Miniature high-current neutron generator

A neutron generator and strong current technology, applied in nuclear technology and application fields, can solve the problems that neutrons cannot be effectively used, increase the complexity of the device, etc., meet the requirements of in-situ irradiation and detection, have a simple structure, reduce The effect of heat flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

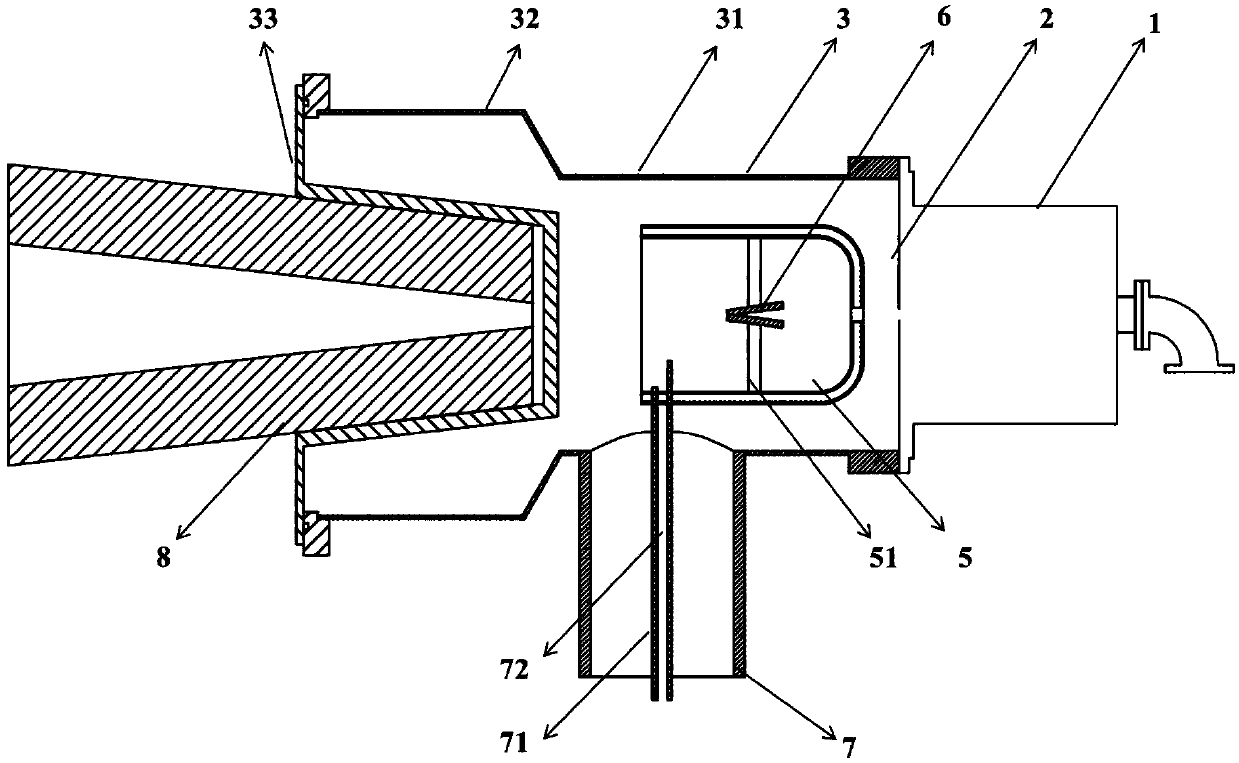

[0037] see figure 1 , a miniaturized high-current neutron generator of this embodiment adopts a three-electrode extraction acceleration structure, including an ion source 1, a plasma electrode 2, and a vacuum vacuum coaxially connected to the ion source 1 and the plasma electrode 2 through a flange. The cavity 3, the suppression electrode 5 and the target electrode 6 contained in the vacuum cavity 3, the high-voltage feed-in mechanism 7 connected to the vacuum cavity 3, and the collimator 8 embedded in the rear end cover 33 of the vacuum cavity 3 , the ion source 1, the plasma electrode 2, the suppression electrode 5, the vacuum cavity 3 and the collimator 8 are coaxial. Wherein, the ion source 1 , the plasma electrode 2 and the vacuum cavity 3 are grounded, the suppression electrode 5 and the target electrode 6 are connected to a negative high voltage, and the suppression electrode 6 is in a negative bias relative to the target electrode 6 . In this structure, both the ion s...

Embodiment 2

[0051] see Figure 4 , a kind of miniaturized high-current neutron generator of the present embodiment adopts four-electrode extraction acceleration structure, and adopts the neutron generator of three-electrode extraction acceleration structure in the structure and embodiment 1 (referring to figure 1 ) are essentially the same, with the main differences being:

[0052] The neutron generator comprises an ion source 1, a plasma electrode 2, a vacuum chamber 3 connected to the ion source 1 and the plasma electrode 2 by a flange, an extraction electrode 4 contained in the vacuum chamber 3, a suppression electrode 5 and The target electrode 6, the high-voltage feed-in mechanism 7 connected to the vacuum chamber 3, and the collimator 8 embedded in the rear end cover 33 of the vacuum chamber 3, the ion source 1, the plasma electrode 2, and the extraction electrode 4 , the suppression electrode 5, the vacuum cavity 3 and the collimator 8 are coaxial. Among them, the ion source 1 an...

Embodiment 3

[0057] A kind of specific test of the miniaturized high-current neutron generator in the above-mentioned embodiment 1 of the present embodiment:

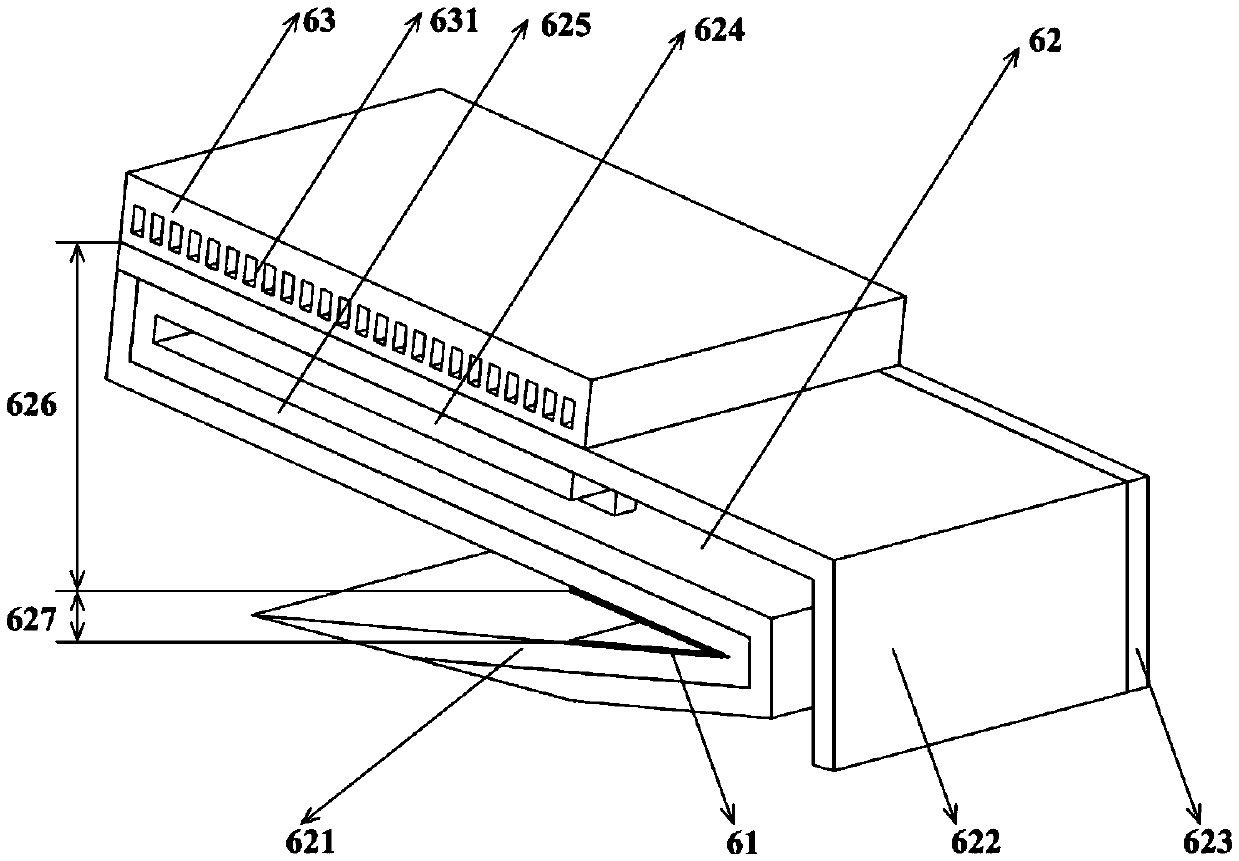

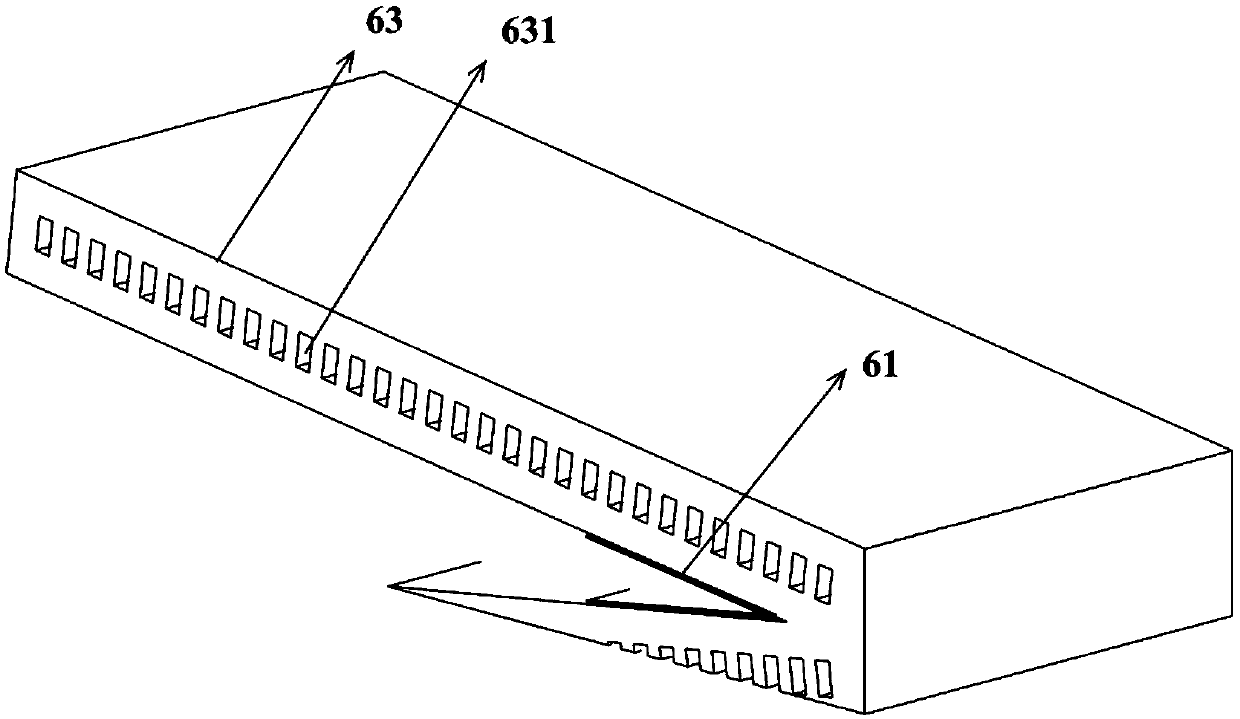

[0058]The working gas of the ion source 1 is deuterium gas, the voltage of the suppression electrode 5 is -151 ~ -155kV, and the voltage of the target electrode 6 is -150kV; the vacuum chamber 3 is connected to a vacuum pump to maintain a working vacuum of 10 -3 Pa level; use ion plating process to plate a 2.5μm thick titanium film on the surface of the target electrode, and place it in a deuterium absorbing device to make a deuterium titanium target. The deuterium beam drawn from the ion source 1 is accelerated under the action of the electric field gradient between the plasma electrode 2 and the target electrode 6, and bombards the surface of the deuterium-titanium target. When the included angle of the V-shaped structure of the target electrode 6 is 15°, the interaction area between the ion beam and the surface of the target elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com