Patents

Literature

54results about How to "Avoid leakage loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

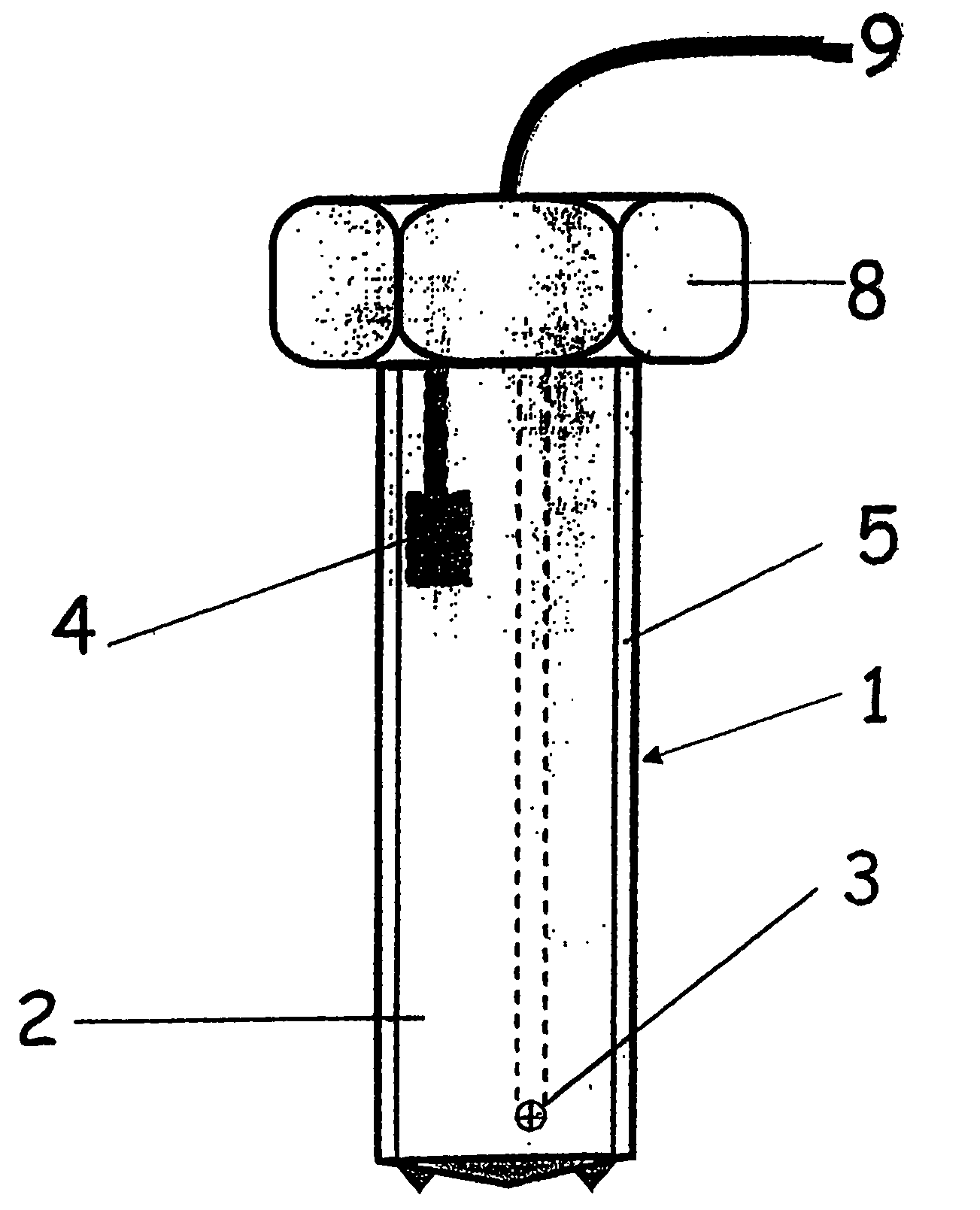

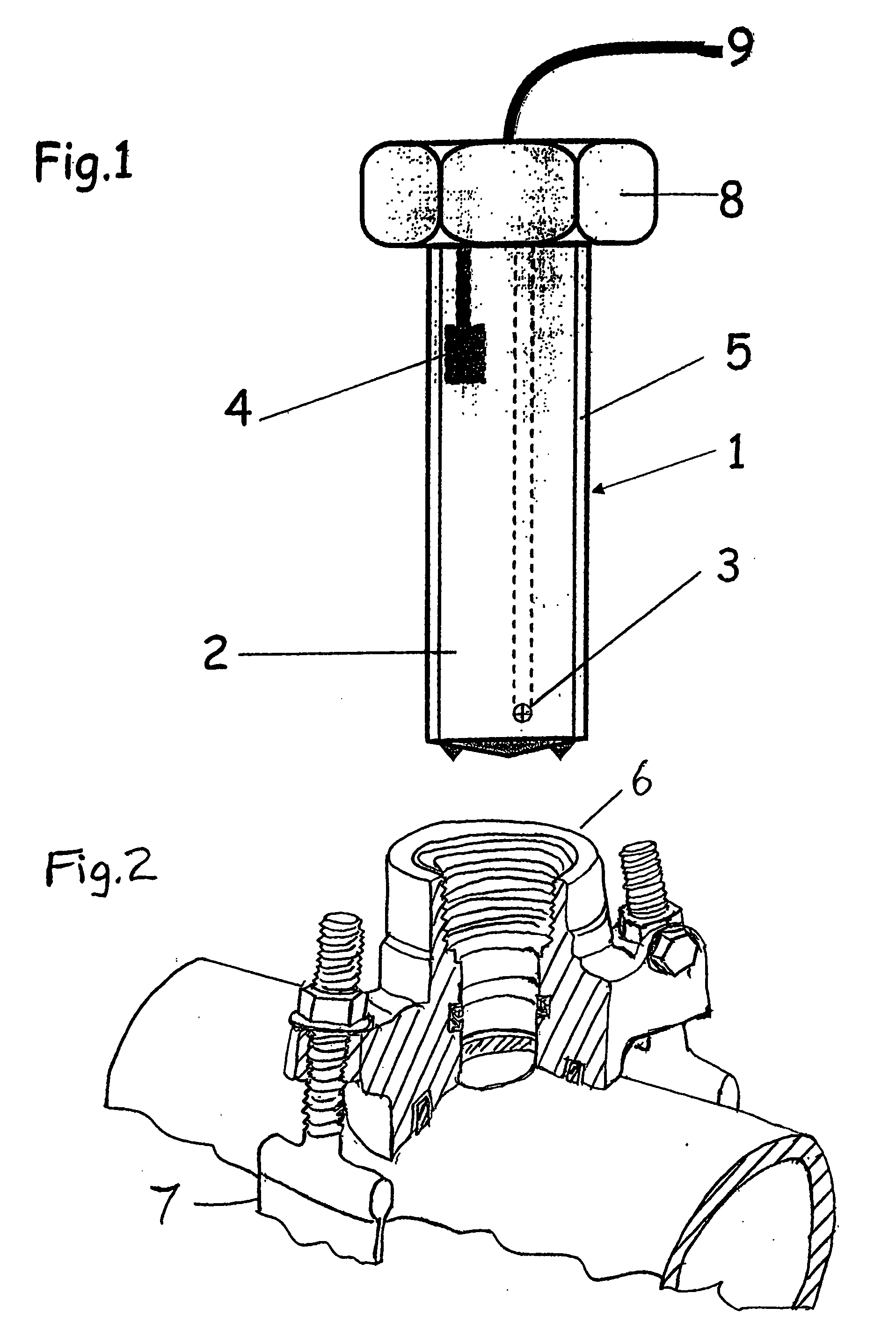

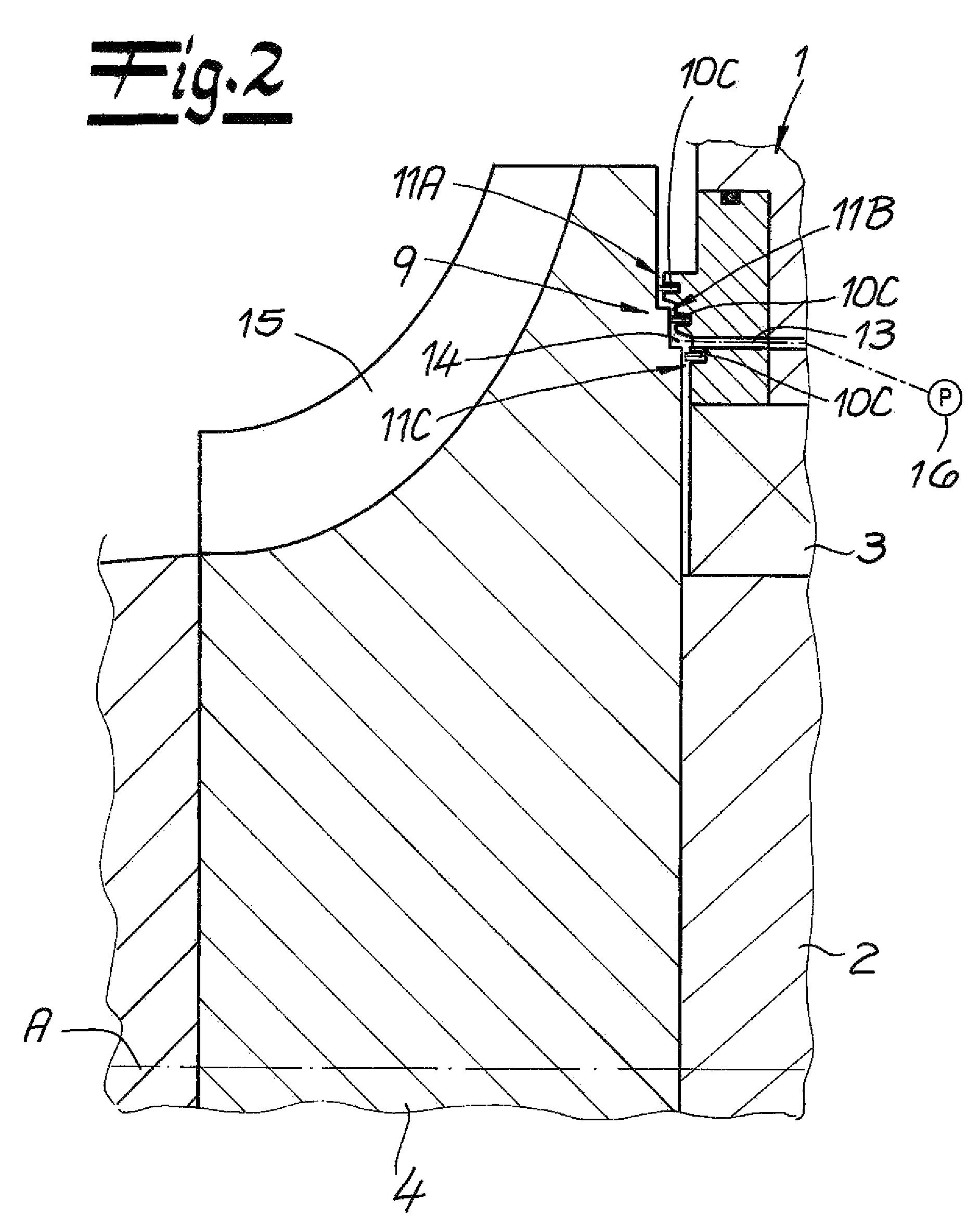

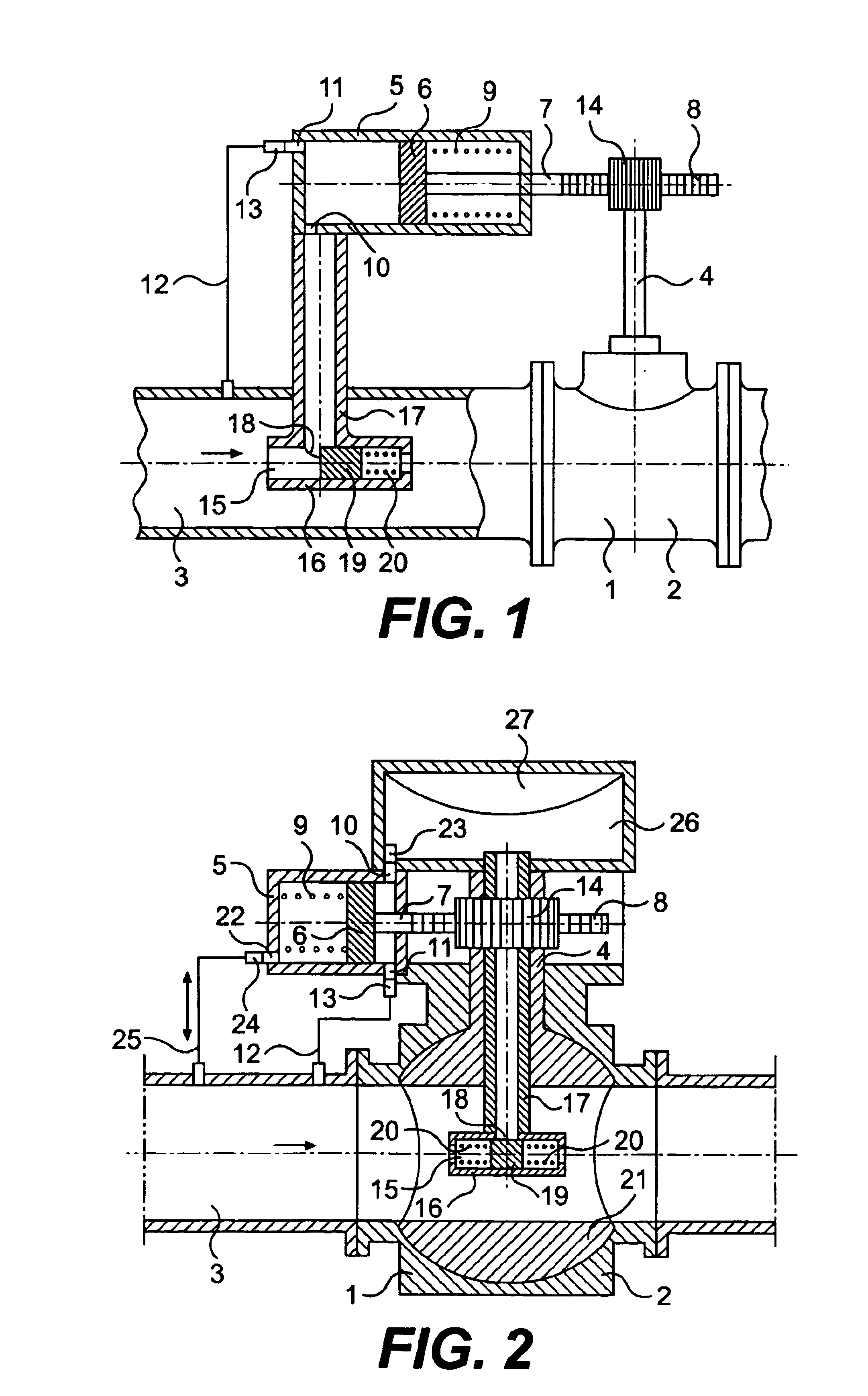

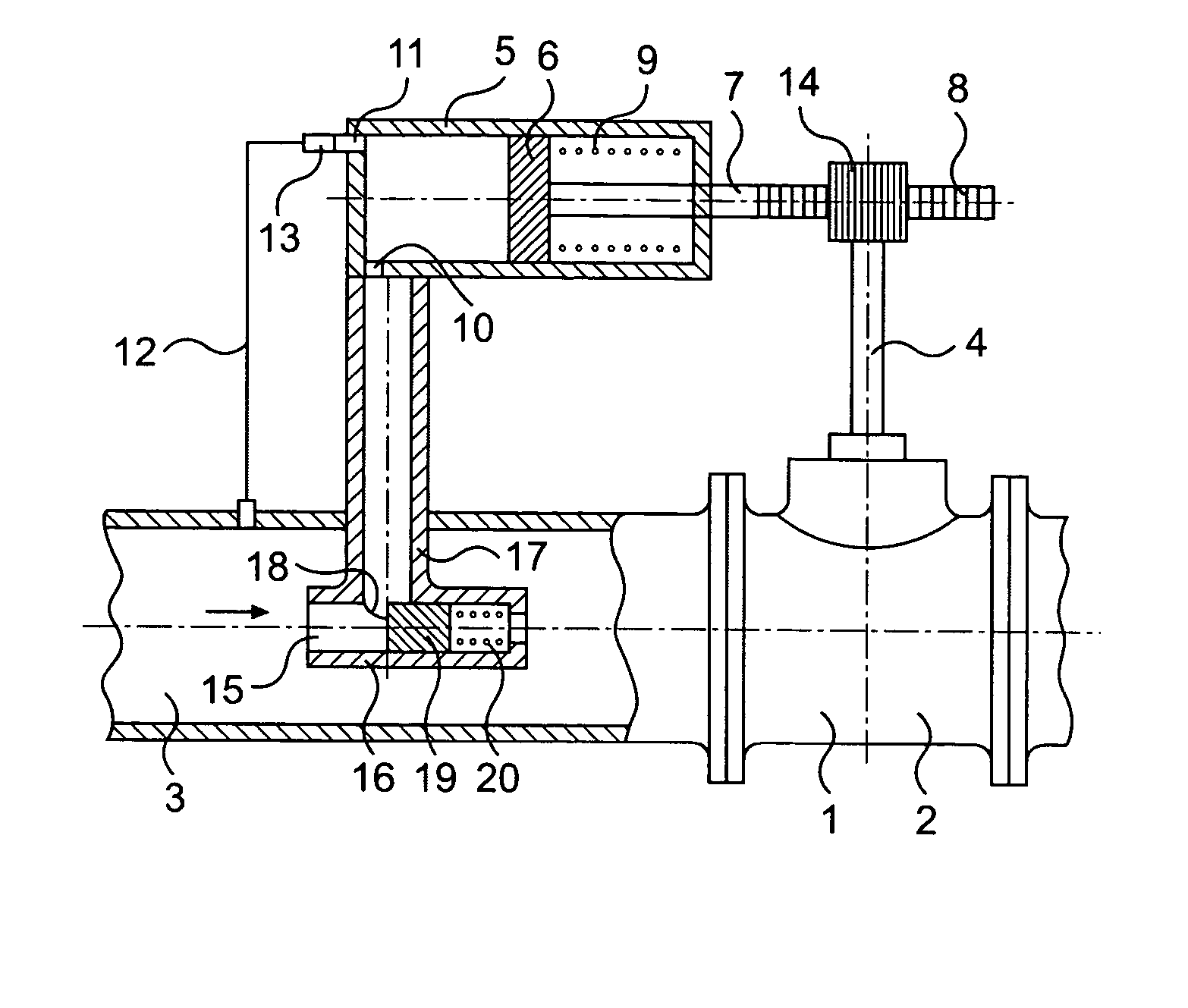

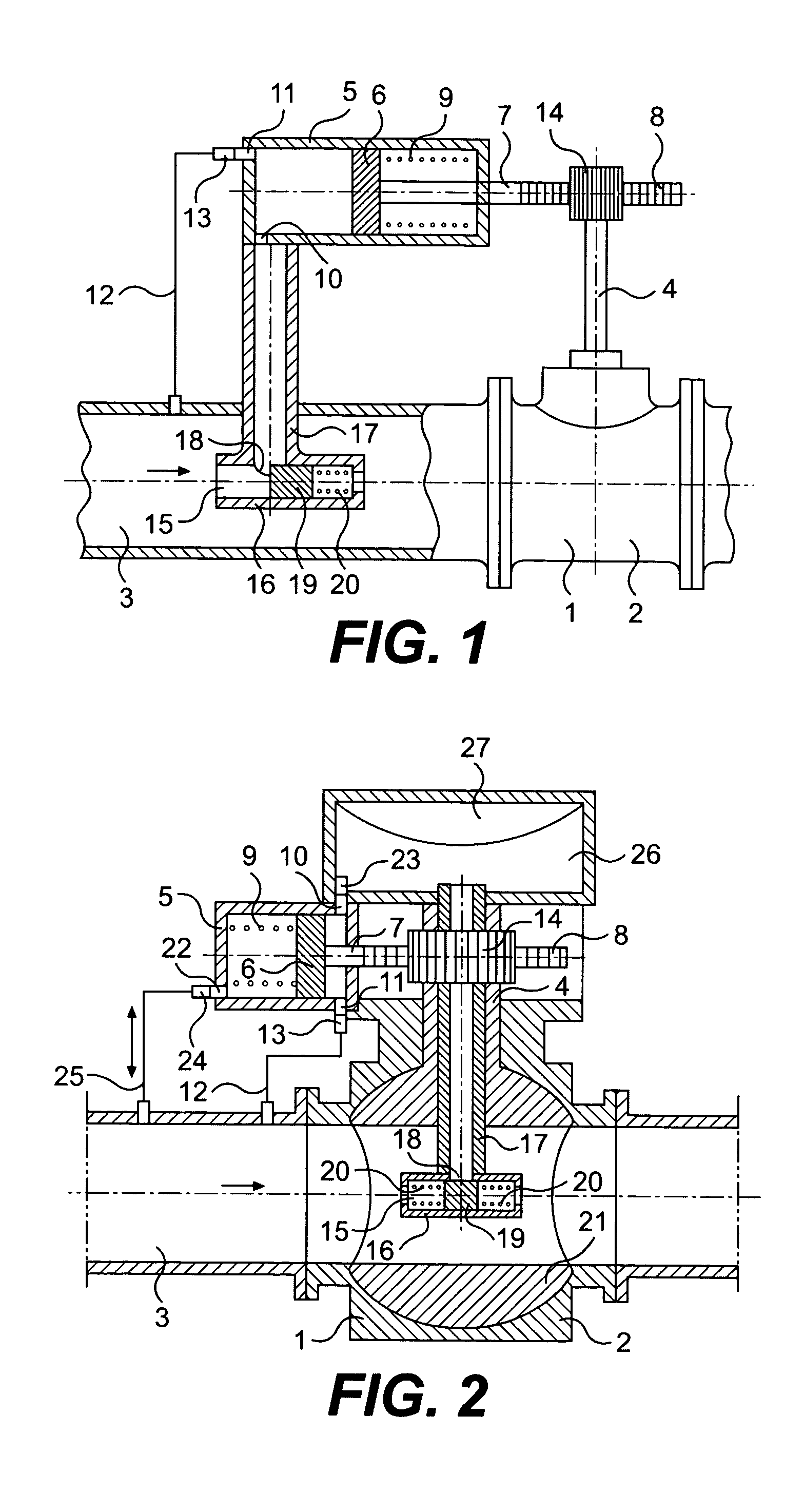

Method and measurement probe for the performance of measurements in water supply systems

InactiveUS7007545B1Improve gripEfficient use ofDetection of fluid at leakage pointMeasurement of fluid loss/gain rateModem deviceMeasurement point

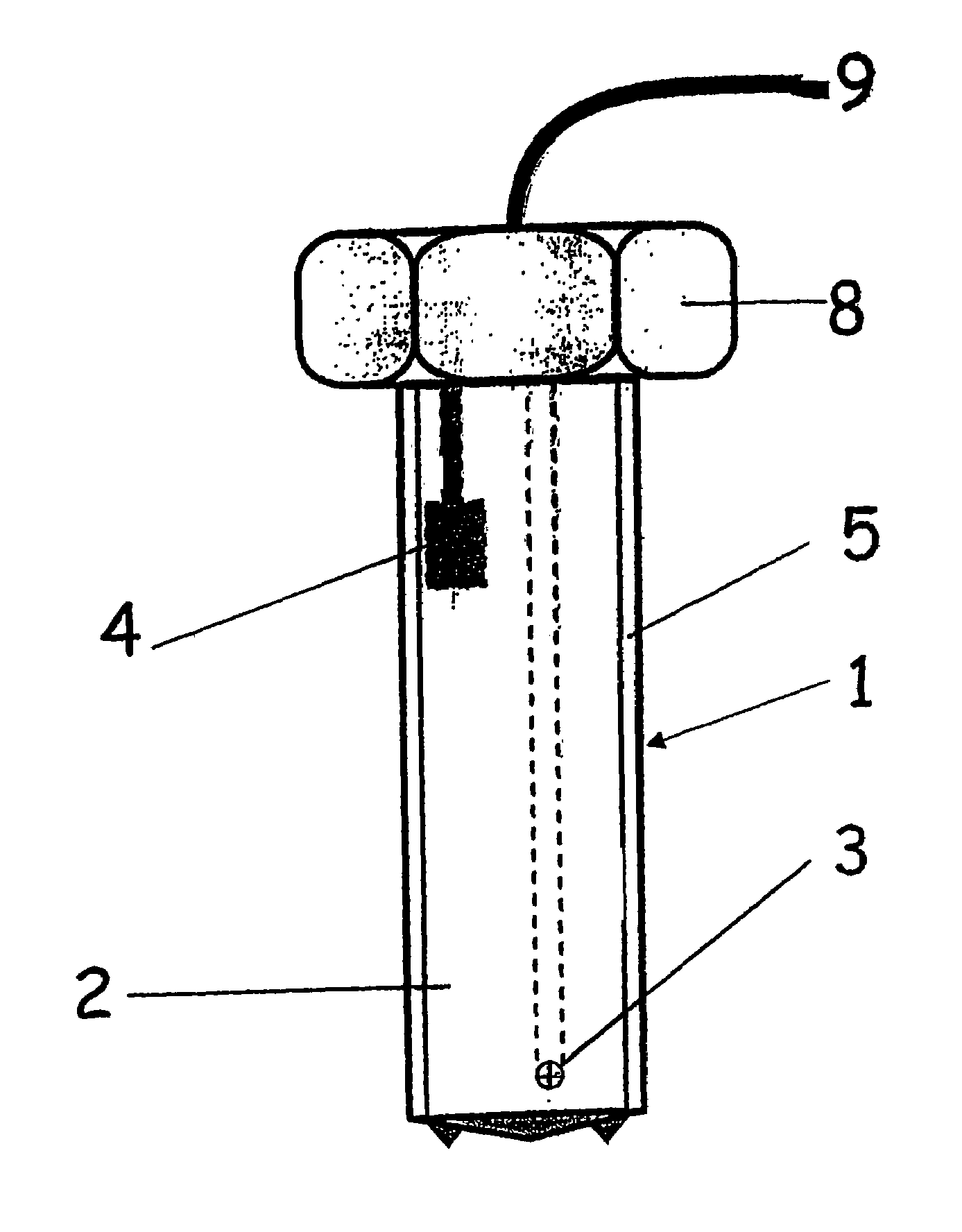

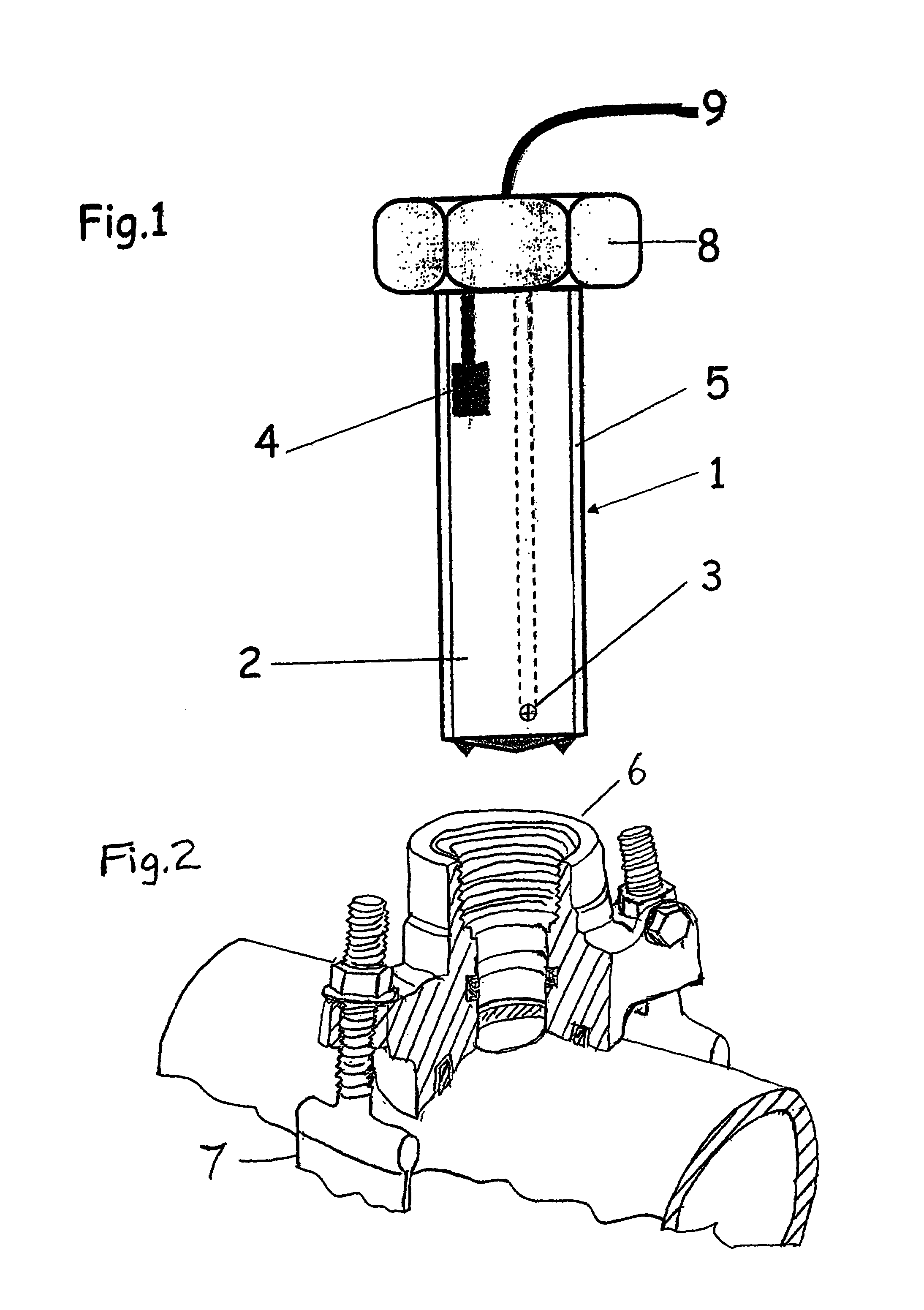

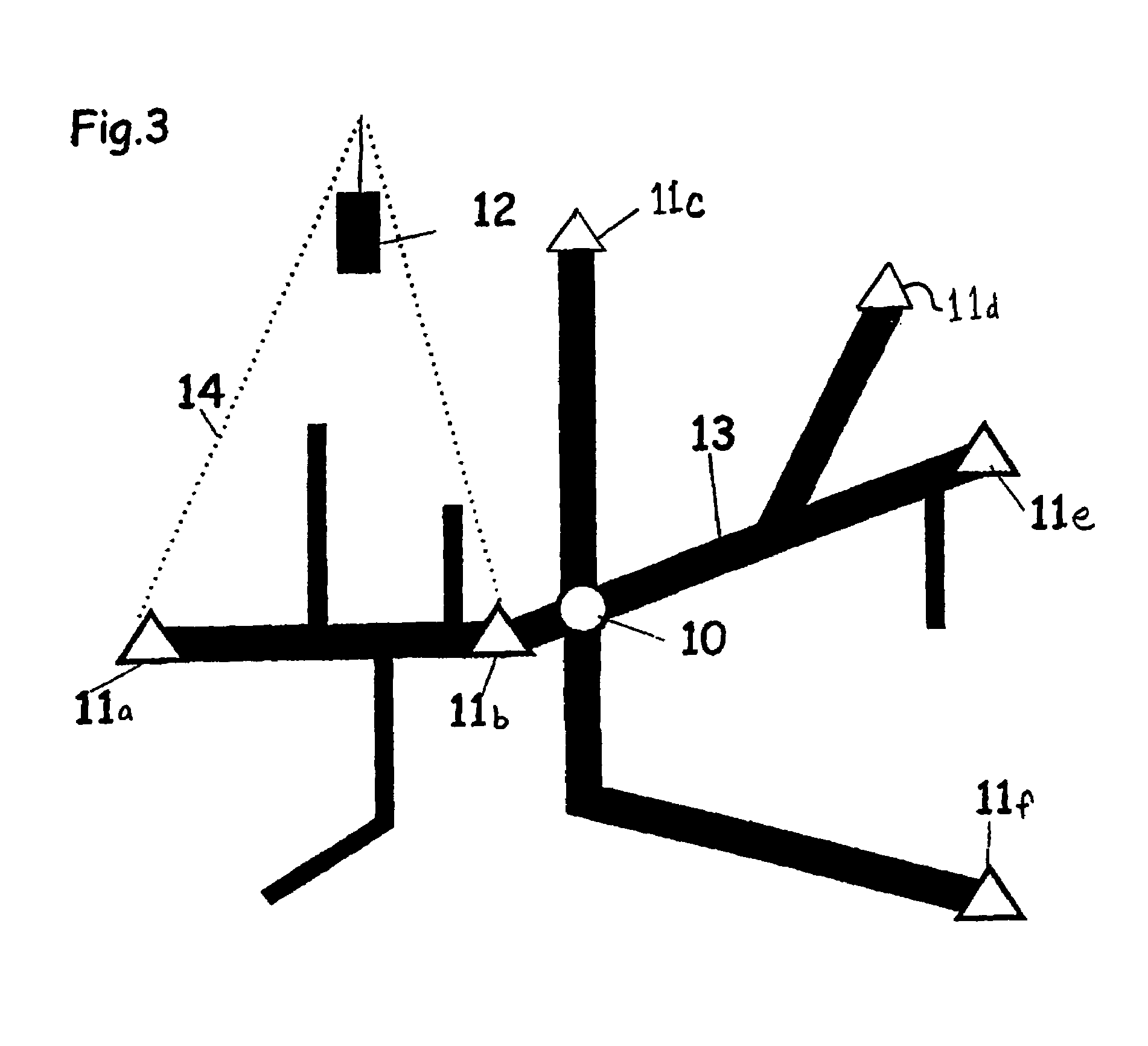

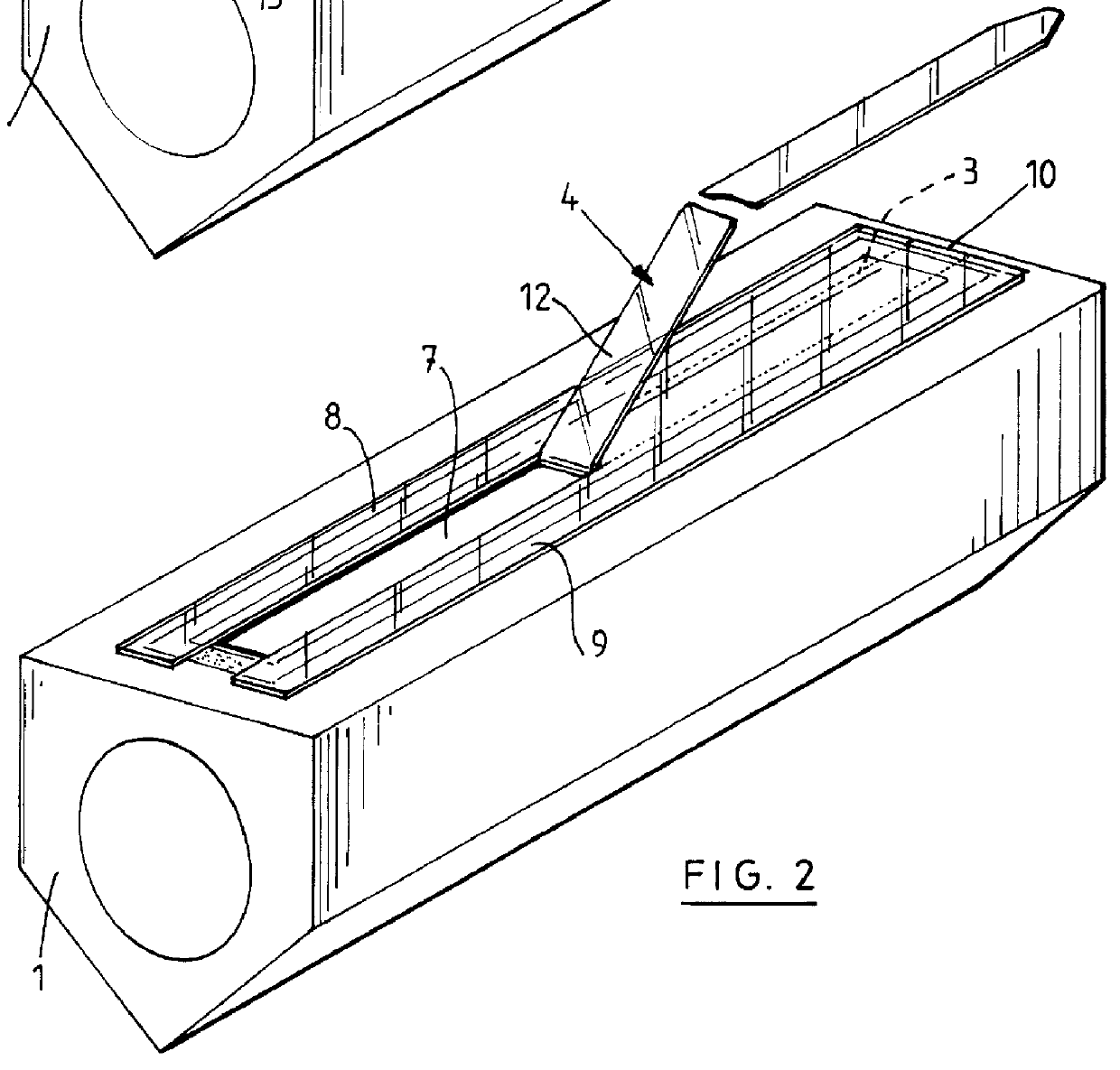

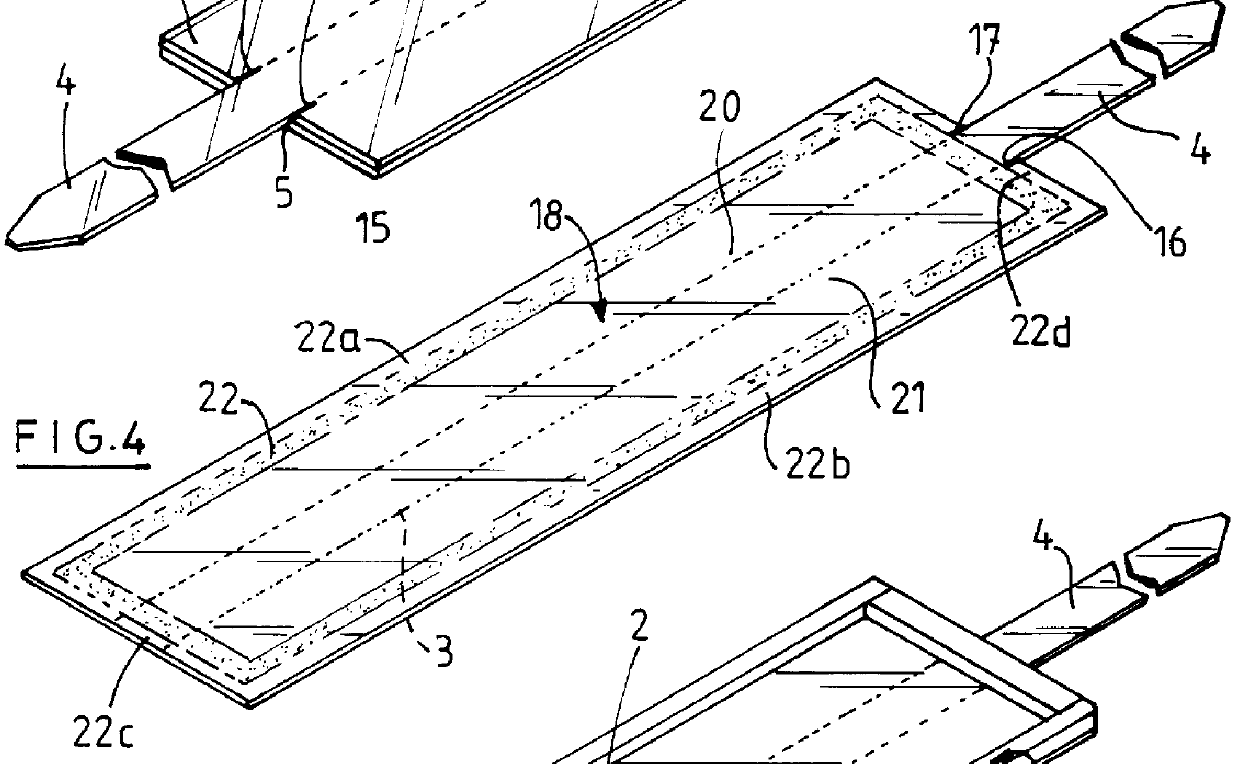

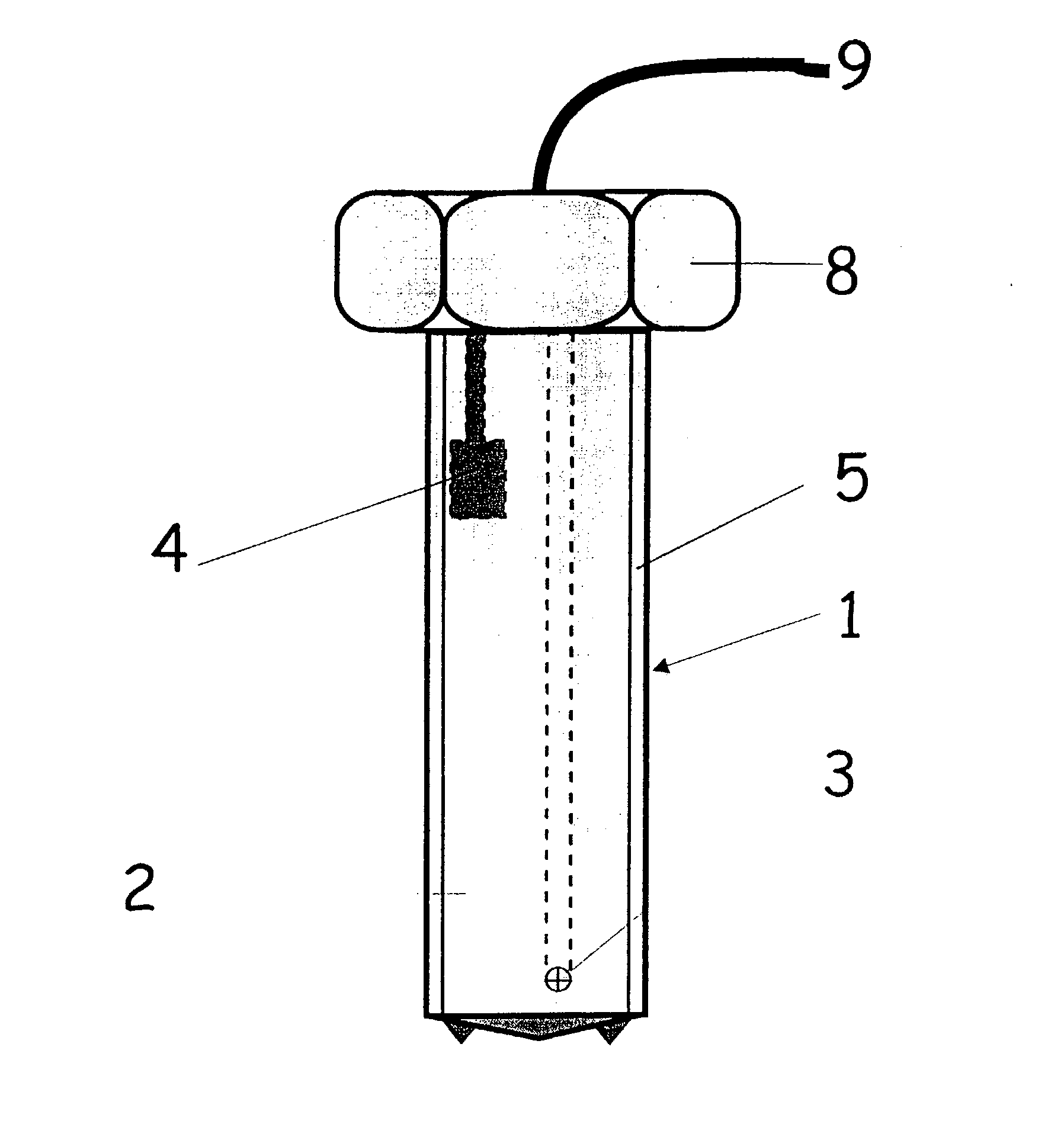

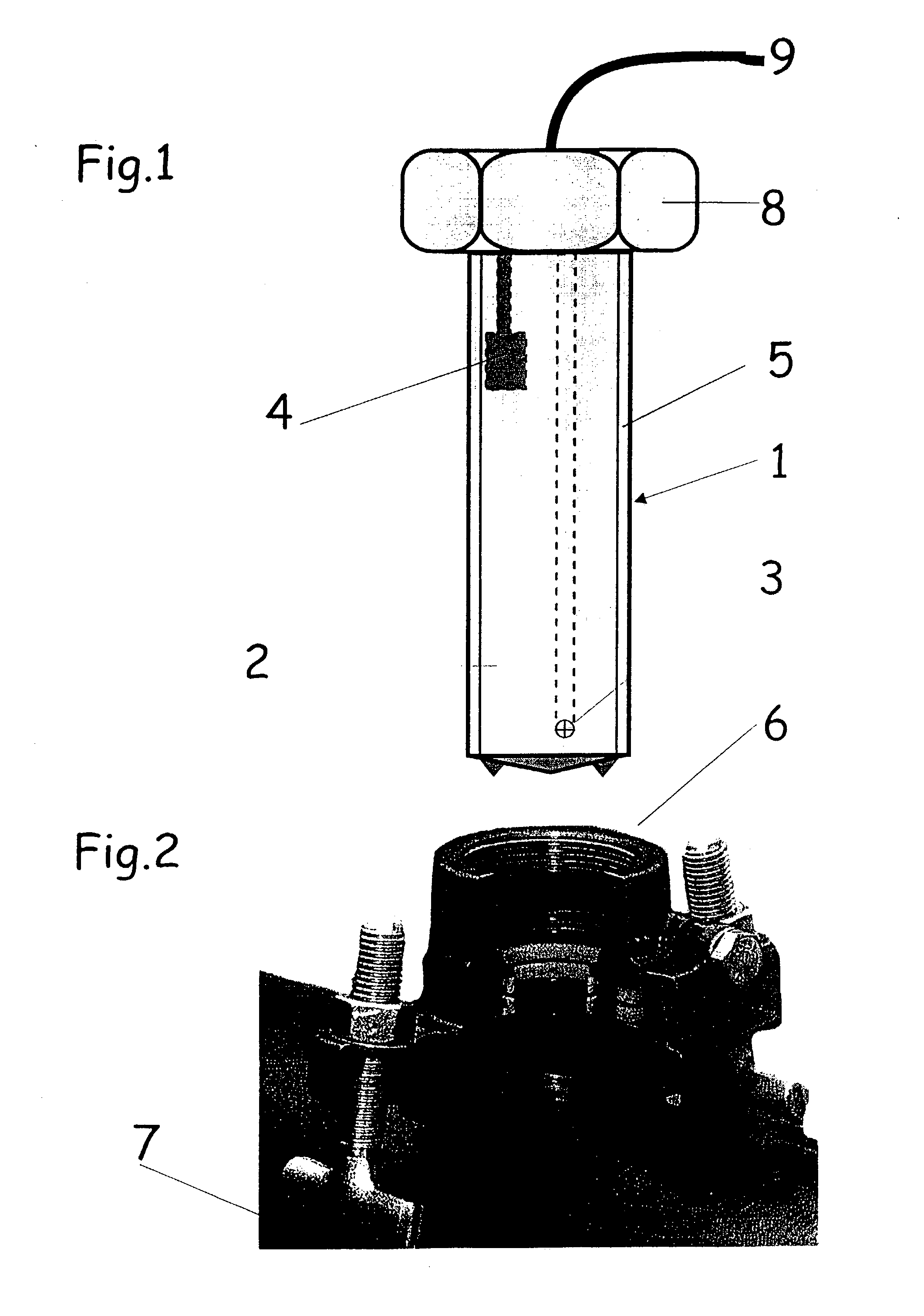

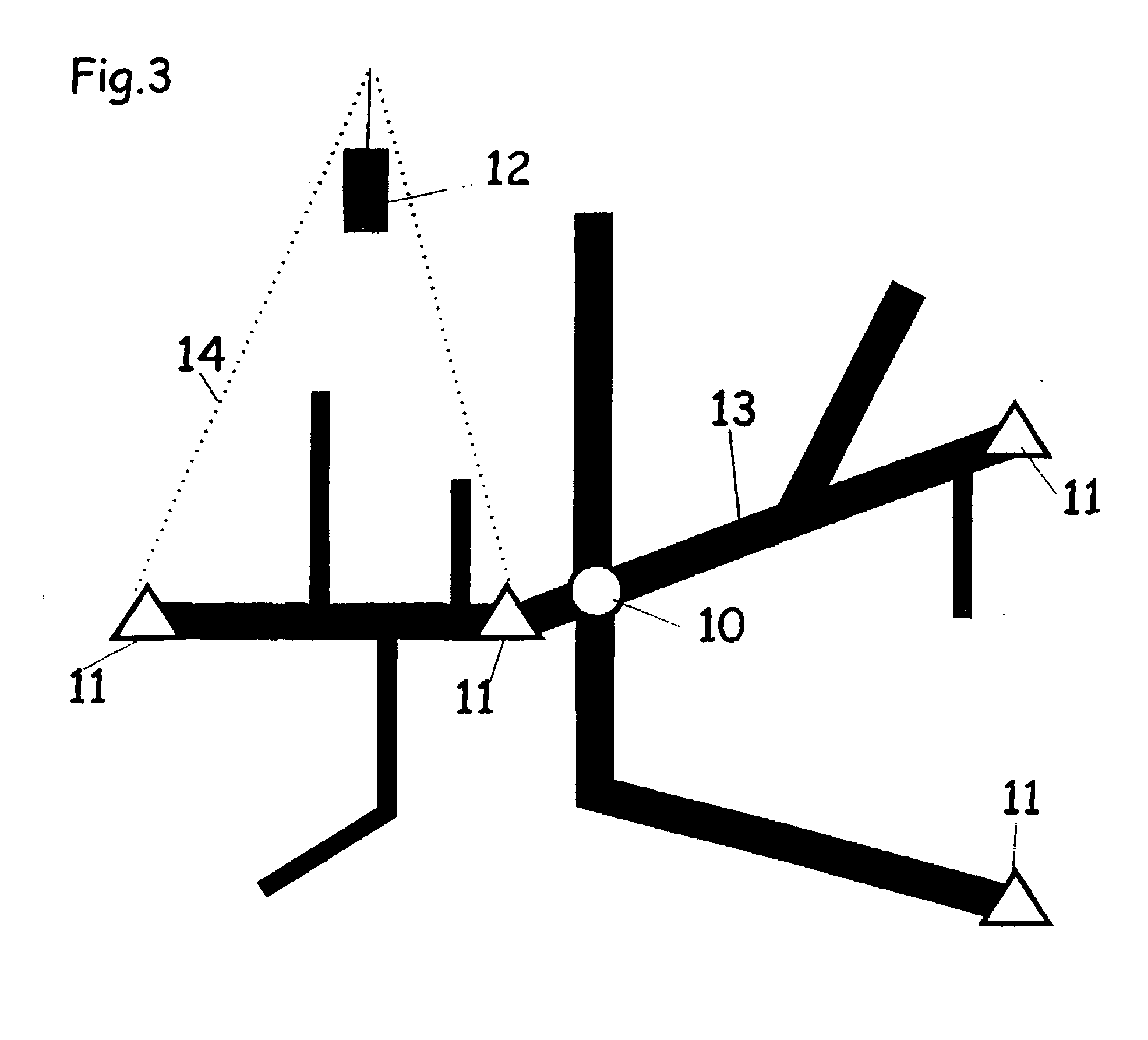

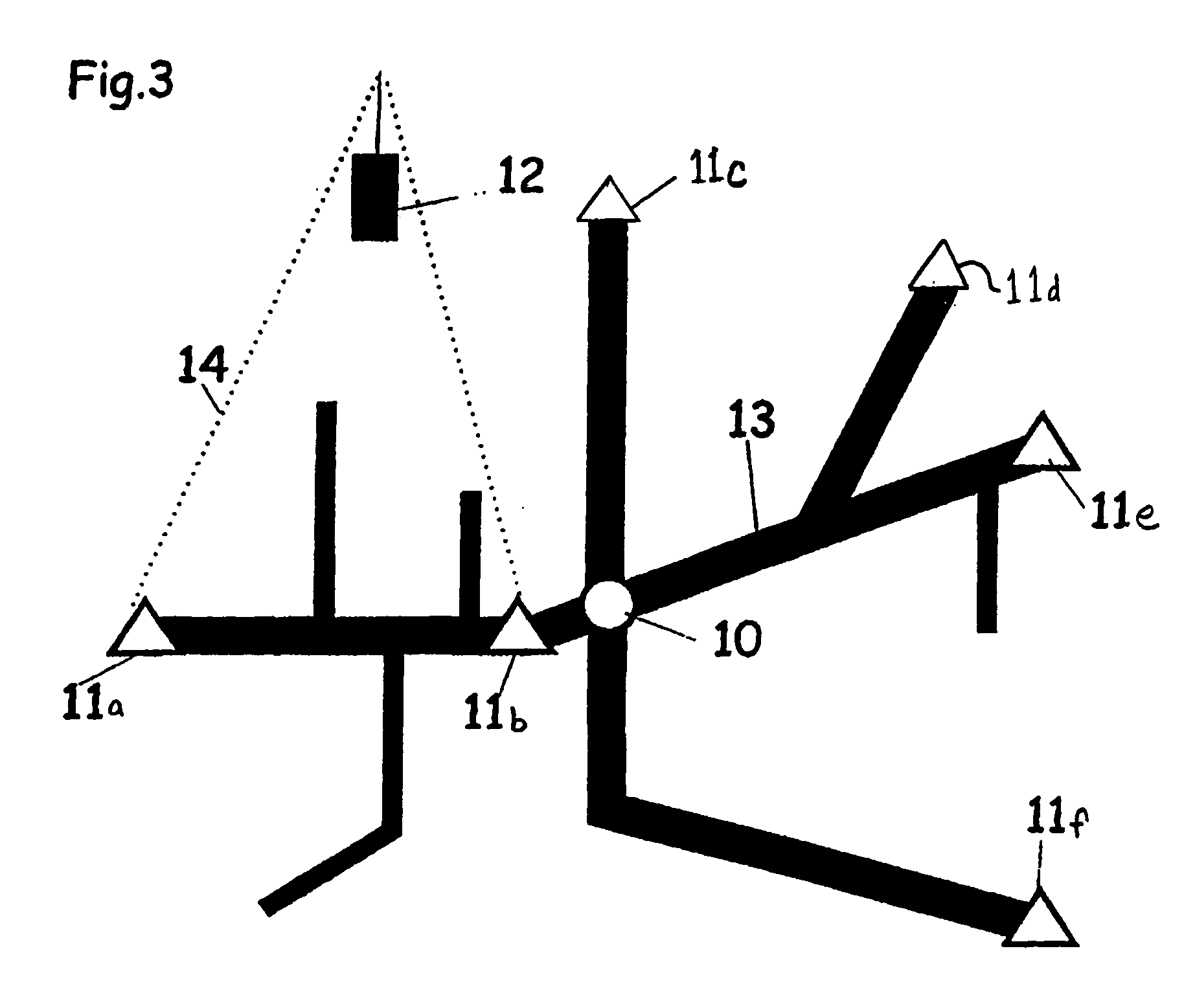

Measuring elements for the output of measured quantities in respect of the flow, namely the flow quantity and direction, the water pressure and the flow noise are integrated in a measurement probe (1) for water supply networks (13), whereby all these measuring elements are connected or can be connected to a data collector (12) by means of transmission by radio, modem or cable connection. The measurement probes are installed permanently at the key points (10) and at the most varied measurement points (11) following one another as closely as possible in the water supply network (13) and can thus contribute, by delivering all the necessary data, to the rapid tracing of leaks with pinpoint accuracy as well as to constant monitoring.

Owner:MARTINEK PETER

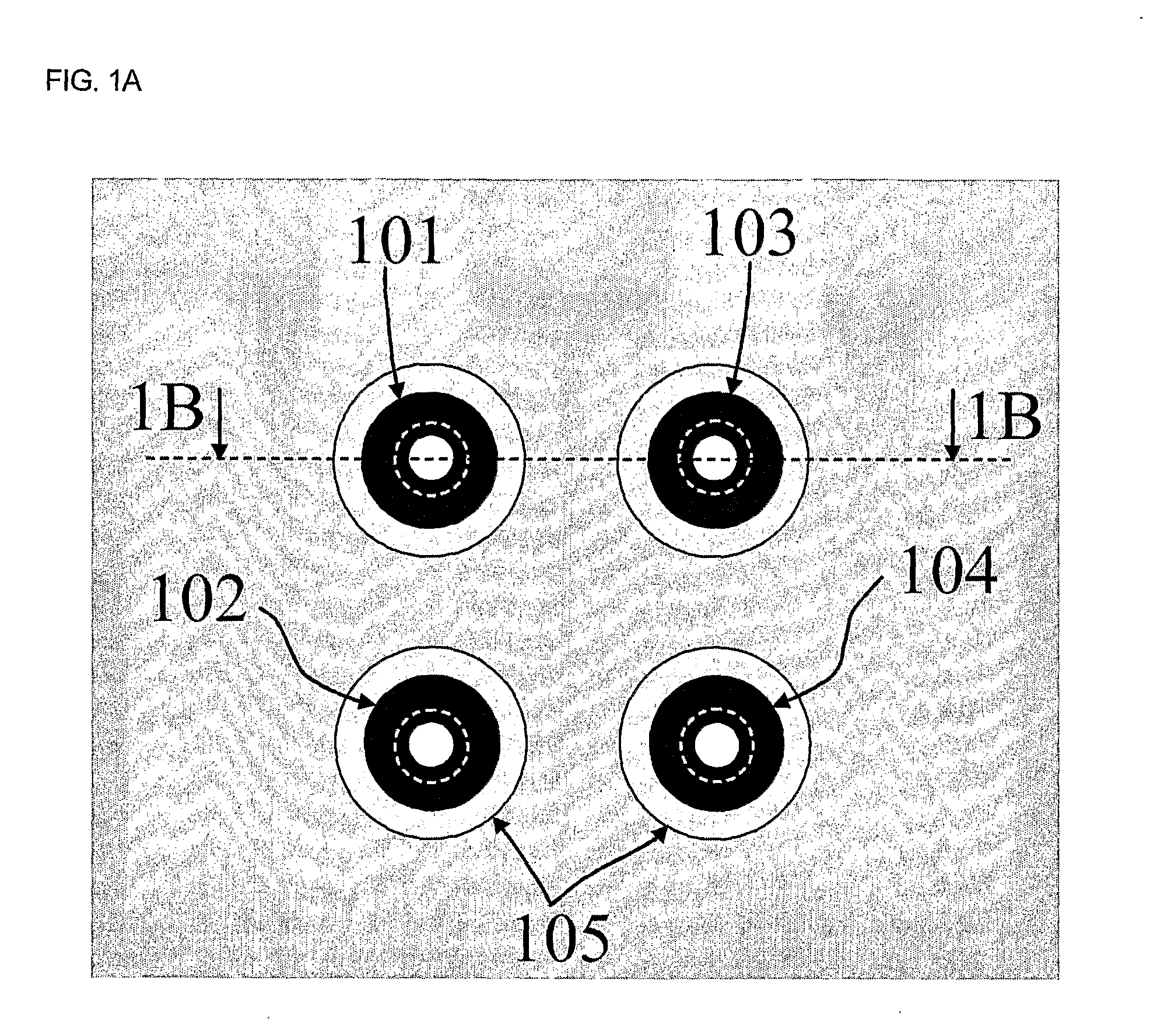

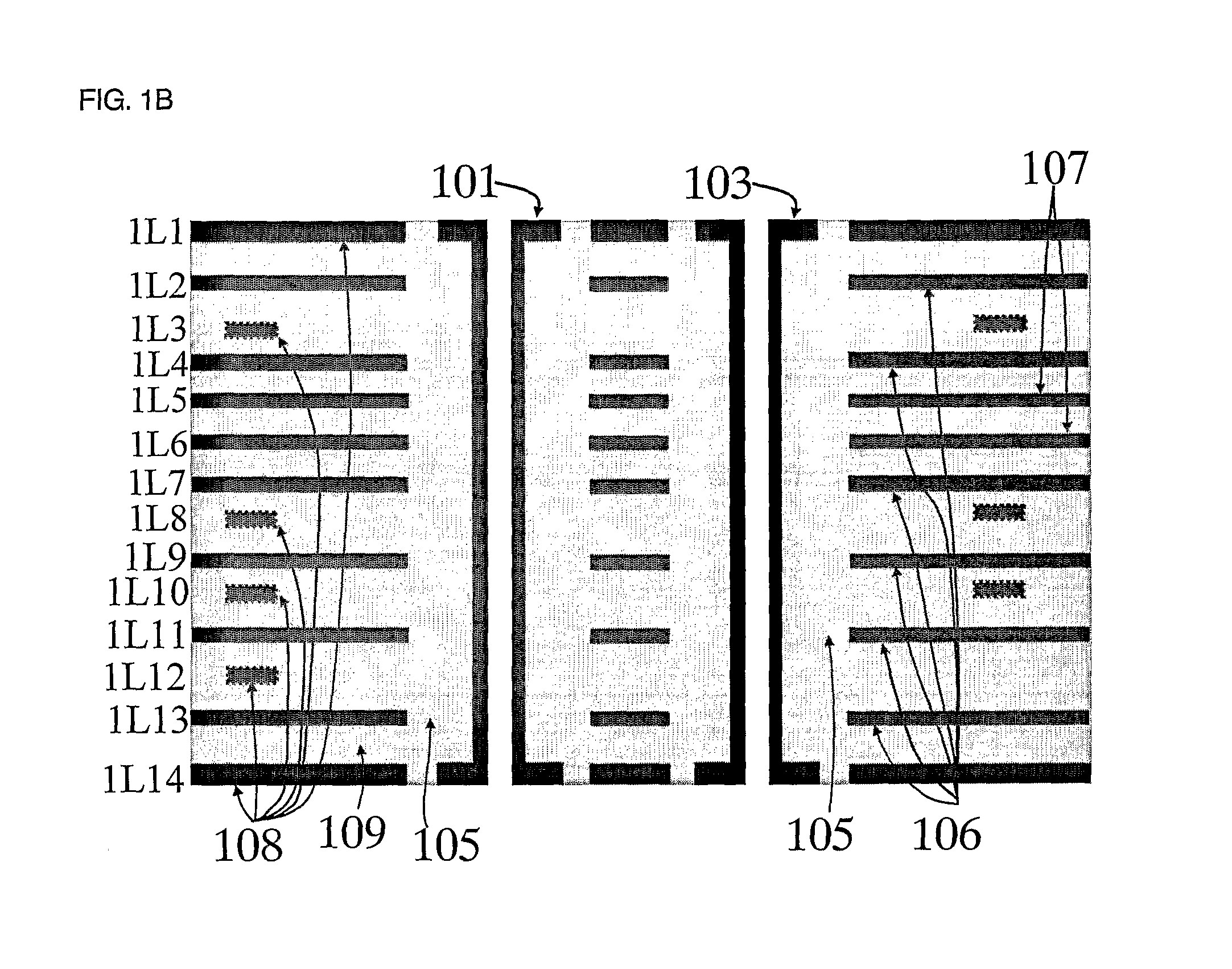

Multilayer substrate

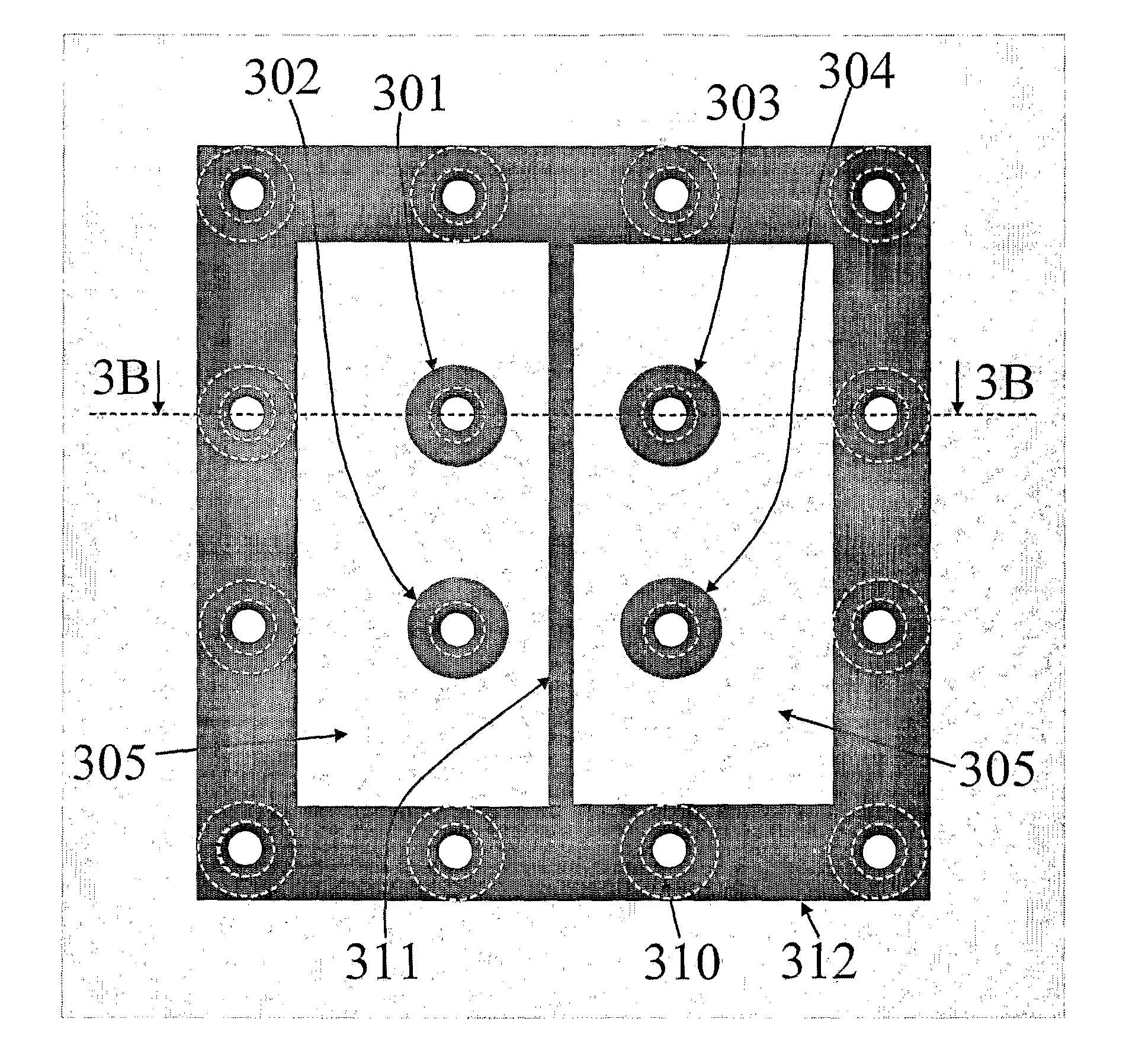

InactiveUS20110203843A1Avoid leakage lossLeakage loss increaseMagnetic/electric field screeningCross-talk/noise/interference reductionCompact dimensionBroadband

To provide more compact dimensions of a via structure formed by signal via pairs and ground vias in multilayer substrate. A multilayer substrate is provided such that the multilayer substrate comprising a high-isolated via cell wherein the high-isolated via cell comprises: two signal via pairs; a shield structure around two signal via pairs consisting of ground vias and ground strips connected to ground vias wherein the shield structure is formed symmetrically in respect to two via pairs to reduce the transformation between mixed modes and also leakage from two signal via pairs; a clearance hole separating signal via pairs from other conductive parts of the multilayer substrate and having predetermined dimensions to provide broadband operation of the high-isolated via cell; and the separating strip disposed symmetrically between said signal via pairs to provide crosstalk reduction between two signal via pairs and common mode decrease.

Owner:NEC CORP

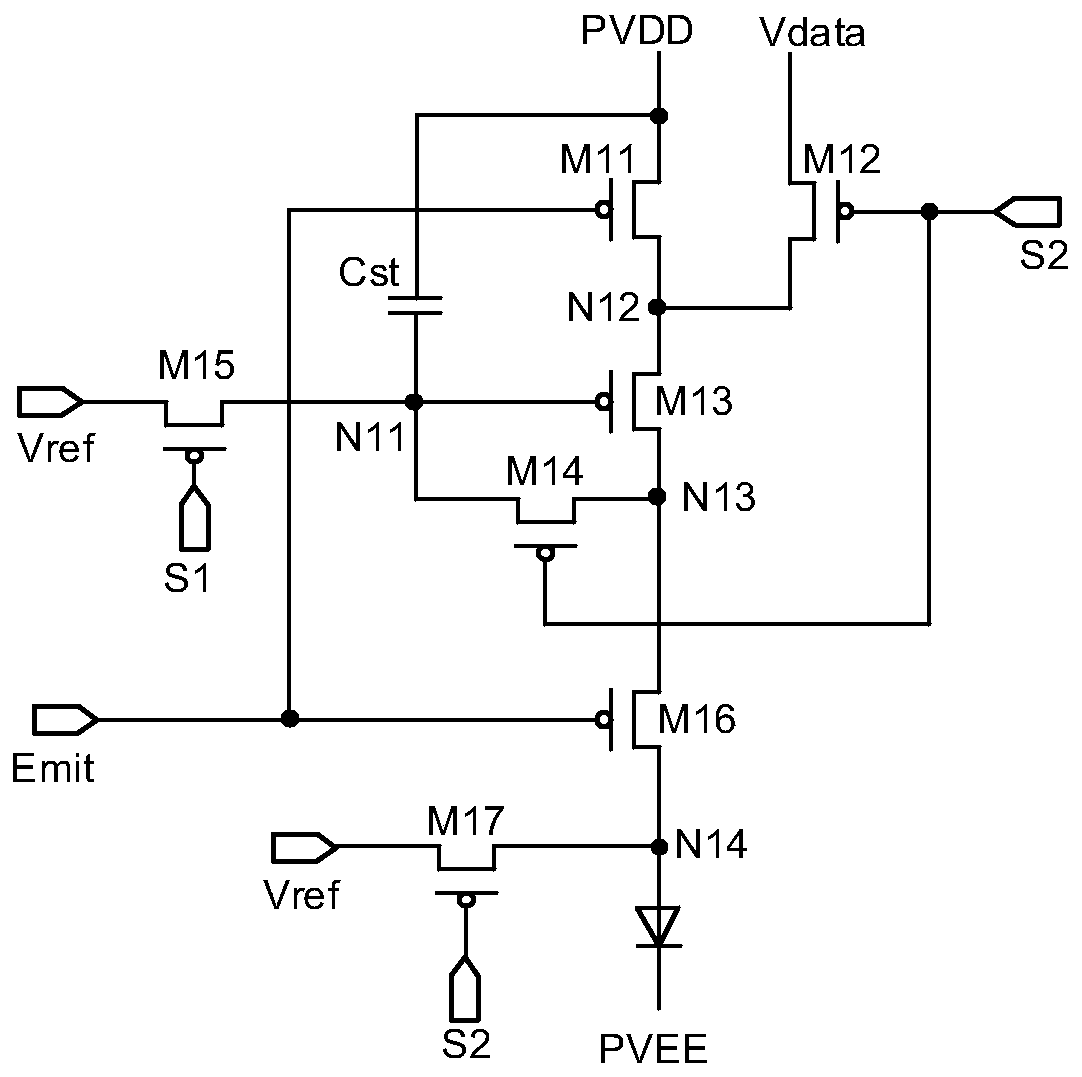

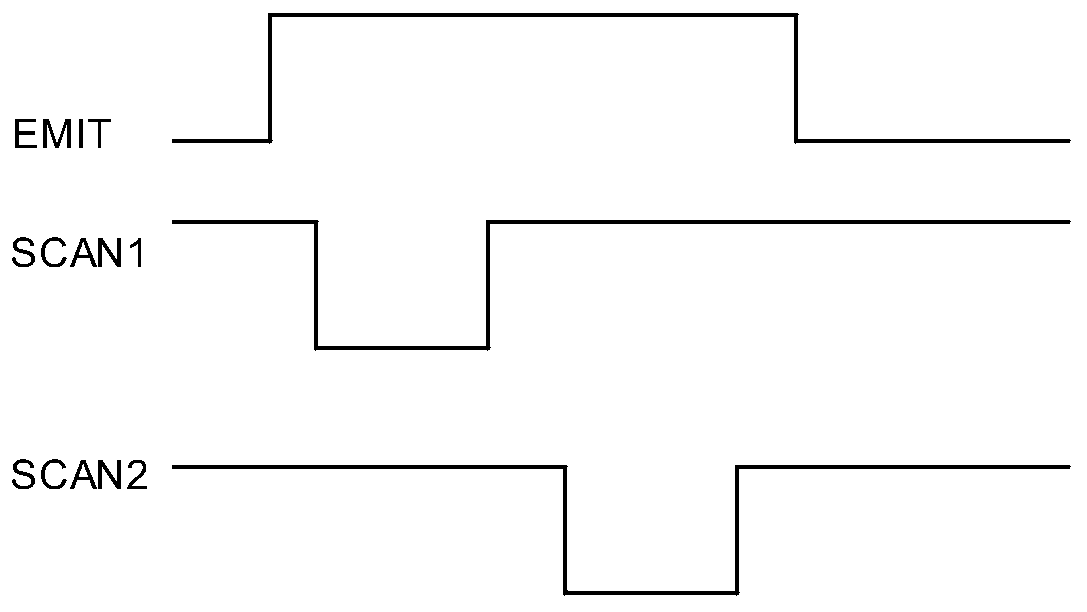

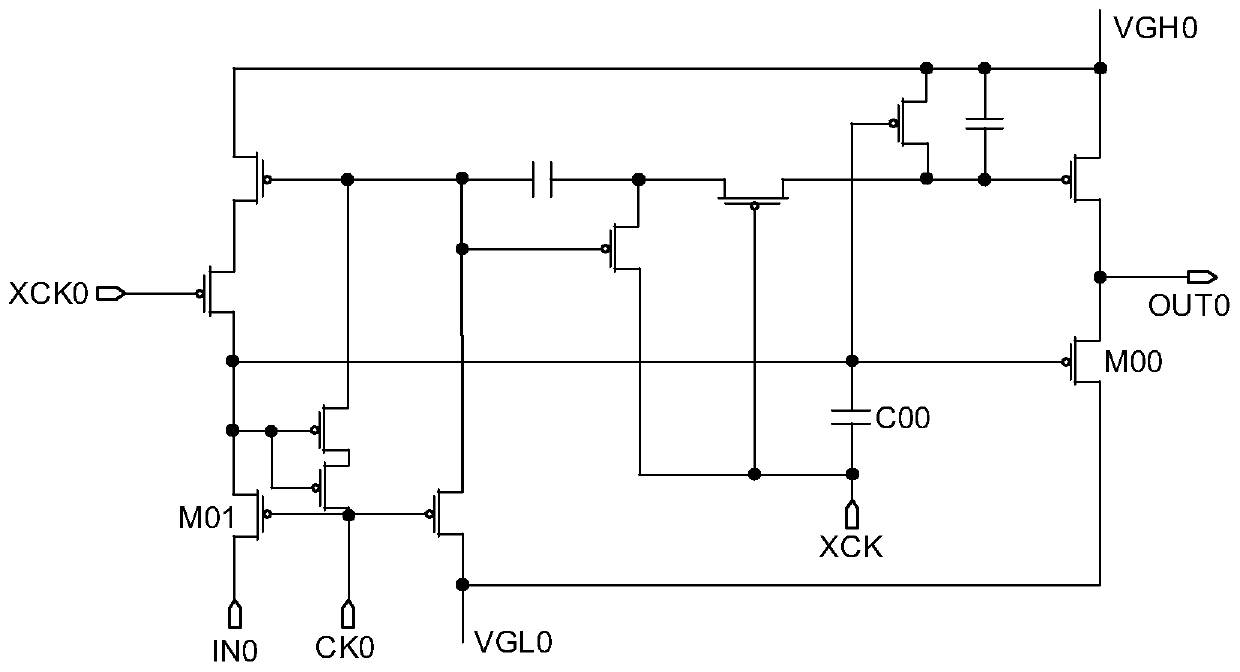

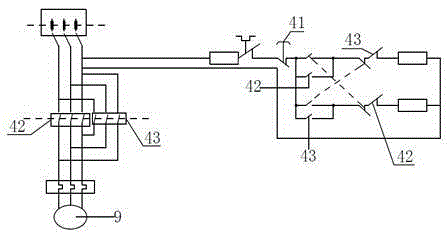

Shift register, gate drive circuit, display panel and display device

ActiveCN111145823ANo lossGood offStatic indicating devicesDigital storageShift registerDriver circuit

The invention discloses a shift register, a gate drive circuit, a display panel and a display device. The shift register comprises a second output module and a coupling module, and the two ends of thecoupling module are electrically connected with a third node and a second signal output end respectively. At the second stage, the potential of a fourth node is an enable potential, and the second output module transmits a high-potential signal of the first power supply signal input end to the second output end; at the third stage, the potential of the third node is an enable potential, and the second output module transmits a low-potential signal of the second power supply signal input end to the second output end, i.e., the signal of the second output end jumps from high to low, and at themoment, the low-potential signal of the second output end is coupled to the third node through the coupling effect of the coupling module, so that the potential of the third node is lower than that ofthe second stage, the low-potential signal of the second power supply signal input end has no transmission loss, the transistor controlled by the second signal output end can be completely turned off, and the leakage current loss is avoided.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

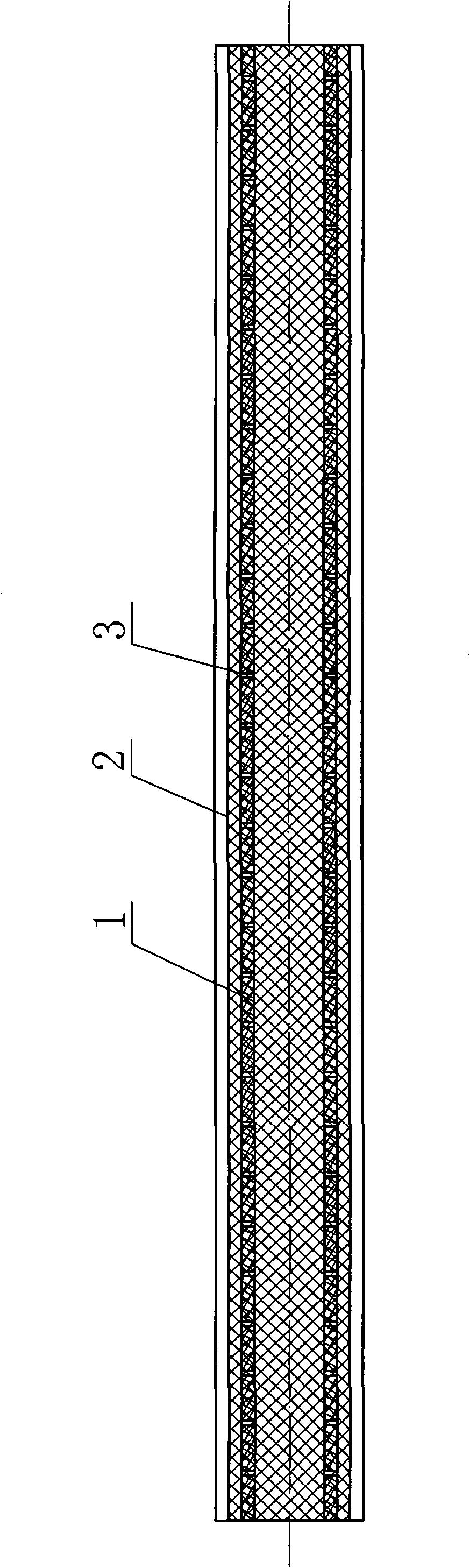

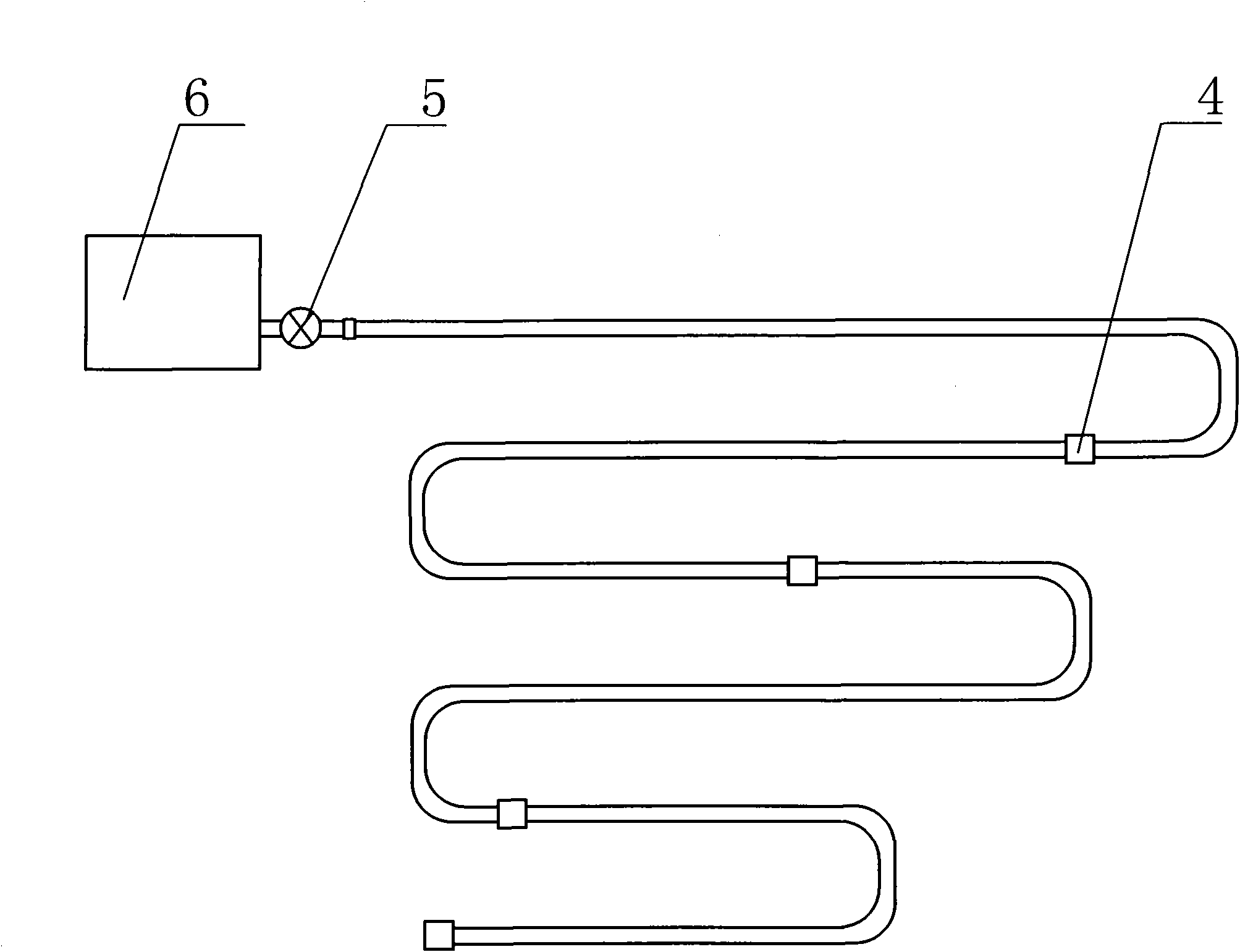

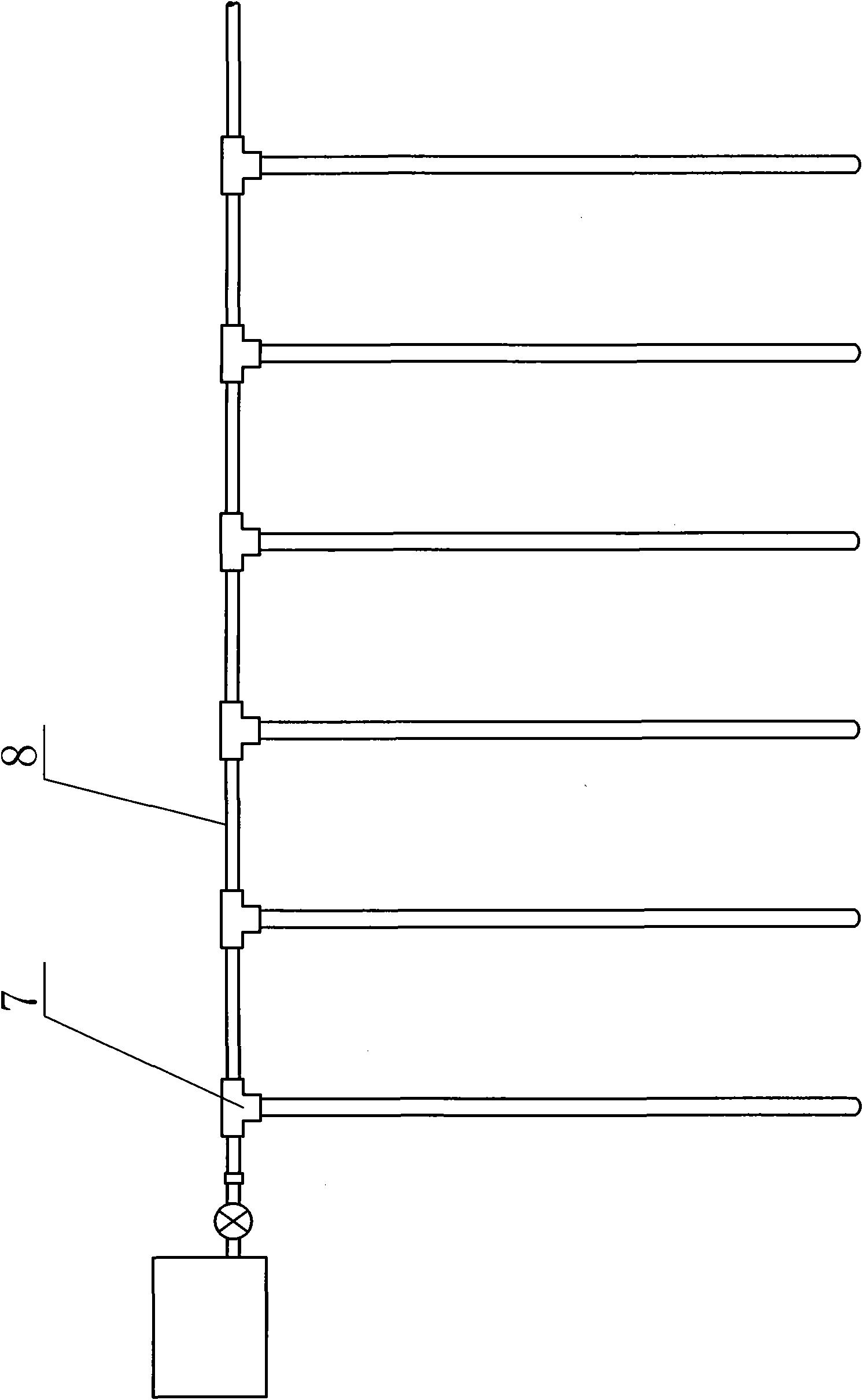

Micro-moistening pipe and micro-moistening irrigation system

InactiveCN102069044ASolve the problem of supply and demand mismatchAvoid or reduce evaporation lossWatering devicesSpray nozzlesWater savingAgricultural irrigation

The invention relates to a micro-moistening pipe and a micro-moistening irrigation system. The traditional agricultural irrigation methods, such as water irrigation, canal irrigation and the like, are coarse and low in efficiency, and the utilization rate of water is about 10%, therefore, the waste of water resources is astonishing, and a series of problems, such as soil salinization and the like, are easy to cause. For overcoming the disadvantages existing in the traditional irrigation, the irrigation methods, such as sprinkling irrigation, trickle irrigation and the like, are spread and applied at home and abroad, but when these irrigation methods are used, the utilization rate of water is only about 50%, and about half of irrigation water is still wasted. The micro-moistening pipe comprises a hose with a double-layer structure, and the hose is composed of an inner pipe (1), and an outer pipe (2) of a permeable protective sleeve, wherein the wall of the inner pipe is provided with micro through holes (3), and the diameter of the micro through hole is 10-900 nm. The micro-moistening pipe and the micro-moistening irrigation system provided by the invention are used for water-saving agricultural irrigation and water-saving reclamation on saline-alkali lands.

Owner:杨潇

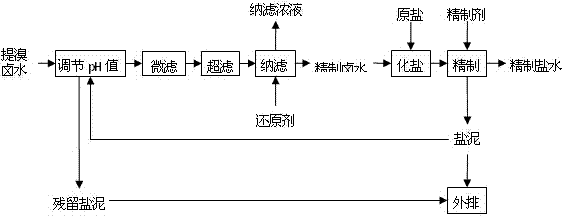

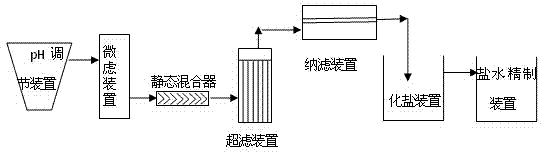

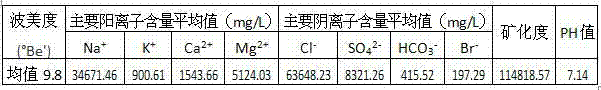

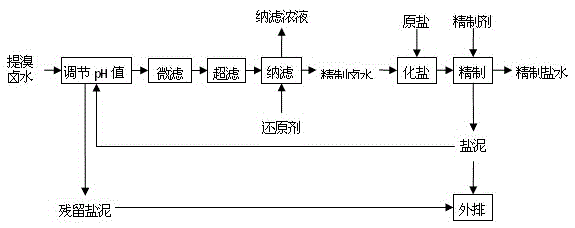

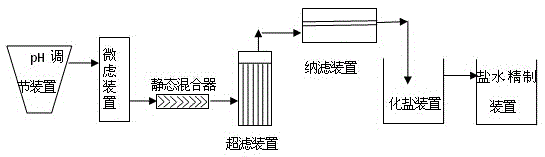

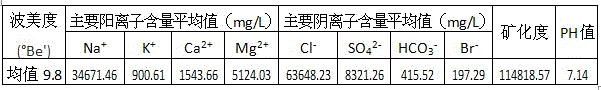

Method and device for producing refined brine by utilizing bromine extraction brine

ActiveCN104743582AReduce acidityReduce refining costsAlkali metal halide purificationSludgeSolid particle

The invention discloses a method and a device for producing refined brine by utilizing bromine extraction brine. The method comprises the following steps: adjusting the pH value of the bromine extraction brine to 5-8, intercepting solid particles and mechanical impurities through mechanical microfiltration, adding a reducing agent to remove oxidized substances, carrying out ultrafiltration to remove small particles, colloids and macromolecular organic compounds, then, removing most of sulphate radicals and calcium and magnesium ions through nanofiltration interception so as to obtain brine dissolved raw salt, preparing the brine dissolved raw salt into saturated brine, further refining to remove the calcium and magnesium ions by adopting a chemical method so as to obtain refined brine and brine sludge, and returning the brine sludge back to the first step to adjust the pH value of the bromine extraction brine. By means of the method disclosed by the invention, high-efficiency utilization of sodium chloride in the bromine extraction brine is realized; the sun-curing and dissolving processes of a part of sodium chloride are saved; the leakage loss of underground salt brine resources in the salt basking process is avoided; the recovery rate of raw salt in the bromine extraction brine is increased; furthermore, the brine refining cost of a sodium carbonate factory is lowered, so that the production cost is lowered.

Owner:CHINA NAT OFFSHORE OIL CORP +1

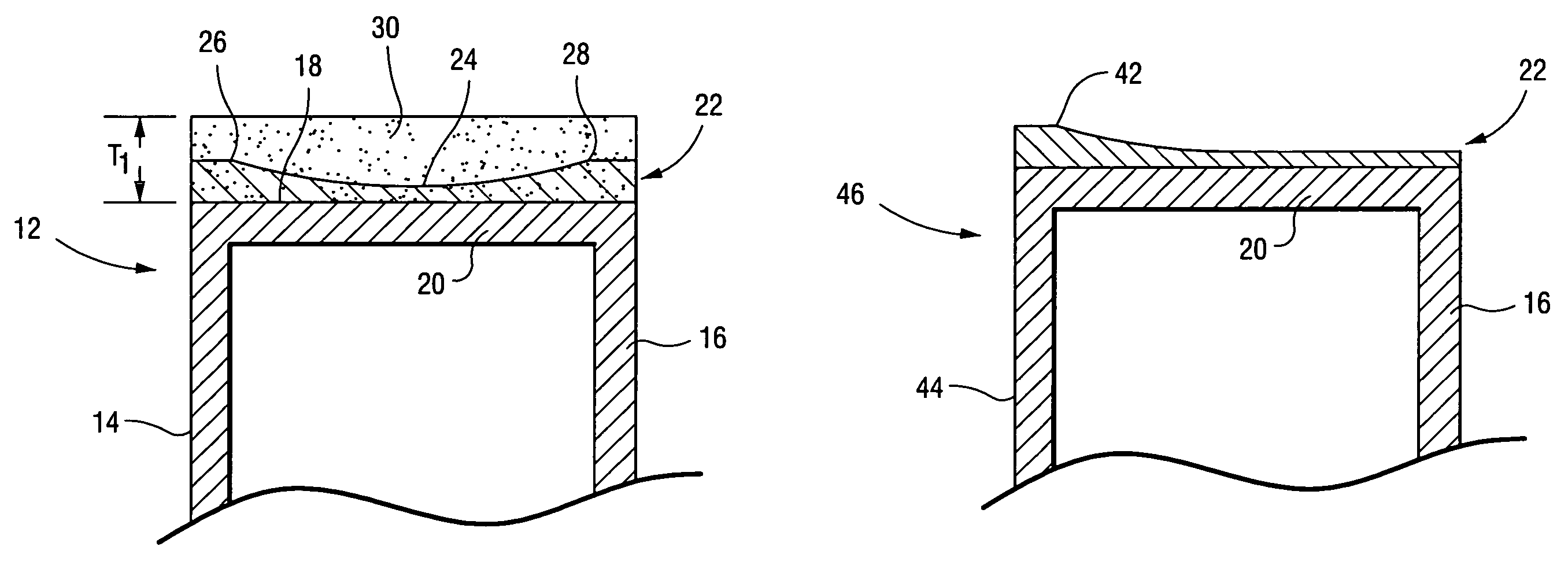

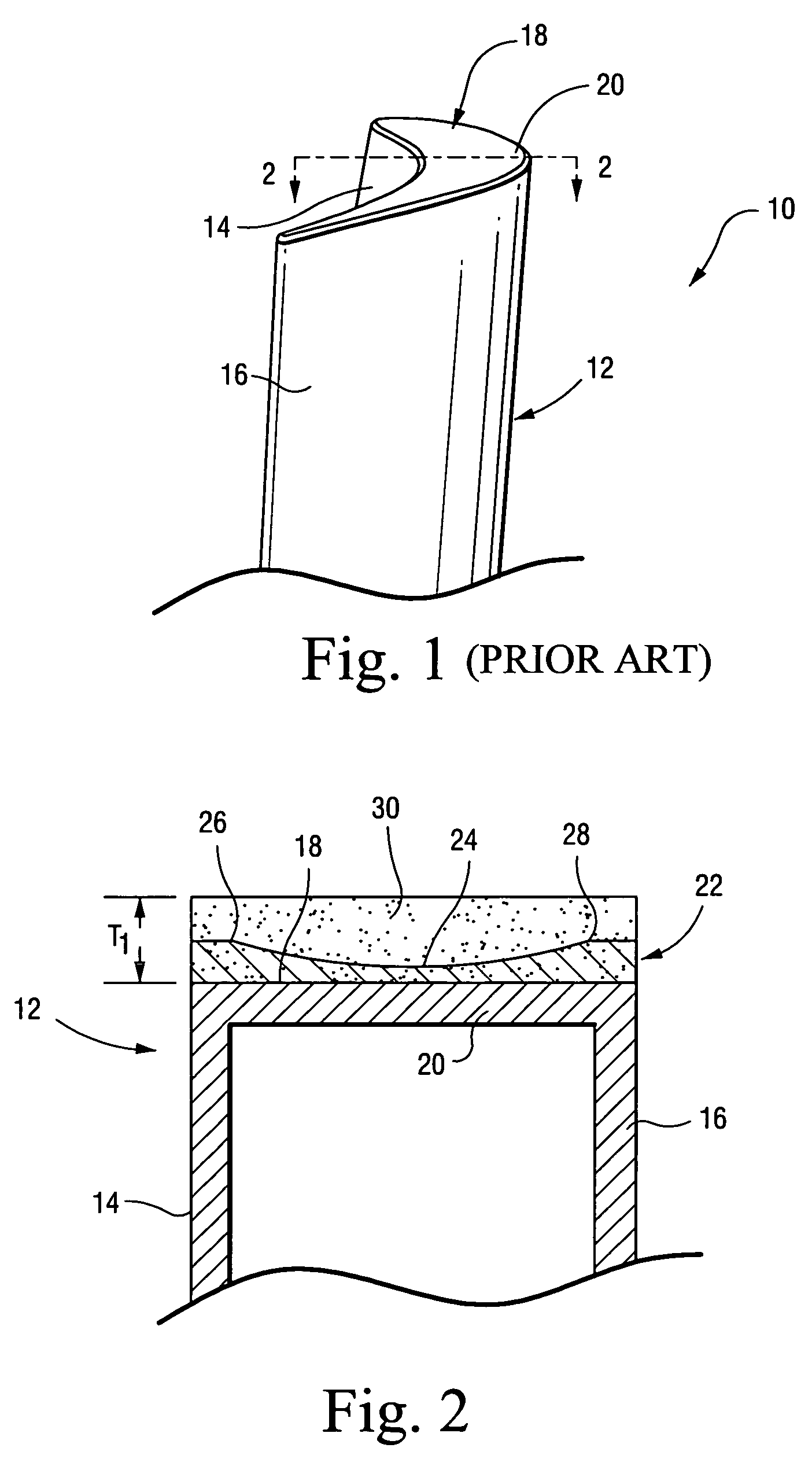

Seal for a toner cartridge assembly

InactiveUSRE36920E1Avoid lostAvoid lossElectrographic process apparatusEngineeringMechanical engineering

A seal for a toner cartridge assembly used in printers, copy machines and facsimile machines. The seal is a strip which can be torn out so as to define an opening for the passage of toner. The strip has a structure which lowers the tearing force required when starting to tear the strip with respect to the tearing force required for other parts of the seal, or the seal has a structure which increases the binding of parts of the seal adjacent to the strip on the cartridge.

Owner:BMT LIMITED

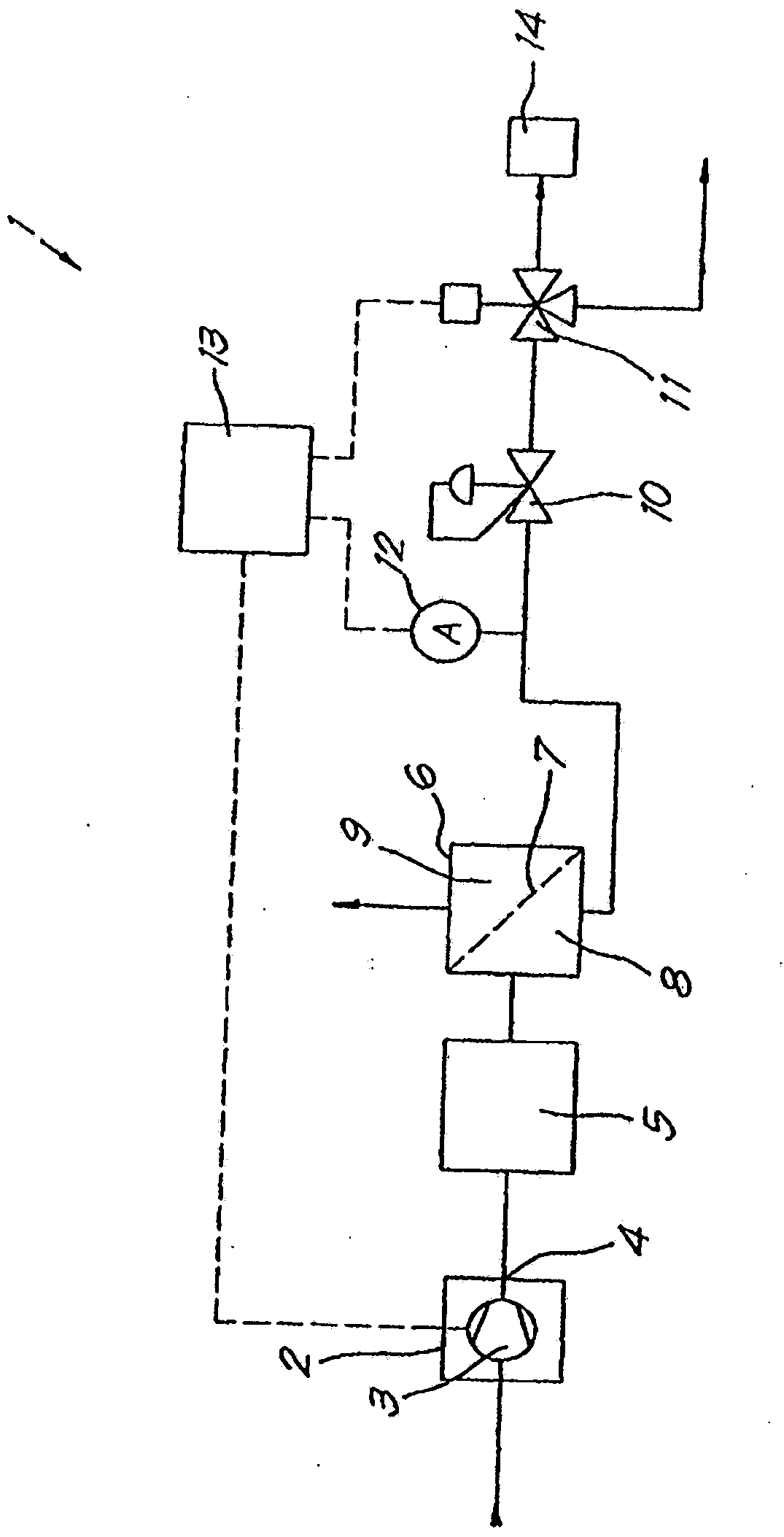

Method and measurement probe for the performance of measurements in water supply systems

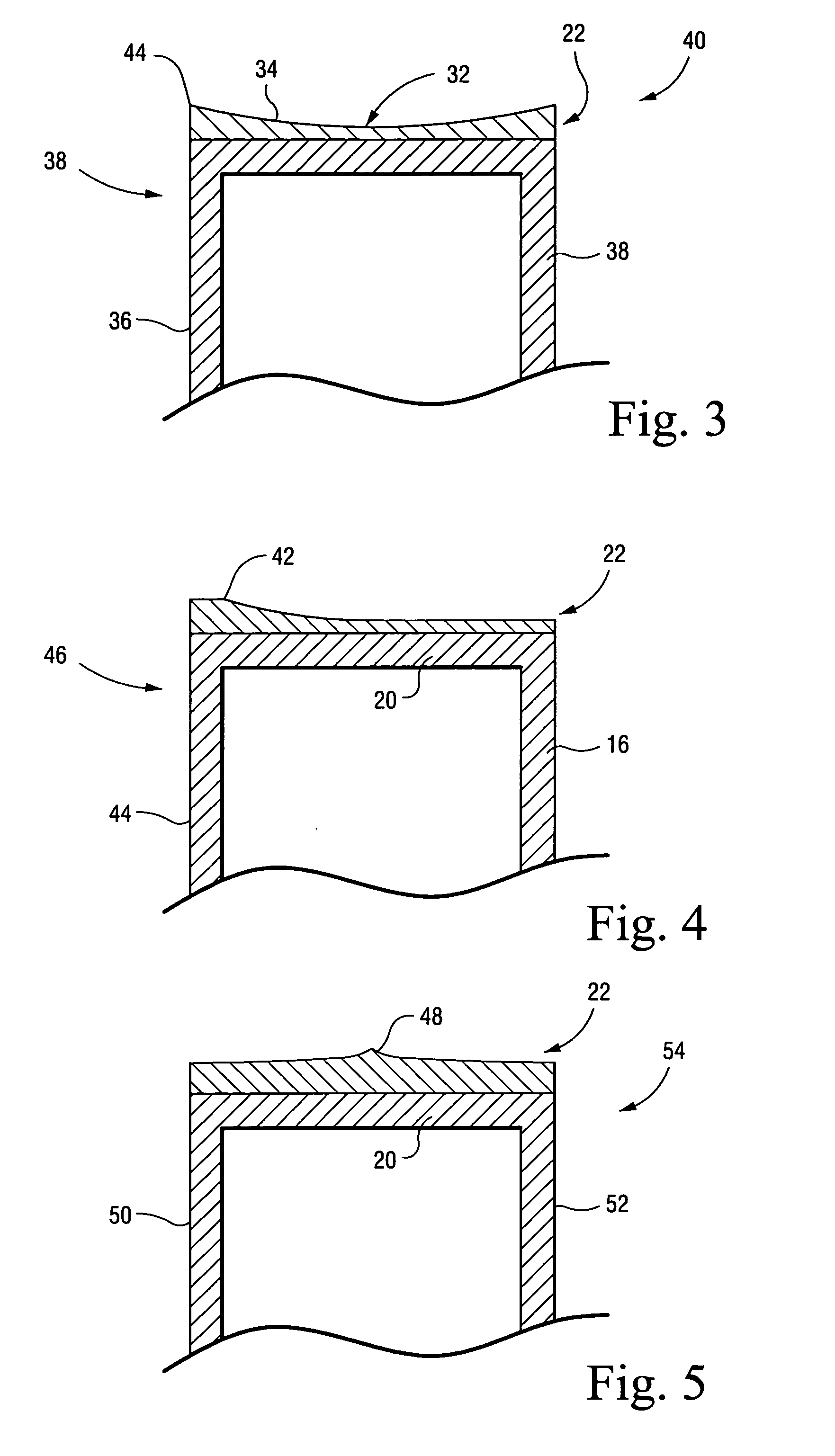

InactiveUS20030204338A1Avoid leakage lossMassive lossDetection of fluid at leakage pointMeasurement of fluid loss/gain rateModem deviceMeasurement point

Measuring elements for the output of measured quantities in respect of the flow, namely the flow quantity and direction, the water pressure and the flow noise are integrated in a measurement probe (1) for water supply networks (13), whereby all these measuring elements are connected or can be connected to a data collector (12) by means of transmission by radio, modem or cable connection. The measurement probes are installed permanently at the key points (10) and at the most varied measurement points (11) following one another as closely as possible in the water supply network (13) and can thus contribute, by delivering all the necessary data, to the rapid tracing of leaks with pinpoint accuracy as well as to constant monitoring. (FIG. 3).

Owner:MARTINEK PETER

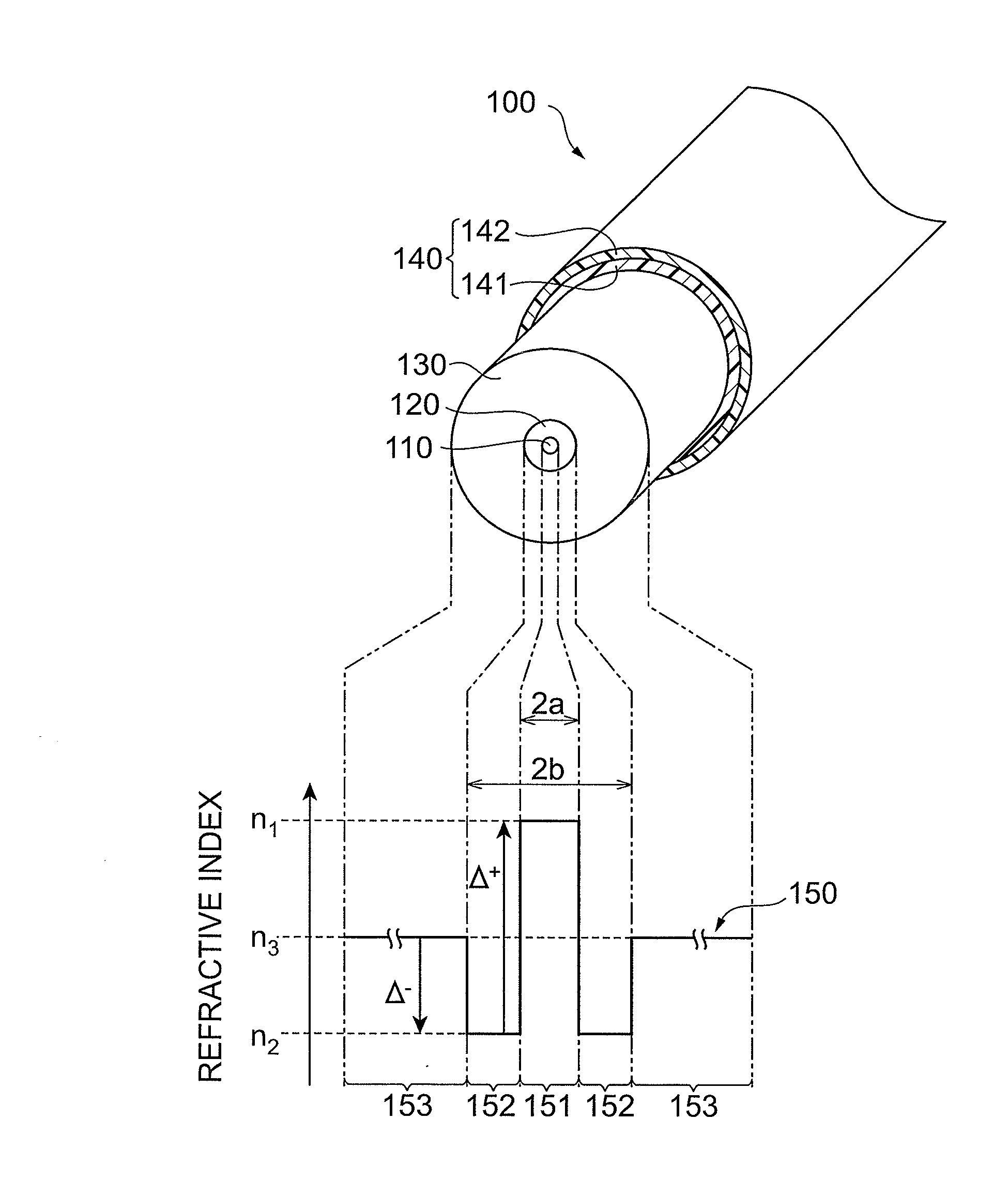

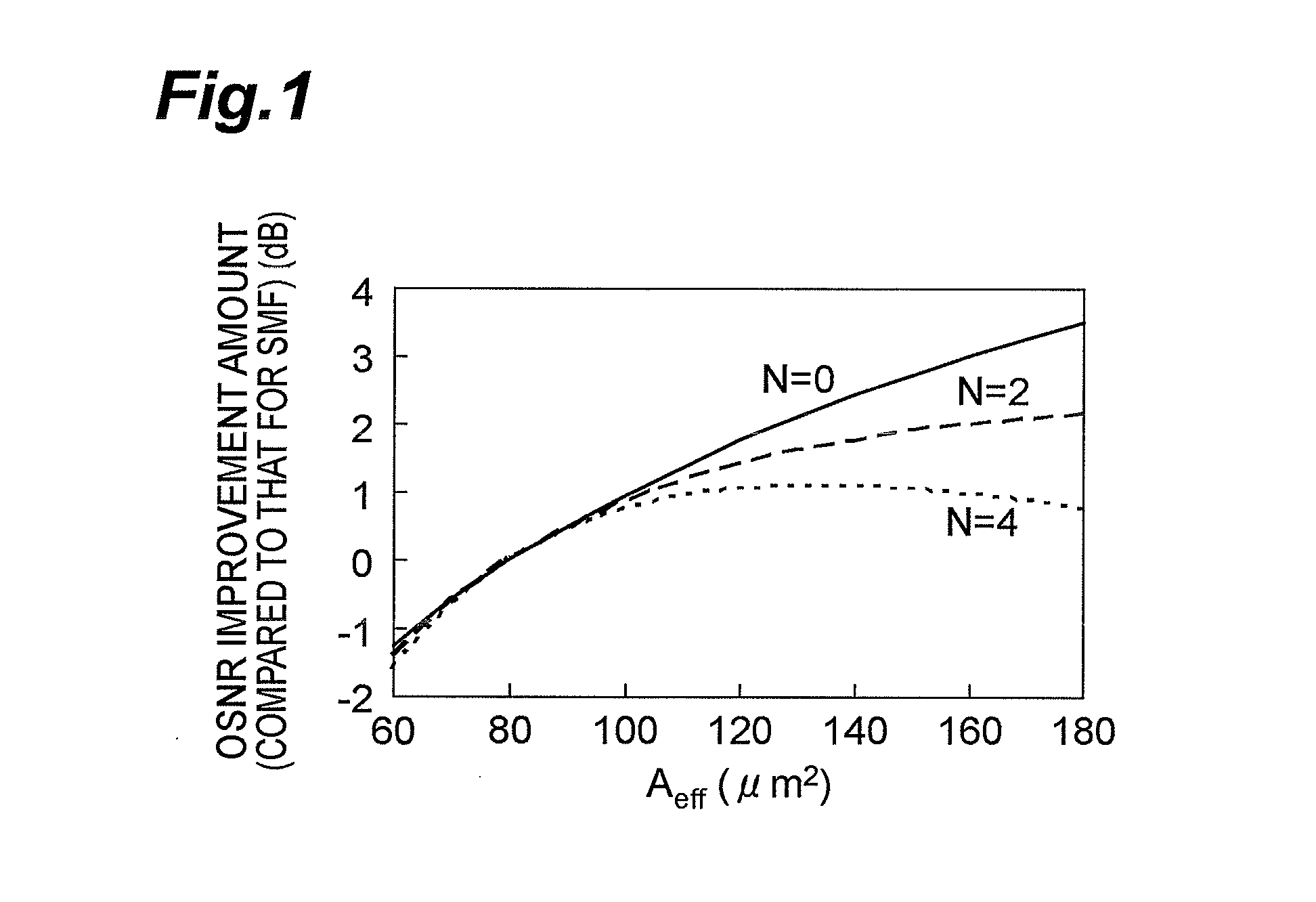

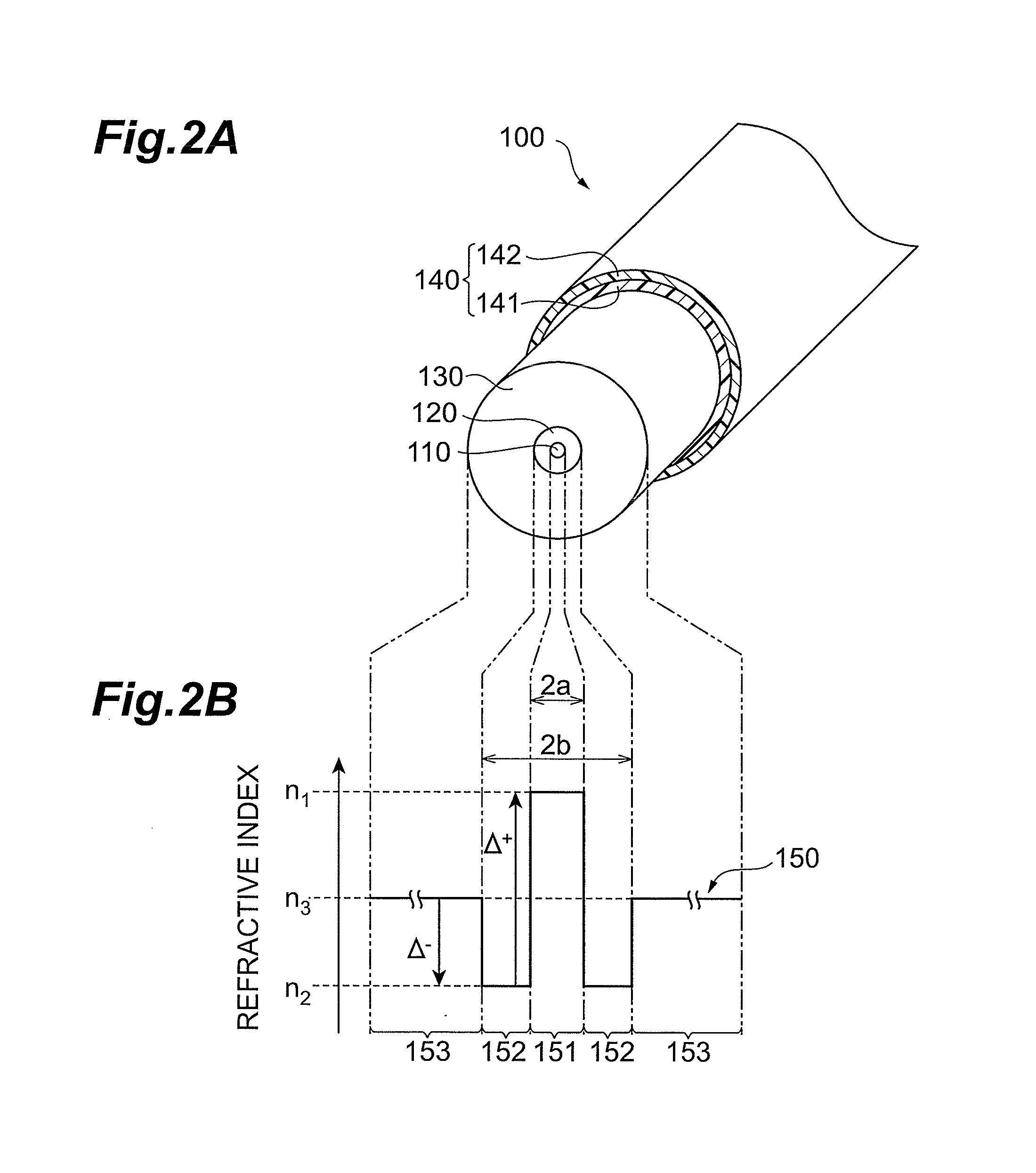

Optical fiber and optical communication system including same

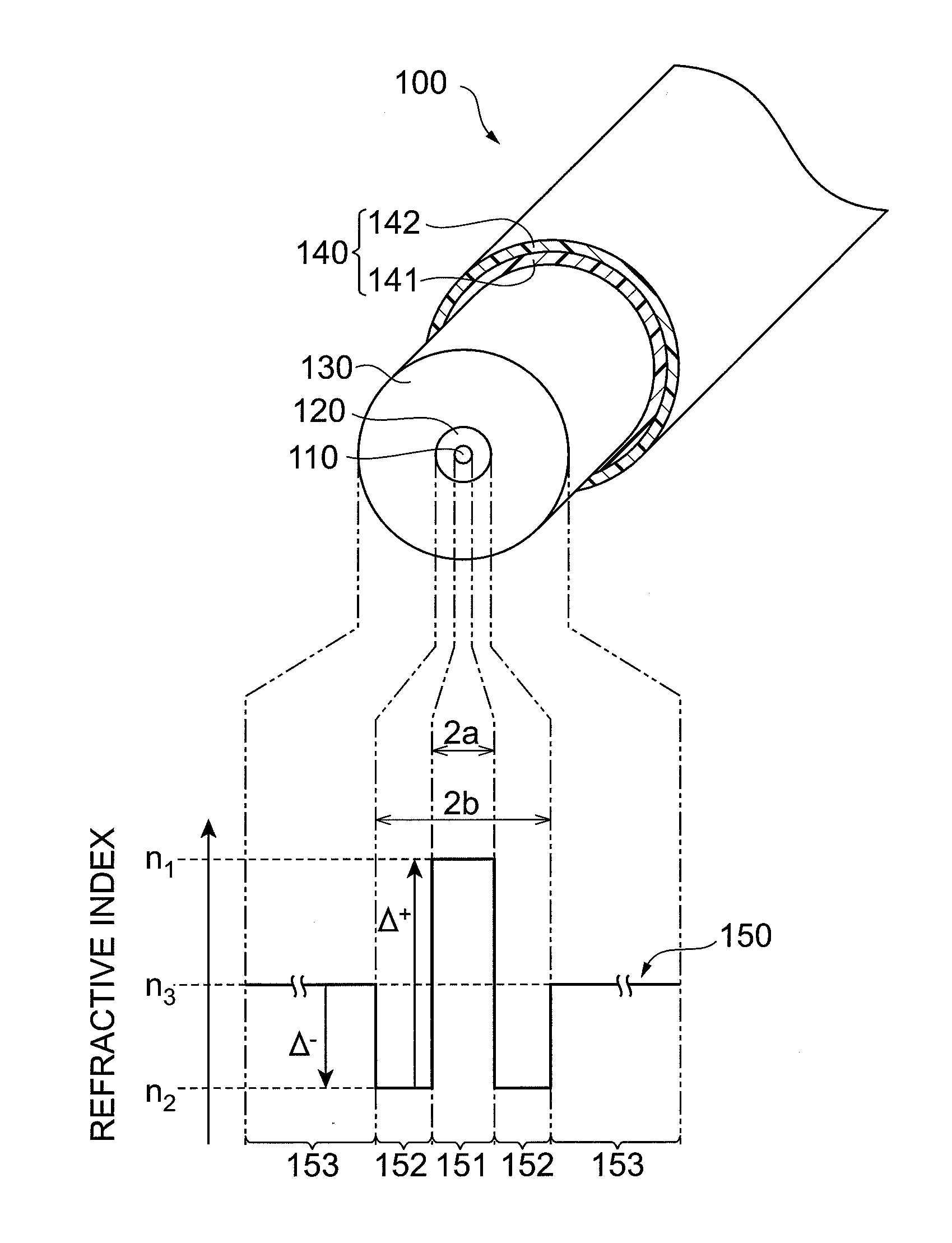

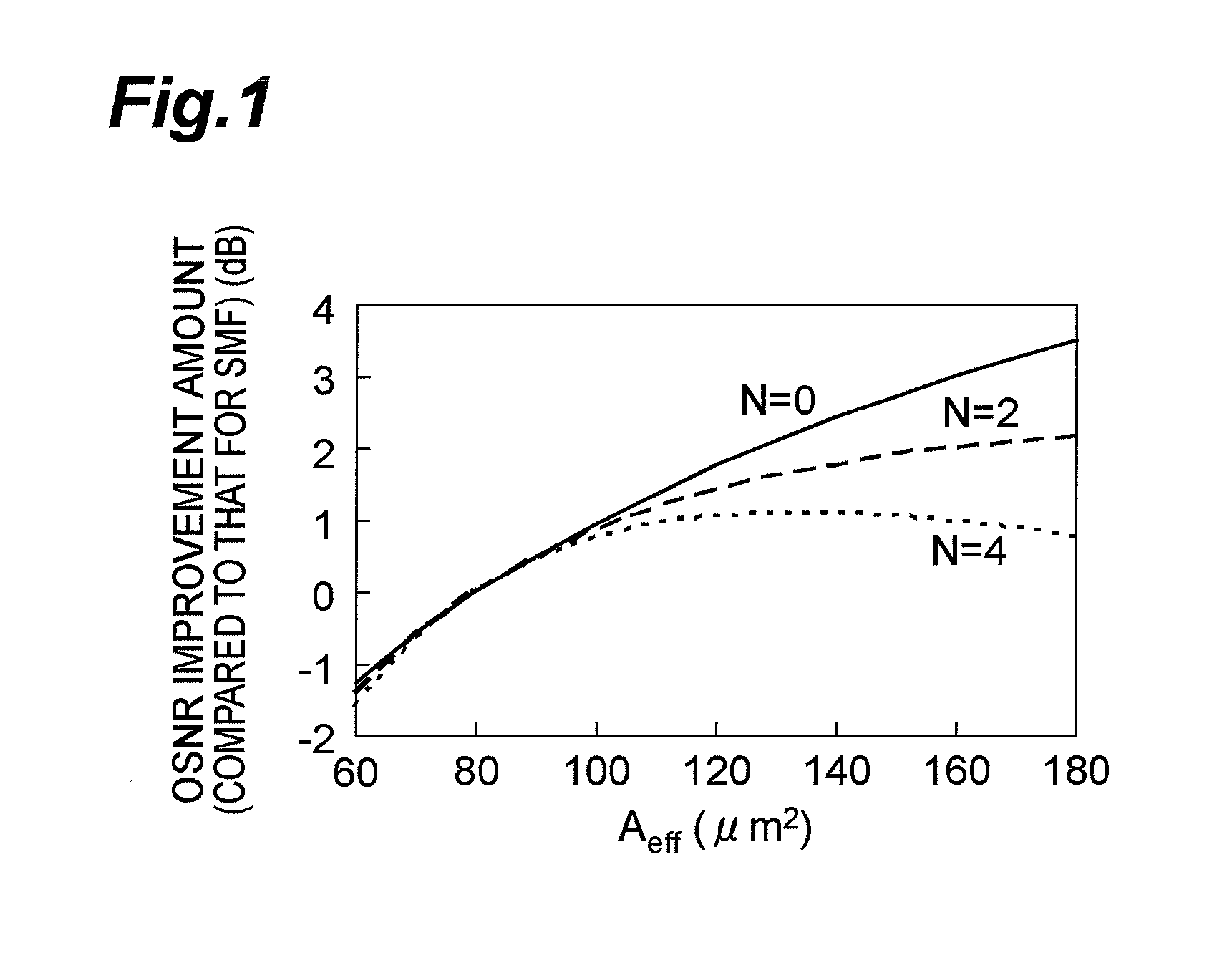

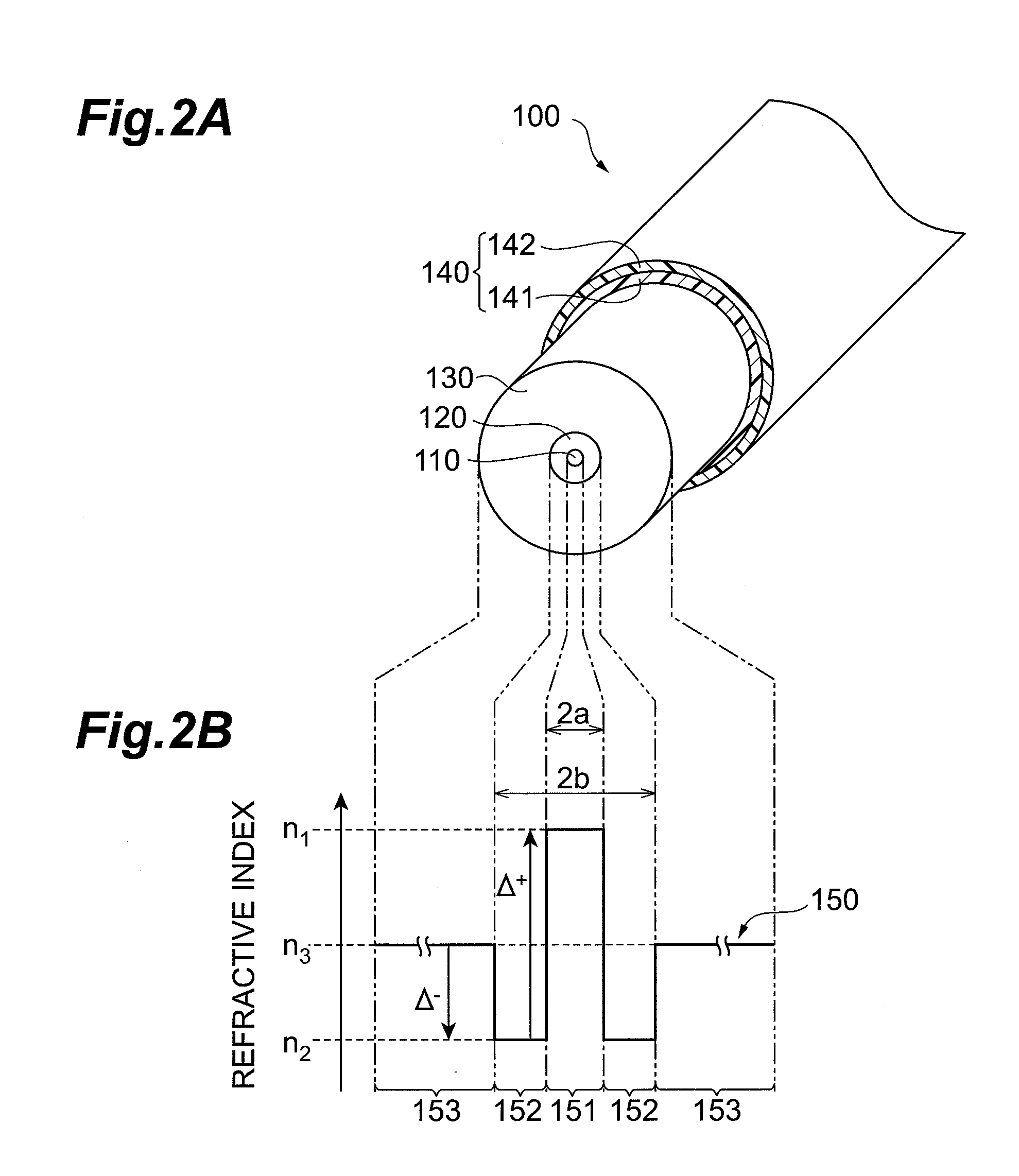

ActiveUS20110211788A1High powerEnhance the imageGlass optical fibreCoupling light guidesPhysicsRefractive index profile

The invention relates to an optical fiber employable in an optical communication system using Raman amplification and adapted to improve OSNR and suppress bending loss at the same time, and the like. The optical fiber is a silica-based optical fiber having a depressed refractive index profile constituted by at least a core, an inner cladding having a low refractive index, and an outer cladding, an effective area Aeff of 110 μm2 or more at the wavelength of 1550 nm, and a fiber cutoff wavelength λC of 1.3 μm or more but 1.53 μm or less. The depressed refractive index profile is designed such that the ratio Ra(=2b / 2a) of the diameter of the inner cladding to the diameter of the core is 2.5 or more but 3.5 or less and that the relative refractive index difference Δ− of the inner cladding with respect to the outer cladding is at least the relative refractive index difference Δ−min where the bending loss at the wavelength for use is minimized but not exceeding (Δ−min+0.06) %.

Owner:SUMITOMO ELECTRIC IND LTD

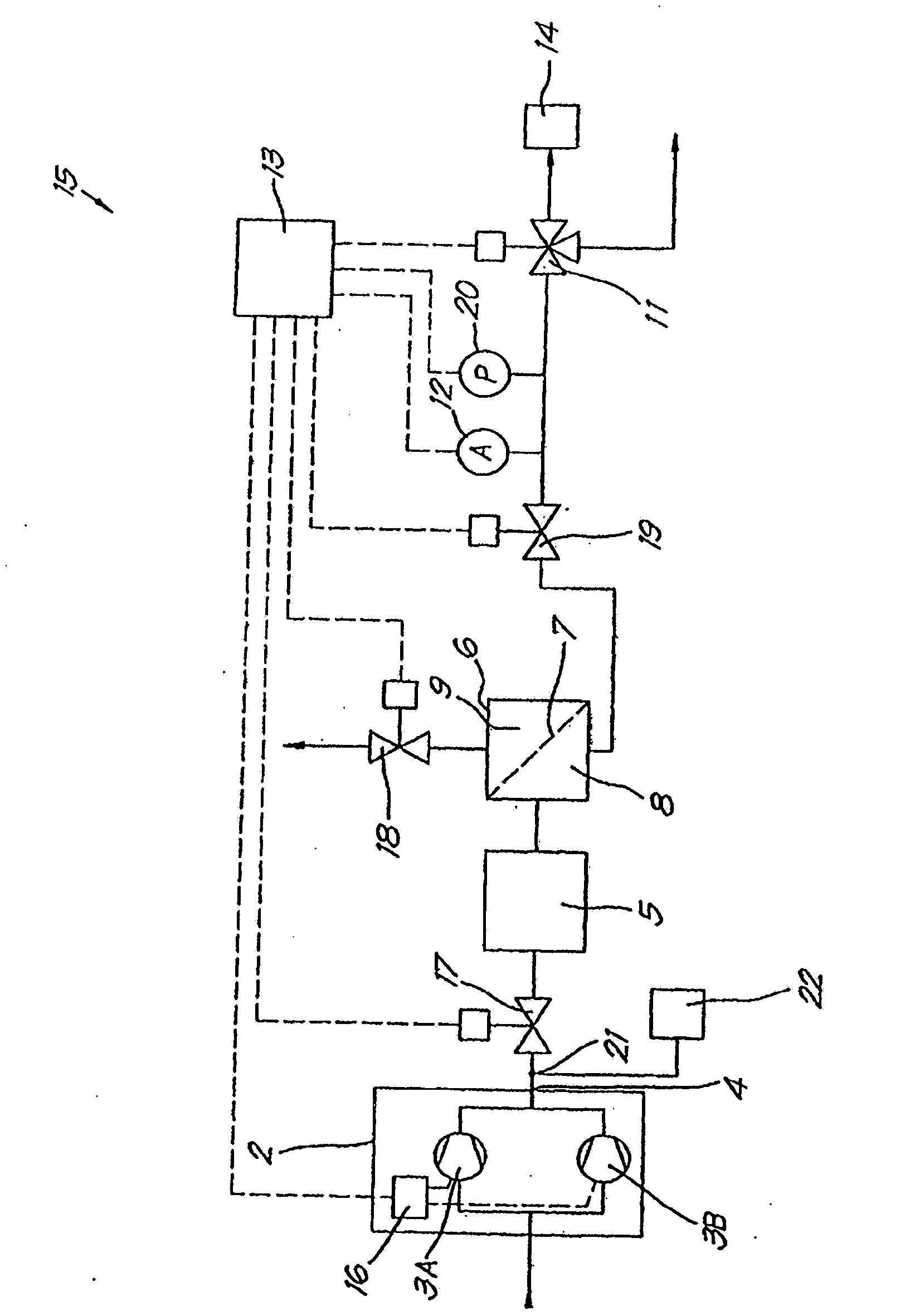

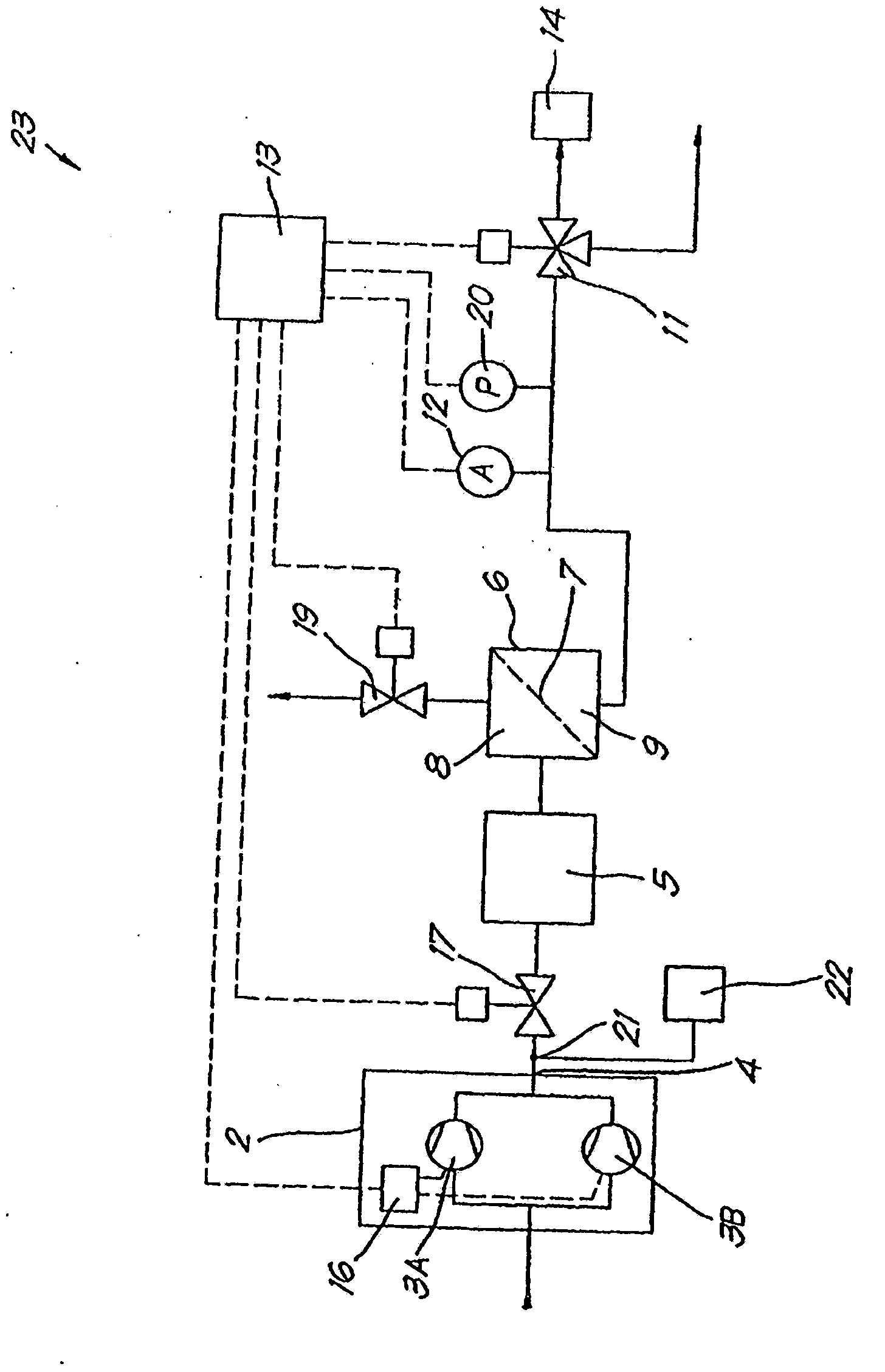

Method and measurement probe for the performance of measurements in water supply systems

InactiveUS20060048563A1Avoid leakage lossMassive lossDetection of fluid at leakage pointMeasurement of fluid loss/gain rateModem deviceMeasurement point

Measuring elements for the output of measured quantities in respect of the flow, namely the flow quantity and direction, the water pressure and the flow noise are integrated in a measurement probe (1) for water supply networks (13), whereby all these measuring elements are connected or can be connected to a data collector (12) by means of transmission by radio, modem or cable connection. The measurement probes are installed permanently at the key points (10) and at the most varied measurement points (11) following one another as closely as possible in the water supply network (13) and can thus contribute, by delivering all the necessary data, to the rapid tracing of leaks with pinpoint accuracy as well as to constant monitoring.

Owner:MARTINEK PETER

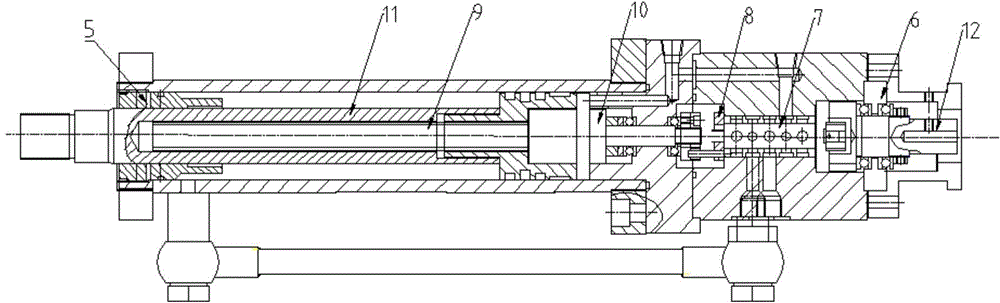

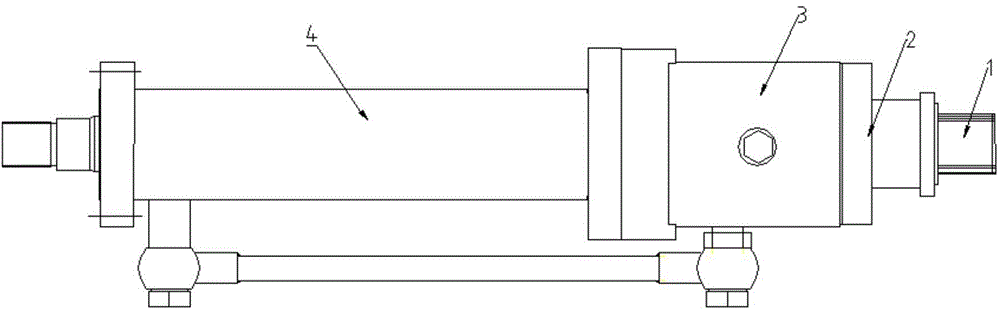

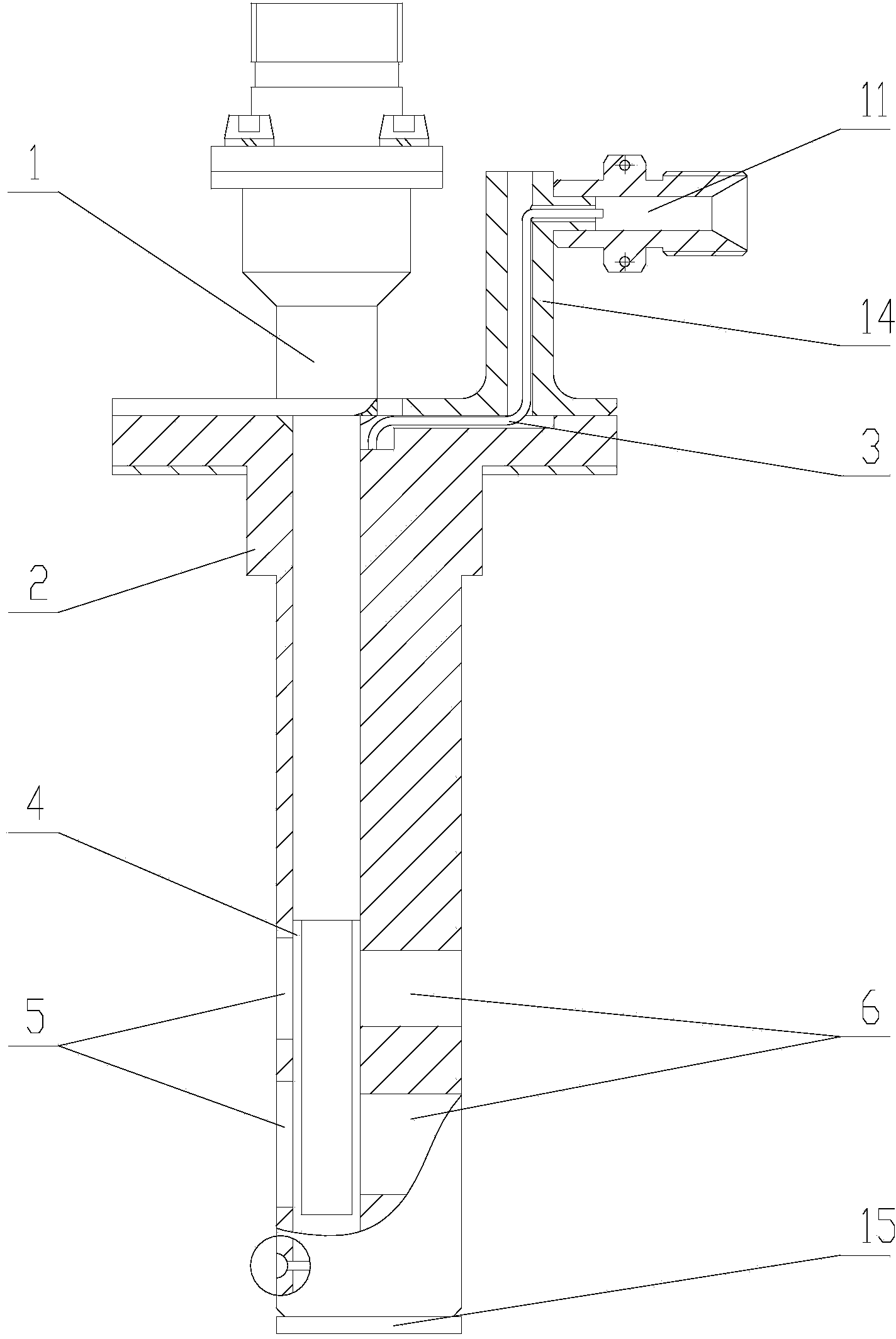

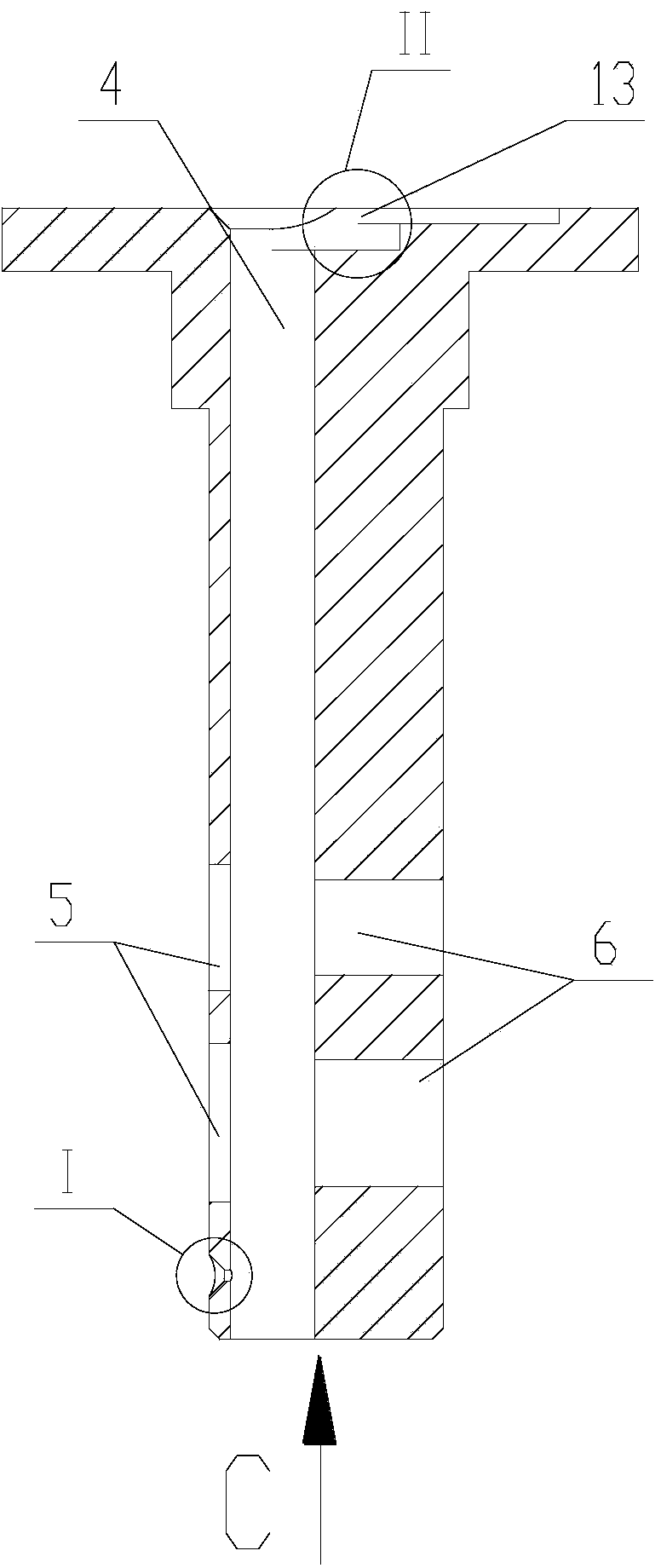

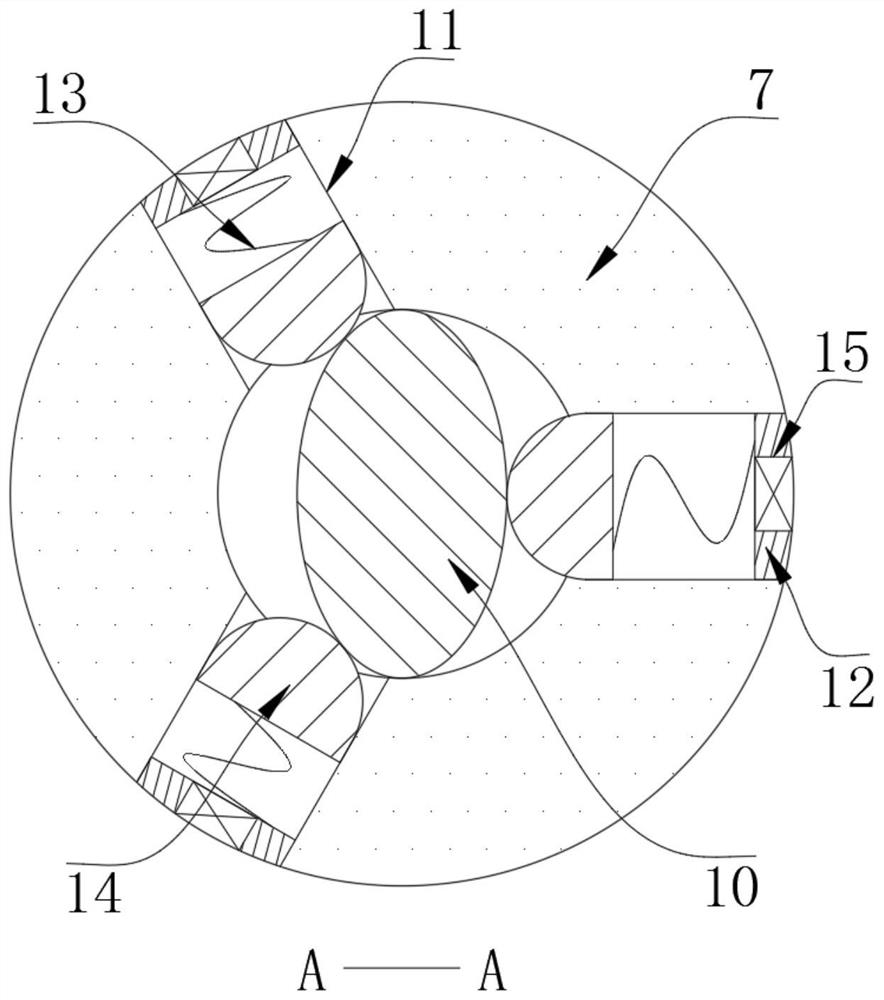

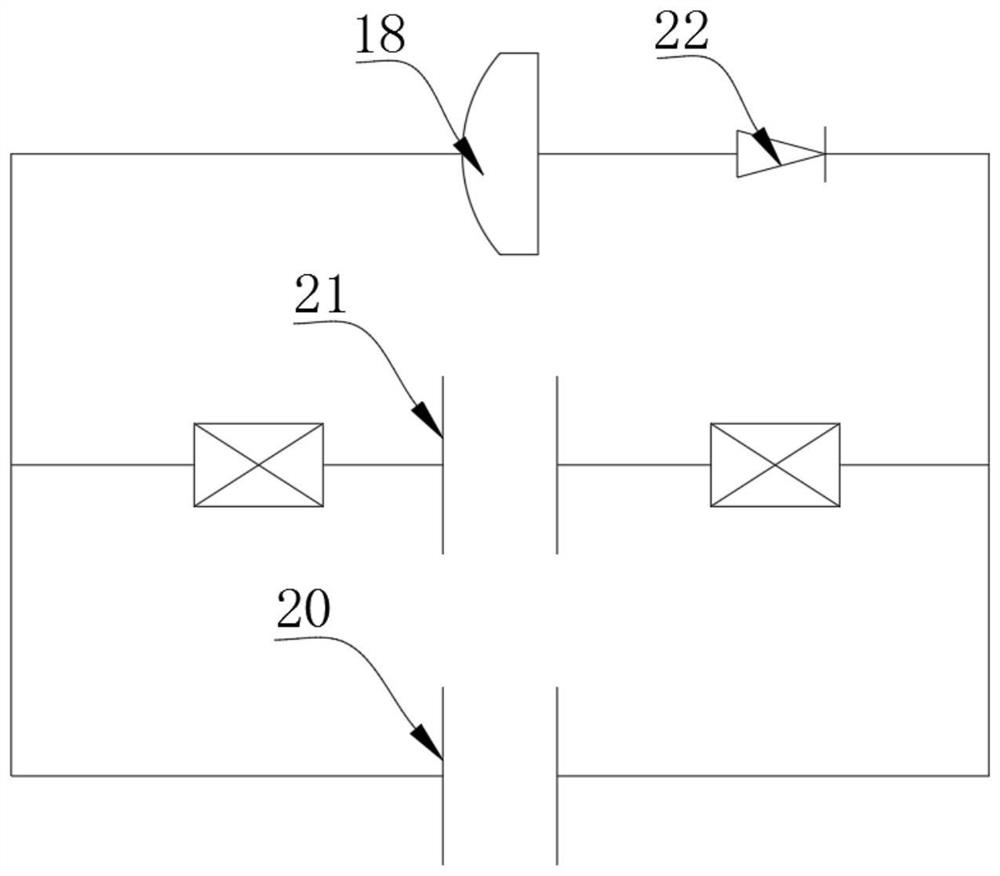

Digital servo hydraulic cylinder

InactiveCN104930014AImprove anti-pollution performanceAvoid leakage lossFluid-pressure actuatorsSynchronous motorClosed loop

The invention relates to the field of mechanical digital control, in particular to a digital servo hydraulic cylinder. A stepping motor directly drives a valve spool, large closed-loop control is realized by the aid of mechanical rigid feedback, leakage loss of a pilot stage is avoided by direct-acting design, the anti-pollution capacity of a valve is improved, a hydraulic system is simplified, single-cylinder multistage speed and directions can be controlled, multi-cylinder synchronous and reverse synchronous control and multi-cylinder interpolated linkage real-time control can also be realized, bidirectional data exchange with a field bus and an Ethernet can be performed, and the digital servo hydraulic cylinder has bus control and continuous control functions.

Owner:上海美西为机电设备有限公司

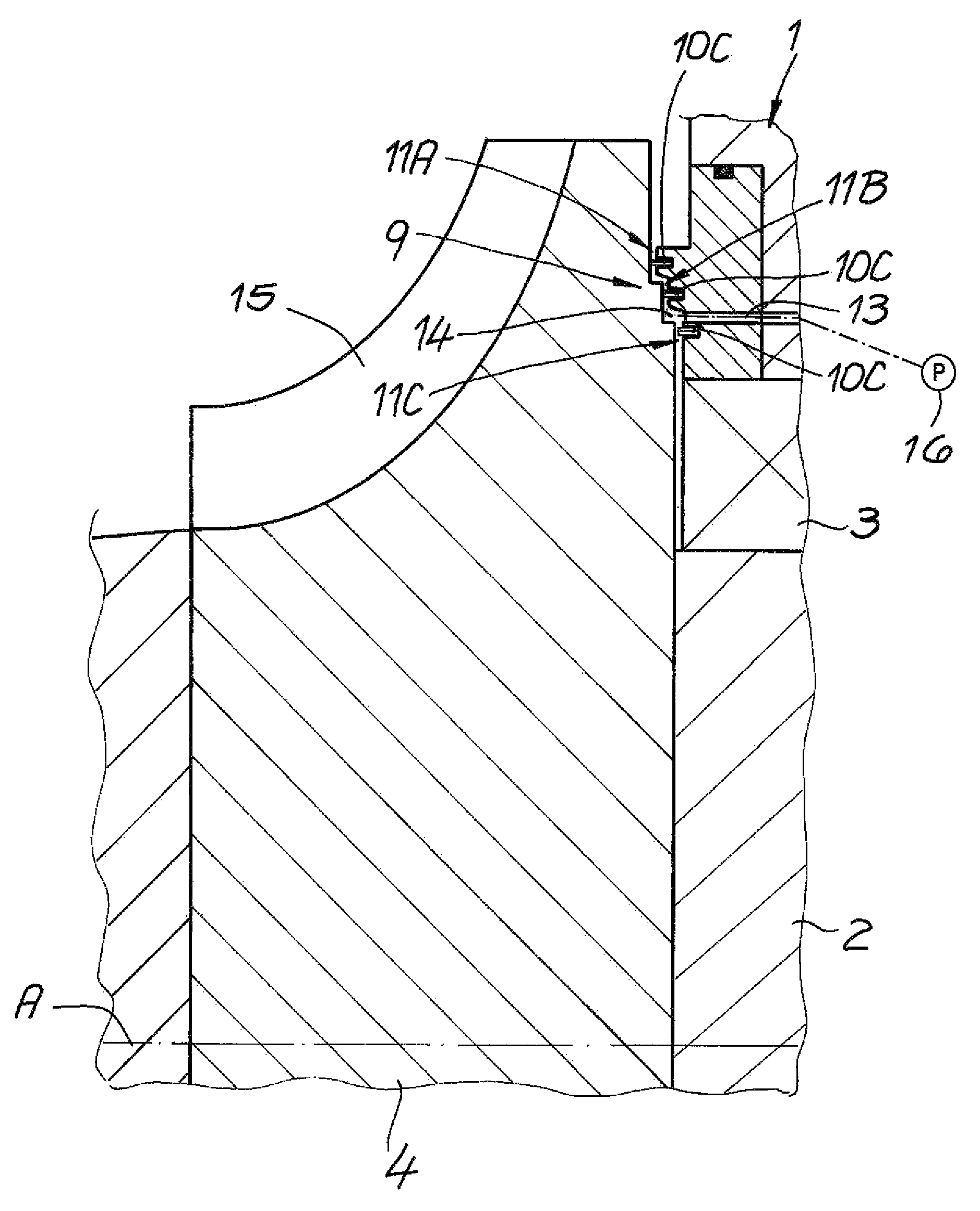

Axial shaft seal for a turbomachine

ActiveUS9133725B2Improve sealingDynamic rotational behavior of the rotor is significantly improvedEngine sealsPump componentsImpellerEngineering

A turbomachine has a housing having a passage extending along an axis and an annular axially directed housing face extending radially from the passage. A shaft extending axially in the passage has an outer shaft surface radially spaced from an inner surface of the passage and forming therewith an annular axially extending gap. A radial impeller fixed to the shaft outside the housing has an axially directed and radially extending impeller face axially spaced from and confronting the radial housing face and forming therewith a radially extending gap opening into the axially extending gap. An impeller housing forms a flow space with the impeller outside the housing. The radial gap opens into the flow space. A plurality of spaced seals engaged in the radial gap between the radial faces of the housing and impeller fluidically separates the axial gap from the flow space.

Owner:ATLAS COPCO ENERGAS

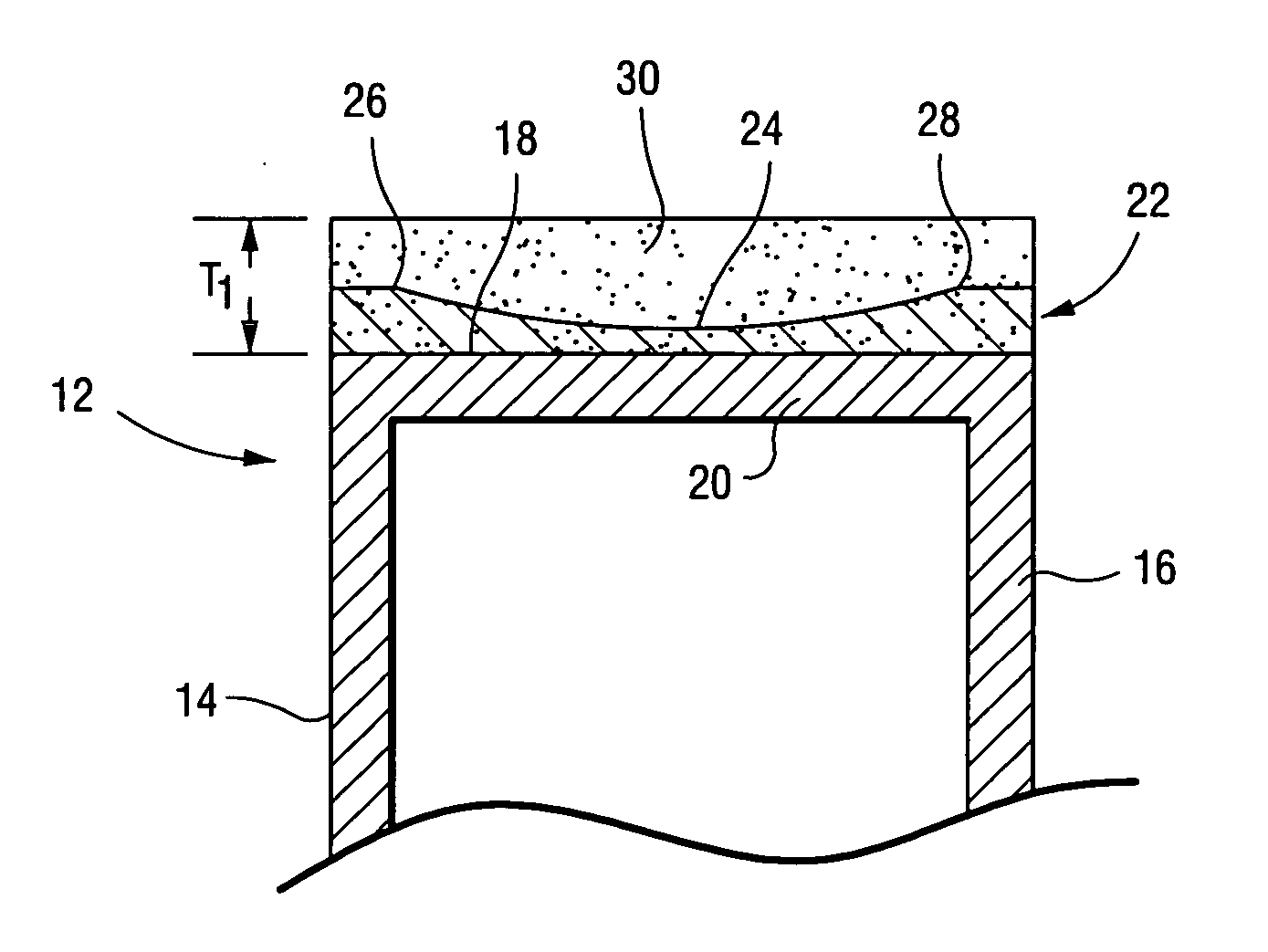

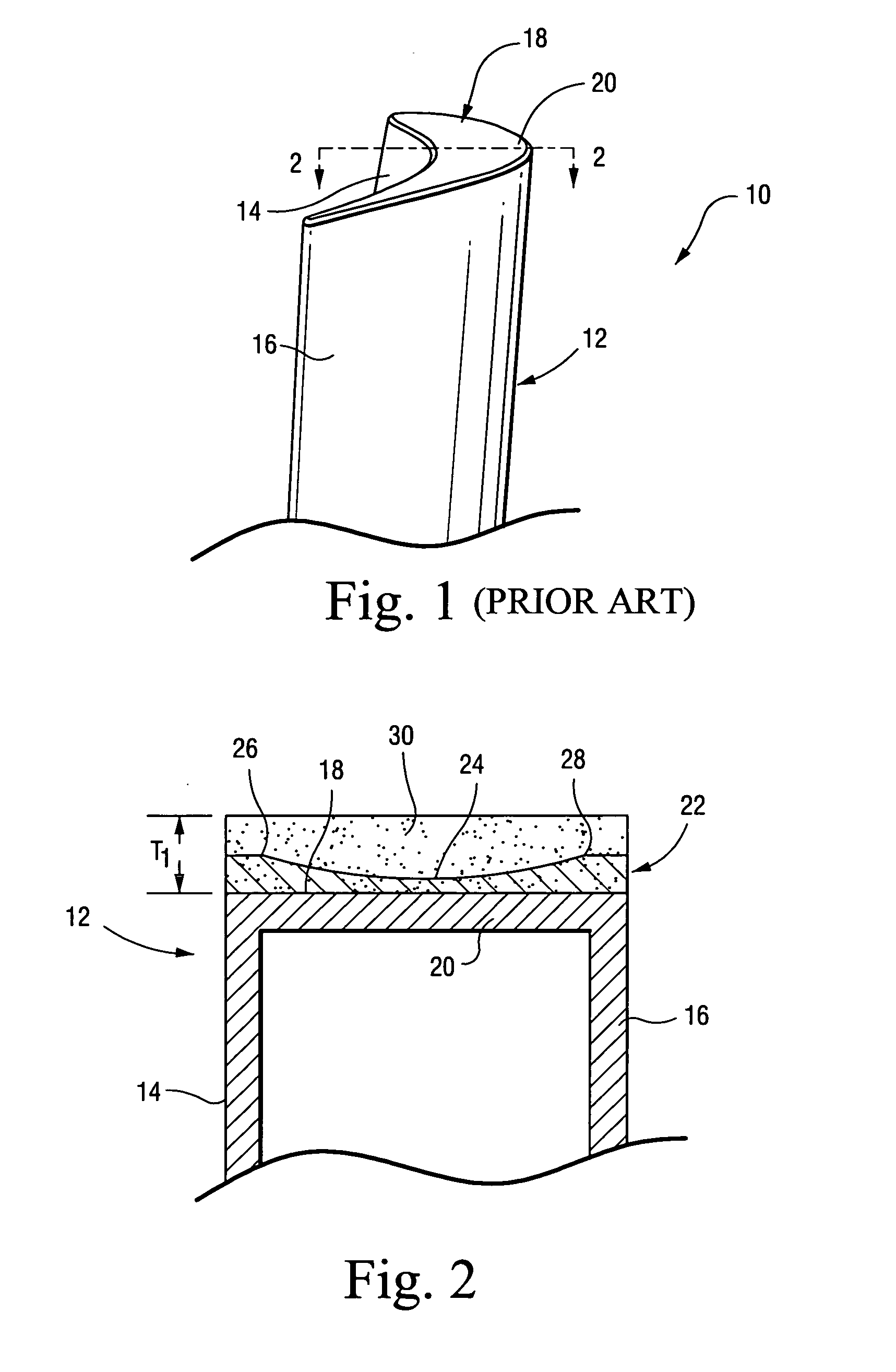

Steam-cooled gas turbine bucket for reduced tip leakage loss

InactiveUS7922455B2Avoid leakage lossReduce gapPump componentsBlade accessoriesEngineeringThermal barrier coating

A bucket for a steam turbine includes an airfoil portion having a radially outer tip, the radially outer tip having a thermal barrier coating applied thereto, and wherein the thermal barrier coating is resurfaced to form at least one ridge along the radially outer tip.

Owner:GENERAL ELECTRIC CO

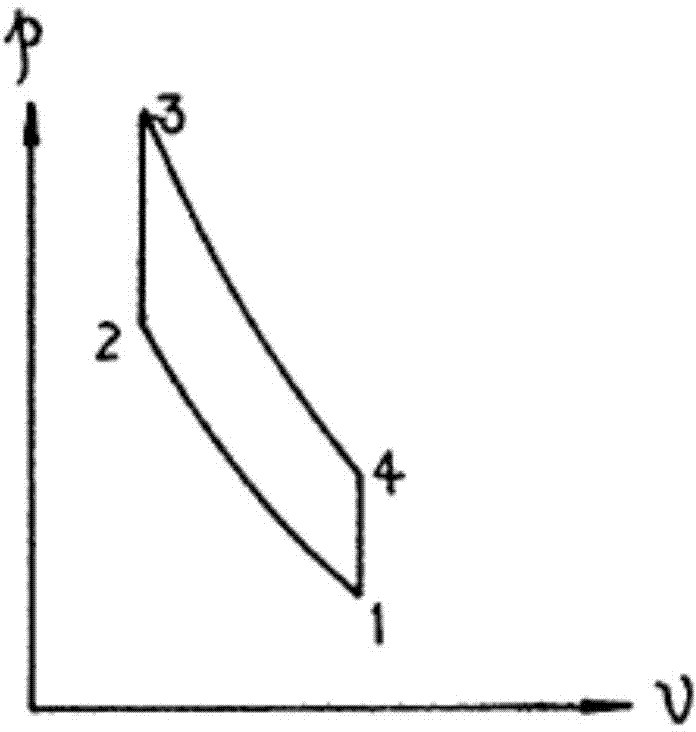

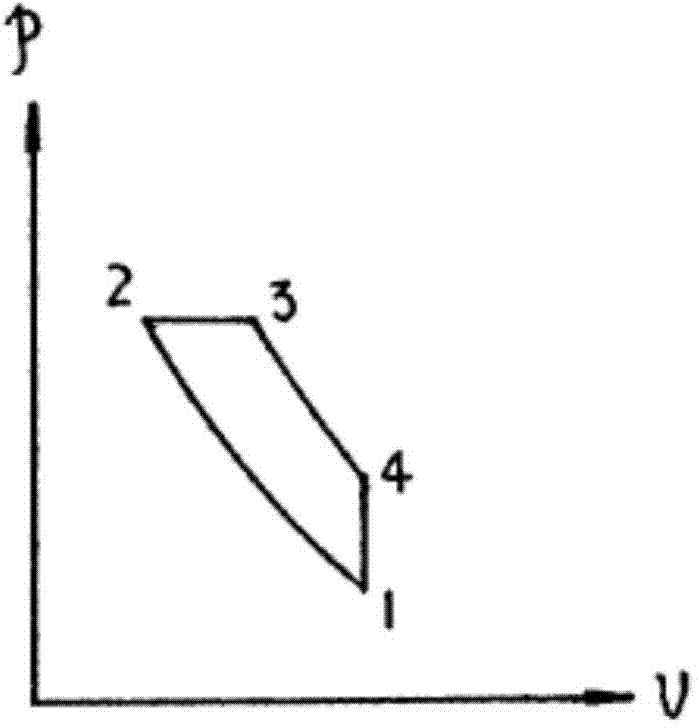

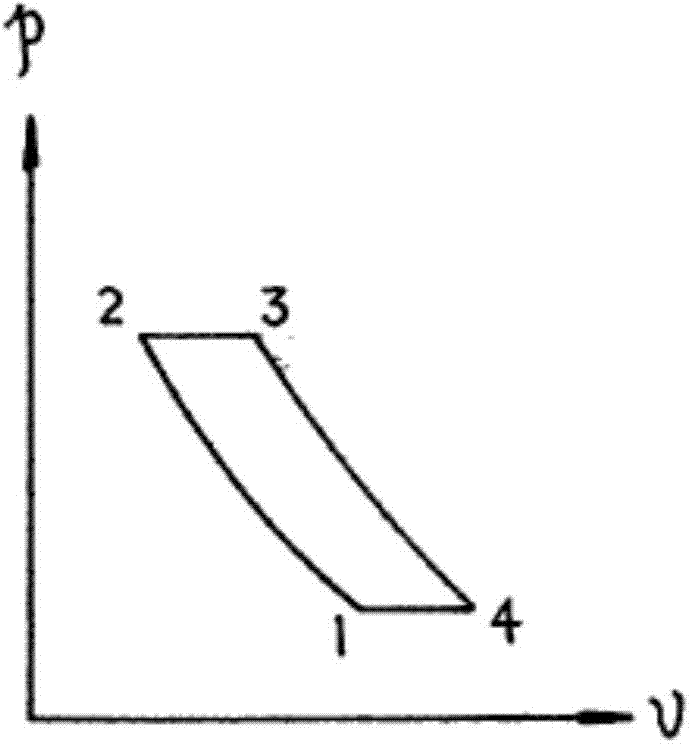

Semi-closed type timing constant-volume thermodynamic circulation method and system of prime motor

ActiveCN103883399AReduced Compression Power ConsumptionReduce fresh working fluid temperatureInternal combustion piston enginesGas turbine plantsThermal dilatationPrime mover

The invention provides a semi-closed type timing constant-volume thermodynamic circulation method and a semi-closed type timing constant-volume thermodynamic circulation system of a prime motor. The thermodynamic circulation method comprises six processes, namely multi-compression-stage intercooling, countercurrent heat exchanging, timing constant-volume burning, adiabatic expansion, aftercooling, and carbon dioxide and water removal. Heat-power conversion is achieved in the thermodynamic circulation. In the process of multi-compression-stage intercooling, compression power consumption is lowered; in the process of countercurrent heat exchanging, the enthalpy of an expanded working medium is recovered to participate in thermodynamic circulation; the process of timing constant-volume burning effectively inhibits the generation of harmful pollutants such as HC, CO, PM and NOx; in the process of adiabatic expansion, complete expansion for working is achieved; in the process of aftercooling, the working medium is further cooled to the environment temperature and the expansion ratio in the process of adiabatic expansion is enhanced; in the process of carbon dioxide and water removal, the carbon dioxide and the water generated in the process of timing constant-volume burning are removed; the remaining work mediums participate in the next thermodynamic circulation. By the method and the system, the direction is defined for designing a high-efficiency low-pollutant-emission and high-performance prime motor in the future.

Owner:GREEN ENERGY HIGH TECH GRP +5

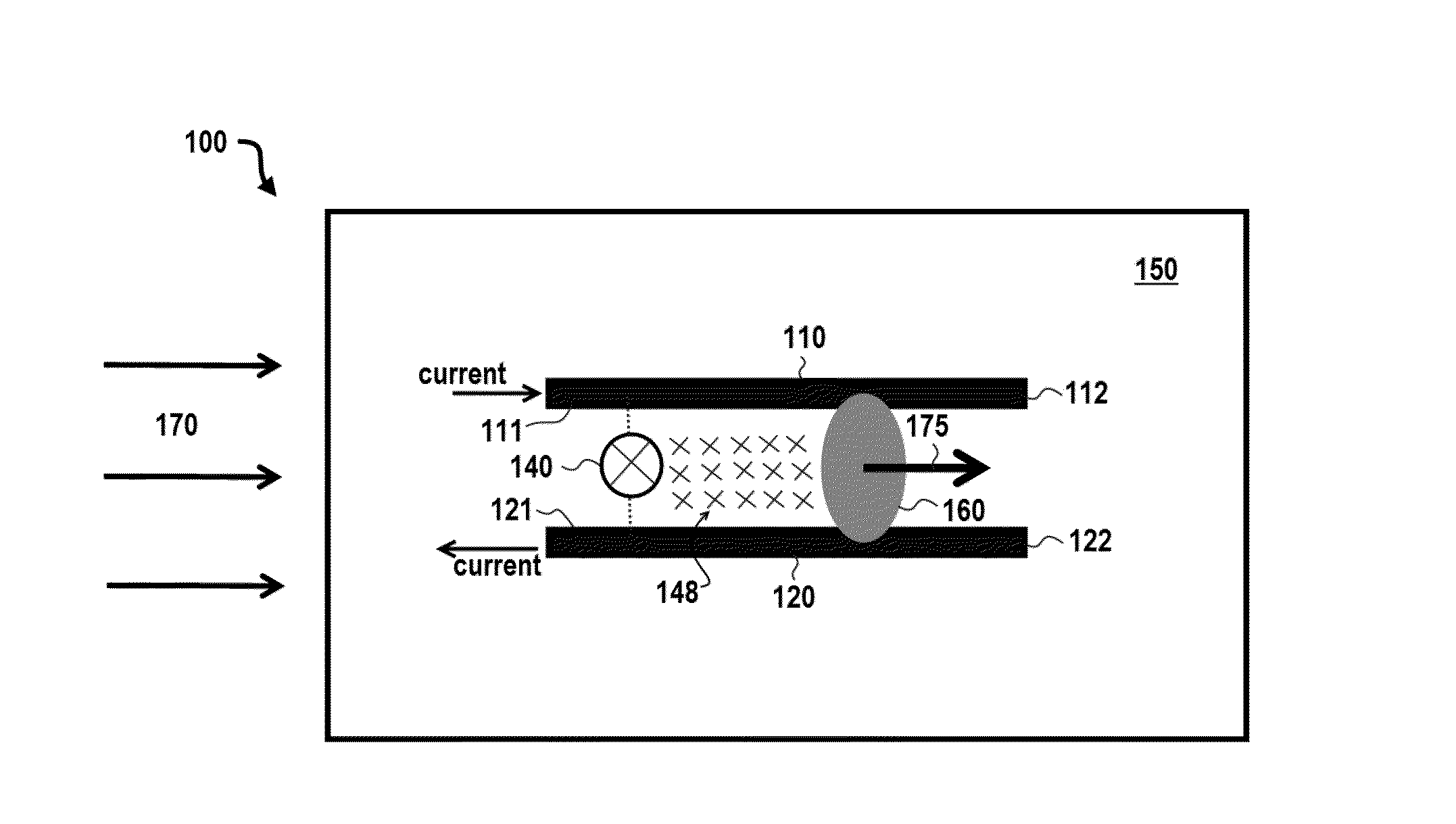

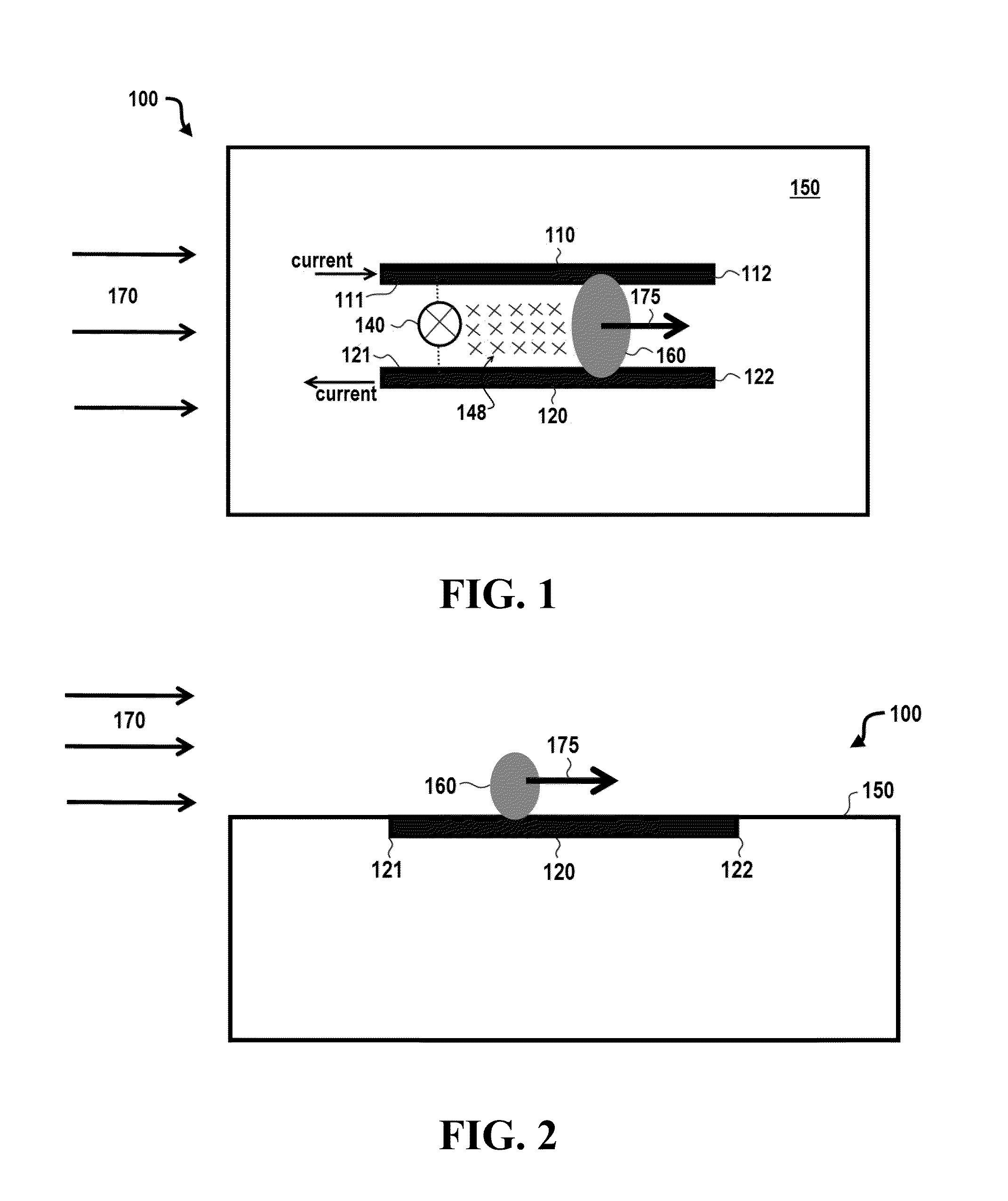

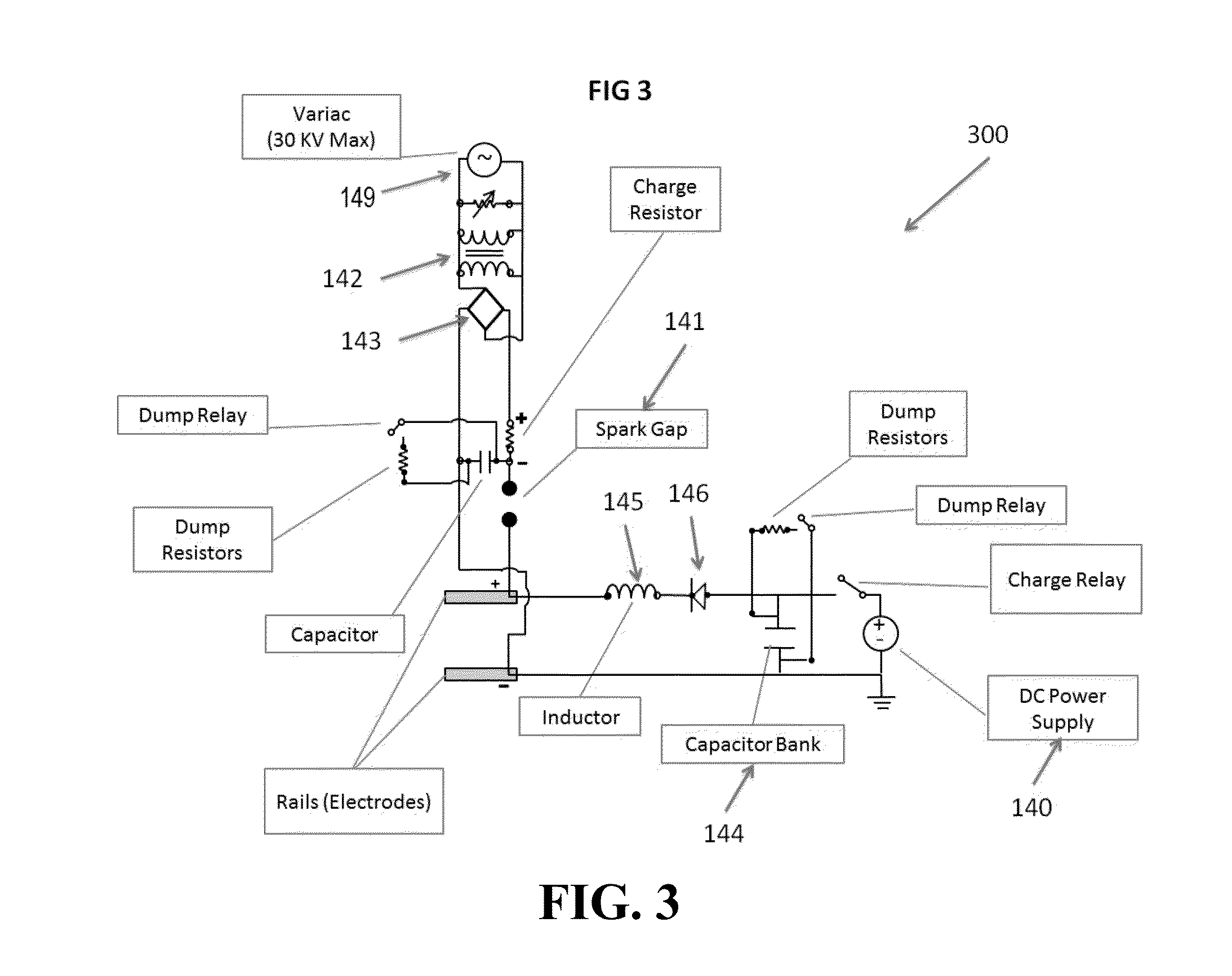

Rail plasma actuator for high-authority flow control

InactiveUS20140144517A1Issue of disruptionReduce the possibilityBoundary layer controlsPipeline systemsPlasma actuatorEngineering

Apparatus and methods for forming and propagating a plurality of plasma armatures along electrodes. In particular embodiments, the electrodes are flush mounted to the surface and the plasma armatures are formed and propagated at a high frequency and velocity.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Steam-cooled gas turbine bucket for reduced tip leakage loss

InactiveUS20070224049A1Impede tip leakage lossAvoid leakage lossPropellersPump componentsEngineeringThermal barrier coating

A bucket for a steam turbine includes an airfoil portion having a radially outer tip, the radially outer tip having a thermal barrier coating applied thereto, and wherein the thermal barrier coating is resurfaced to form at least one ridge along the radially outer tip.

Owner:GENERAL ELECTRIC CO

A method and device for producing refined brine using bromine-extracting brine

ActiveCN104743582BReduce acidityReduce refining costsAlkali metal halide purificationSaline waterSulfate radicals

The invention discloses a method and a device for producing refined brine by utilizing bromine extraction brine. The method comprises the following steps: adjusting the pH value of the bromine extraction brine to 5-8, intercepting solid particles and mechanical impurities through mechanical microfiltration, adding a reducing agent to remove oxidized substances, carrying out ultrafiltration to remove small particles, colloids and macromolecular organic compounds, then, removing most of sulphate radicals and calcium and magnesium ions through nanofiltration interception so as to obtain brine dissolved raw salt, preparing the brine dissolved raw salt into saturated brine, further refining to remove the calcium and magnesium ions by adopting a chemical method so as to obtain refined brine and brine sludge, and returning the brine sludge back to the first step to adjust the pH value of the bromine extraction brine. By means of the method disclosed by the invention, high-efficiency utilization of sodium chloride in the bromine extraction brine is realized; the sun-curing and dissolving processes of a part of sodium chloride are saved; the leakage loss of underground salt brine resources in the salt basking process is avoided; the recovery rate of raw salt in the bromine extraction brine is increased; furthermore, the brine refining cost of a sodium carbonate factory is lowered, so that the production cost is lowered.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Total temperature and total pressure wing-shaped sensing part

ActiveCN104034532AGuaranteed StrengthReduce distractionsGas-turbine engine testingJet-propulsion engine testingVibration attenuationPlatinum

The invention discloses a total temperature and total pressure wing-shaped sensing part, and belongs to the technical field of testing of aerodynamic parameters of an aero-engine. The total temperature and total pressure wing-shaped sensing part is characterized by comprising a temperature measuring rod, a wing-shaped shell body, a metal conduit and a flange, wherein the temperature measuring rod and a wing-shaped shell are fastened by the flange, inserted into a testing hole of an engine case, and sealed in a vibration attenuation manner by a copper pad. A platinum resistor precise thermo-sensitive element is arranged in the terminal end of the temperature measuring rod to sense and measure a temperature of an airflow which is delayed by air inlet and air outlet of the wing-shaped shell, and a total pressure of a flow field is extracted from a semispherical hole in the bottom of the shell. Compared with former pneumatic gauging structures, the total temperature and total pressure wing-shaped sensing part has the advantages of small flow resistance and high intensity, avoids turbulence of a uniform flow field of an engine inlet and the like caused by testing structural members; meanwhile, the total temperature and total pressure parameters are measured integrally, so that the mounting number of the testing structural members is reduced, the weight is lightened, and flow loss caused by flow damage ratio, leakage and the like is reduced.

Owner:AECC SHENYANG ENGINE RES INST

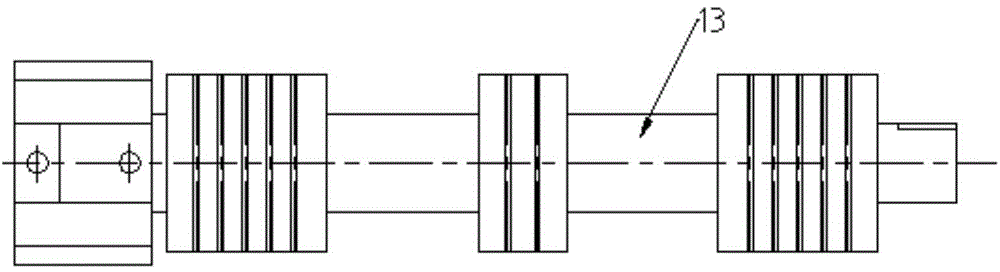

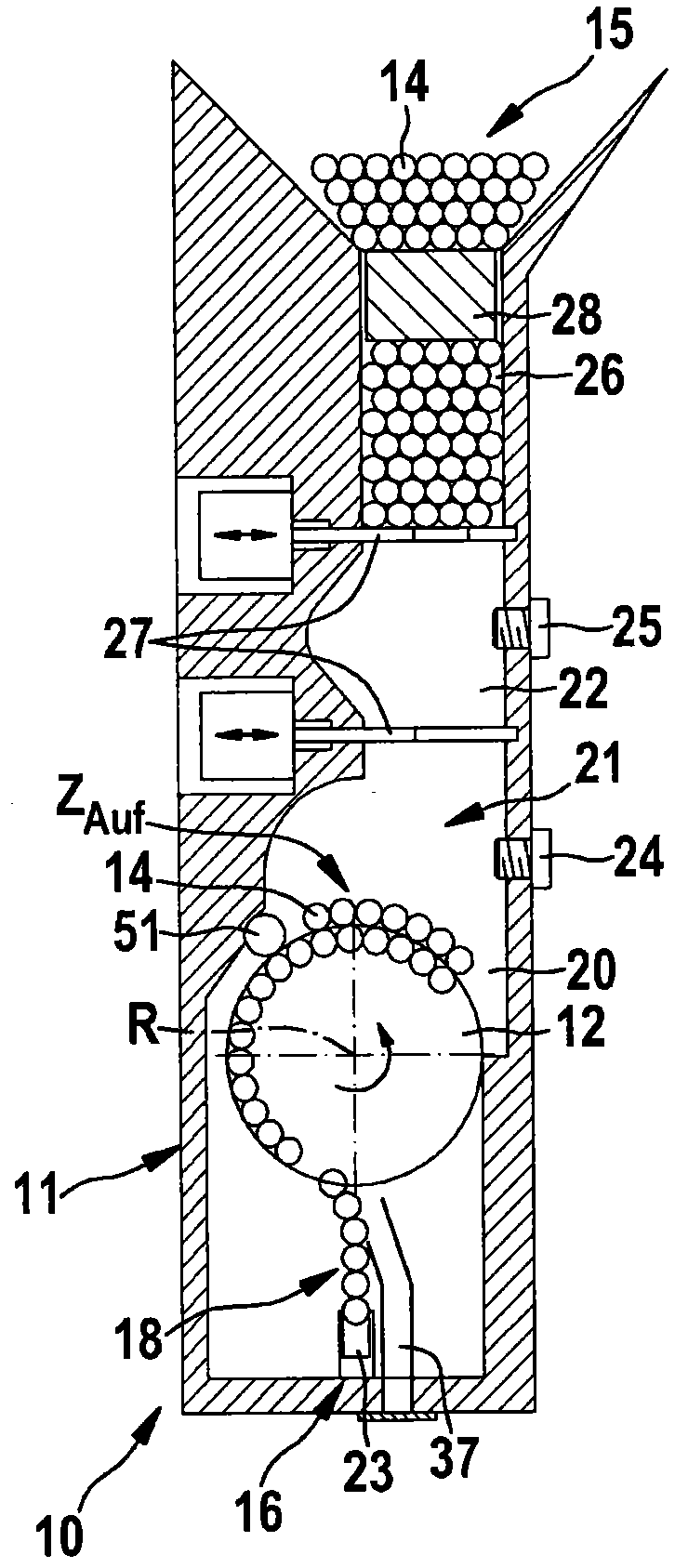

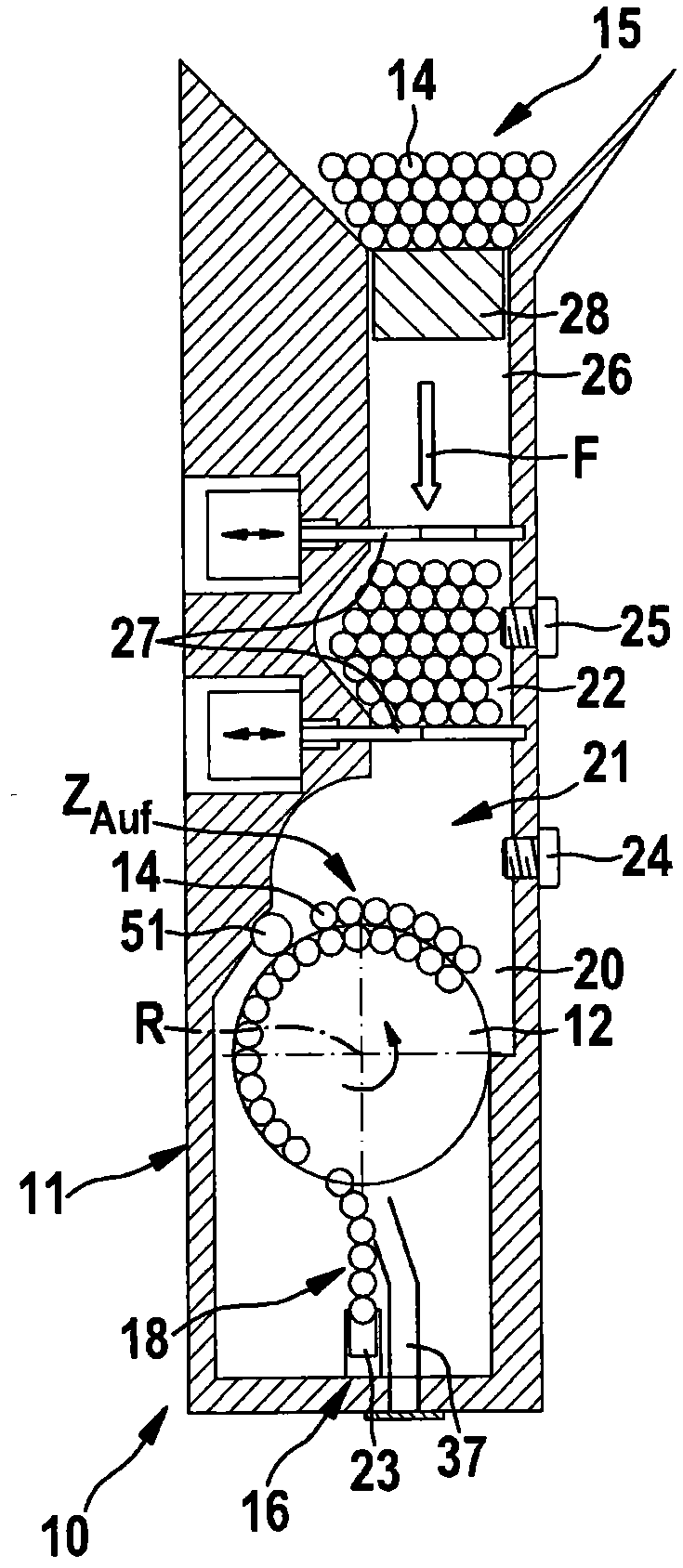

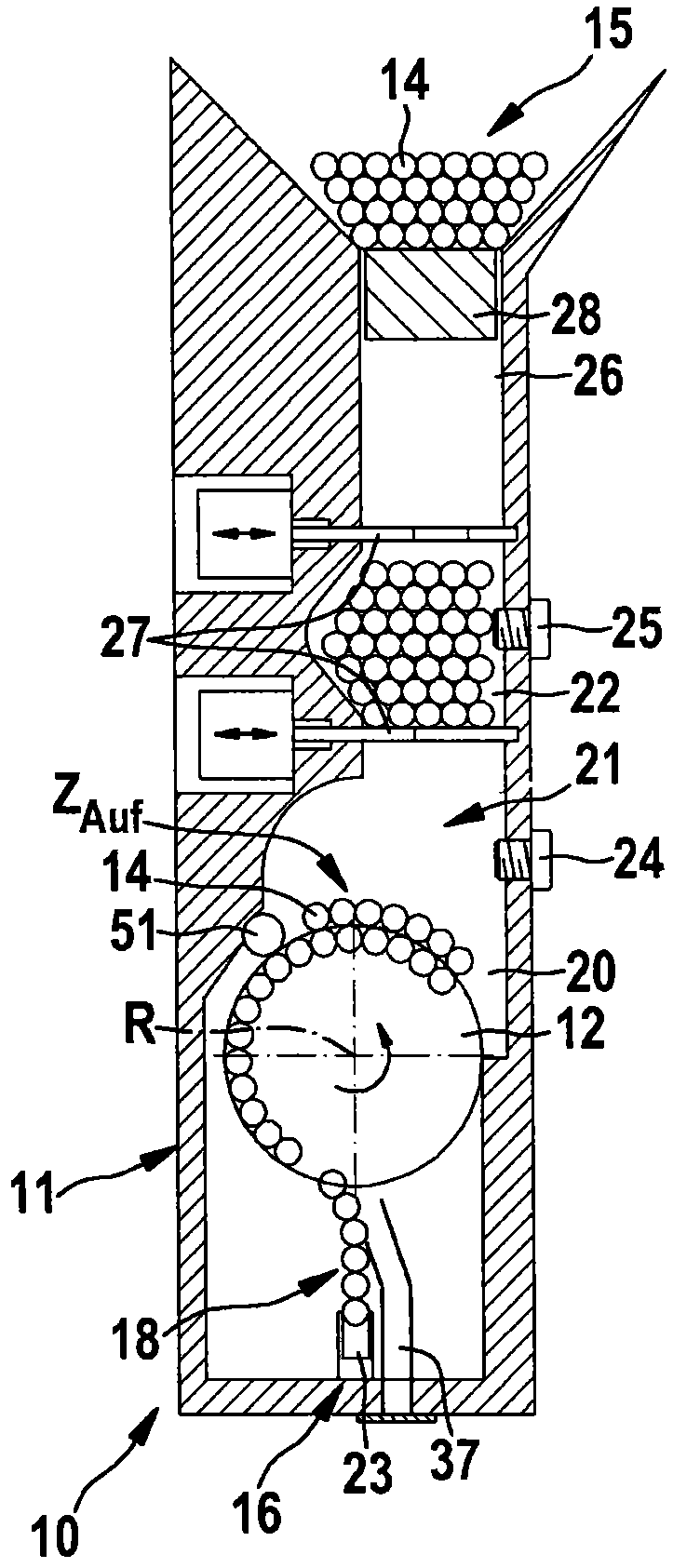

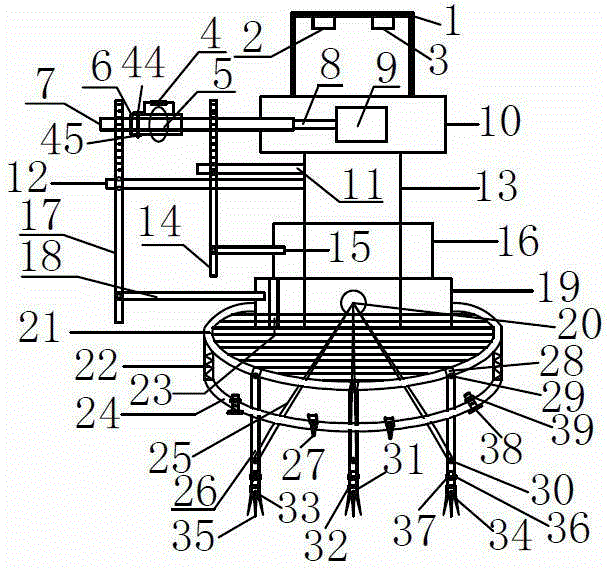

Device and method for transferring rod-shaped items for tobacco industry from storage bunker into conveyor pipe

ActiveCN102166040ASimple structureIncrease delivery speedCigarette manufactureEngineeringMechanical engineering

The invention relates to a device and a method for transferring rod-shaped items for a tobacco industry from a storage bunker into a conveyor pipe. The device comprises a transmitter unit which consists of a rotatably-driven roller with recesses for receiving and transverse axially supplying of the rod-shaped articles from a storage bunker into an exhaust area. The roller and the exhaust area are connected with each other by a blocking shaft for transversely and axially supplying of the articles from the roller to the exhaust area. A conveying unit composed by the roller and the blocking shaft is arranged in a main chamber which is formed as pressure chamber. A pressure dividing chamber is disposed in front of the main chamber along a conveying direction (F) of the articles and is used for receiving and storing articles. The invention also relates to a relative method.

Owner:KOERBER TECH GMBH

Optical fiber and optical communication system including same

ActiveUS8655133B2Enhance the imageSuppression of bending lossGlass optical fibreOptical fibre with multilayer core/claddingCommunications systemRelative refractive index

Owner:SUMITOMO ELECTRIC IND LTD

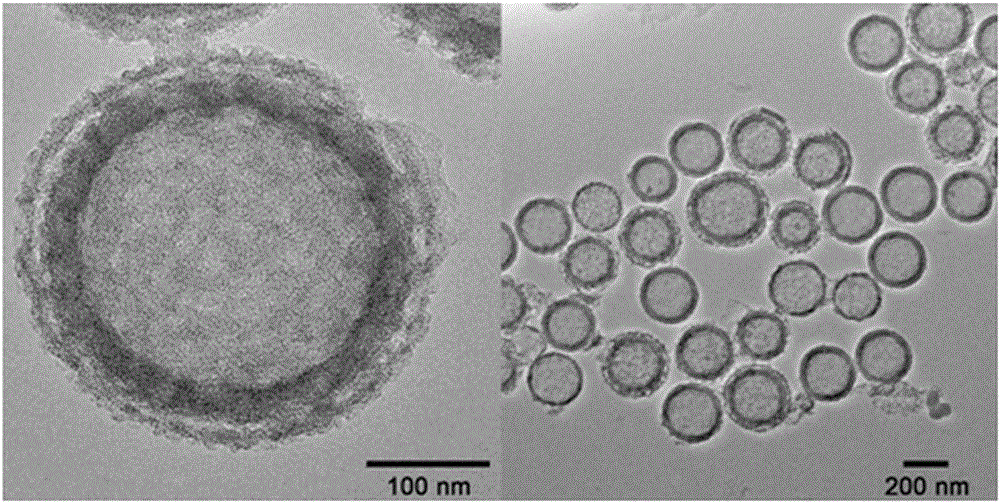

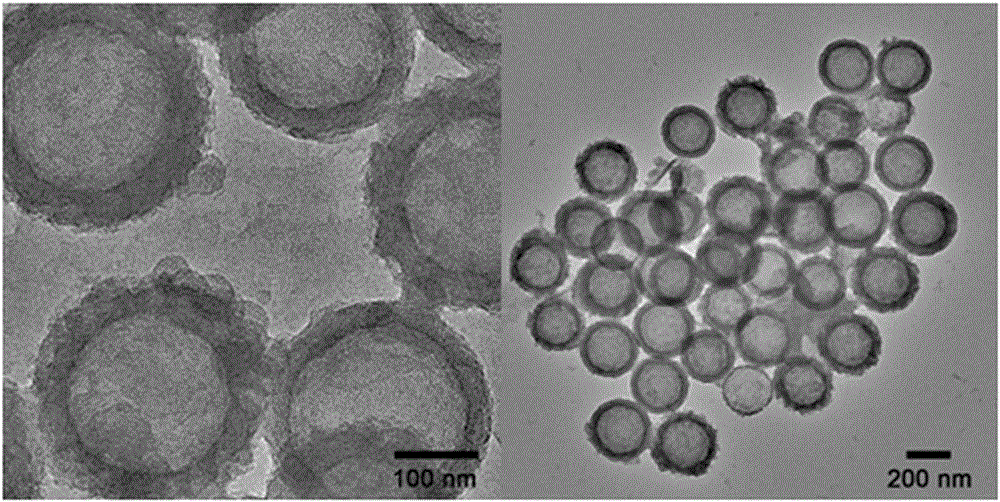

Synthesis method of hollow mesoporous silicon dioxide nano-drug capsule

InactiveCN106619570AAvoid leakage lossIncrease densityHeavy metal active ingredientsOrganic active ingredientsDrug capsuleSynthesis methods

The invention belongs to the field of nano-drugs, and particularly relates to a synthesis method of a hollow mesoporous silicon dioxide nano-drug capsule. The synthesis method comprises the following steps: modifying hollow mesoporous silicon dioxide through an acrylic acid propyl ester group, dispersing the hollow mesoporous silicon dioxide into a drug-containing buffer solution, then adding polyethylene glycol diacrylate and ammonium persulfate serving as an initiator, and dripping N,N,N',N'-tetramethylethylenediamine serving as an accelerator to enable the polyethylene glycol diacrylate and the acrylic acid propyl ester group to generate polymerization reaction on the surface of the hollow mesoporous silicon dioxide to form a polymer coated layer. Loading of a drug and encapsulation of a nano capsule are completed in the drug-containing buffer solution, so that leakage of the drug in an encapsulation process can be avoided; the synthesis process is simple, and the coating thickness and the compactness can be adjusted.

Owner:XINYANG NORMAL UNIVERSITY

Self-operated protection device for pipeline

InactiveUS6895994B2Avoid leakage lossSmall volumeOperating means/releasing devices for valvesEqualizing valvesLinear motionHydraulic cylinder

Owner:ZENG XIANGWEI

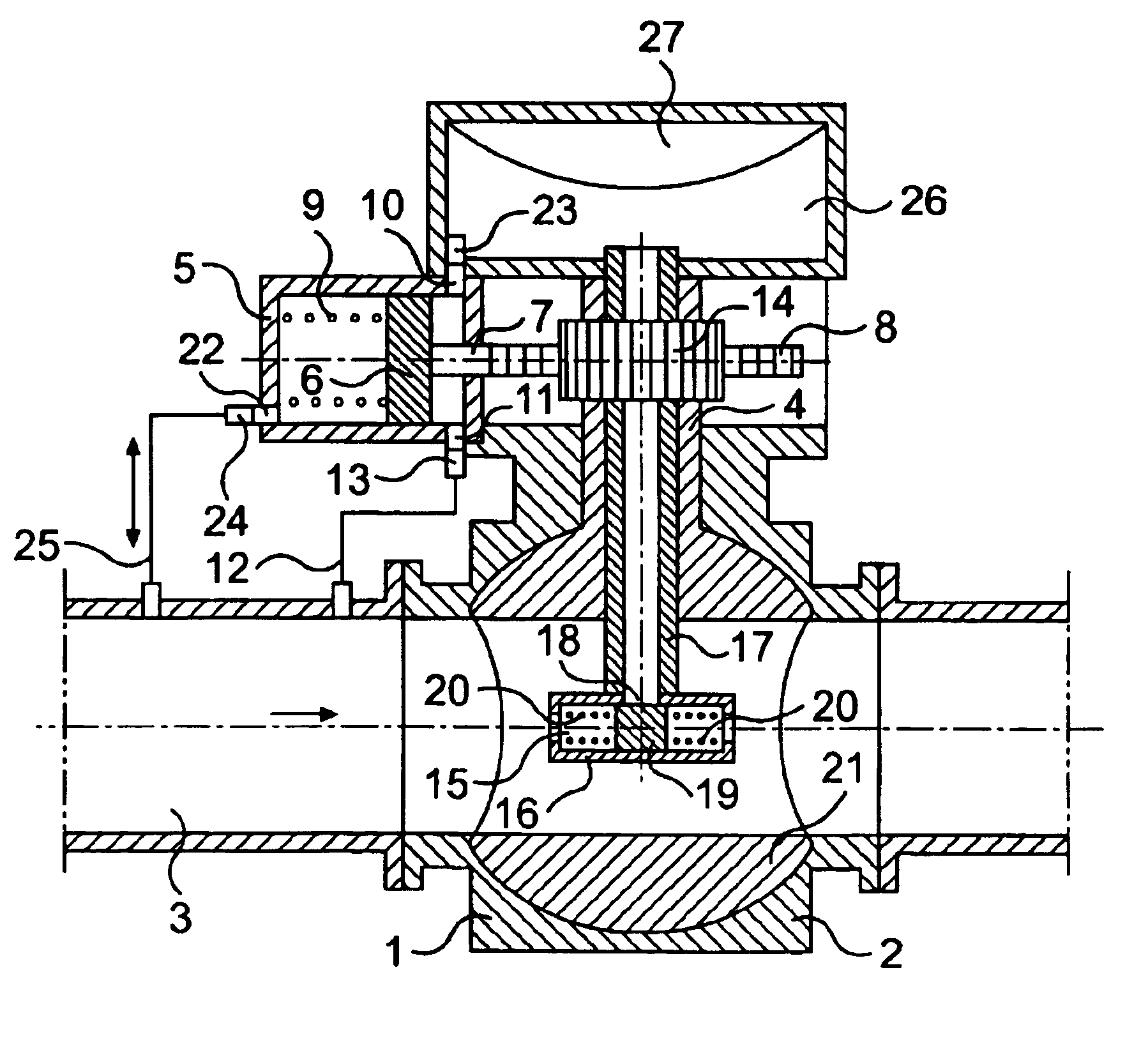

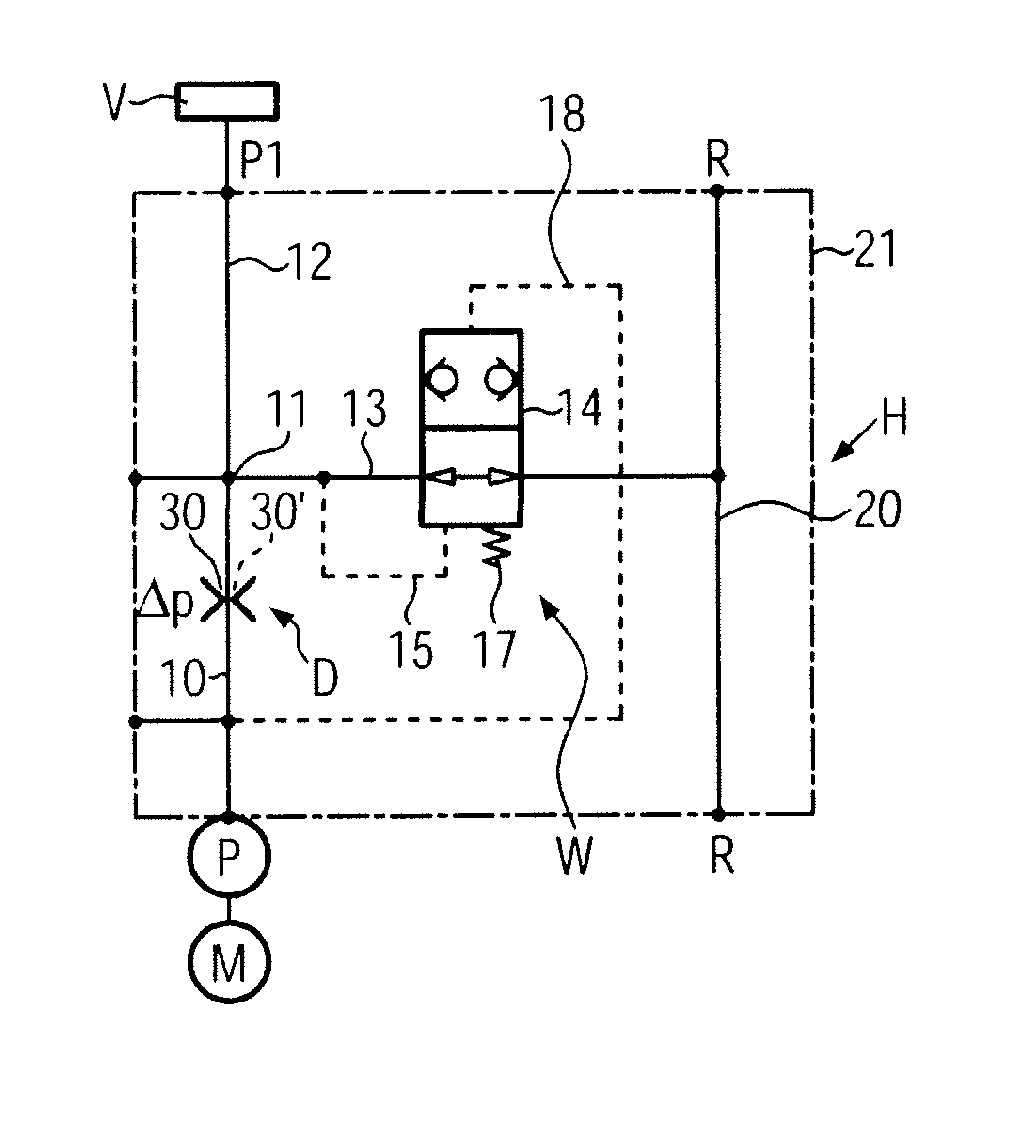

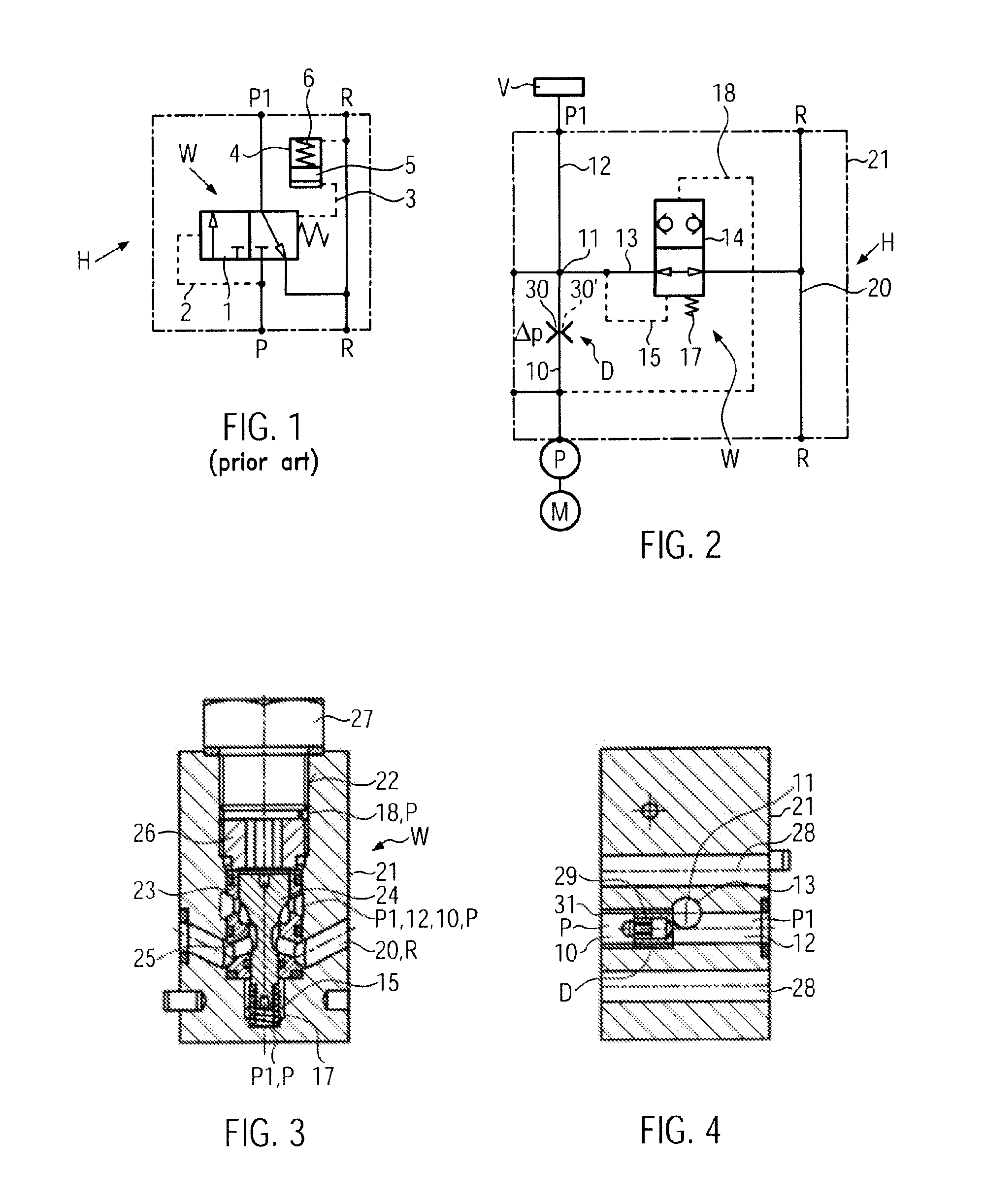

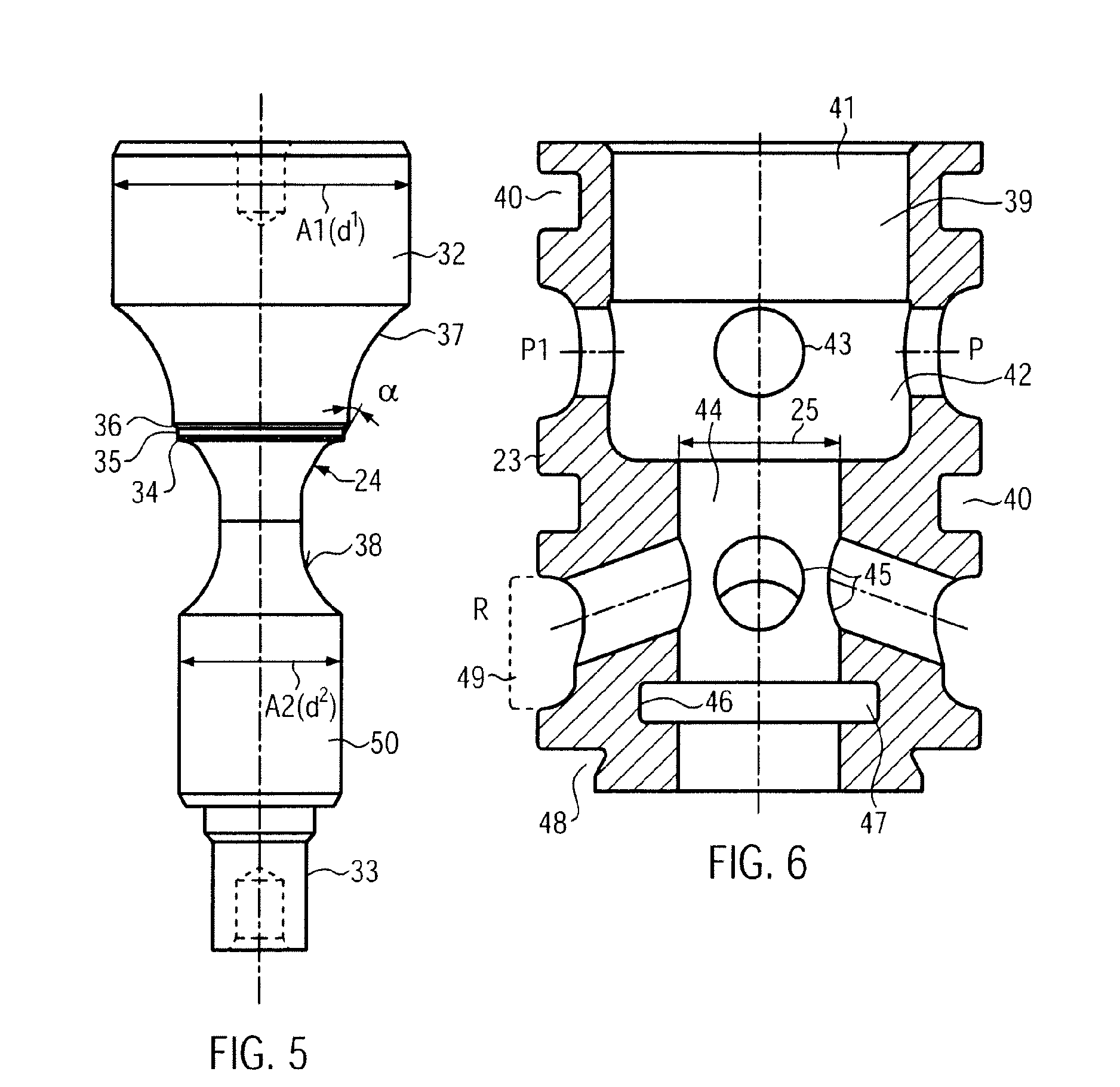

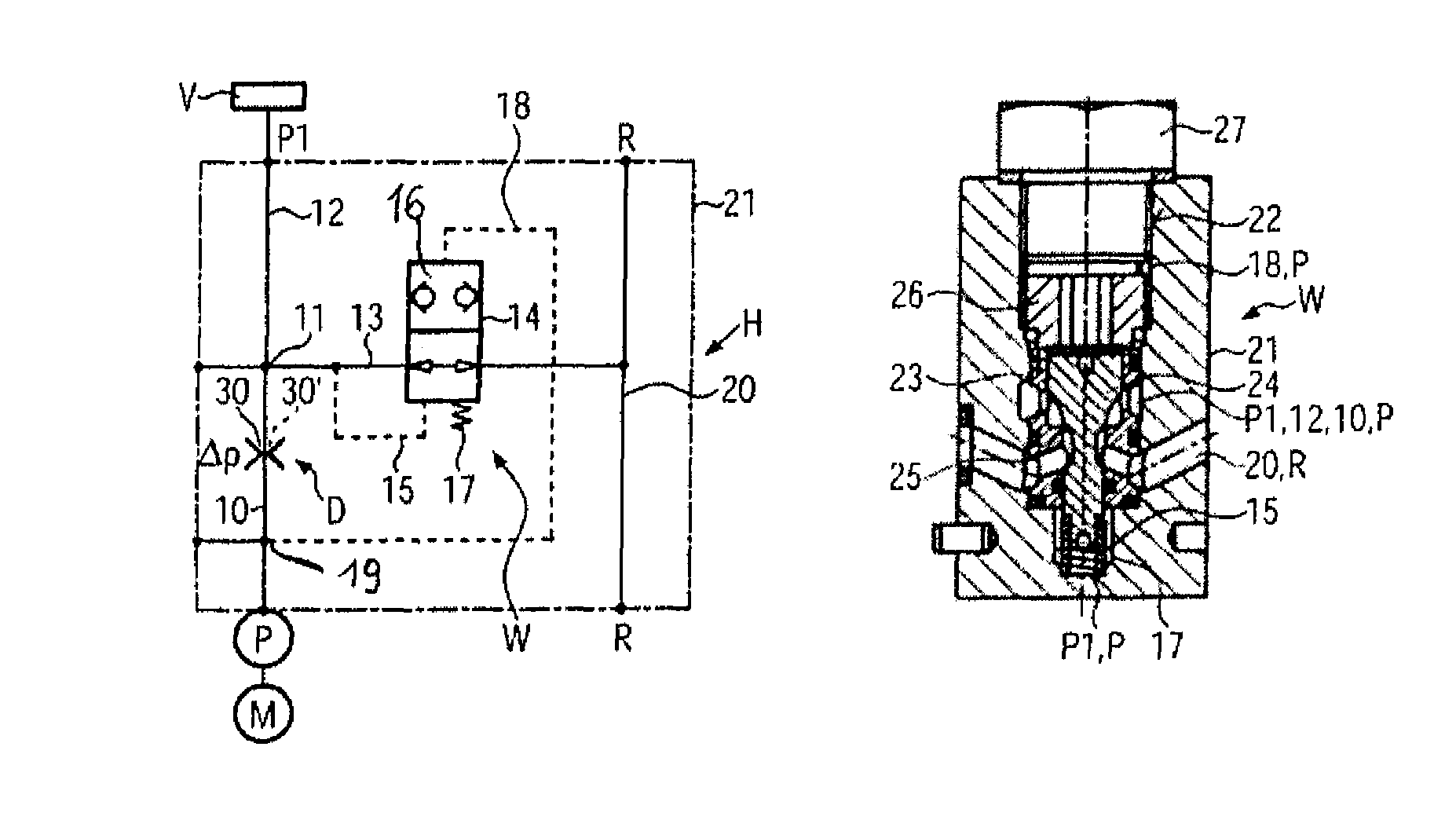

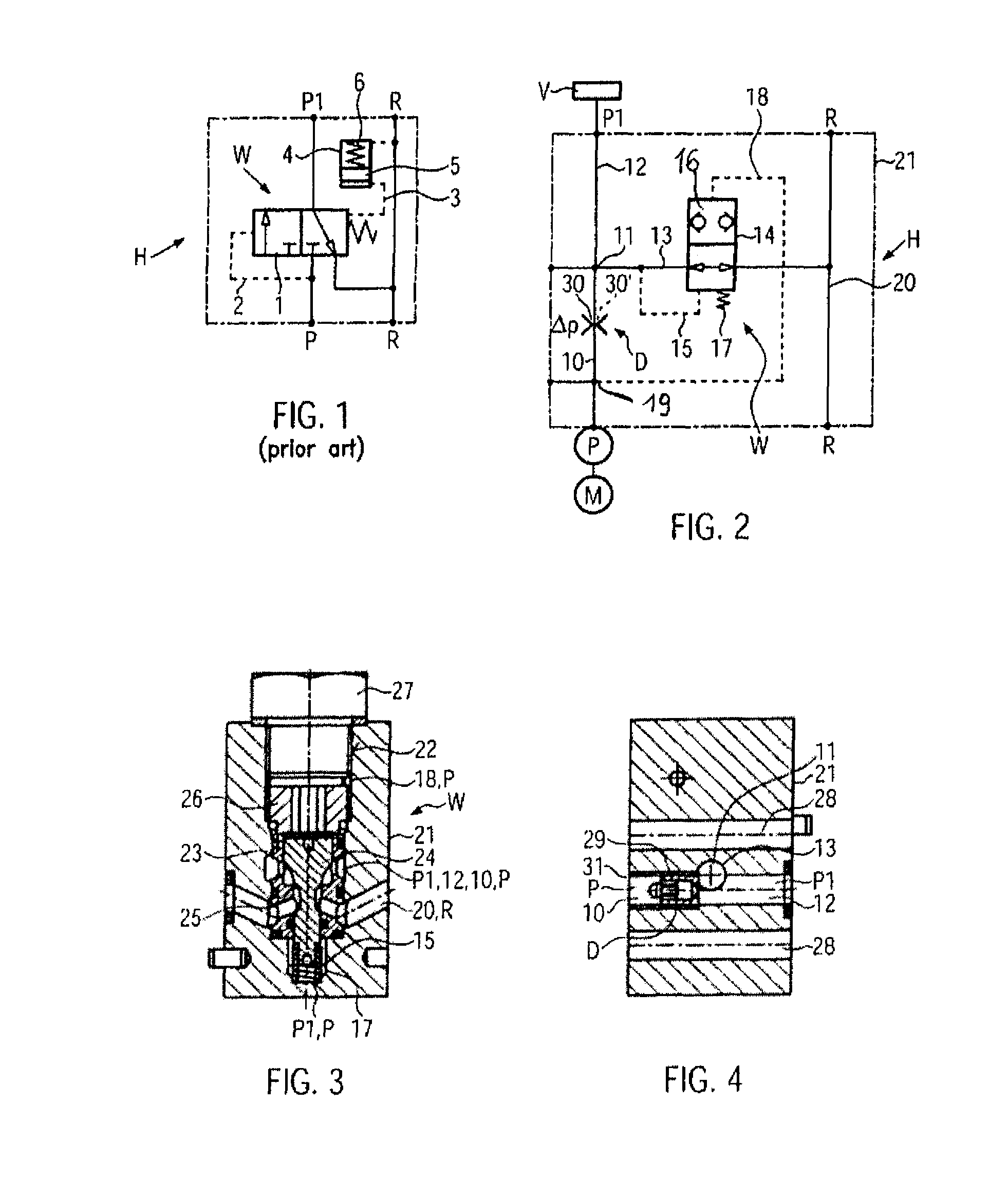

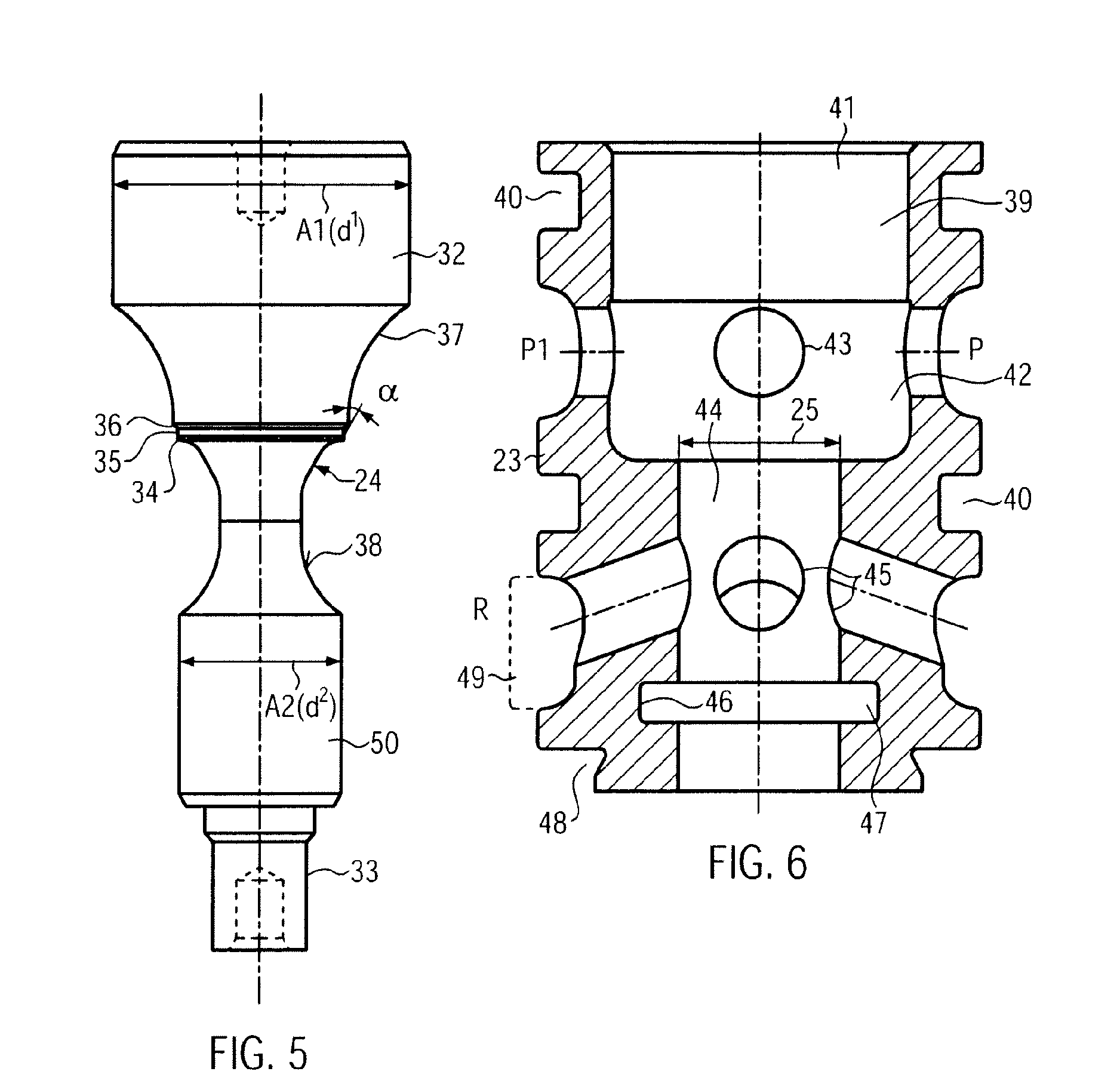

Hydraulic control device and pressure switch

InactiveUS20100263363A1Promote startupRelieves any residual pressureFluid couplingsServomotor componentsMain channelEngineering

In a hydraulic control device H comprising a pressure source P which can be switched on and switched off, a reservoir R and a pressure switch W located in a discharge path 13 from a valve assembly V to the reservoir R, which pressure switch W either connects the valve assembly V with the reservoir R or blocks the valve assembly V versus the reservoir R, the pressure switch W contains a displaceable control member 16 which is actuated in a first switching direction by a spring 17 and a pilot pressure originating from the pressure P1 acting at the valve assembly V and in a second switching direction to a control position blocking the discharge path 13 by a pilot pressure originating from the supply pressure of the pressure source, the pressure switch W is designed as a 2 / 2-multi-way seat valve 16 operating with a blocking position without leakage. A valve member 24 forms the control member 16 and co-operates with a valve seat 25 arranged in the discharge path 13. The pressure source P and the valve assembly V are permanently connected via a main channel 10, 11 containing a restrictor D. The discharge path 13 branches off from the main channel 10, 11, 12 between the valve assembly V and the restrictor D. The pilot pressure actuating the valve member 26 in the switching direction towards the valve seat 25 originates from the supply pressure taken between the pressure source P and the restrictor D.

Owner:HAWE HYDRAULIK SE

Self-operated protection device for pipeline

InactiveUS20050022873A1Avoid leakage lossSmall volumeOperating means/releasing devices for valvesEqualizing valvesHydraulic cylinderEngineering

A protection device which is capable of cutting off a pipeline when the pipeline leaks due to the rupture of the pipe, self-operatedly closes the pipeline using fluid kinetic energy. A control rod converts linear movement of a piston into the opening and closing movement of a main valve core. The piston separates a hydraulic cylinder chamber into a first chamber and a second chamber. A restoring spring in the first chamber restores a control piston to an initial position. A control valve in the second chamber controls discharge of fluid from the second chamber. A flow state-sensing device introduces fluid in the fluid pipe to the second chamber when the fluid pipe ruptures and leaks.

Owner:ZENG XIANGWEI

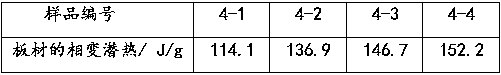

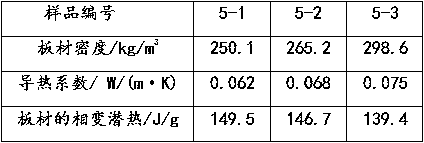

Preparation method of straw phase change plate with phase change heat storage and insulation function

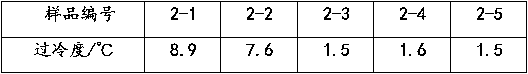

InactiveCN110434974AConducive to loadReduce subcoolingFlat articlesDomestic articlesCompression moldingApparent density

The invention discloses a preparation method of a straw phase change plate with a phase change heat storage and insulation function. According to the straw plate, environment-friendly and renewable crop straws are used as raw materials, a large number of micropores existing in the straw are used for loading and packaging an inorganic phase change material Na2SO4.10H2O, and the inorganic phase change material and the inorganic binder geopolymer cement are subjected to compression molding to obtain the straw plate. The preparation method comprises the first step of straw pretreatment, the secondstep of loading and packaging of phase change materials in micropores of straw, and the third step of compression molding of the straw plate. Compared with the prior art, according to the prepared straw plate, the apparent density is less than or equal to 300 kg / m<3>, the thermal conductivity is less than or equal to 0.08 W / (m.K), the phase change heat can reach 143.3 J / g, and the straw plate hasa good application prospect in the field of thermal insulation building materials.

Owner:江苏禾吉新材料科技有限公司 +1

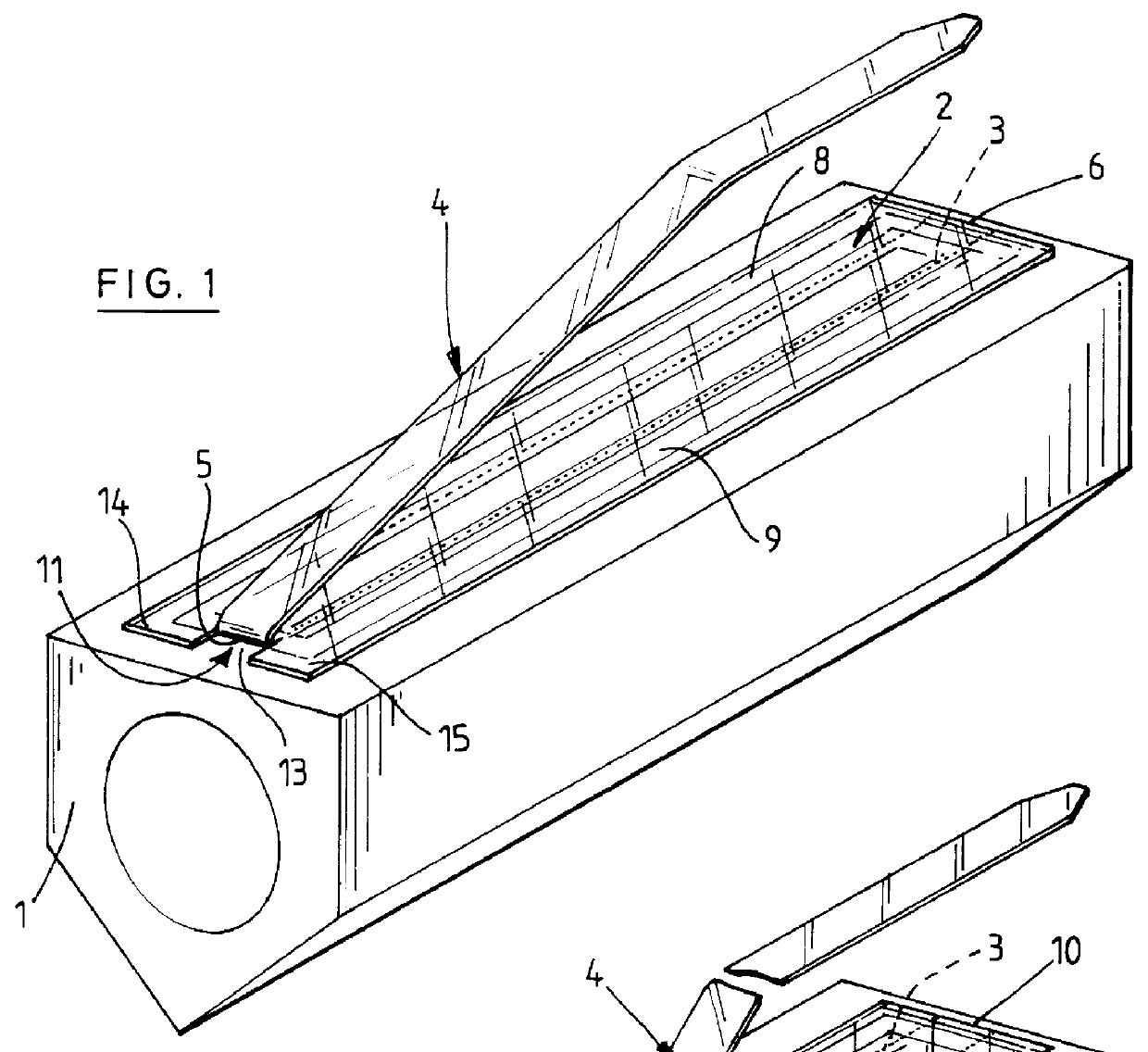

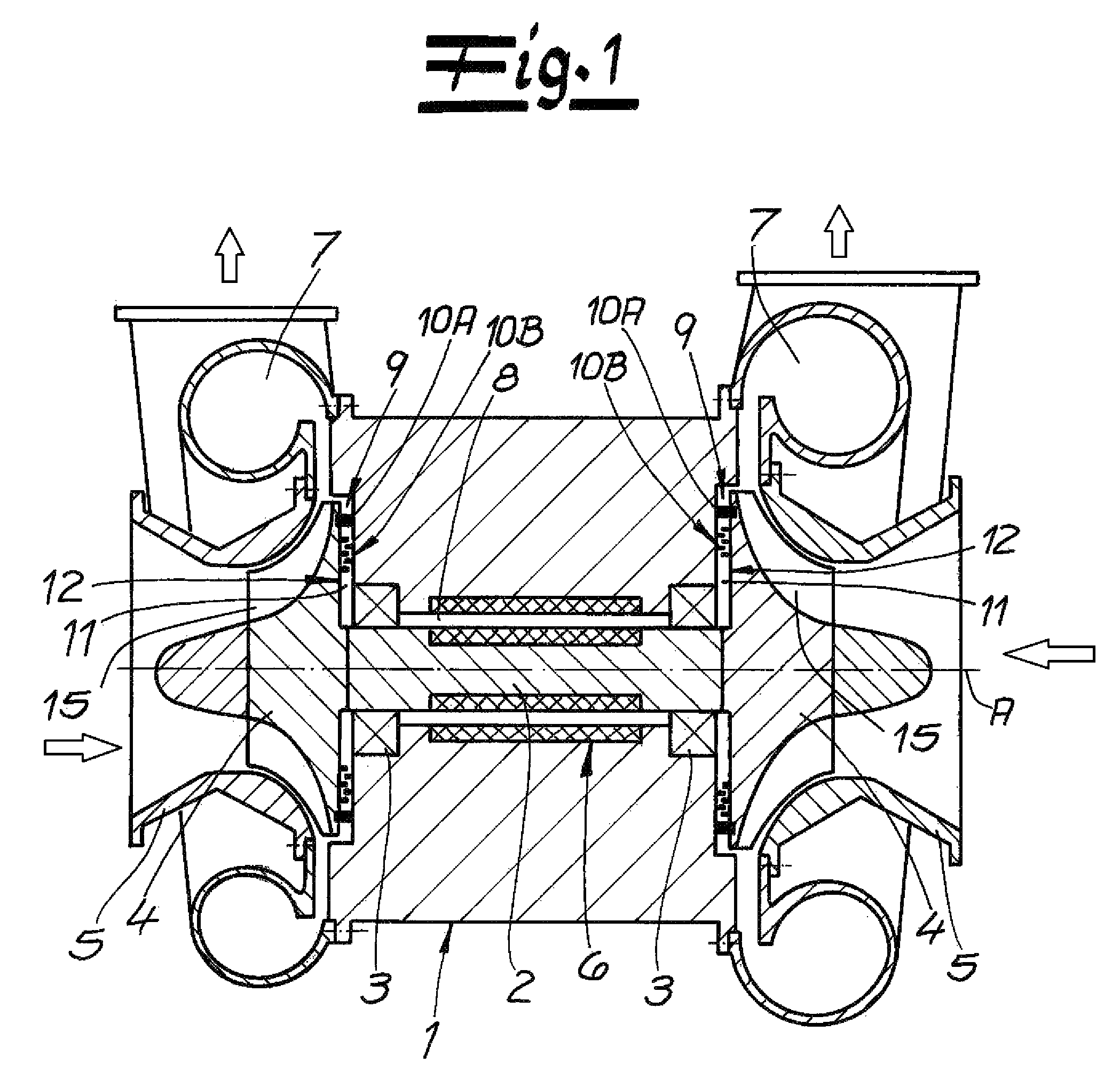

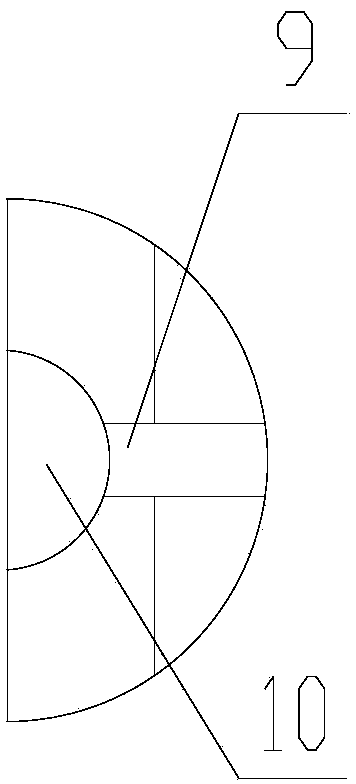

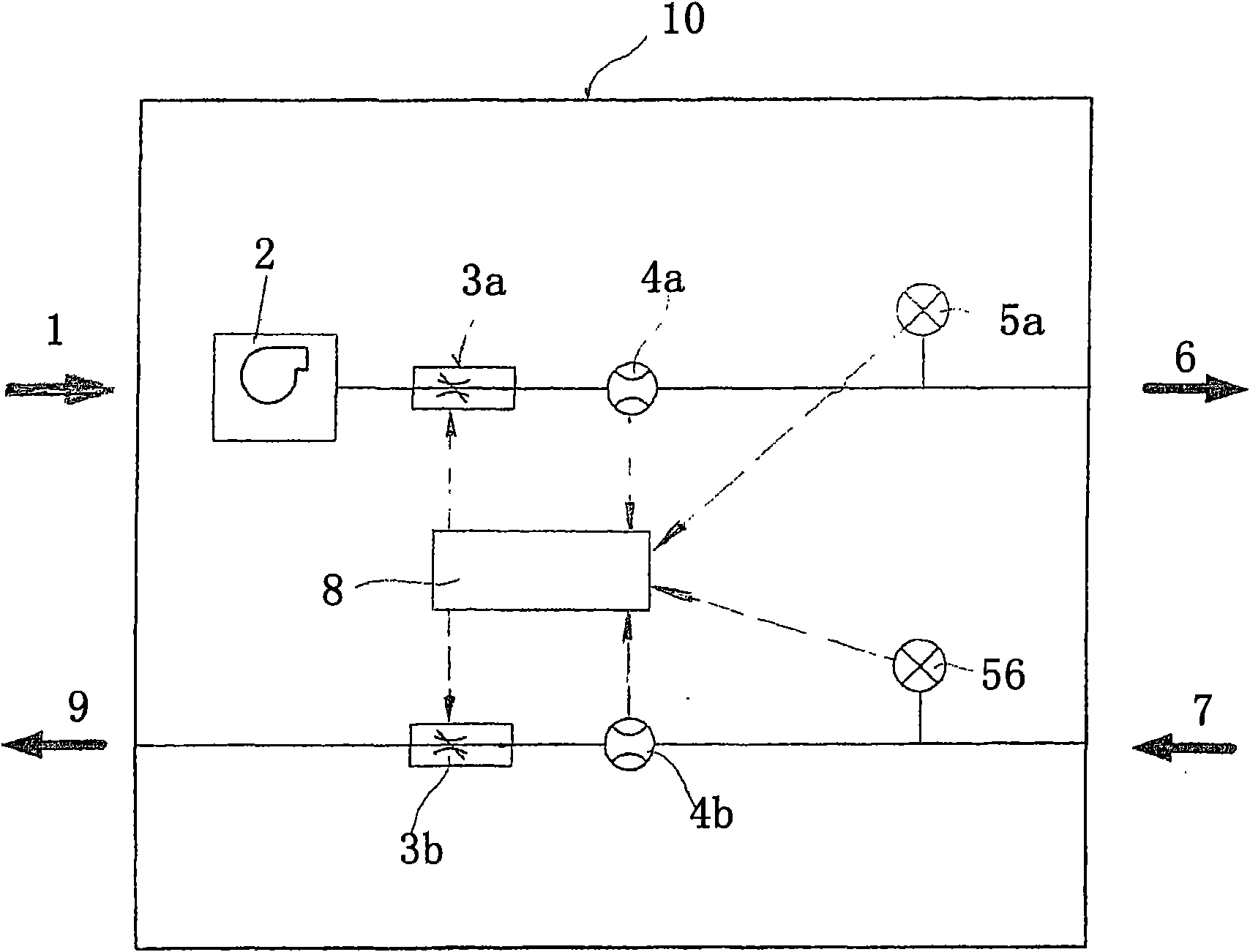

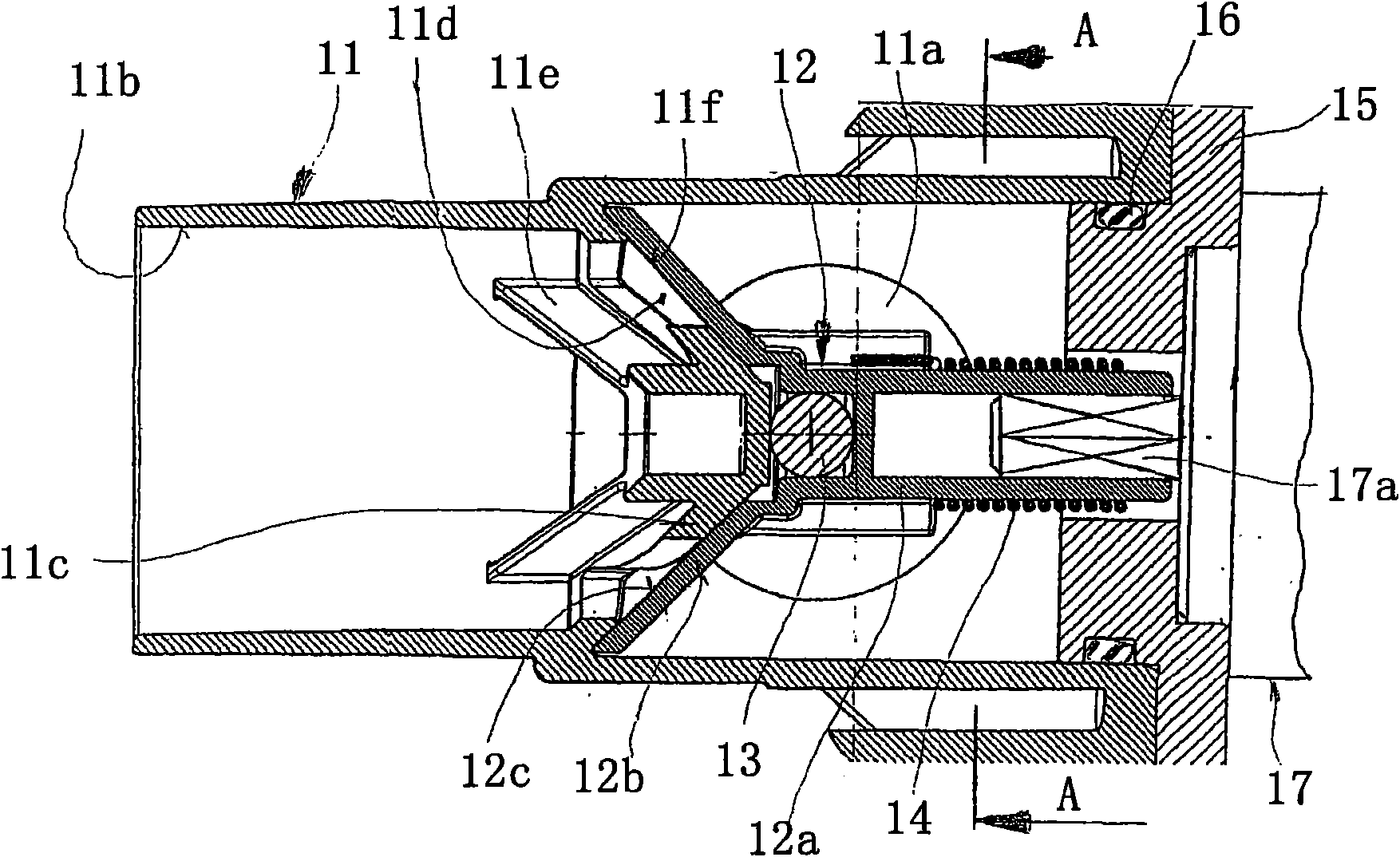

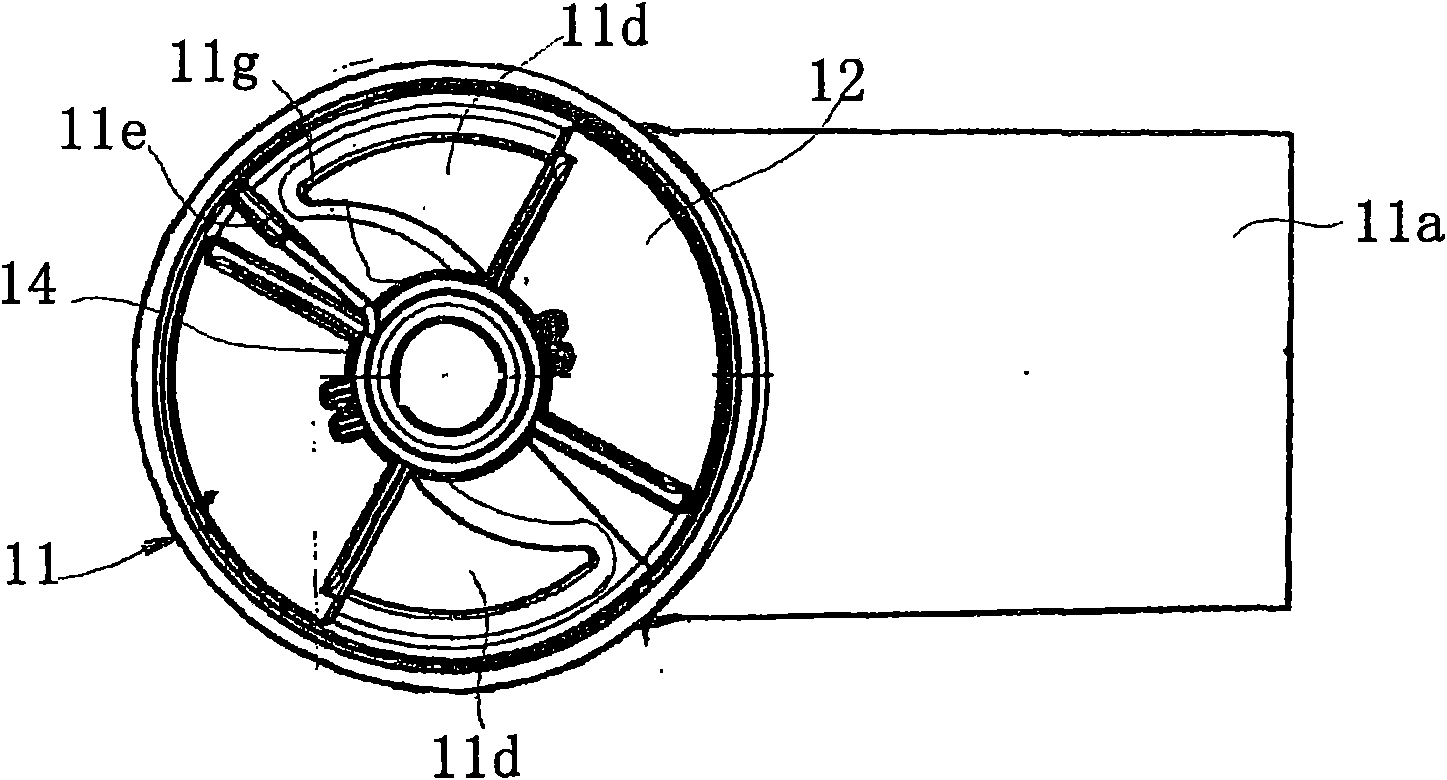

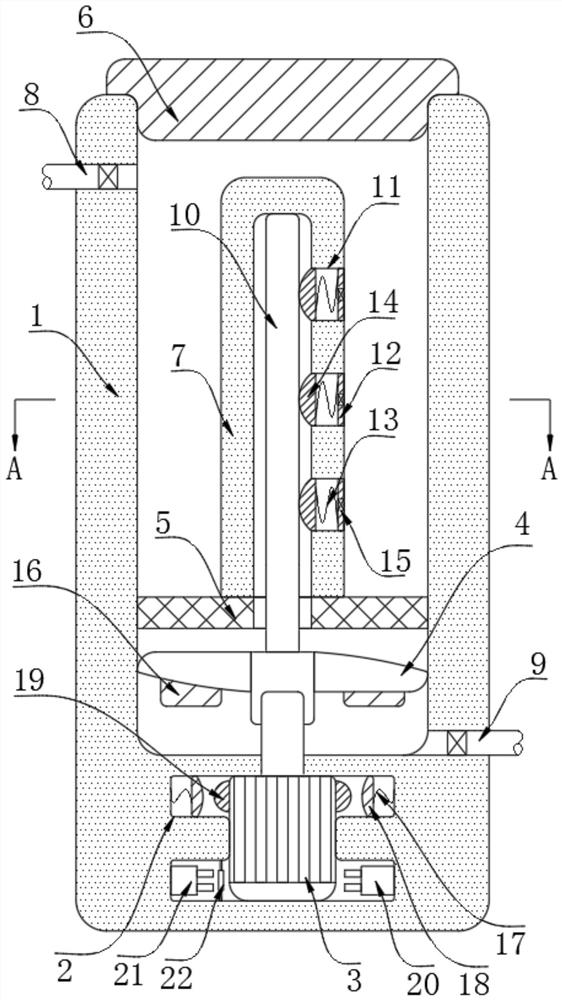

Control valve for respiratory devices

The invention relates to a respiratory device for keeping a patient breathing artificially or support his or her breathing naturally. Said respiratory device comprises an air inlet, an air source, and at least one proportionally adjustable control valve. The control valve is provided with a housing (11) and a rotary valve (12) which is arranged in the housing so as to be twistable about the longitudinal axis thereof and which allows through-holes (11d) of the housing (11) to be entirely or partially closed by twisting the rotary valve (12). The rotary valve (12) and a corresponding support surface (11f) of the housing (11) have a conical shape, the support surface (11f) cooperating with the rotary valve (12). The through-holes (11d) are disposed in the area of the support surface (11f).

Owner:IMTMEDICAL

Soft pill for promoting hair growth and blacking hair and preparation process of soft pill

InactiveCN105521336AFast and full extractionFast absorptionOrganic active ingredientsPill deliveryIsomaltooligosaccharideSemen

The invention belongs to the technical field of medicine, and in particular relates to a soft pill for promoting hair growth and blacking hair and a preparation process of the soft pill. The soft pill is prepared from the following raw materials: black beans, radix polygoni multiflori, radix rehmanniae preparata, radix rehmanniae, radix angelicae sinensis, caulis spatholobi, cortex moutan, radix paeoniae alba, fructus corni, fructus mori, glossy privet fruit, herba ecliptae, fruit of Chinese wolfberry, fructus psoraleae, radix achyranthis bidentatae, black sesames, semen cassia, seed of Chinese dodder, radix ophiopogonis, poria cocos, cortex albiziae, radix bupleuri, fructus tribuli, radix saposhnikoviae, sodium alginate, gellan gum, tamarind gum, curdle polysaccharide, isomalto-oligosaccharide and black glutinous rice wine through such processes as extracting, dropping and curing, sterilizing with steam at 118 DEG C for 30min, thermally coagulating and the like. The soft pill disclosed by the invention is significant in functions of promoting hair growth, blacking hair and beautifying the hair; and the soft pill is innovative in dosage form and is fashionable and interesting in taste.

Owner:DONGGUAN MENGCHUANG HEALTH CARE TECH CO LTD

Method and device for separating gases

InactiveCN104254383AAssurance of expected puritySave energyNitrogen purification/separationMembranesControl systemProduct gas

Device for separating gases that comprises the following components: a source for the gases and flow adjustment means; a membrane unit (6) for the production of a permeate gas and a retentate gas, one of which is the product gas; purity determining means for the product gas; a first control unit (13) for the device; a retentate control system (19) and a product gas pressure measurement, whereby the source has a second control unit (16) for the flow adjustment means as a function of a target value of the gases and the first control unit (13) is connected to the second control unit and to the retentate control system (19), whereby the first control unit (13) can determine the target value and can control the retentate control system (19).

Owner:ATLAS COPCO AIRPOWER NV

Down feather non-destructive cleaning method

ActiveCN112501695AWon't hurtAchieve cleaningWool fibre washing/scouringSpiral bladeElectric machinery

The invention discloses a down feather non-destructive cleaning method. The method mainly comprises the following processing steps of filler water injection, spiral water flow cleaning, automatic water changing and circulating cleaning and collection. According to the down feather non-destructive cleaning method, processing equipment used in a processing process comprises a cleaning box; a power cavity is formed in the lower portion of the cleaning box; a motor is fixed to the inner wall of the power cavity; an output shaft of the motor penetrates through the top of the power cavity and is fixedly provided with spiral blades located in the cleaning box; and partition plates are fixed to the inner wall of the cleaning box. The down feather non-destructive cleaning method has the advantagesthat by arranging the spiral blades, under the driving of the motor, the spiral blades continuously rotate to drive water flow to move, and down feathers move along with the water flow to continuouslyrub against one another and rub against the inner wall of the cleaning box, so that self-cleaning can be achieved, and impurities are separated from the down feathers; and the partition plates are arranged, so that the down feathers are not damaged by the spiral blades, and the down feathers are not greatly damaged in the cleaning process.

Owner:杭州华俊实业有限公司

Soil loosening device for potted plants

InactiveCN104206056BAvoid leakage lossAccelerate evaporationSoil-working equipmentsAgricultural engineeringControl switch

The invention relates to a potted plant soil loosening device, and belongs to the field of agricultural machines. The potted plant soil loosening device comprises a lifting handle, a main switch, a control switch, a handle, a gear, a sleeve III, a connecting shaft III, a central shaft, a stepping motor, a motor box, a straight pole I, a straight pole II, a central pole, a rack I, a connecting shaft I, a sleeve I, a rack II, a connecting shaft II, a sleeve II, a fixed knob I, an annular base I, a spring, a groove, an annular base II, a diagonal rod, a ridger, a spring latch, an anti-swinging shield, a pin, a fixed knob II, a sleeve IV, a soil loosening pointed end I, a soil loosening pointed end II, a bolt I, a nut I, a bolt II, a nut II, a sheet, a circuit main switch, a positive rotation switch, a reverse rotation switch, a bolt III and a nut III. By adopting the potted plant soil loosening device, the leakage and loss of soil moisture and soil elements caused by cracks can be effectively avoided; flattening and proper compacting operation on loosened soil can be realized; semi-automation can be realized.

Owner:KUNMING UNIV OF SCI & TECH

Hydraulic control device and pressure switch

InactiveUS8549853B2Minimised starting resistanceAvoid leakage lossFluid couplingsServomotor componentsMain channelEngineering

In a hydraulic control device H comprising a pressure source P which can be switched on and switched off, a reservoir R and a pressure switch W located in a discharge path 13 from a valve assembly V to the reservoir R, which pressure switch W either connects the valve assembly V with the reservoir R or blocks the valve assembly V versus the reservoir R, the pressure switch W contains a displaceable control member 16 which is actuated in a first switching direction by a spring 17 and a pilot pressure originating from the pressure P1 acting at the valve assembly V and in a second switching direction to a control position blocking the discharge path 13 by a pilot pressure originating from the supply pressure of the pressure source, the pressure switch W is designed as a 2 / 2-multi-way seat valve 16 operating with a blocking position without leakage. A valve member 24 forms the control member 16 and co-operates with a valve seat 25 arranged in the discharge path 13. The pressure source P and the valve assembly V are permanently connected via a main channel 10, 11 containing a restrictor D. The discharge path 13 branches off from the main channel 10, 11, 12 between the valve assembly V and the restrictor D. The pilot pressure actuating the valve member 26 in the switching direction towards the valve seat 25 originates from the supply pressure taken between the pressure source P and the restrictor D.

Owner:HAWE HYDRAULIK SE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com