Method and measurement probe for the performance of measurements in water supply systems

a technology for water supply systems and measurement probes, applied in the direction of measurement devices, structural/machine measurement, instruments, etc., can solve the problems of leakage loss, large case size, and only rarely detected leakage losses, and achieve easy application and good gripping facilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

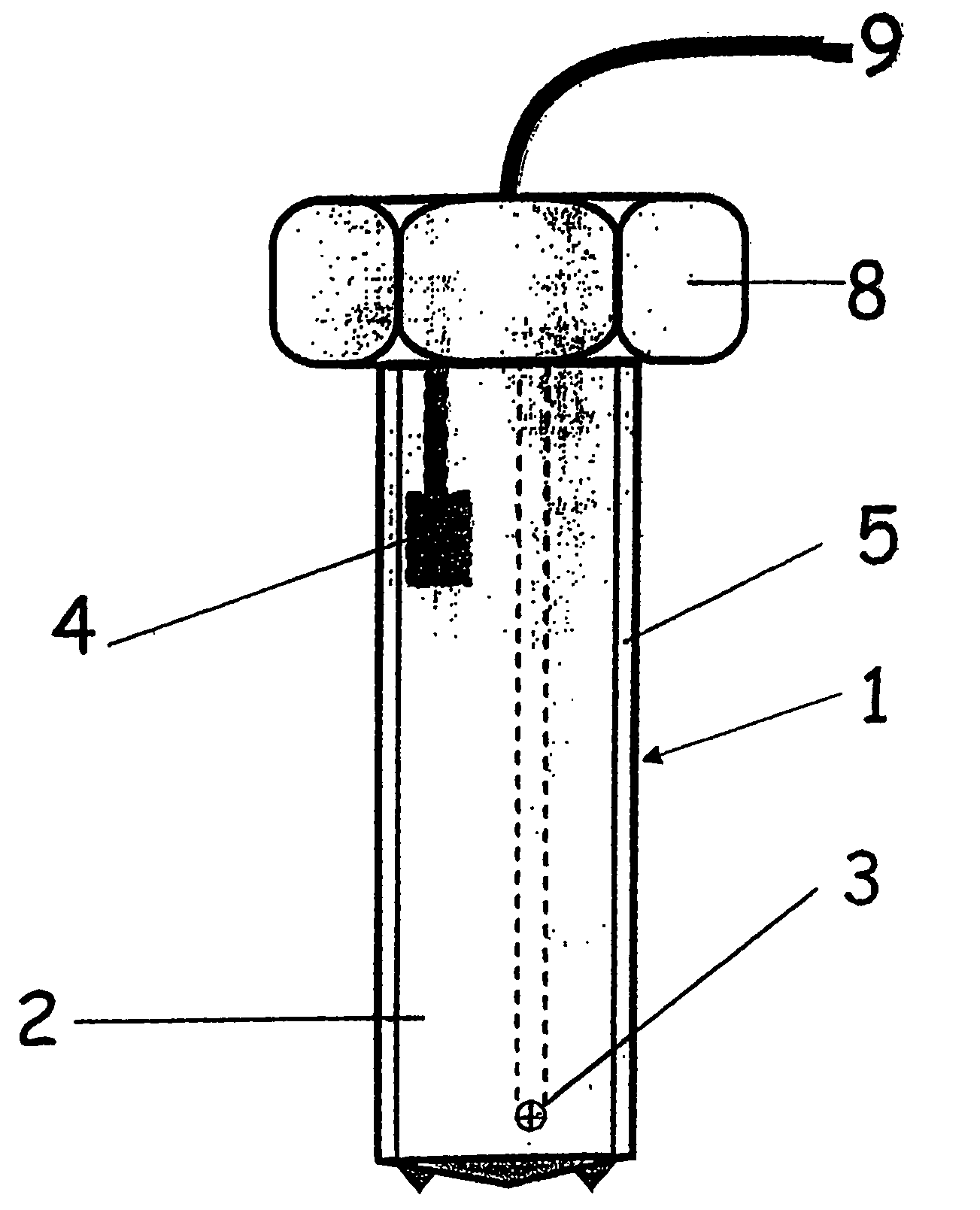

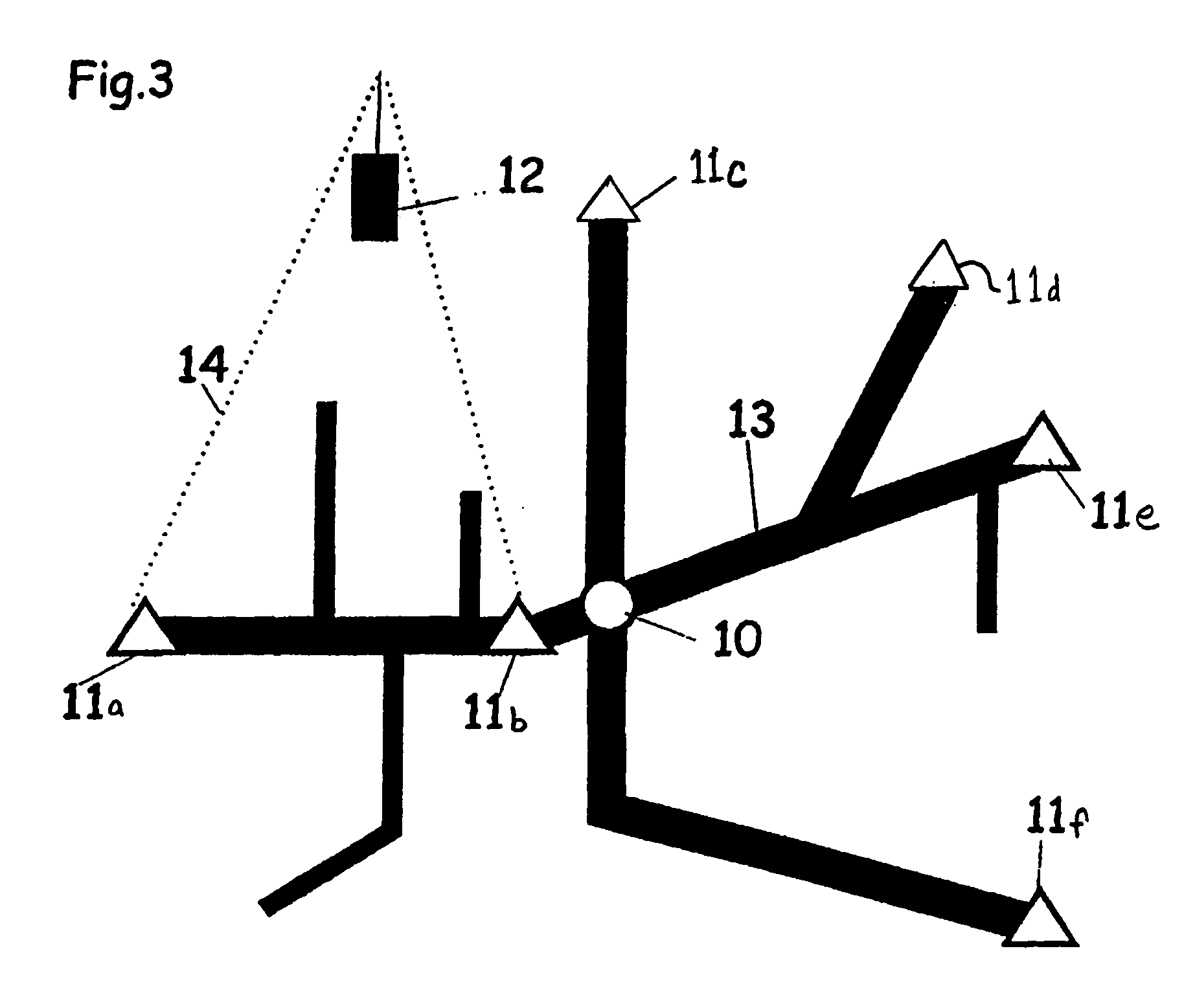

[0024] Measuring elements, i.e. a probe 2 for the flow measurement, a pressure sensor 3 and a noise detector 4, for the output of measured quantities in respect of the flow, namely the flow rate and direction, the water pressure and the flow noise, are integrated into a measurement probe 1 represented in FIG. 1 for water supply networks. These measuring elements are connected or can be connected by means of transmission via a terminal, by radio, modem or cable connection to an evaluation device or a data collector 12 or, in respect of the noise detector, to a correlator. The essential thing, therefore, is that there are integrated in one measurement probe all the measuring elements that are required for optimum leak location and thus for optimum monitoring and analysis of a water supply network. Measurement probes capable of supplying all the necessary measured values are thus available at all the measurement points.

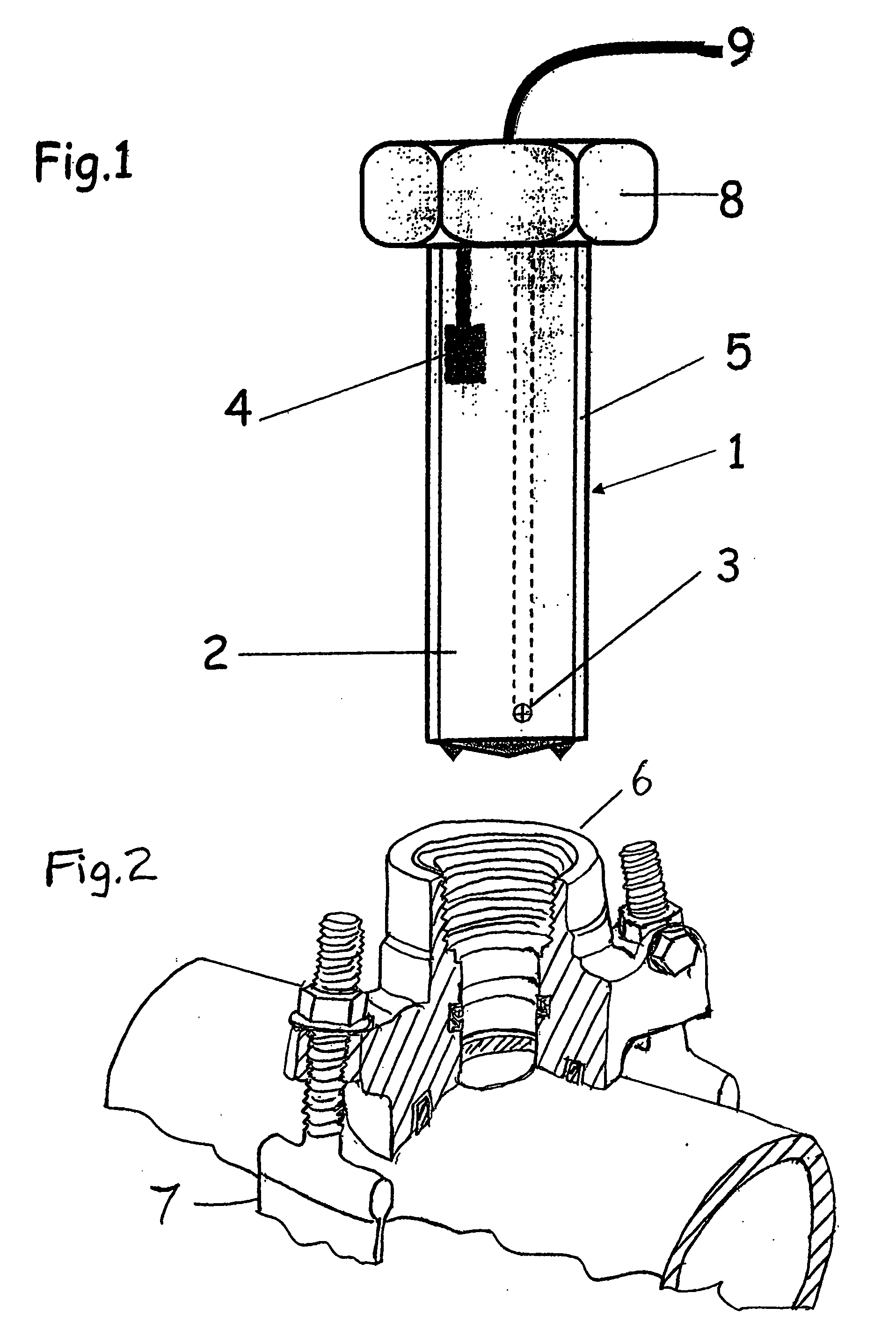

[0025] The measuring elements are placed in a sleeve-like threaded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com