Preparation method for copper oxide nano line array film

A technology of copper oxide nanowires and copper thin films, applied in ion implantation plating, metal material coating process, coating and other directions, can solve problems such as poor controllability and limited substrate materials, and expand the application field and scope , Flexible preparation and good controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

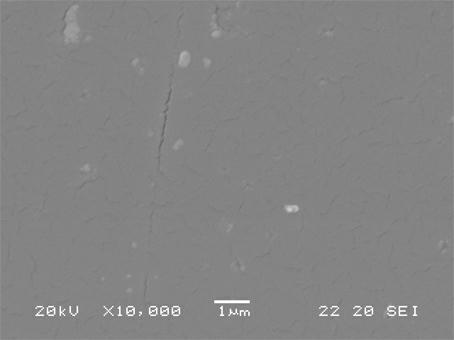

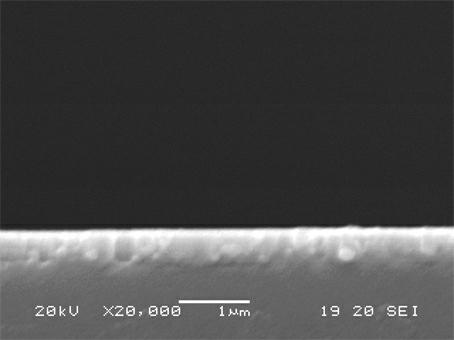

[0026] (1) After putting the copper target with a purity of 99.99% and the cleaned FTO into the sputtering chamber, first use a mechanical pump and a molecular pump to pump the vacuum of the sputtering chamber to 3.0×10 -3 Pa, then filled with argon gas with a purity ≥ 99.999%, the flow rate was 23 sccm, the main valve was adjusted to keep the vacuum at 0.35Pa, the current was adjusted to 0.25A, the voltage was 300V, the substrate speed was 13 r / min, and the sputtering Time 10min, obtain about 500 nanometers thick metal copper film, characterization sees figure 1 and figure 2 .

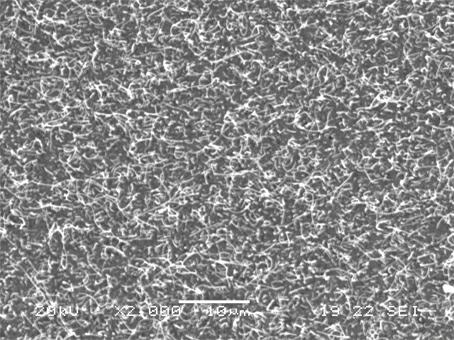

[0027] (2) Put the metal copper film obtained in step (1) into a tube furnace quickly, the tube mouth of the tube furnace close to the sample end is closed, and the other end is connected to the atmosphere; the heating rate is 20°C / min, in the atmosphere After annealing at 500°C for 8 hours, a vertically grown copper oxide nanowire array film was obtained. See the attached Figure 3-6 .

Embodiment 2

[0029] 1) After putting the copper target with a purity of 99.99% and the cleaned FTO into the sputtering chamber, first use a mechanical pump and a molecular pump to pump the vacuum of the sputtering chamber to 4×10 -3 Pa, then filled with argon gas with a purity ≥ 99.999%, the flow rate was 20 sccm, and the main valve was adjusted to keep the vacuum at 3.0×10 -1 Pa, adjust the current to be 0.2A, the voltage to be 350V, and the sputtering time to be 30min to obtain a metal copper film with a thickness of about 1.2μm;

[0030] (2) Put the metal copper film obtained in step (1) into a tube furnace quickly, the tube mouth of the tube furnace close to the sample end is closed, and the other end is connected to the atmosphere; the heating rate is 20°C / min, in the atmosphere After annealing at 450° C. for 10 hours, a vertically grown copper oxide nanowire array film is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com