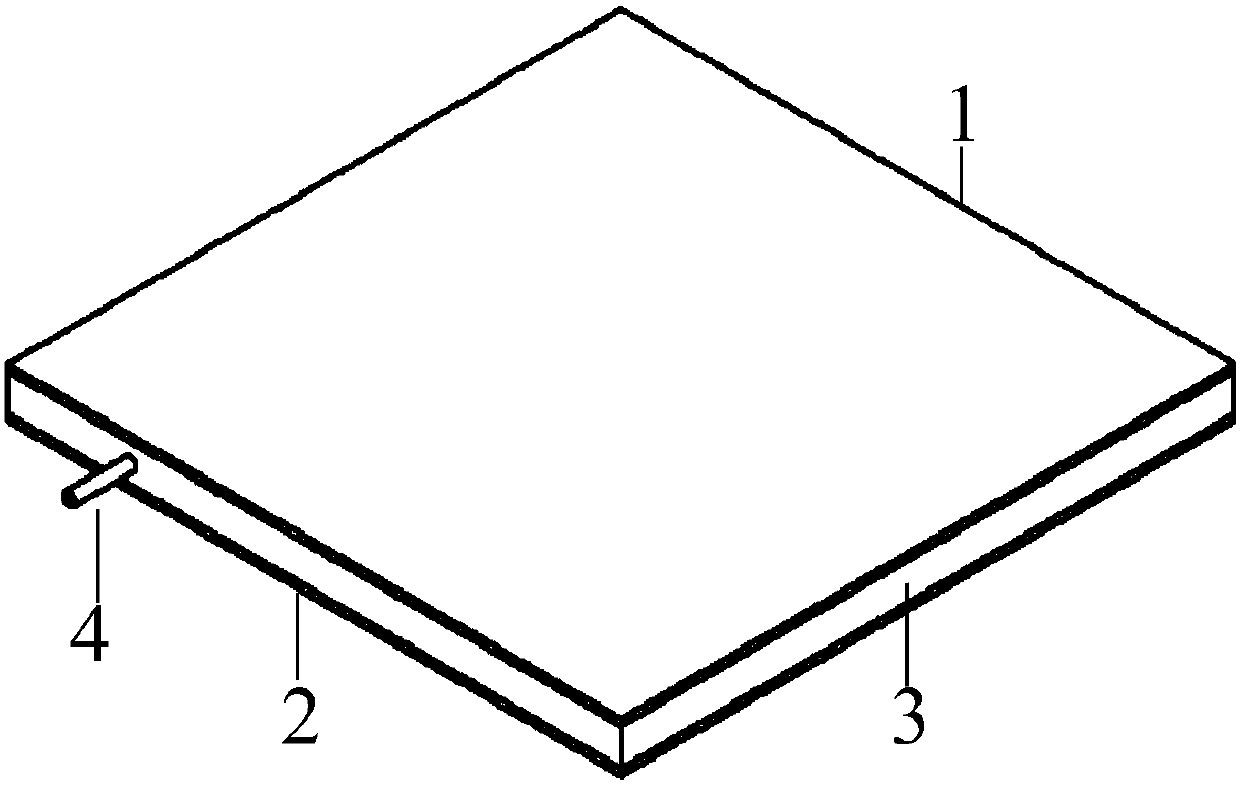

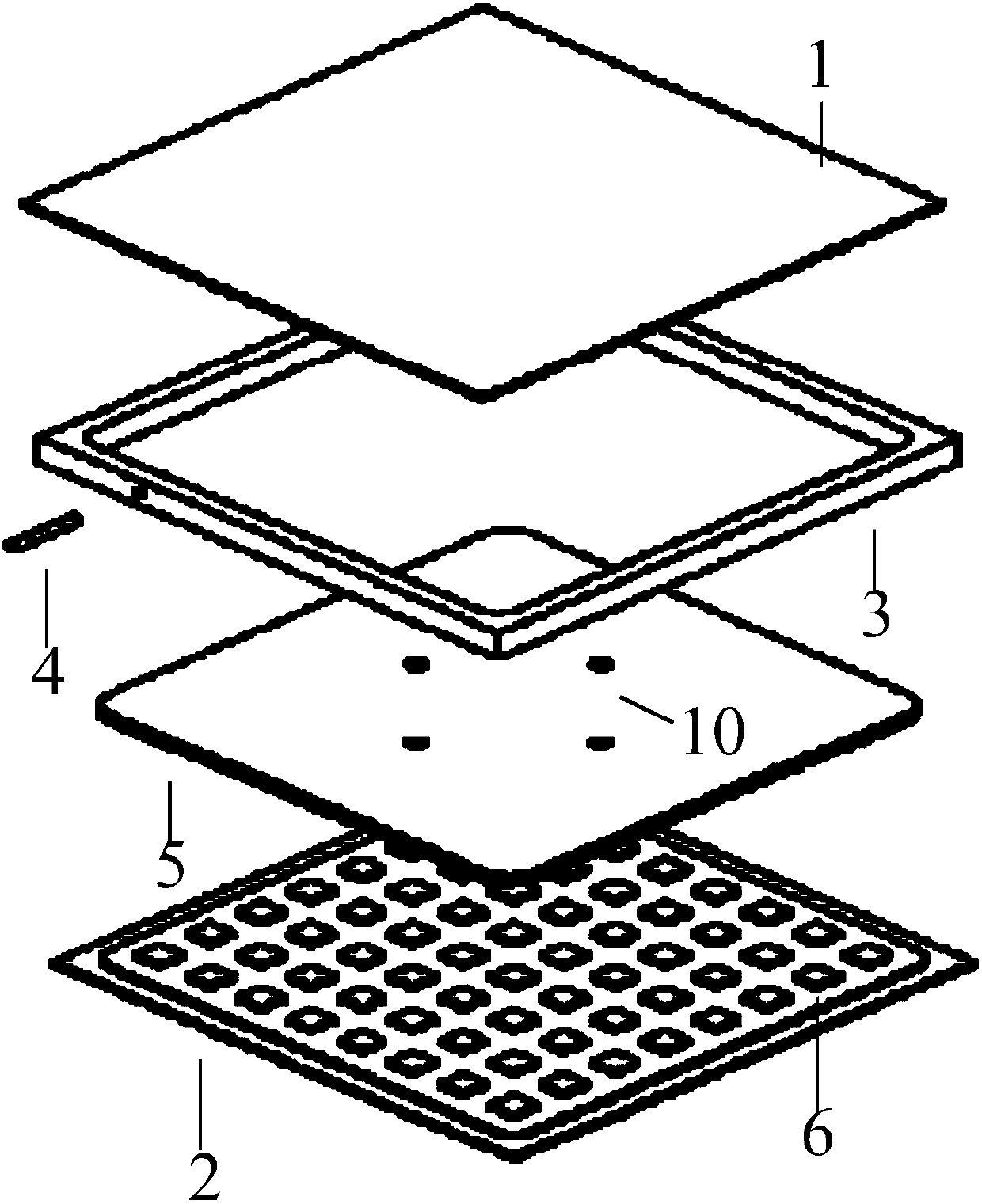

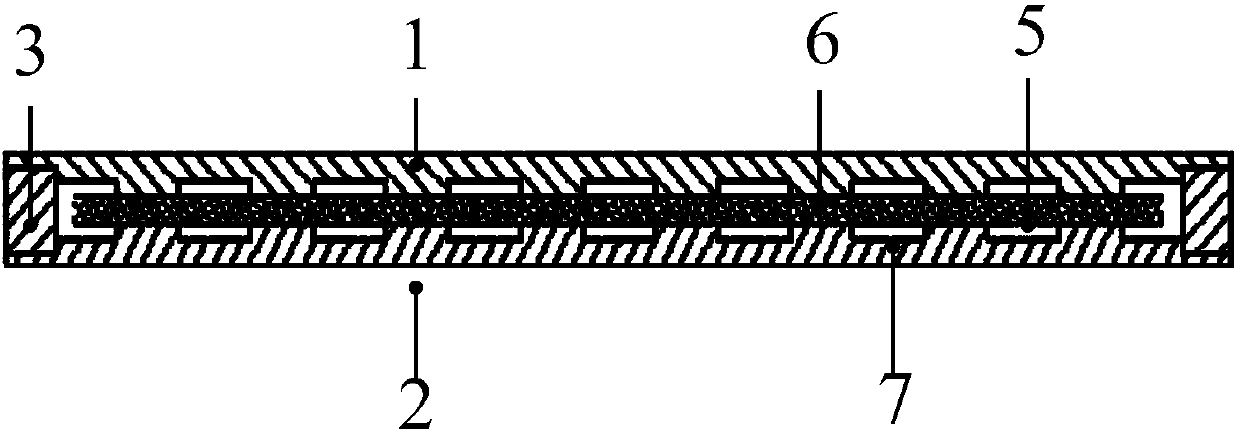

Hypersonic aircraft and thermal protection structure and coolant circulating system thereof

PendingCN109823510AReduce distortionReduce heat fluxAir-treatment apparatus arrangementsHeat reducing structuresInsulation layerThermal insulation

Owner:CENT SOUTH UNIV

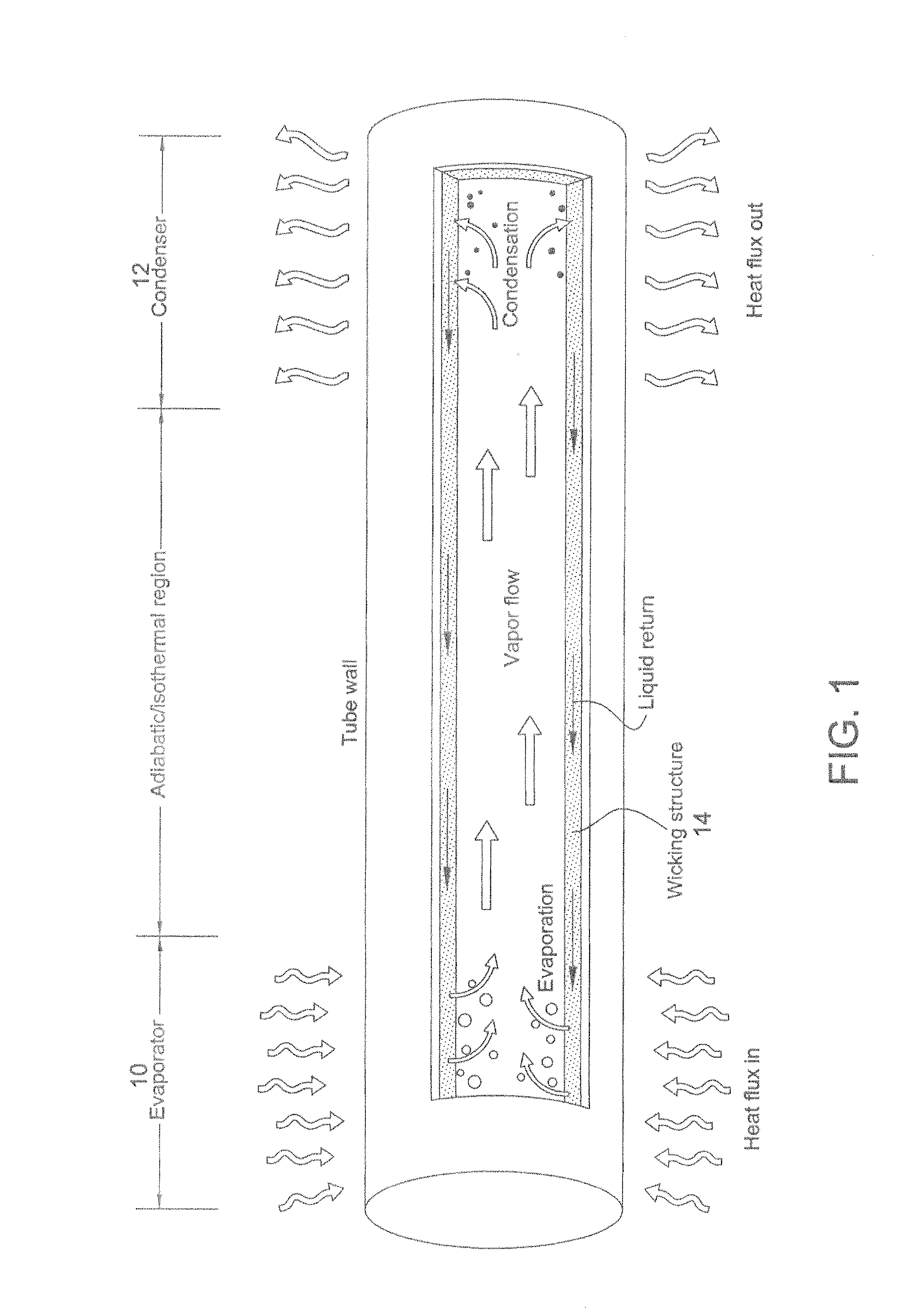

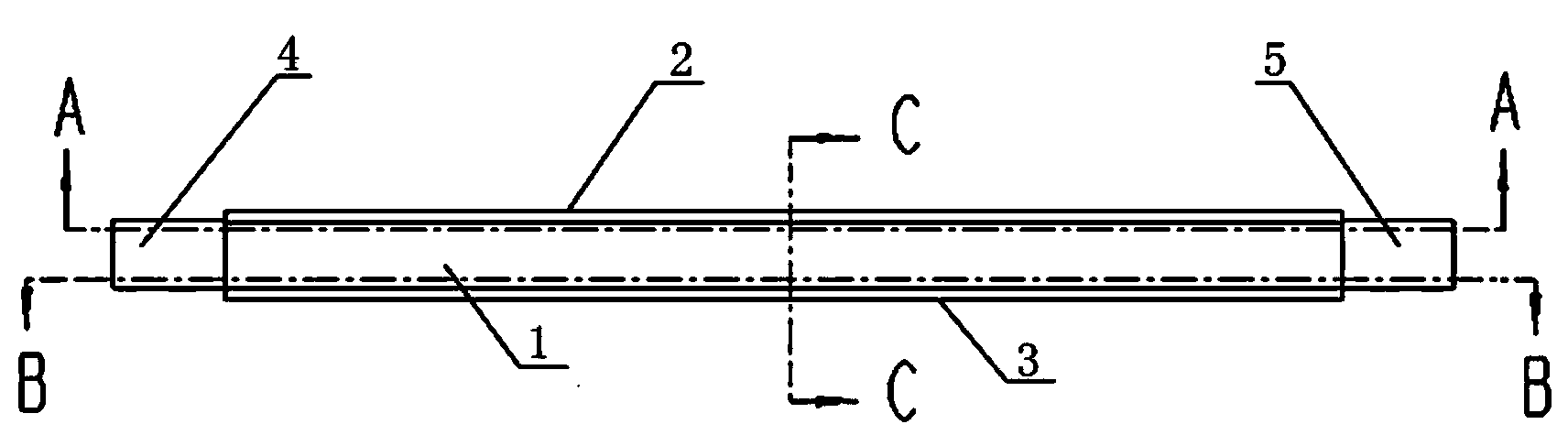

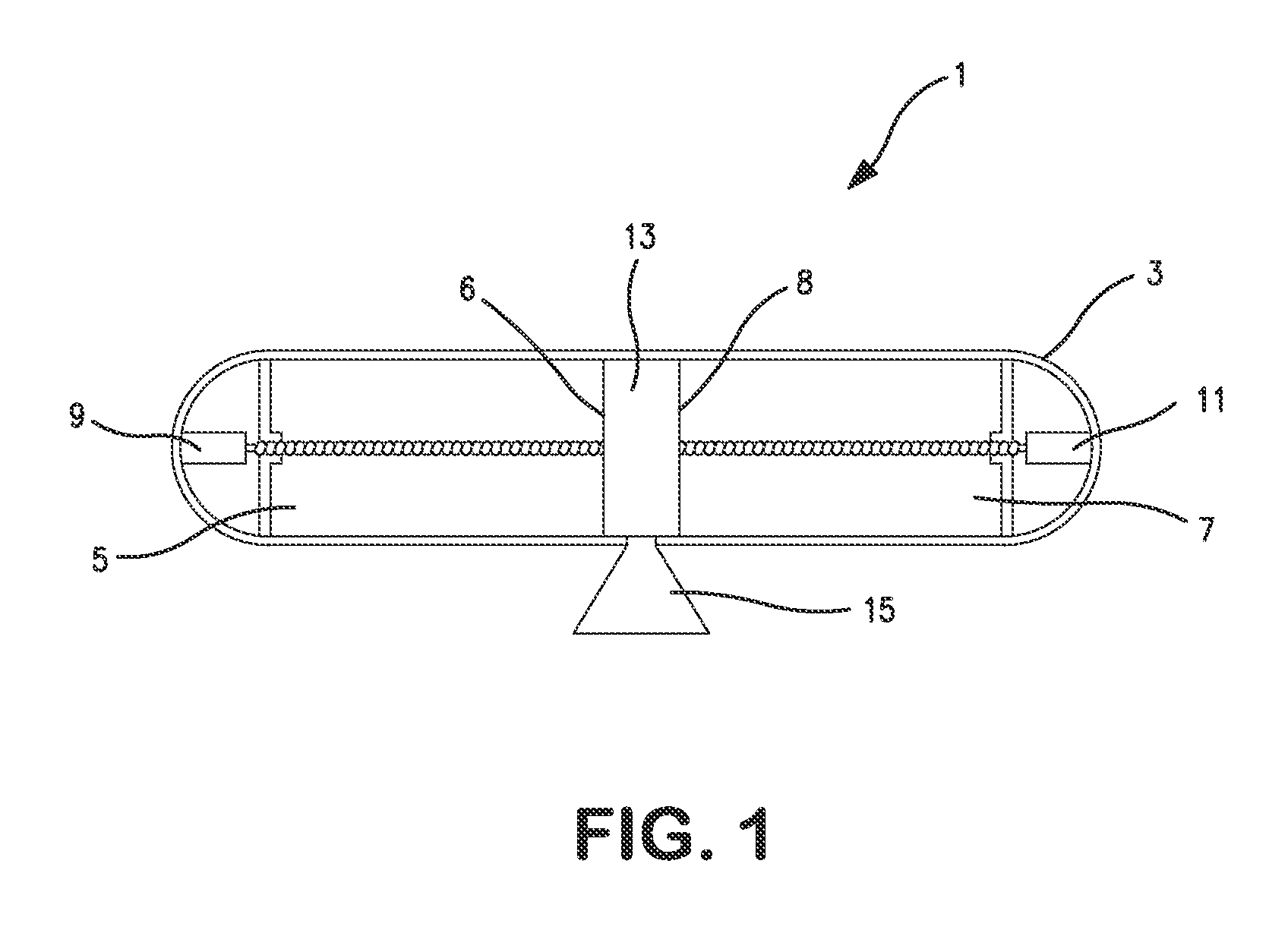

Flat plate heat pipe

The invention provides a flat plate heat pipe which comprises a flat plate shell, a liquid filled pipe and a capillary core. The interior of the flat plate shell is arranged in a hollow manner. Multiple grooves distributed in cross manner are formed in the upper inner surface and the lower inner surface of the flat plate shell, and every two adjacent grooves are spaced by a protrusion. A small hole communicating with the interior of the flat plate shell is formed in the flat plate shell. The liquid filled pipe is fixedly connected to the flat plate shell through the small hole. The capillary core is arranged in the flat plate shell, and the upper surface and the lower surface of the capillary core are in contact with the protrusions on the upper inner surface and the lower inner surface ofthe flat plate shell correspondingly. A section-closed channel is formed by the capillary core and the grooves. According to the flat plate heat pipe, the heat flux of a heat source can be effectively reduced, thermal homogeneity is good, reliability is high, and the excellent thermal homogeneity can be achieved under the antigravity condition.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

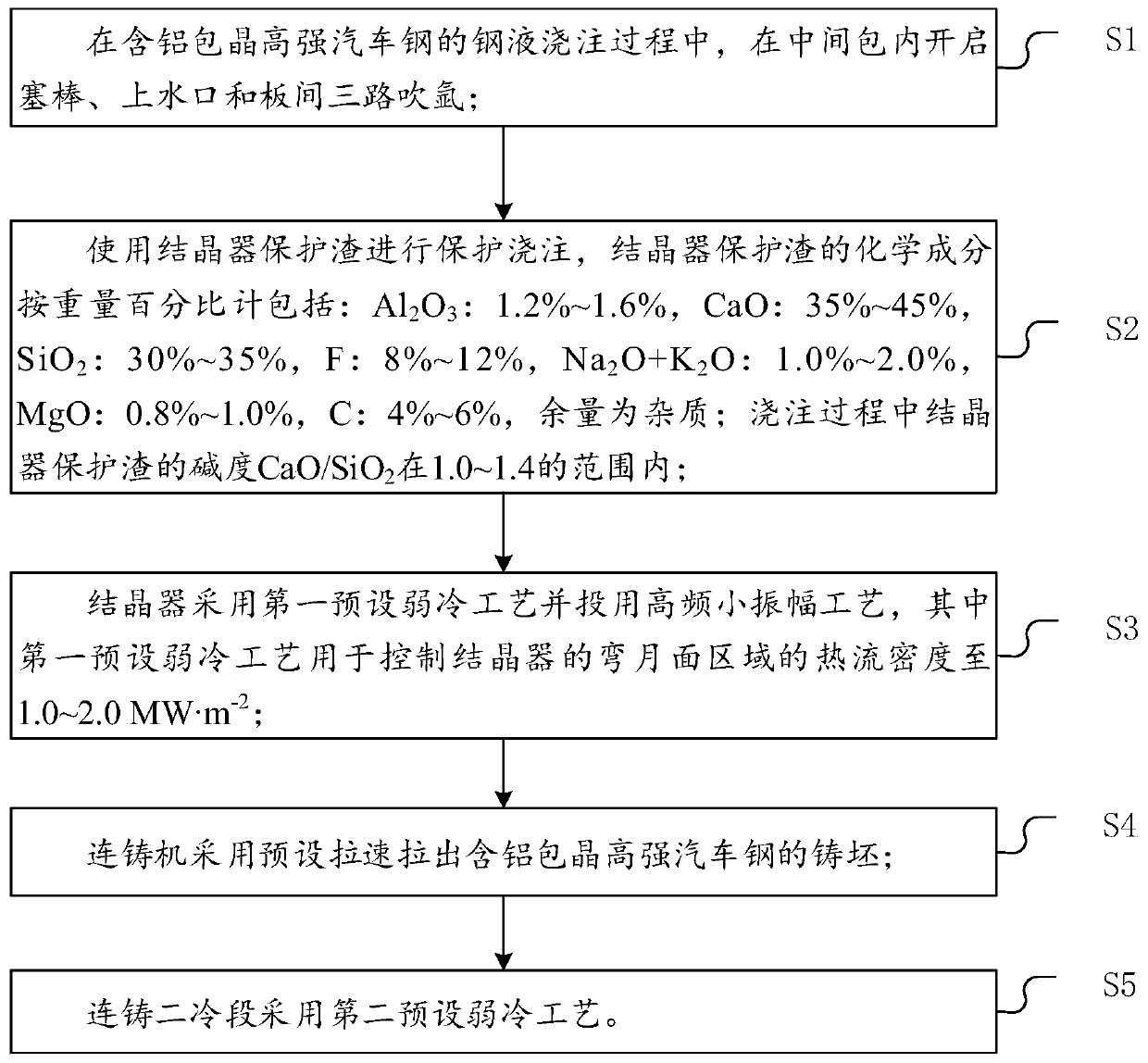

Continuous casting method of aluminum-containing peritectic high-strength automobile steel

The invention discloses a continuous casting method of aluminum-containing peritectic high-strength automobile steel. The method comprises the following steps that in the molten steel pouring processof the aluminum-containing peritectic high-strength automobile steel, a stopper rod, an upper nozzle and an inter-sheet device are opened in a tundish for three-way argon blowing; crystallizer covering slag is used for casting protection, and the crystallizer covering slag comprises the chemical components of, in percentage by weight, 1.2 %-1.6 % of Al2O3, 35 %-45 % of CaO, 30 %-35 % of SiO2, 8 %-12 % of F, 1.0 %-2.0 % of (Na2O + K2O), 0.8 %-1.0 % of MgO and 4 %-6 % of C; a crystallizer adopts a first preset weak cooling process and a high-frequency small-amplitude process is put into use, wherein the first preset weak cooling process is used for controlling the heat flux density of a meniscus area of the crystallizer to be 1.0-2.0 MW.m <-2>; a casting blank of the aluminum-containing peritectic high-strength automobile steel is cast by a continuous casting machine at a preset casting speed; and a continuous casting secondary cooling section adopts a second preset weak cooling process.According to the scheme, surface cracks and bonding defects of the casting blank are remarkably reduced.

Owner:SHOUGANG CORPORATION

Steam-cooled gas turbine bucket for reduced tip leakage loss

InactiveUS20070224049A1Impede tip leakage lossAvoid leakage lossPropellersPump componentsEngineeringThermal barrier coating

A bucket for a steam turbine includes an airfoil portion having a radially outer tip, the radially outer tip having a thermal barrier coating applied thereto, and wherein the thermal barrier coating is resurfaced to form at least one ridge along the radially outer tip.

Owner:GENERAL ELECTRIC CO

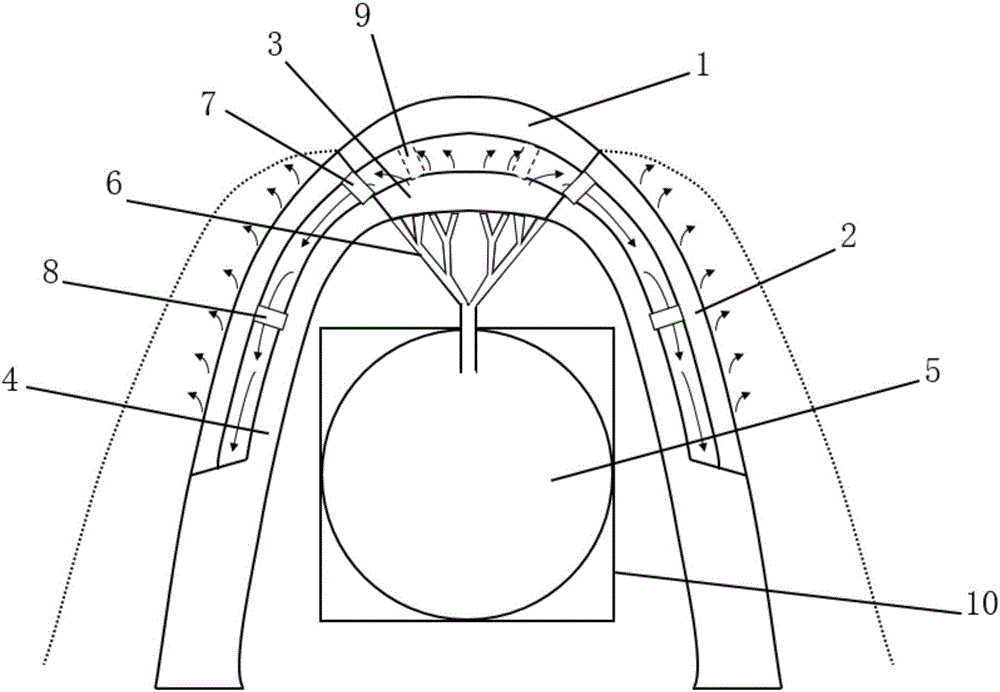

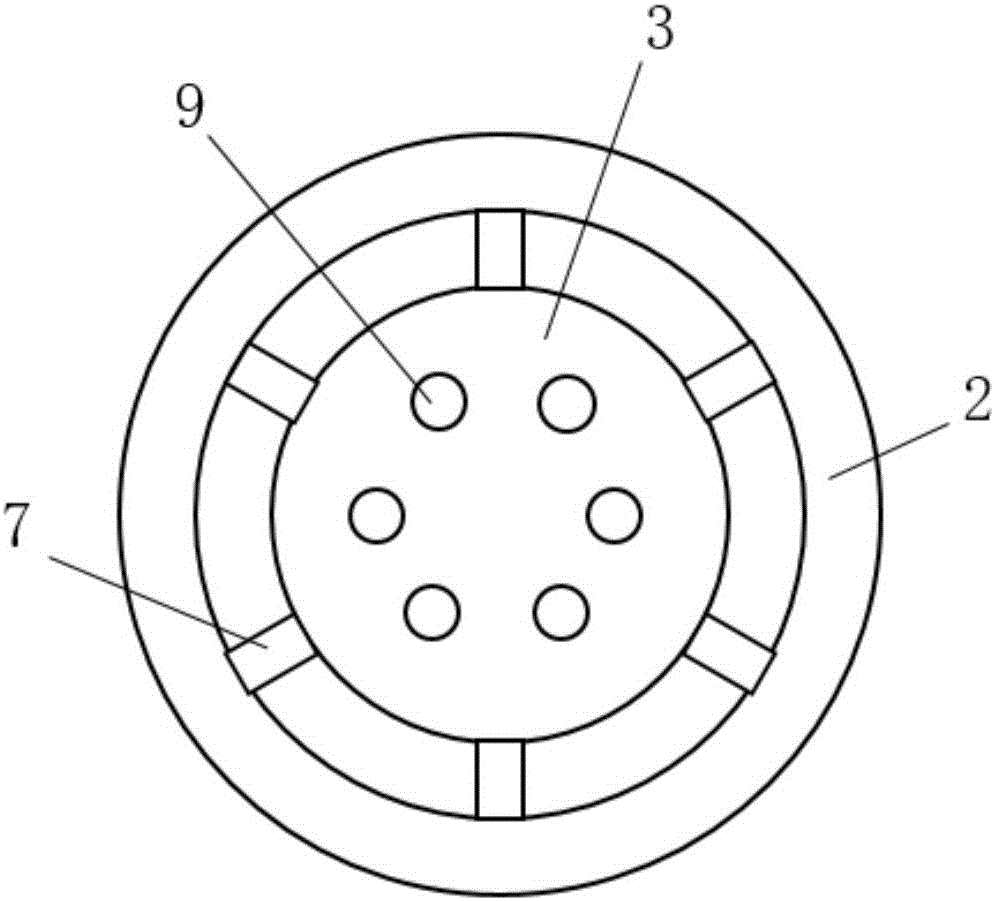

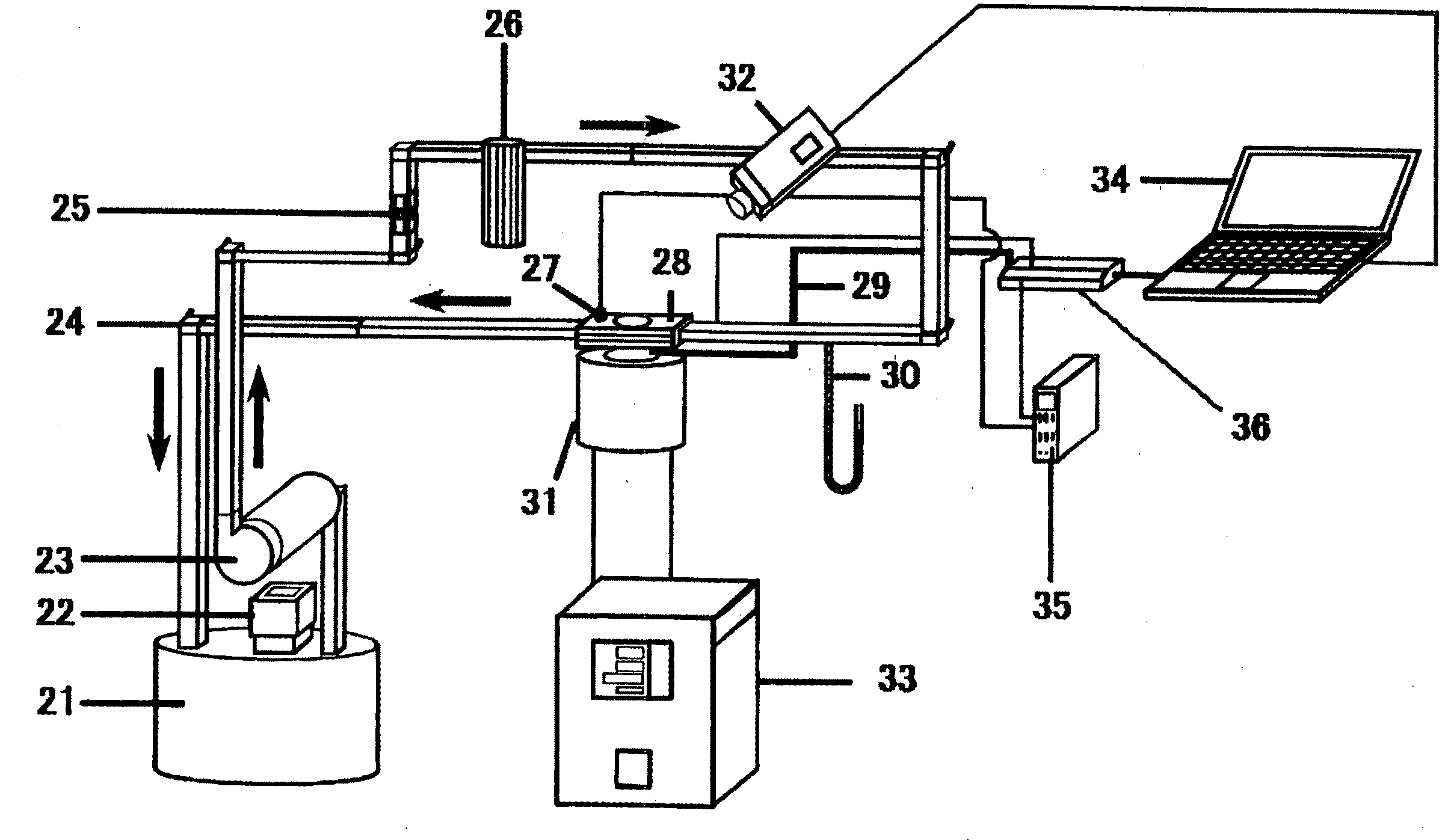

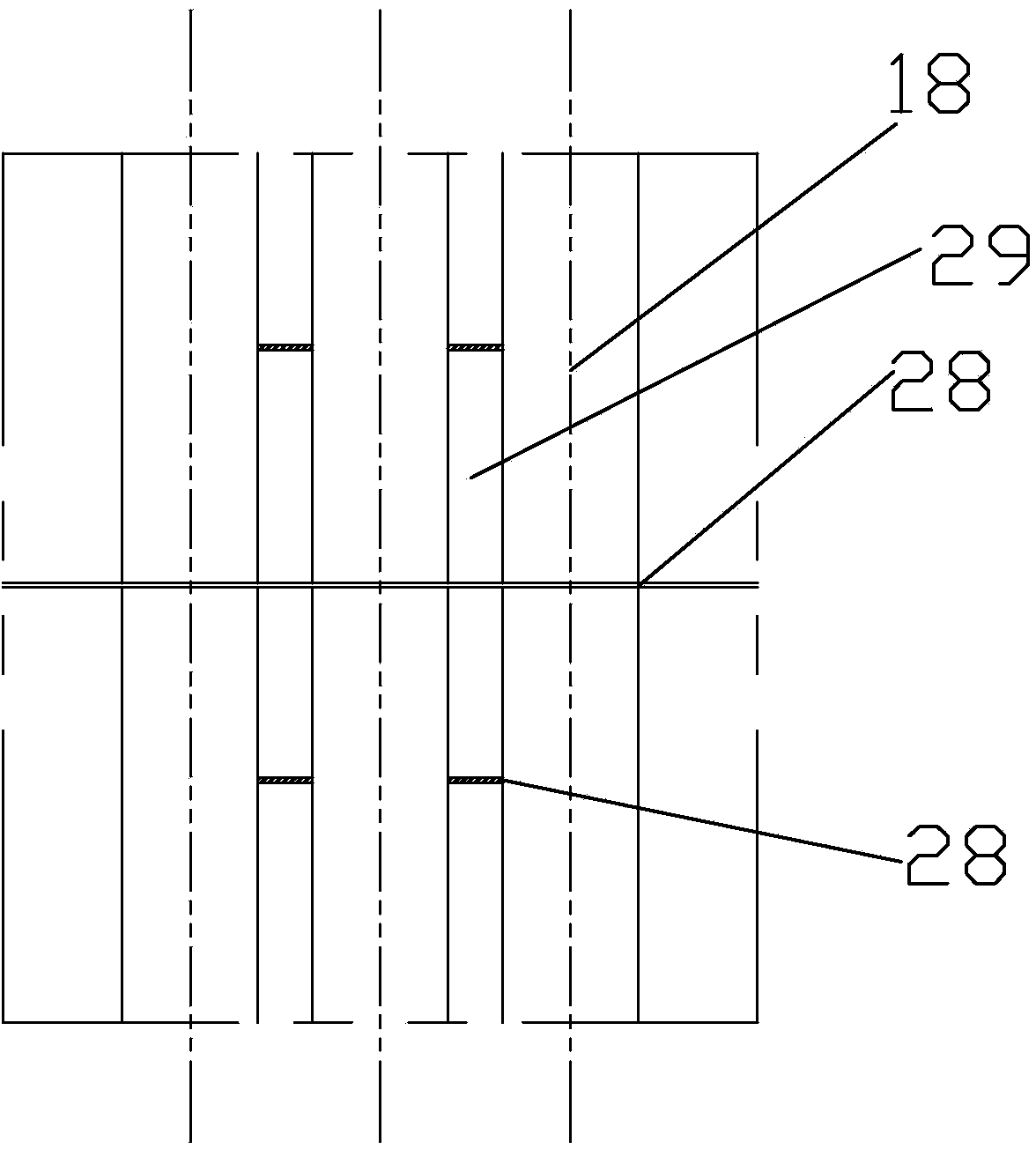

Miniature high-current neutron generator

ActiveCN109587926AImprove cooling effectReduce heat fluxDirect voltage acceleratorsHigh pressureVacuum chamber

The invention provides a miniature high-current neutron generator. A three-electrode or four-electrode leading-out acceleration structure is employed. When the three-electrode leading-out accelerationstructure is employed, the neutron generator comprises an ion source, a plasma electrode, a vacuum cavity, a suppression electrode, a target electrode, a high-voltage feeding mechanism and a collimator, wherein the vacuum cavity is coaxially connected with the ion source and the plasma body, the suppression electrode and the target electrode are contained in the vacuum cavity, the high-voltage feeding mechanism is connected with the vacuum cavity, the collimator is embedded to a rear end cover of the vacuum cavity, the ion source, the plasma electrode and the vacuum cavity are connected withground, the suppression electrode and the target electrode are connected with negative high pressure, and the suppression electrode is arranged at negative bias relative to the target electrode. Whenthe four-electrode leading-out acceleration structure is employed, the neutron generator also comprises a leading-out electrode, the leading-out electrode is contained in the vacuum cavity, the voltage of the leading-out electrode is arranged between ground potential and negative high pressure of the target electrode, the target electrode is of a V-shaped structure, and a hot pipe or a fine passage mode is used for cooling. By the neutron generator, high-throughput and high-quality neutron beam conforming to demand can be provided for a mobile neutron camera device, a neutron treatment deviceand the like.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

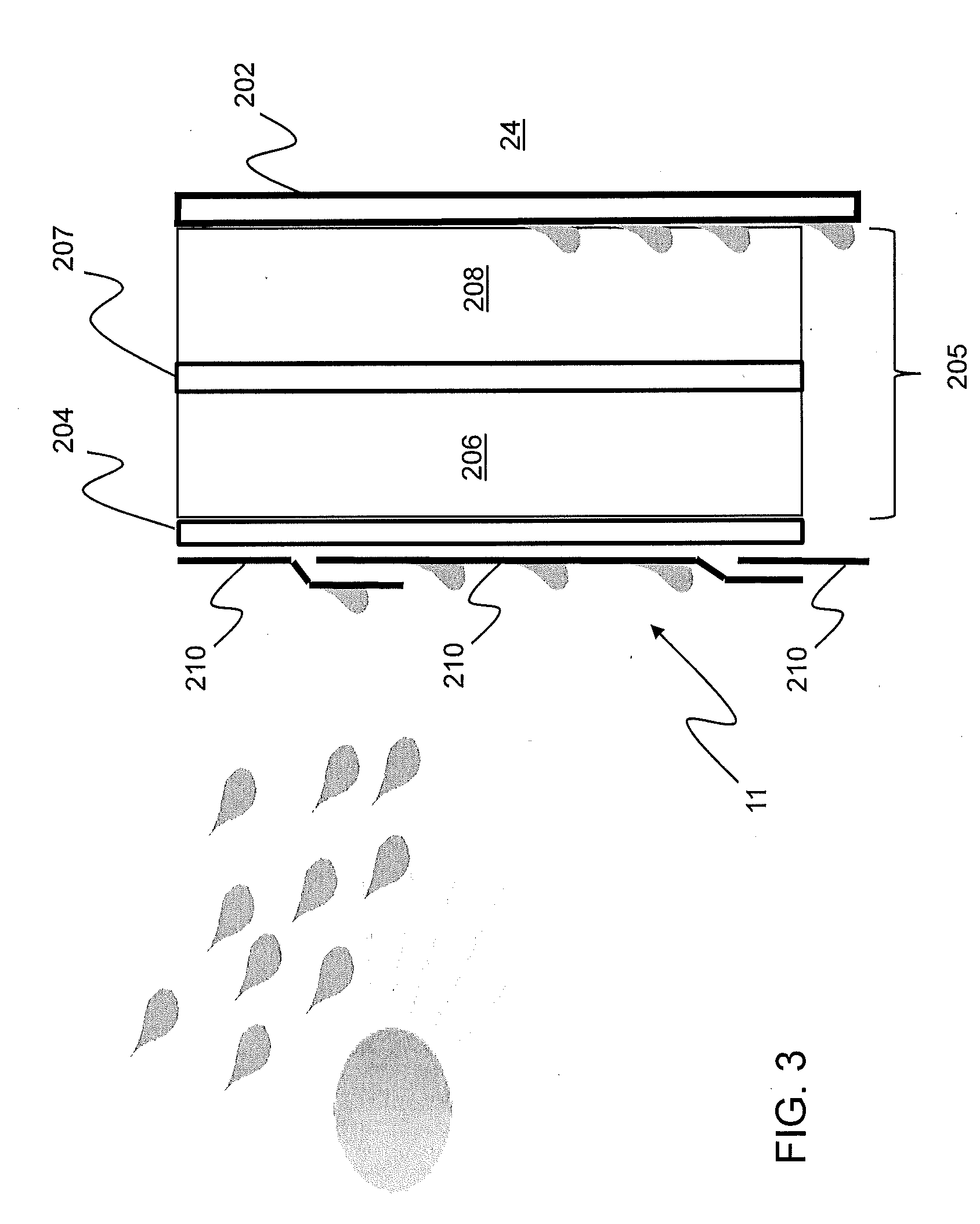

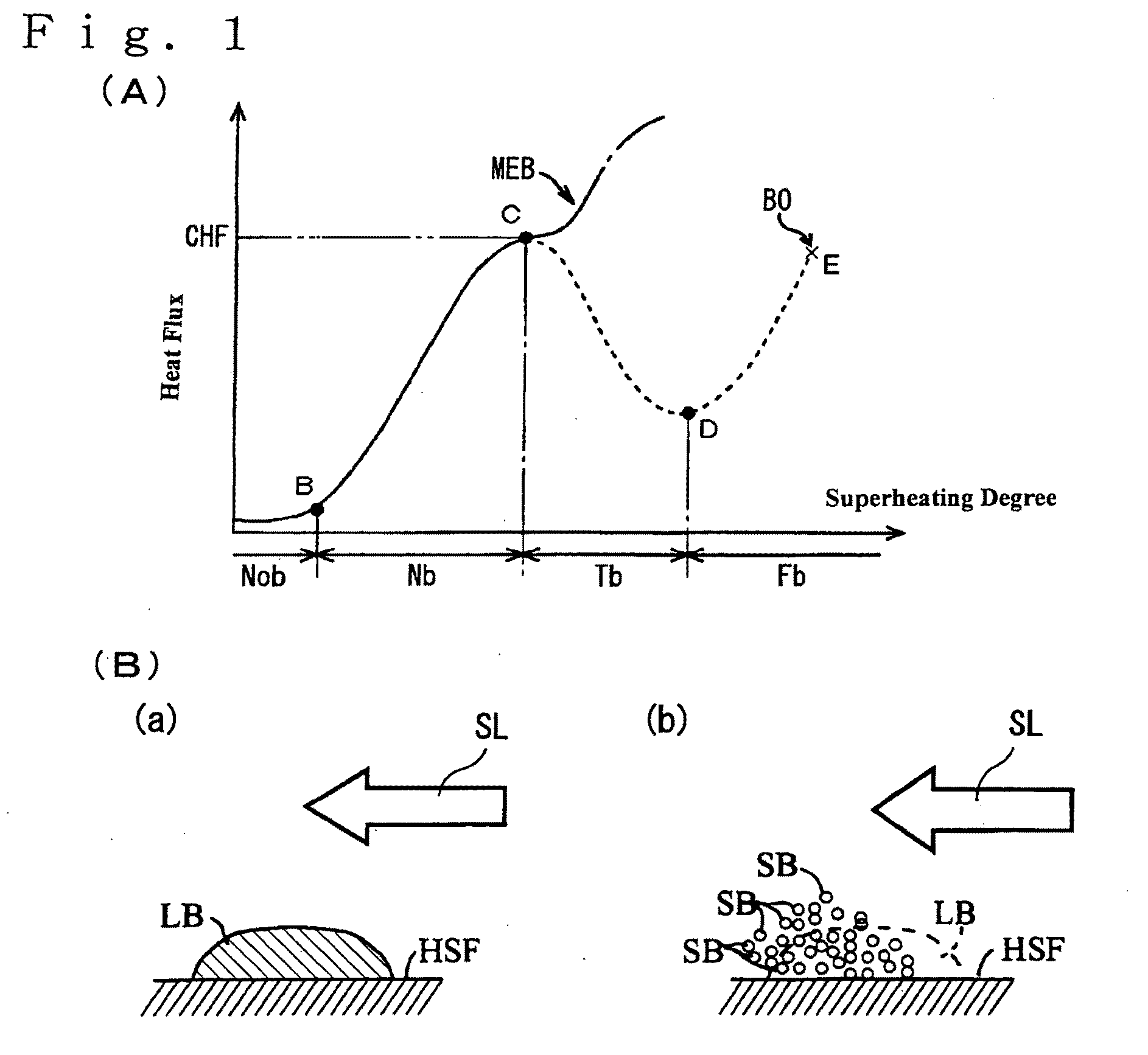

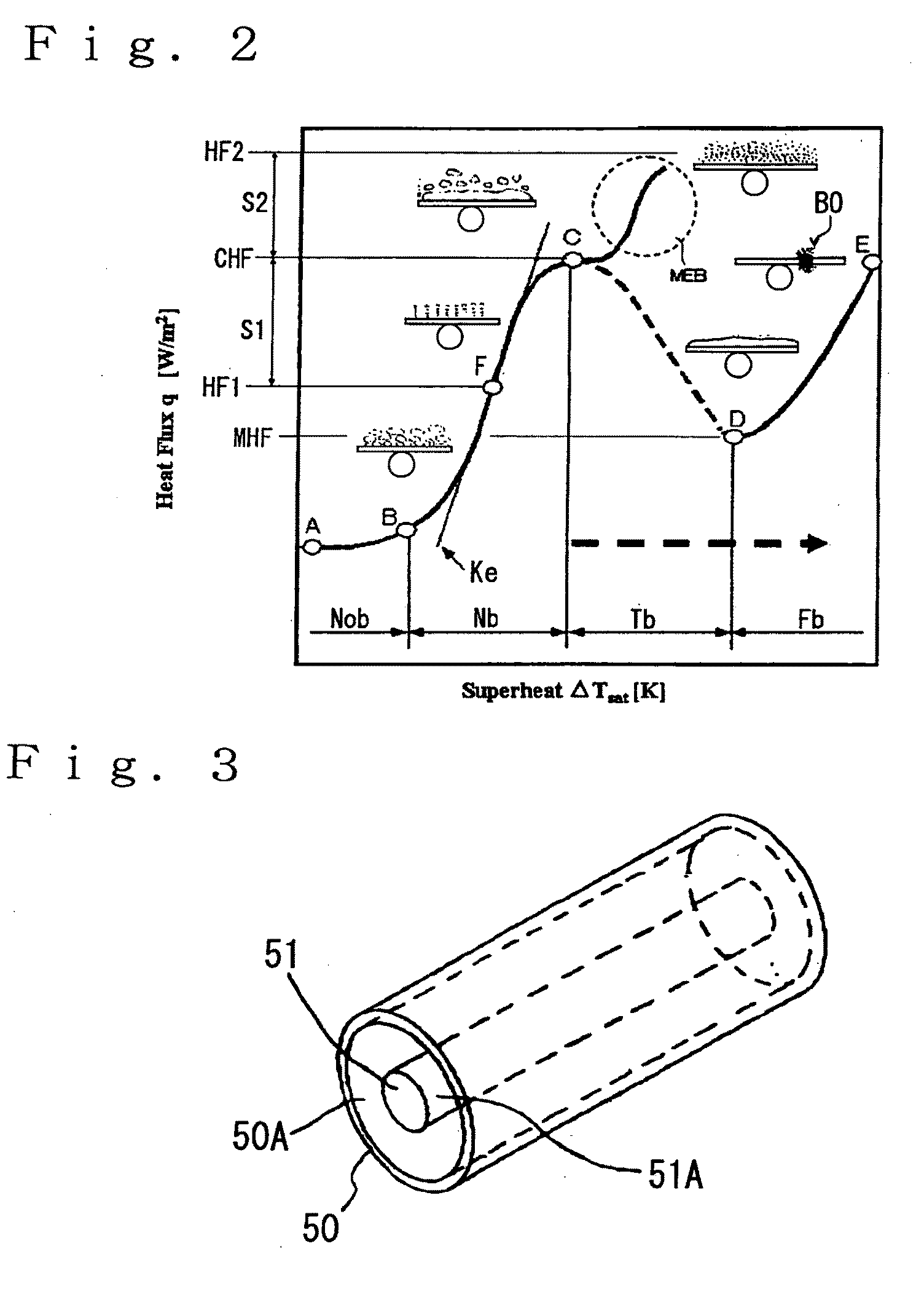

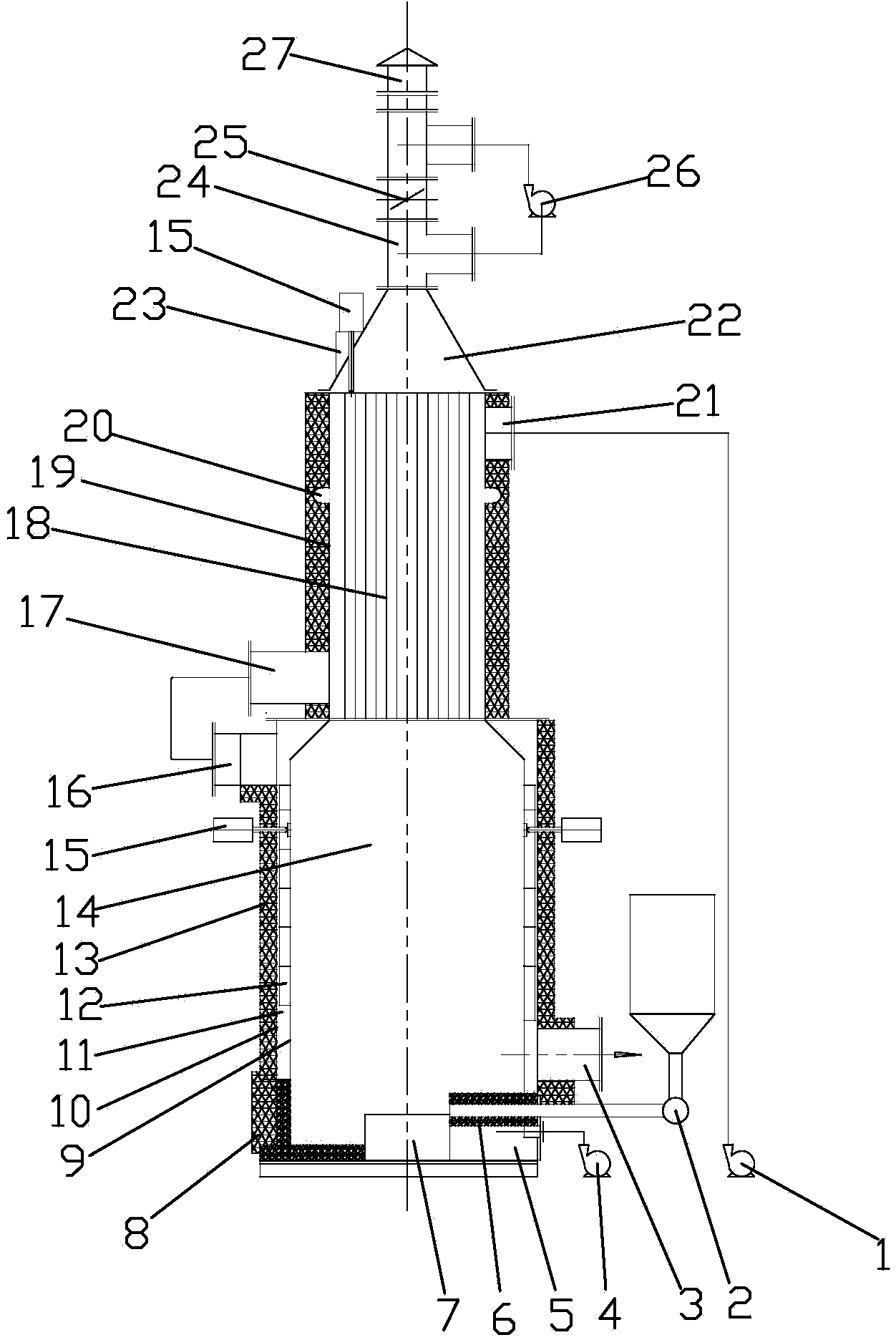

Boil Cooling Method, Boil Cooling Apparatus, Flow Channel Structure and Applied Product Thereof

InactiveUS20090260783A1High heat fluxReduce air pressureSafety devices for heat exchange apparatusSemiconductor/solid-state device detailsEngineeringCooling fluid

The invention provides a boil cooling method, a boil cooling apparatus, a flow channel structure, and applied products thereof, by which noise and vibration attending on cooling by microbubble emission boiling can be effectively reduced, and efficient boil cooling can be realized.A subcooled cooling liquid is caused to flow through a flow channel structure, which is formed by using a surface of an object 10 to be cooled as a surface 10A to be cooled and the surface 10A to be cooled as a tubular wall and has a tubular flow channel 16, through which the subcooled cooling liquid is caused to flow, and a structure that a group of rigid needles N1, N2, . . . Ni . . . is protruded within the tubular flow channel 16 from the tubular wall of the tubular flow channel, thereby conducting cooling by microbubble emission boiling.

Owner:TOKYO UNIVERSITY OF SCIENCE

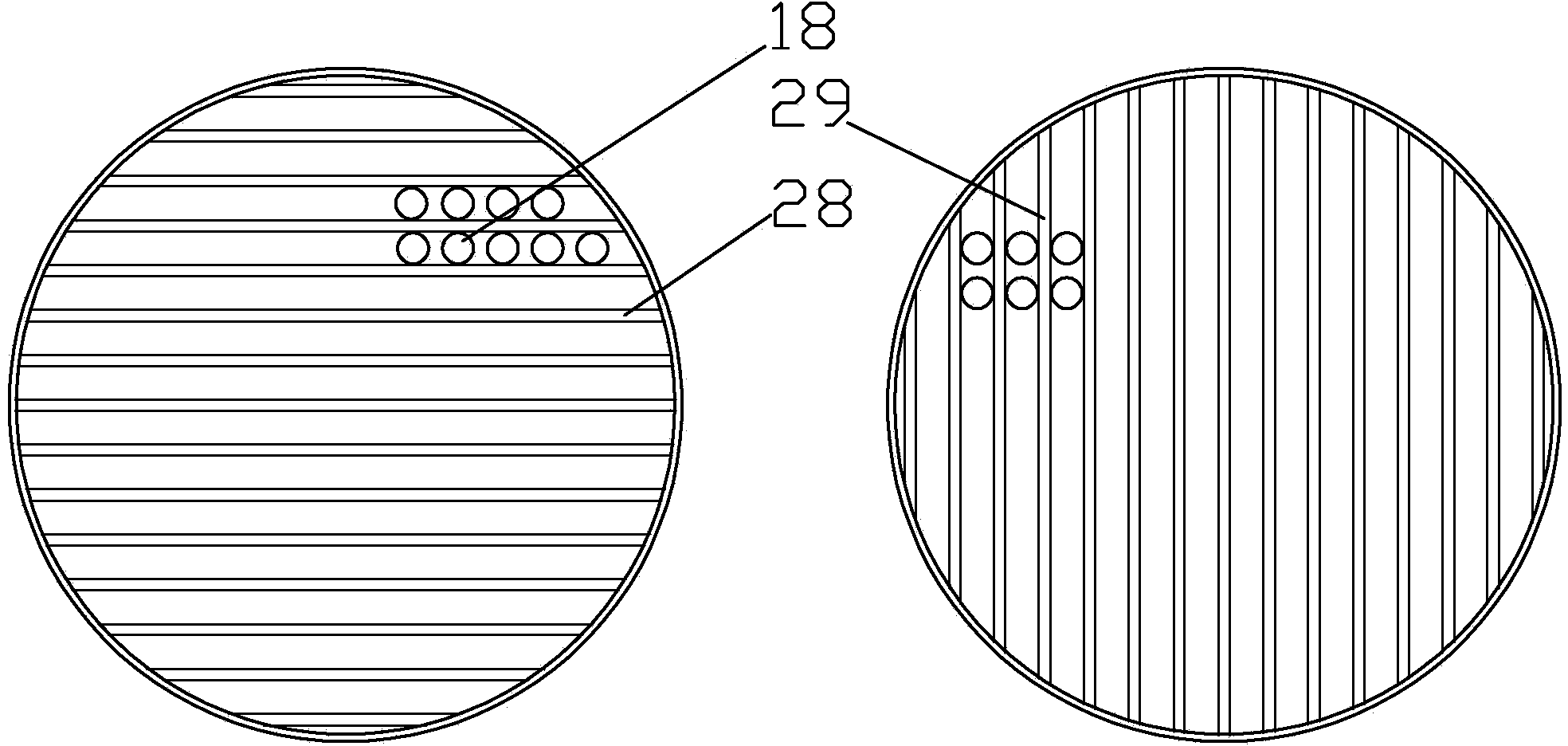

Cylindrical high-temperature biomass hot blast furnace

The invention relates to a cylindrical high-temperature biomass hot blast furnace. The cylindrical high-temperature biomass hot blast furnace comprises a cylindrical heat exchanger and a cylindrical hearth section. The cylindrical heat exchanger is perpendicularly installed on the upper portion of the cylindrical hearth section and is a convective heat transfer section, and the cylindrical hearth section is a radiative heat transfer section. A biomass combustor assembly is installed at the bottom of the cylindrical hearth section. A slurry removing door is installed on the left side of the bottom of the cylindrical hearth section. Electromagnetic vibrators are installed on the cylindrical hearth section and the cylindrical heat exchanger respectively. The hot blast temperature of the cylindrical high-temperature biomass hot blast furnace can reach 450DEG C, ash removing inside a hearth and ash removing of smoke wall surfaces of the heat exchanger are carried out together, namely, ash cleaning is carried out in the hearth and ash removing rooms and corresponding furnace doors are reduced, and therefore the cylindrical high-temperature biomass hot blast furnace is compact in structure. Because the electromagnetic vibrators are installed, ash accumulated in a heat exchanging pipe and ash accumulated on heat exchanging surfaces can be automatically removed in the operation process, permanent and efficient heat transmission can be kept, and ash forming and scale forming can be effectively avoided. The volume and structure of the hearth of the furnace are designed according to the principles of heat transfer theories so that heat transfer amount of the radiation section is large, metal heat transfer surface temperature and fault rate are low, and the cylindrical high-temperature biomass hot blast furnace is long in service life.

Owner:浙江光炎节能环保科技股份有限公司

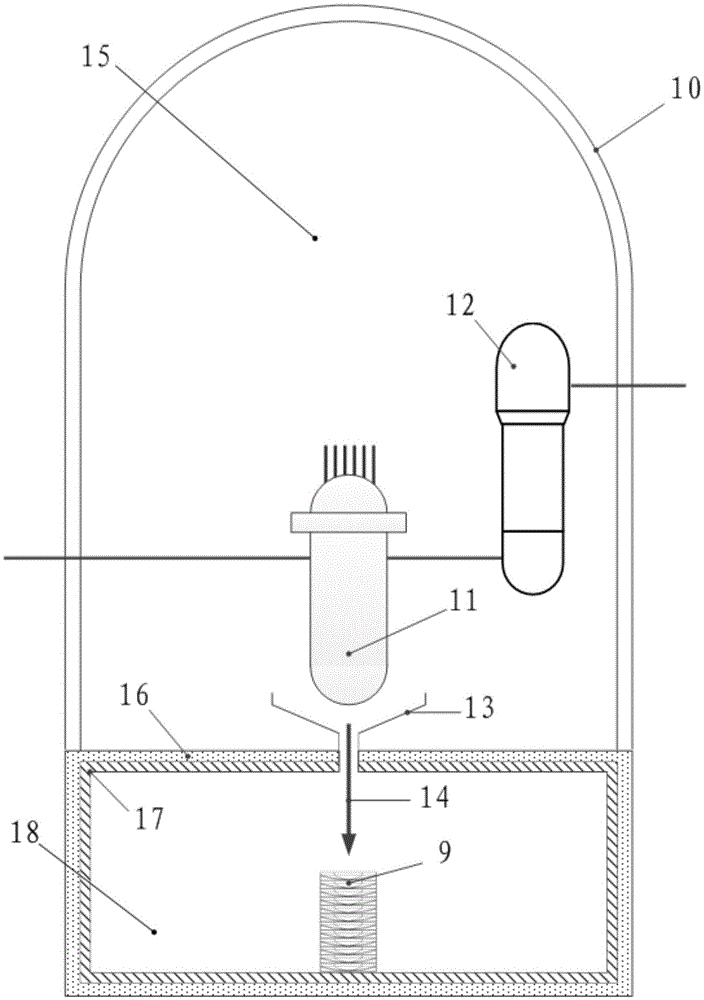

Reactor core fused mass catching device

ActiveCN105609146AMaximum spreadImprove usabilityNuclear energy generationEmergency protection arrangementsNuclear reactor

The invention belongs to the technical field of nuclear reactor safety, and particularly relates to a reactor core fused mass catching device. The reactor core fused mass laying and spreading of the existing fused mass catching device is nonuniform; the process is slow; a kinetic component can easily fail in serious accidents; the laying and spreading temperature reduction operation on the reactor core fused mass is influenced, and great potential safety hazards are caused. The reactor core fused mass catching device provided by the invention comprises a fused mass retention compartment, wherein the fused mass retention compartment is provided with a fused mass guiding device and is positioned under the reactor; a fused mass blasting laying and spreading device is arranged in the fused mass retention compartment; the laying and the spreading on the reactor core fused mass are uniform and fast; a non-kinetic mode is used; the reliability during the occurrence of the serious accidents is high.

Owner:CHINA NUCLEAR POWER ENG CO LTD

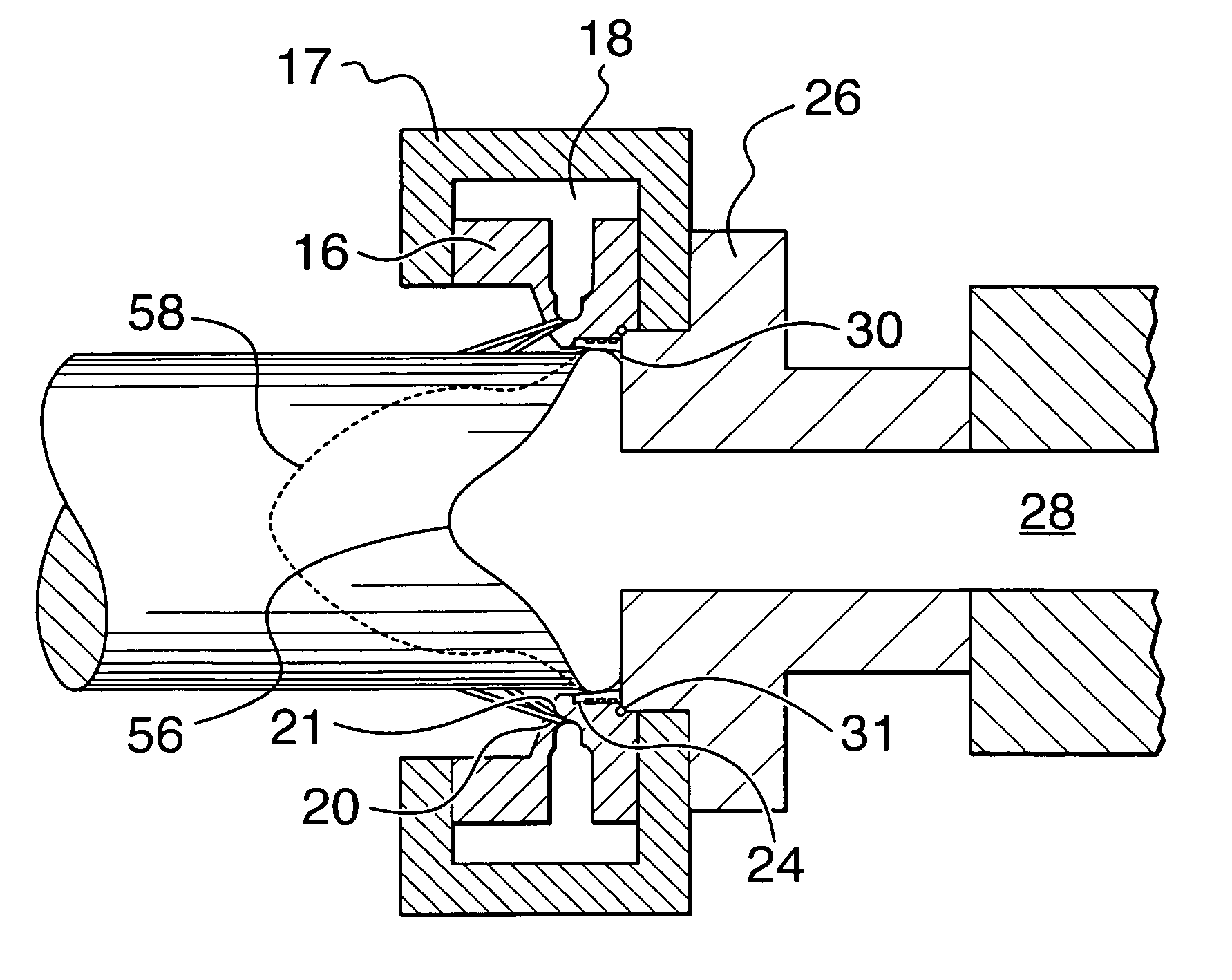

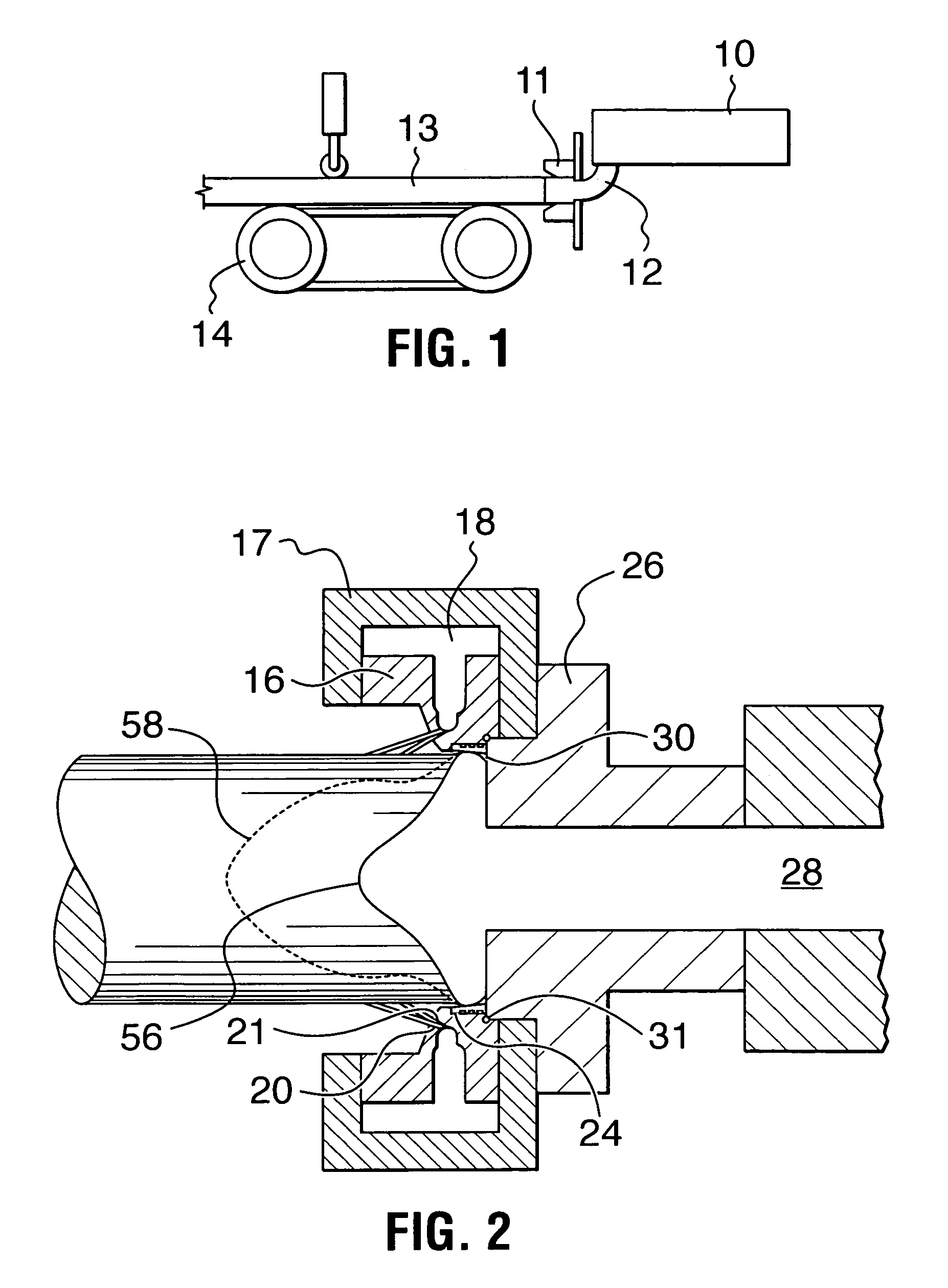

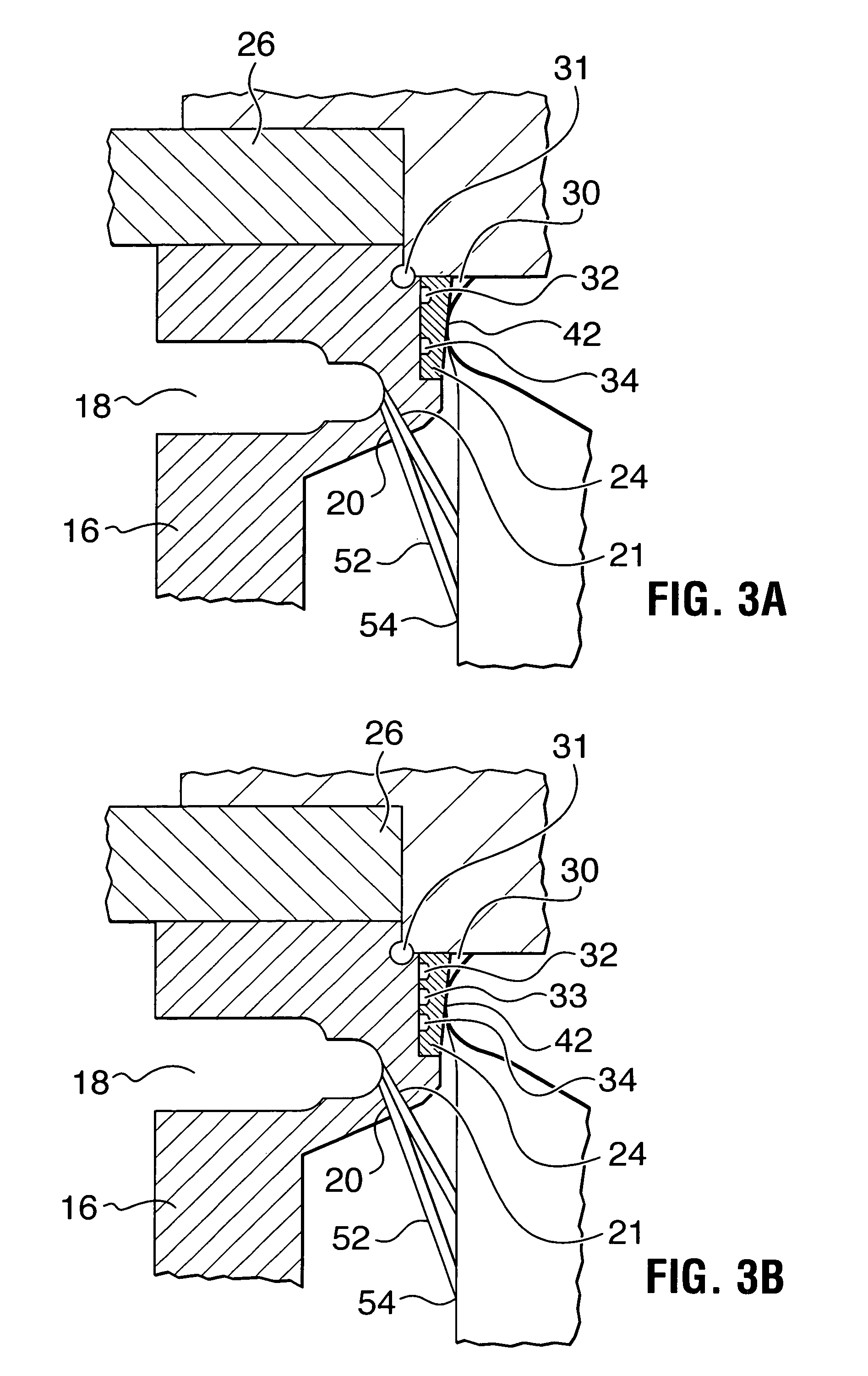

Horizontal continuous casting of metals

A mold for horizontal casting of molten metal comprising a mold body forming an open-ended mold cavity having an inlet end and an outlet end. An annular permeable wall member is mounted in the mold body adjacent the inlet end of the mold cavity with an inner face thereof forming an interior face of the mold. A refractory transition plate is mounted at the inlet end of the mold cavity, this transition plate providing a mold inlet opening having a cross-section less than that of the mold cavity. This provides an annular shoulder at the inlet end of the cavity. Means are provided for feeding molten aluminum through the inlet opening. Separate conduits are also provided for feeding a gas into the shoulder and via the permeable wall means for providing a layer of gas between the metal and the inner face of the mold. A gas that is more reactive with molten aluminum is fed into the shoulder and a less reactive gas is fed via the permeable wall. The reactions with the molten aluminum create a skin or shell on the aluminum which provides smooth passage through the mold and allows for more rapid secondary cooling of the emerging ingot.

Owner:NOVELIS INC

Droplet dispensing device and light source comprising such a droplet dispensing device

ActiveUS9307625B2High precisionImprove efficiencySpray nozzlesX-ray tube with very high currentPiezoelectric actuatorsSpray nozzle

A droplet dispensing device includes a reservoir for receiving a liquid material, an outlet nozzle in fluid communication with the reservoir and a piezoelectric actuating means acting on the liquid material at the outlet nozzle to exit the outlet nozzle in a sequence of droplets. A piezoelectric actuating means that includes a piston, which is actuated by a piezoelectric actuator at one end and dips the other, free end into the liquid material is provided just upstream of the outlet nozzle.

Owner:ETH ZZURICH

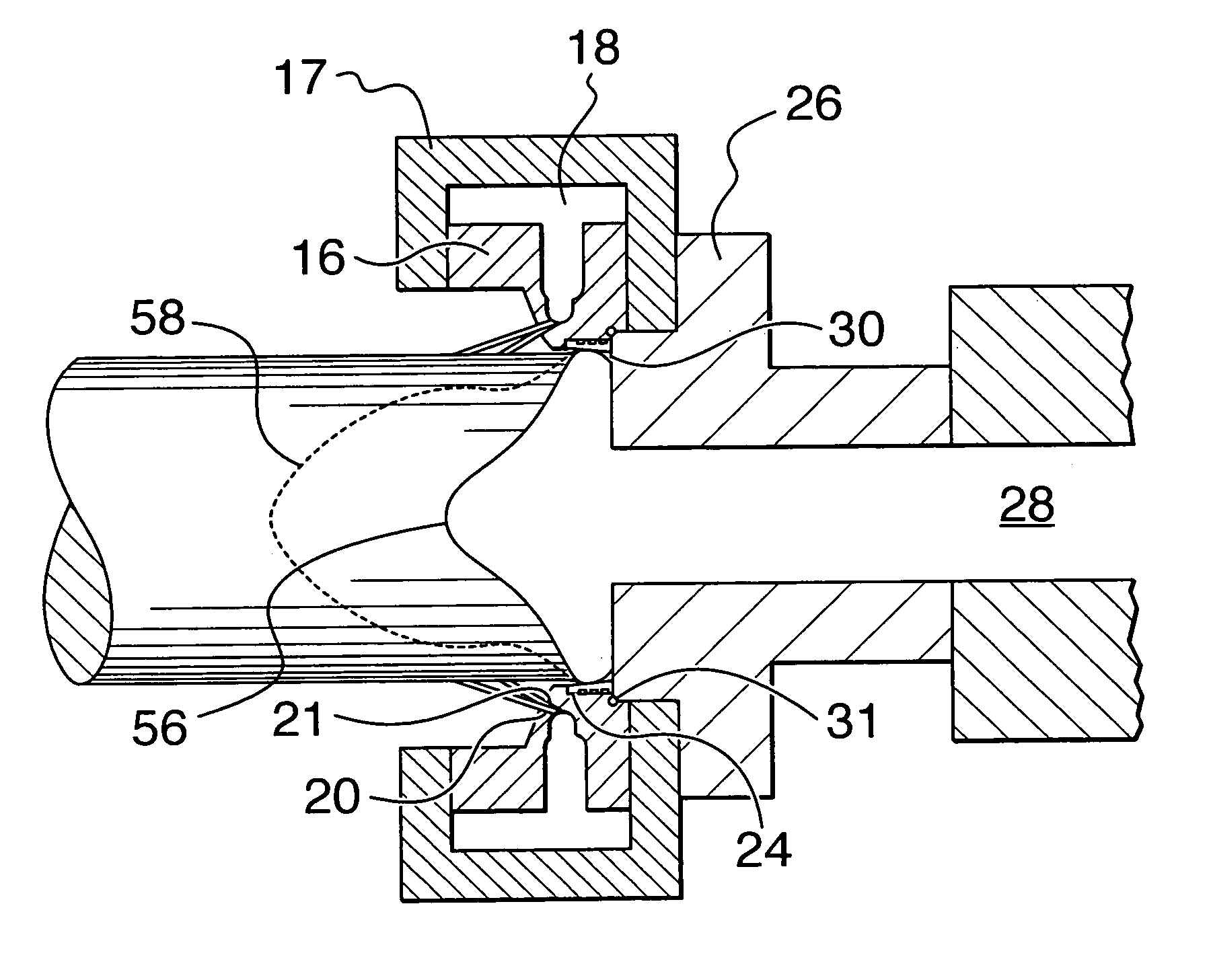

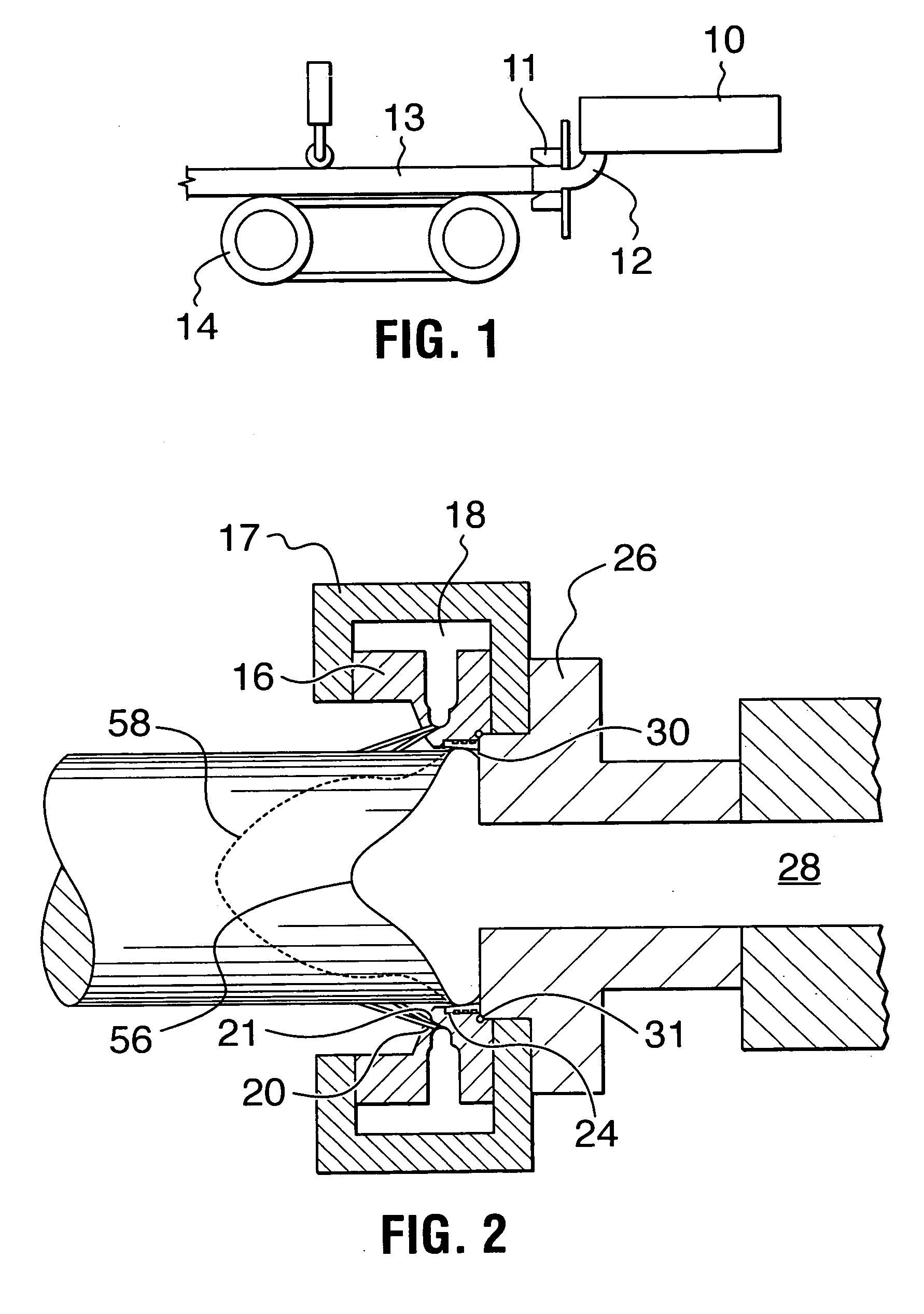

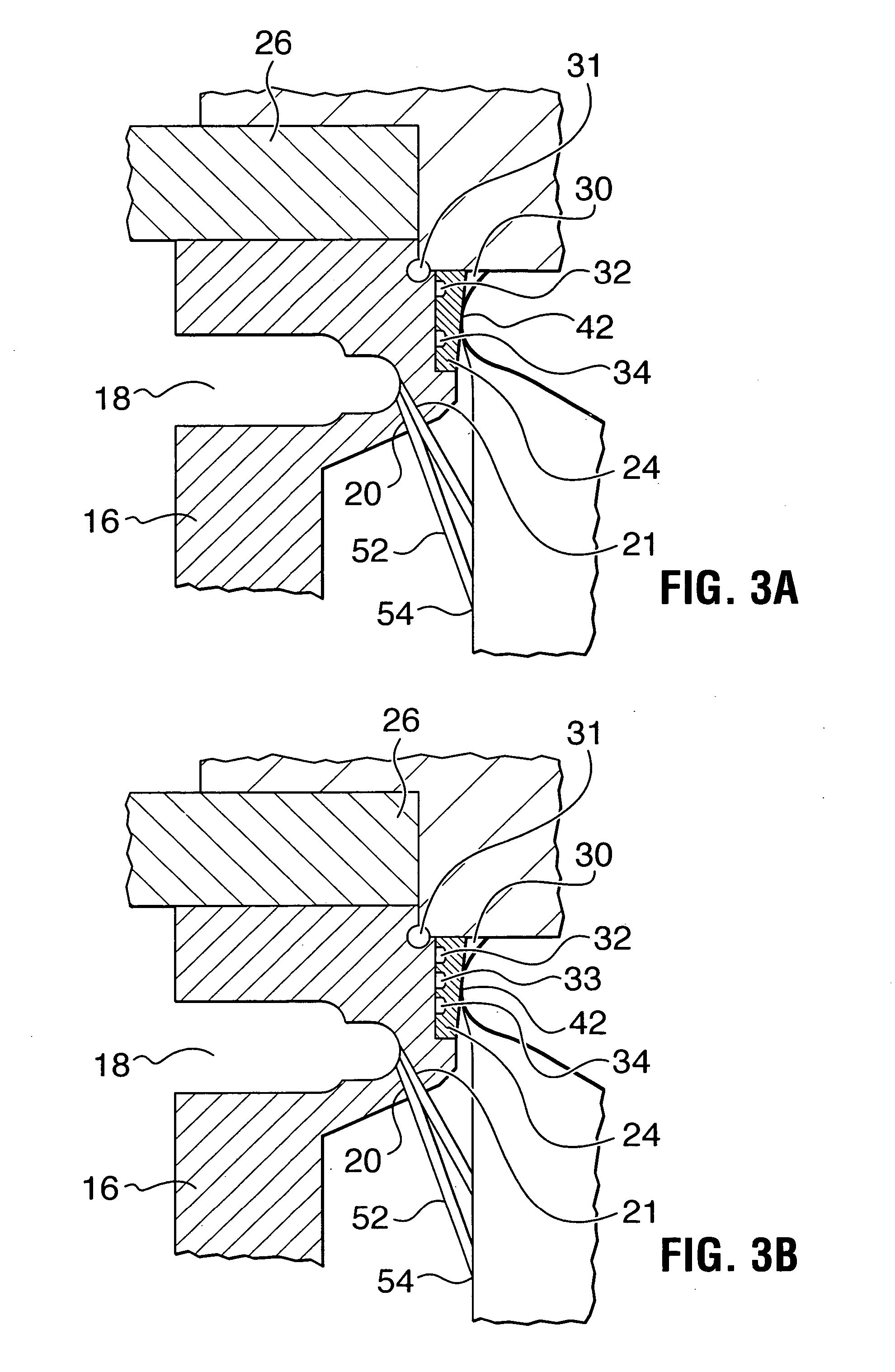

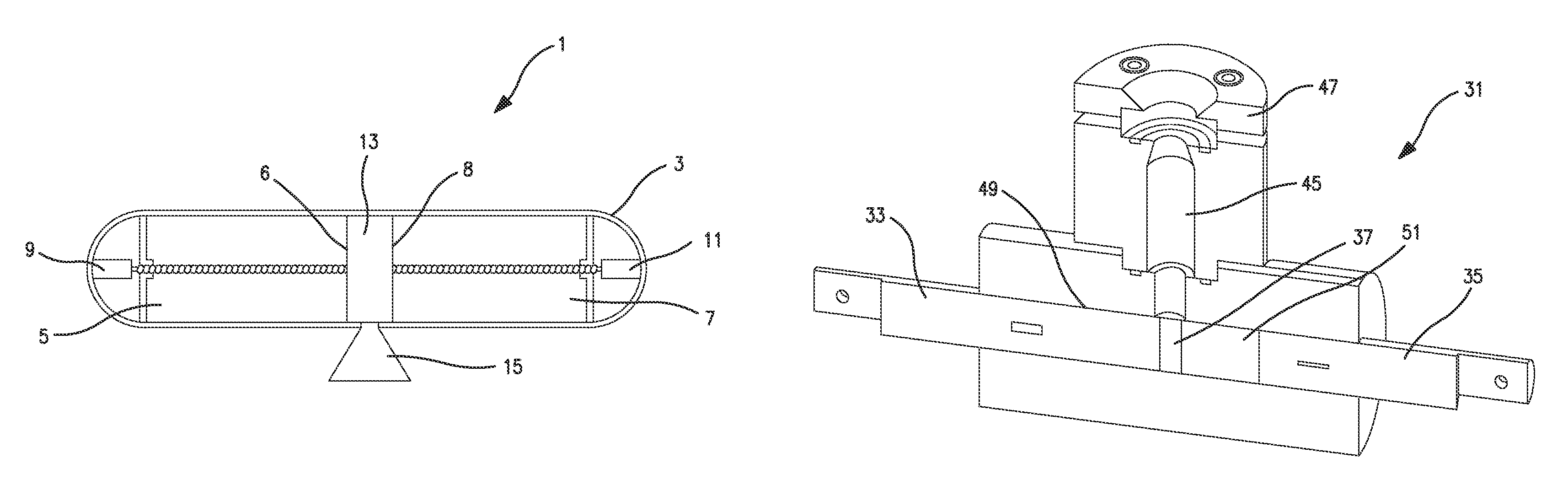

Propulsion system, opposing grains rocket engine, and method for controlling the burn rate of solid propellant grains

InactiveUS8051640B2Increasing the thicknessReduce pressureExplosivesRocket engine plantsControl systemBurn rate

A solid propellant thrust control system, method, and apparatus for controlling combustion of solid propellants in an opposing grains solid propellant rocket engine (OGRE) is provided. In particular, an opposing grains rocket engine and propulsion system is provided, in which actuator means connected are connected to solid propellant grains disposed in the pressure vessel of the engine. The actuator means are operable to selectively move the solid propellant grains together or apart relative to one another, such that the burning ends of the solid propellant grains decrease or increase relative to one another. This action controls the rate of combustion of the solid propellant grains by varying spacing distance between the burning ends of the solid propellant grains, and enables extinguishment and reignition of the OGRE. Further, a method is providing for controlling the burn rate of solid propellant grains undergoing combustion in an opposing grains rocket engine.

Owner:EXQUADRUM

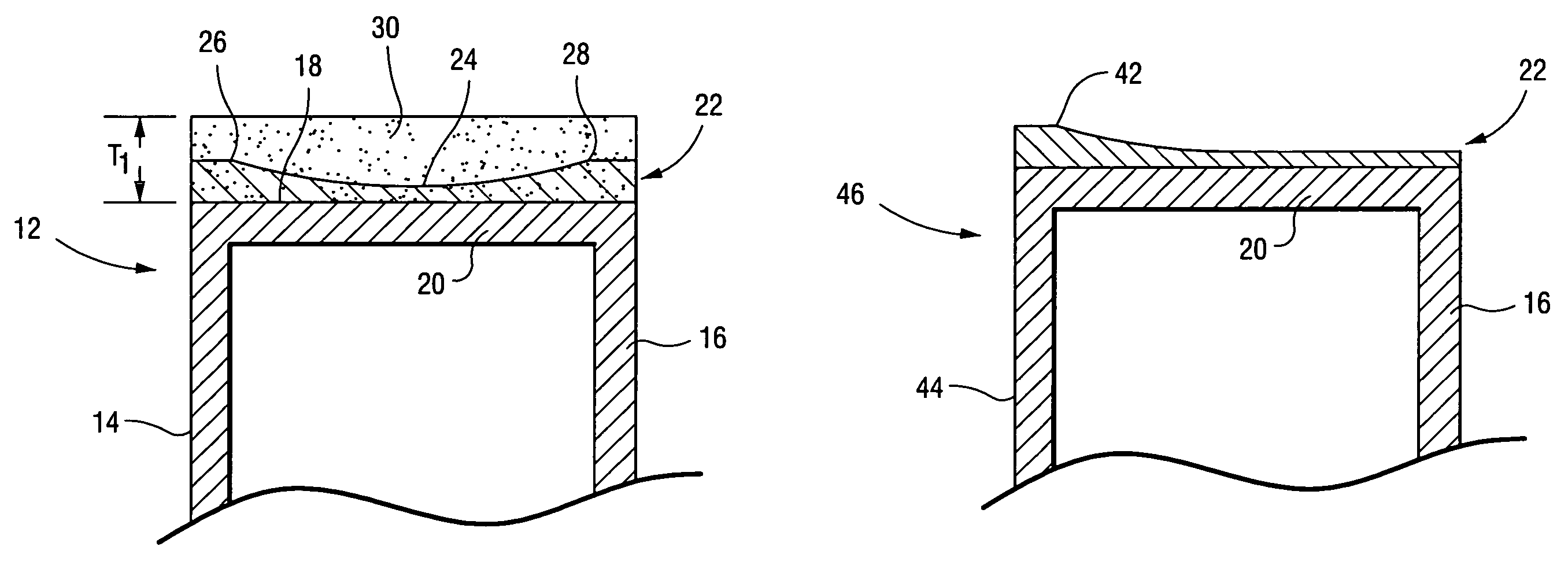

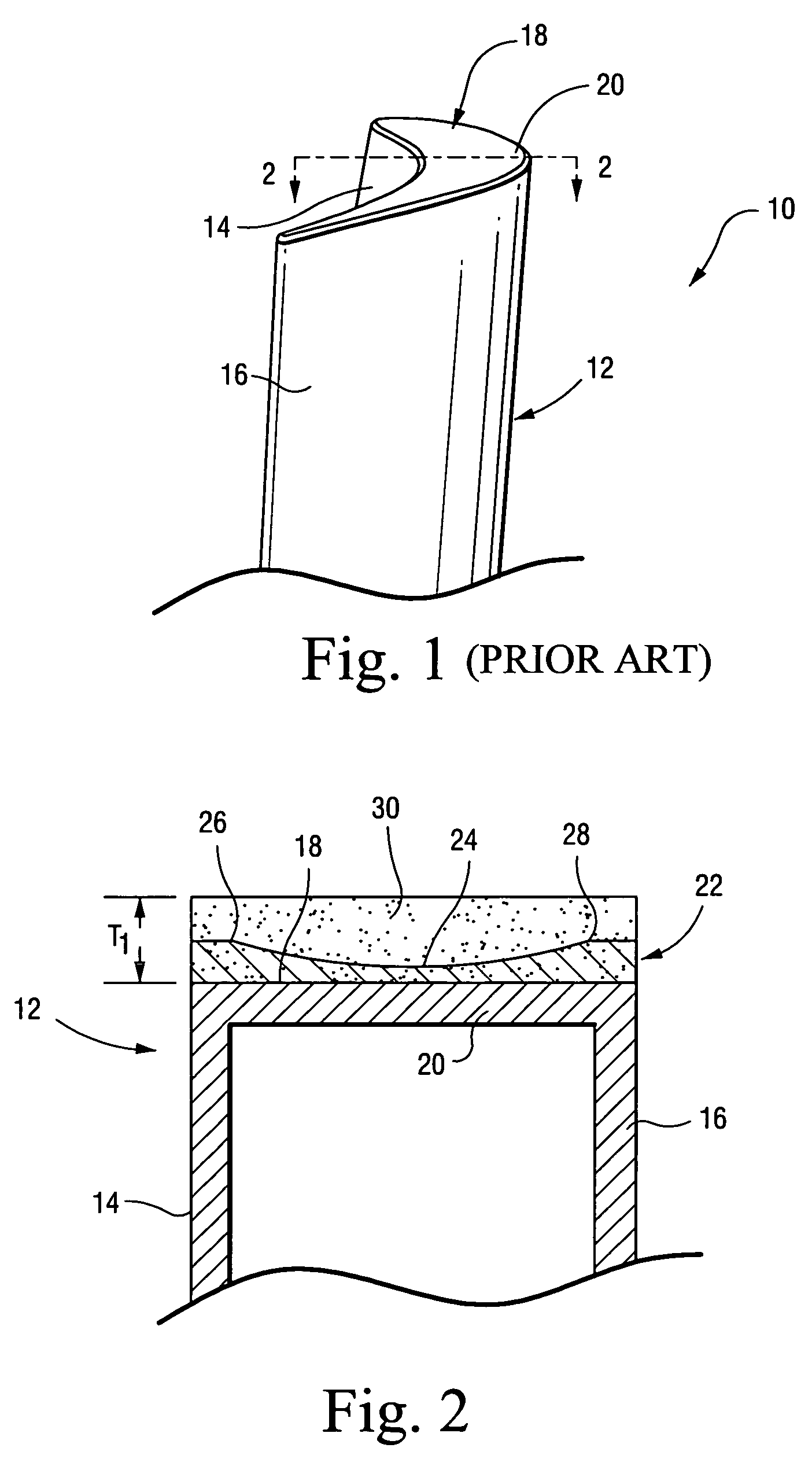

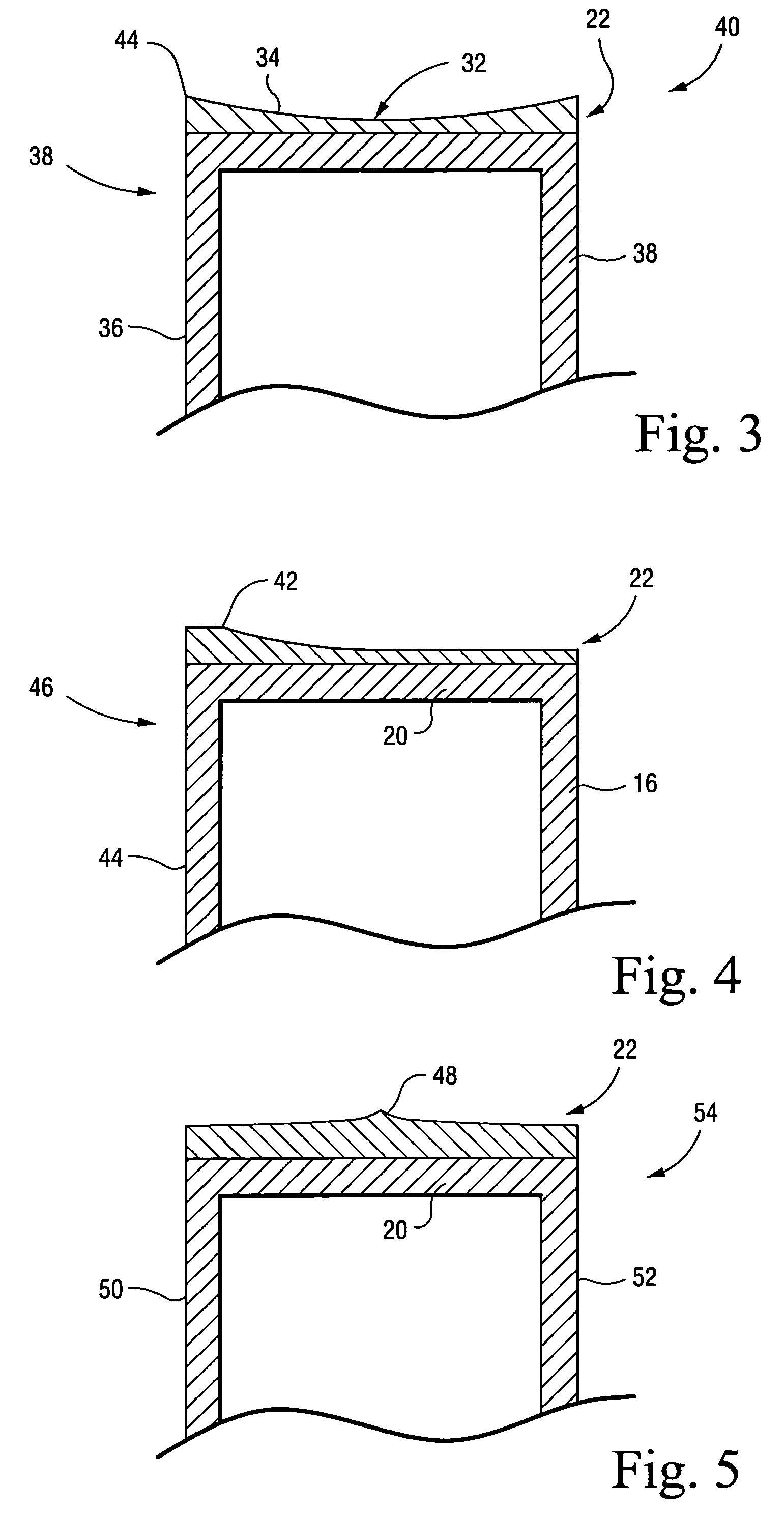

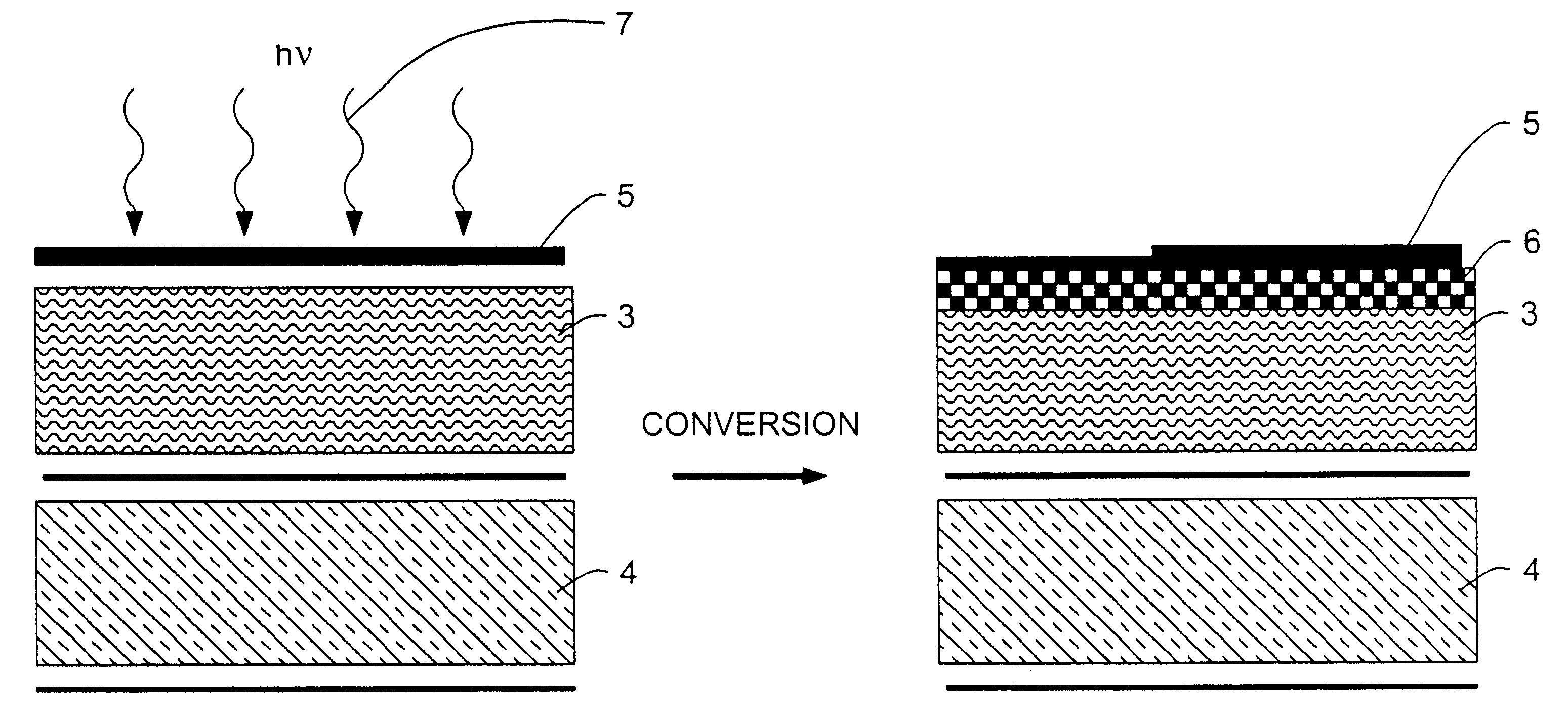

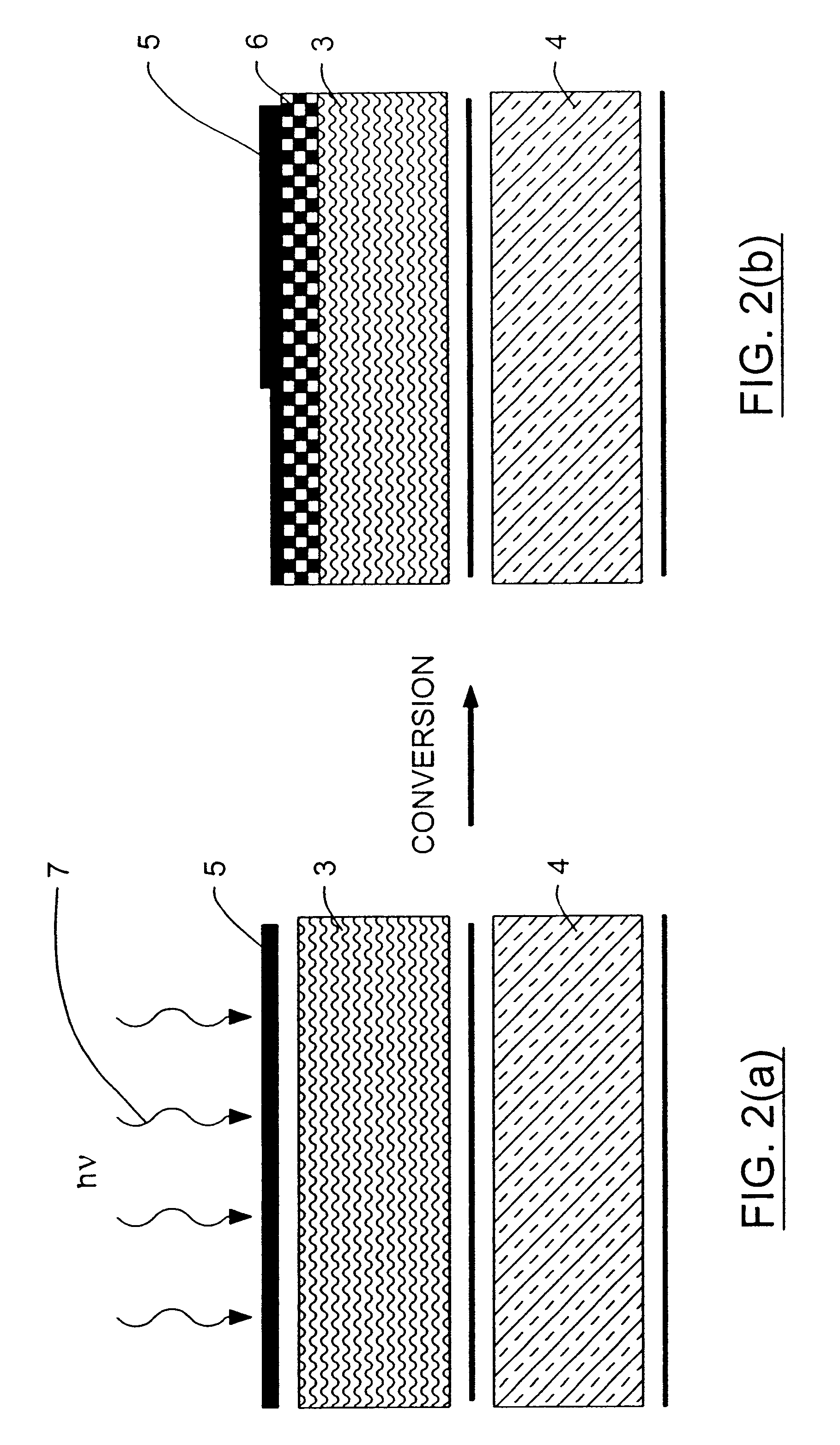

Method for obtaining reduced thermal flux in silicone resin composites

InactiveUS6551663B1Avoid thermal decompositionReduce heat fluxPretreated surfacesSpecial surfacesGlass fiberHeat flux

A method for improving the thermal barrier properties of silicone resin / glass fiber composites. Composites comprising a layer of polysiloxane (silicone resin) matrix with a glass or quartz fiber reinforcement embedded in such matrix and an organic polymeric layer were subjected to multi-cycle heat treatment, preferably with quartz lamps. The polysiloxane layer was pre-coated with graphite dispersion in order to ensure acceptable optical receptivity of the polysiloxane layer. As a result, the silicone resin was converted into a thick porous layer of silicone dioxide, the latter having the improved thermal barrier properties.

Owner:RAYTHEON CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com