Light emitting diode (LED) chip and LED wafer, and chip manufacturing method thereof

A LED chip and chip technology, applied in electrical components, electric solid devices, circuits, etc., can solve the problems of high packaging cost, LED heat dissipation technology and product complexity, and low packaging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

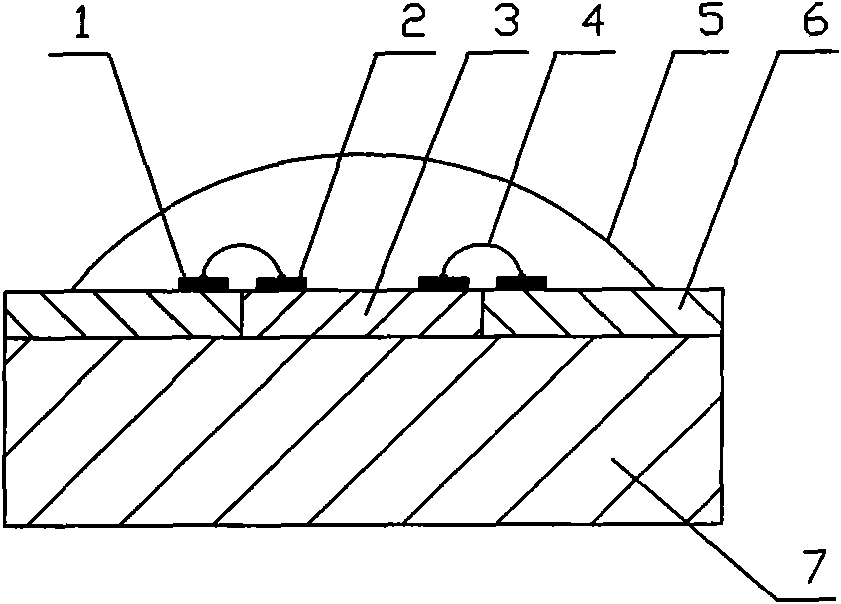

[0033] figure 1 In the shown LED chip of the present invention, the wafer 3 is embedded in the chip socket in the positioning piece 6, and the wafer 3 and the positioning piece 6 are attached to the A surface of the thermal diffusion member 7 together; Protective layer 5; the electrode pad 2 on the chip is close to the lead pad 1 on the positioning sheet, and the conduction connection between the two pads adopts an ultrasonic ball process, and the two ends of the wire 4 (gold wire or aluminum wire) are connected from the pad The surface stands up. Due to the thin wire diameter and low strength, the die-bonding protective layer 5 on the front of the chip should be set by dispensing. As shown in the figure, the thickness of the die-bonding protective layer 5 is uneven.

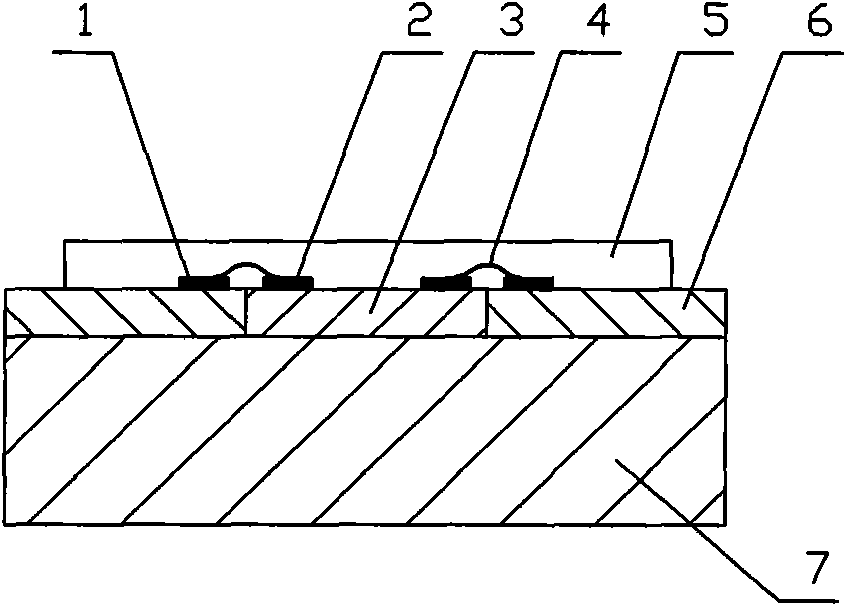

[0034] figure 2 As shown in the LED chip of the present invention, the two ends of the wire 4 are flatly attached to the two pads, and are welded by pressure welding. Since the wire lies flat, the strength is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com