Disilane functionalized carbon dots as well as preparation method and application thereof

A technology for functionalizing carbon and bis-silane, applied in chemical instruments and methods, semiconductor devices, luminescent materials, etc., can solve the problems of uncontrollable fluorescence emission wavelength blue-green light, poor integrated packaging performance, poor use performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

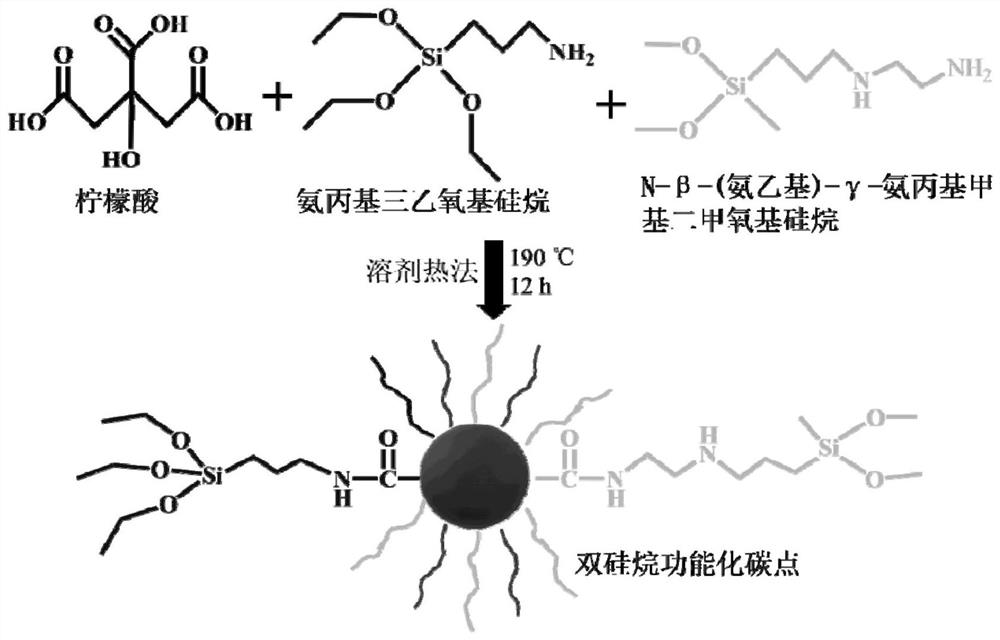

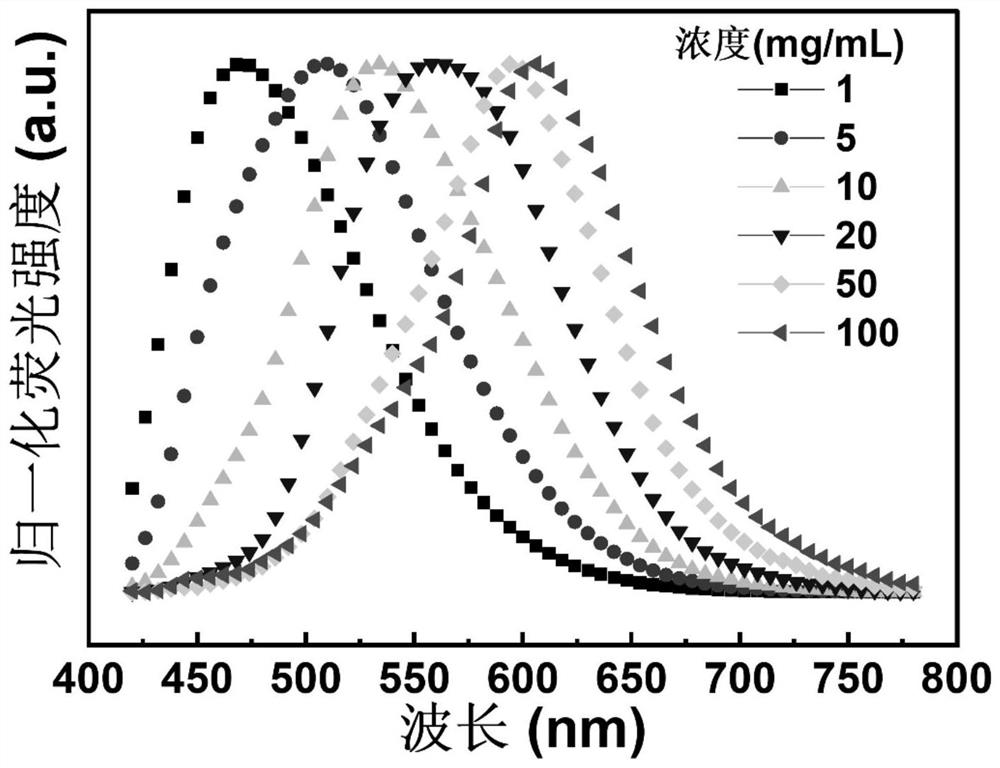

[0033]Weigh 0.003mol of anhydrous citric acid and 0.1mol of absolute ethanol in a high-pressure reaction kettle with a pressure of 1MPa~3MPa, and add 0.0021mol of aminopropyltriethoxysilane and 0.0198mol of N-β-( Aminoethyl)-γ-aminopropyltrimethoxysilane, reacted at a constant temperature of 160 °C in an oven for 14 h, cooled to room temperature to obtain bissilane-functionalized carbon dots, and the bissilane-functionalized carbon dots were excited by 365 nm ultraviolet light. Green fluorescence.

Embodiment 2

[0035] Weigh 0.003mol of anhydrous citric acid and 0.1mol of anhydrous ethanol in an autoclave with a pressure of 1MPa~3MPa, and add 0.0063mol of aminopropyltriethoxysilane and 0.0154mol of N-β-(aminoethyl) to it. base)-γ-aminopropyltrimethoxysilane, reacted in a constant temperature oven at 185 °C for 12 h, and cooled to room temperature to obtain bissilane-functionalized carbon dots, which exhibited yellow fluorescence under the excitation of 365 nm ultraviolet light. .

Embodiment 3

[0037] Weigh 0.003mol of anhydrous citric acid and 0.1mol of anhydrous ethanol in an autoclave with a pressure of 1MPa~3MPa, and add 0.0147mol of aminopropyltriethoxysilane and 0.0066mol of N-β-(aminoethyl) to it. base)-γ-aminopropyltrimethoxysilane, reacted in a constant temperature oven at 210 °C for 10 h, and cooled to room temperature to obtain bissilane-functionalized carbon dots. The bis-silane-functionalized carbon dots exhibited red fluorescence under the excitation of 365 nm ultraviolet light .

PUM

| Property | Measurement | Unit |

|---|---|---|

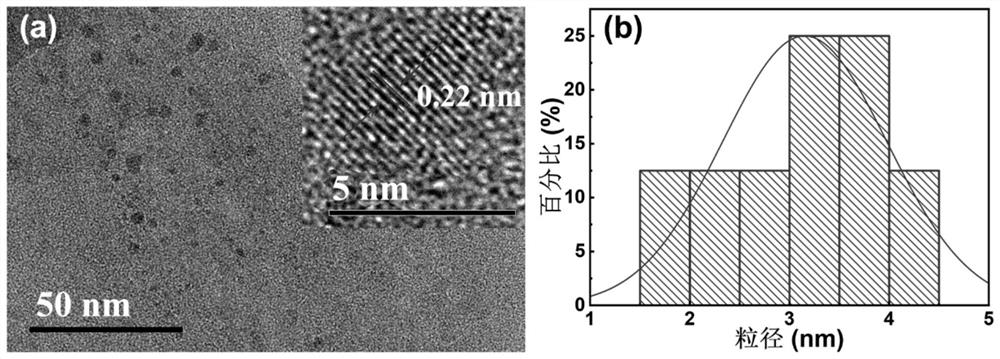

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| color rendering index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com