Laser engraving and 3D printing integrated advertising character manufacturing equipment and manufacturing method

A laser engraving and 3D printing technology, applied in the field of advertising words, can solve the problems of waste of manpower and material resources, high cost, high cost, etc., and achieve the effect of simplifying the production process, low human requirements, and flexible production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

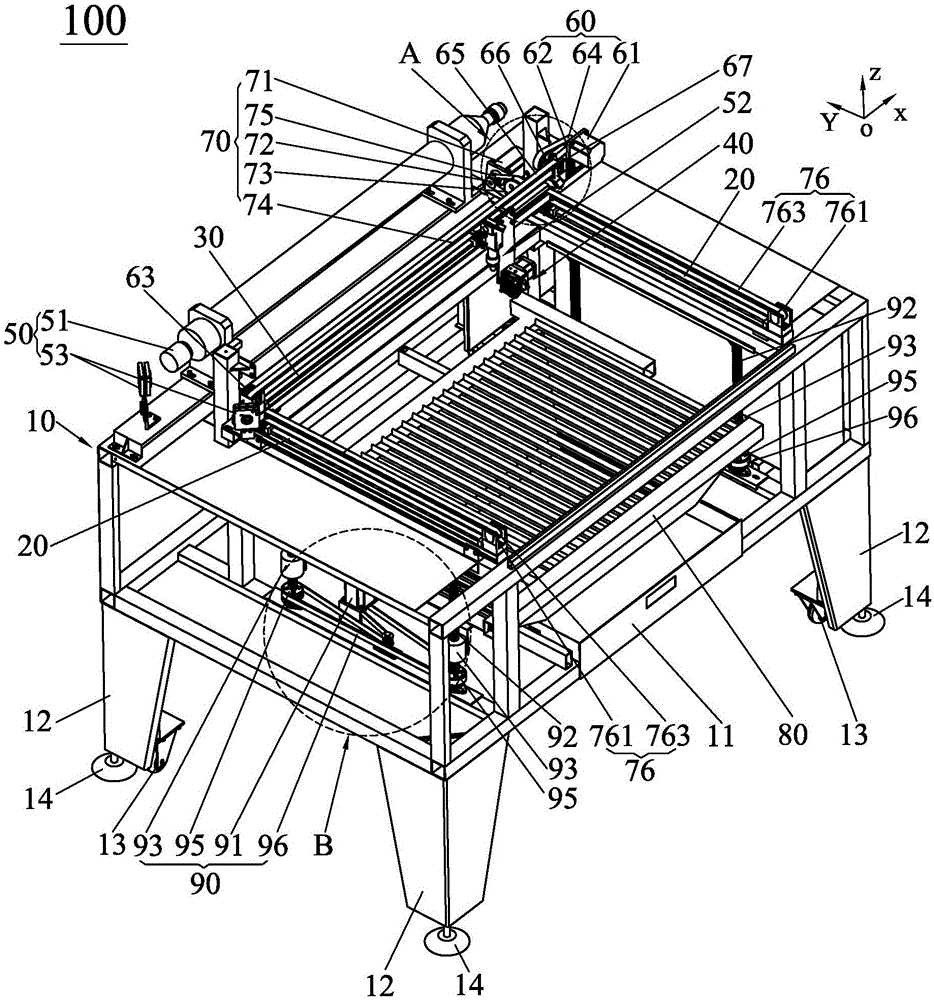

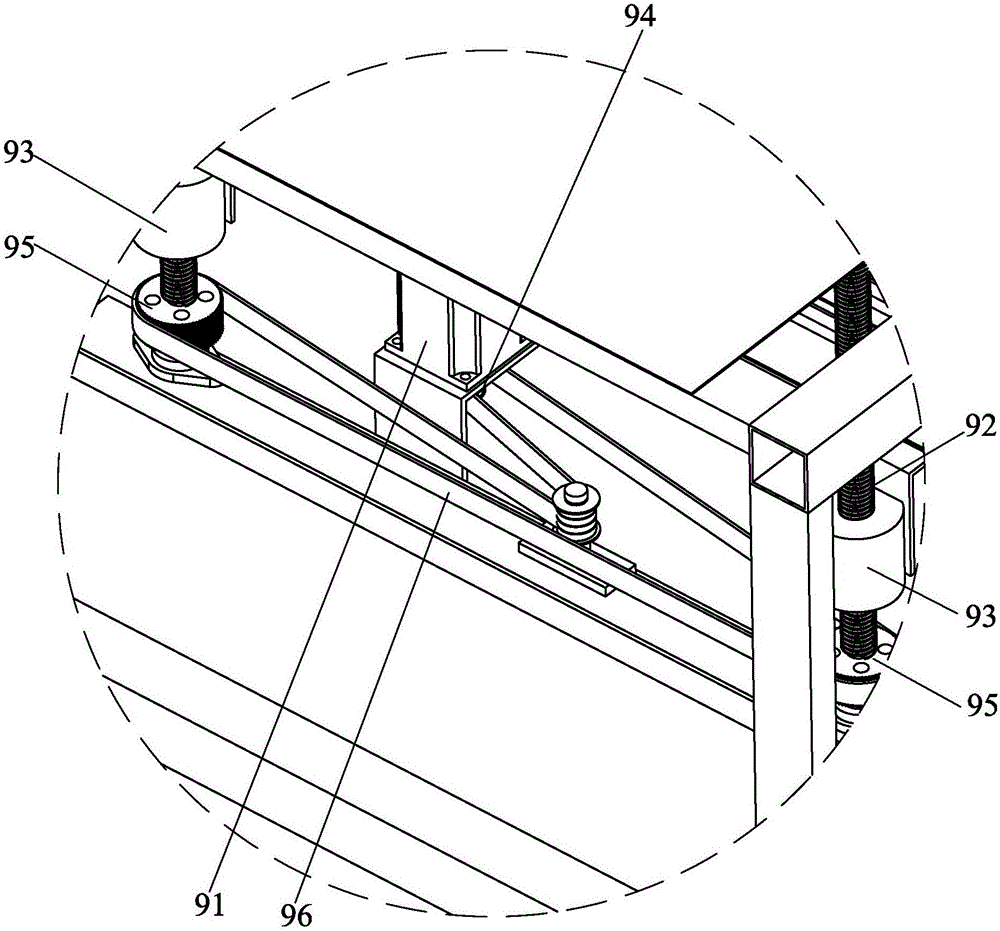

[0035] see figure 1 , the advertising character manufacturing equipment integrating laser engraving and 3D printing of the present invention includes a frame 10, a first linear guide rail 20, a second linear guide rail 30, a printing nozzle assembly 40, a laser engraving device 50, An X-axis driving mechanism 60 , a Y-axis driving mechanism 70 , a worktable 80 and a Z-axis driving mechanism 90 . Specifically, in this embodiment, the frame 10 is a rectangular frame to facilitate external components on the frame 10, but not limited thereto.

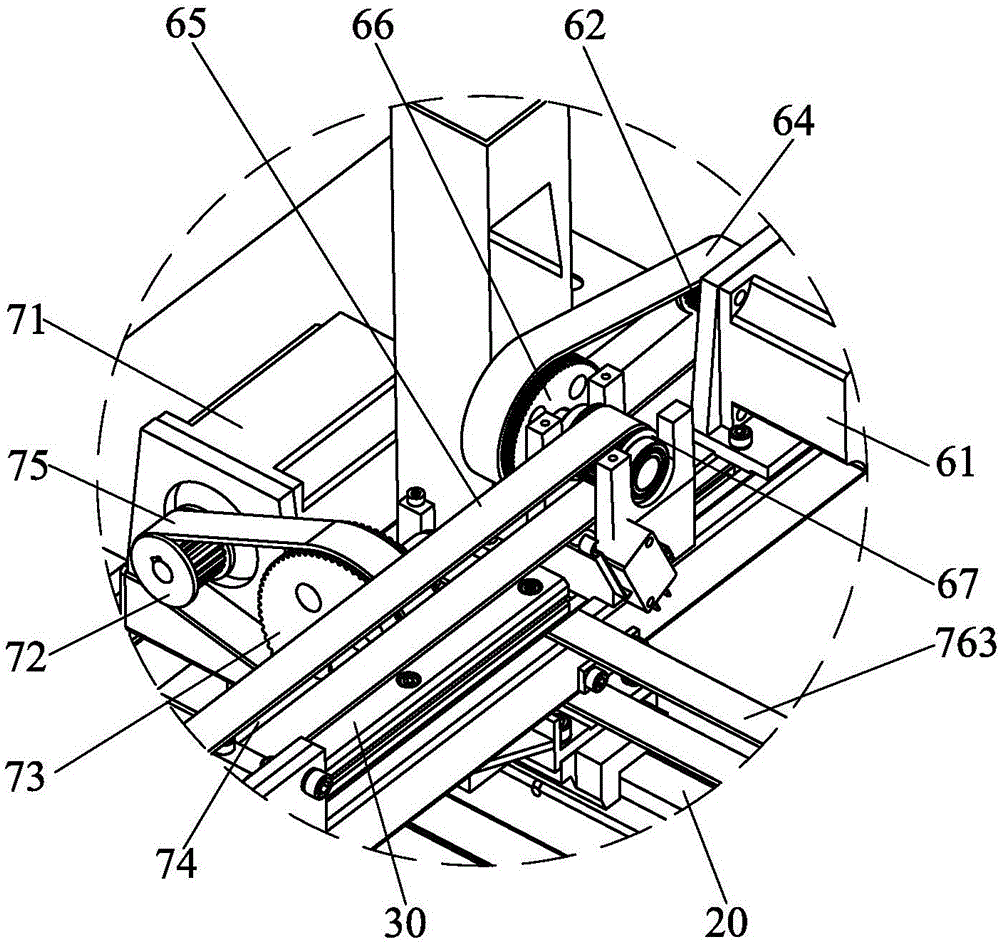

[0036] Such as figure 1 and figure 2As shown, the first linear guide rail 20 is arranged along the Y-axis direction, and the first linear guide rails 20 are respectively assembled at the left and right sides of the frame 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com