Method and device for separating gases

A gas and inlet gas technology, applied in separation methods, semi-permeable membrane separation, nitrogen purification/separation, etc., can solve problems such as inability to build, ineffective solutions, and inability to prevent gas purity problems, so as to save energy and avoid leakage losses Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

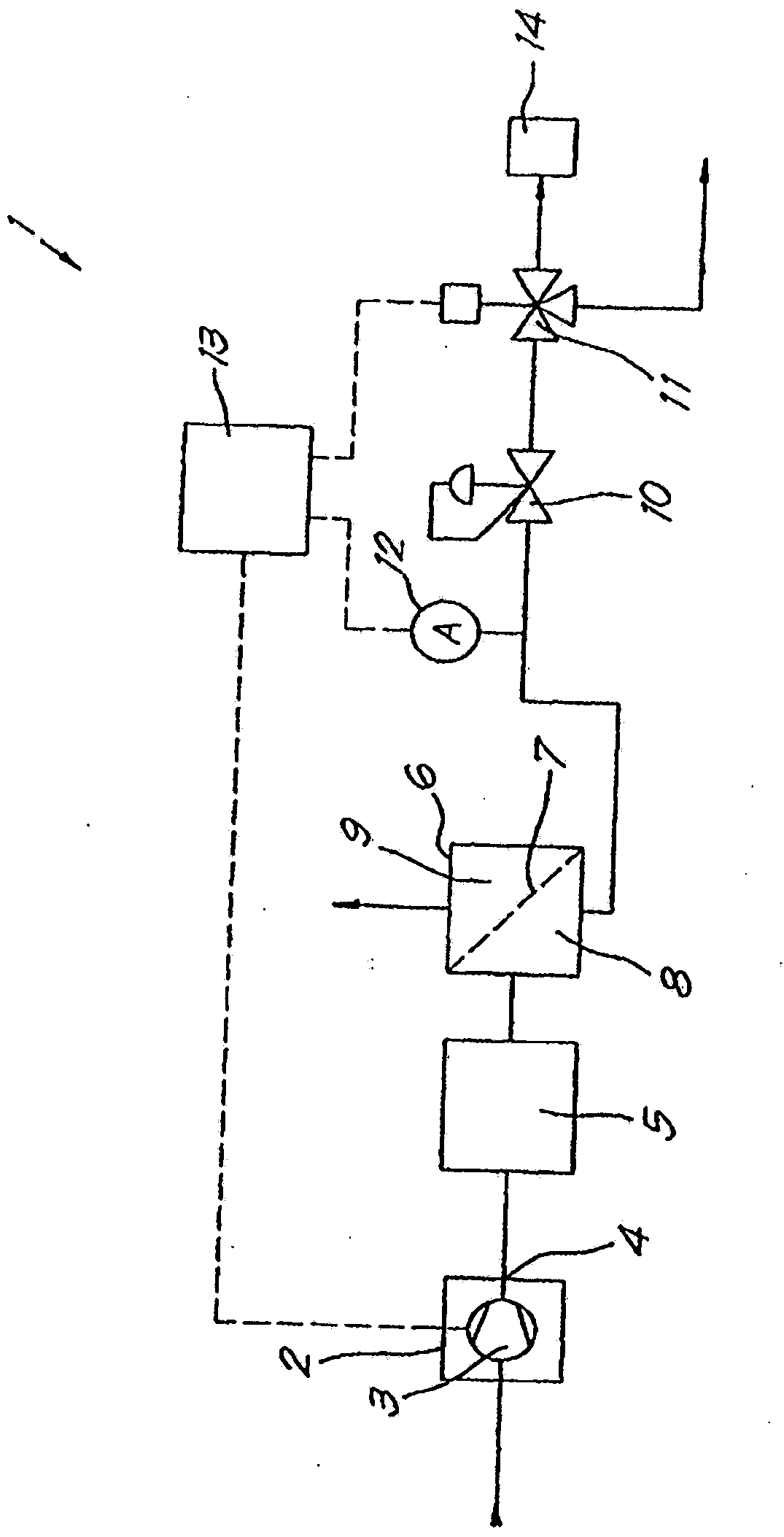

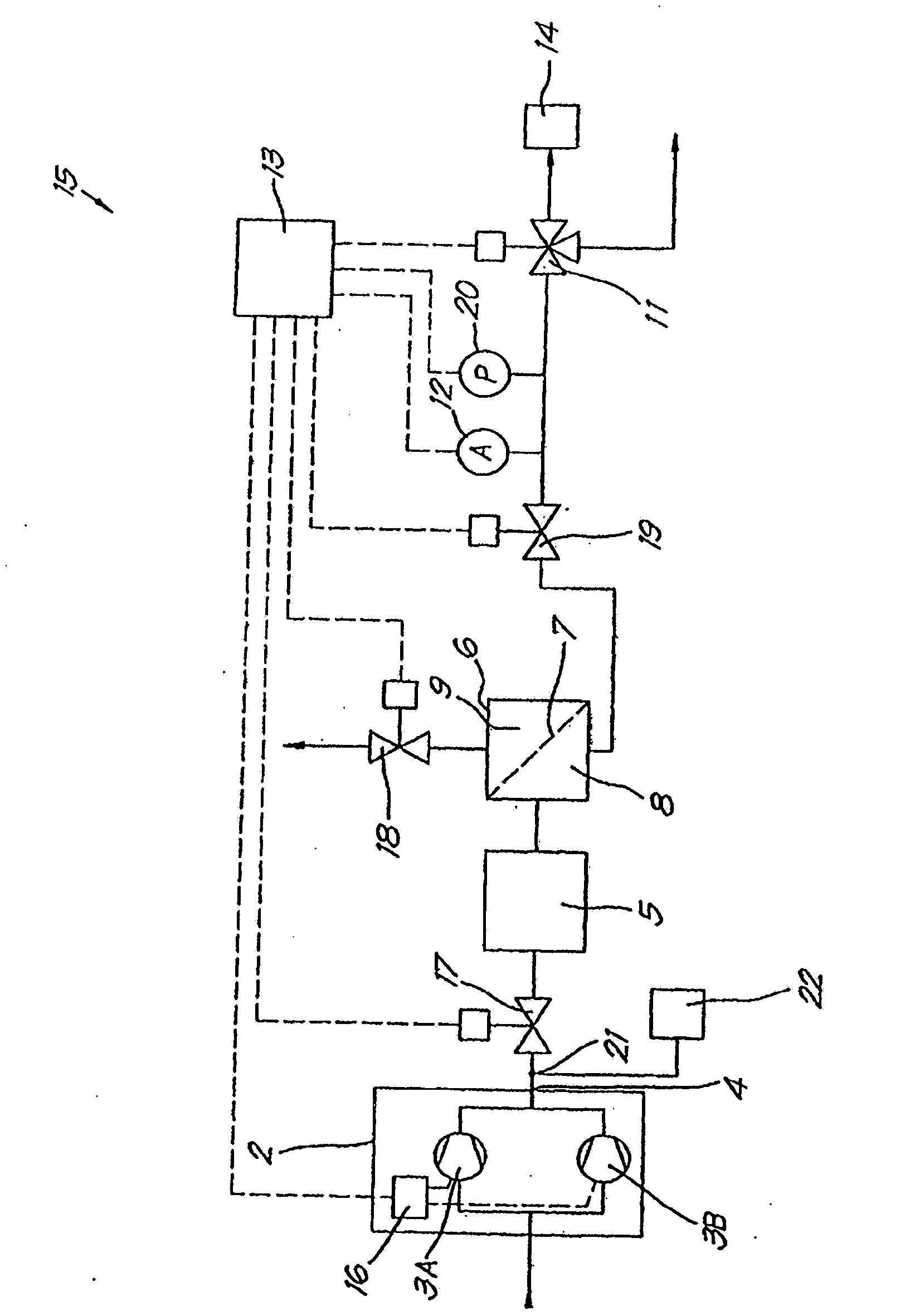

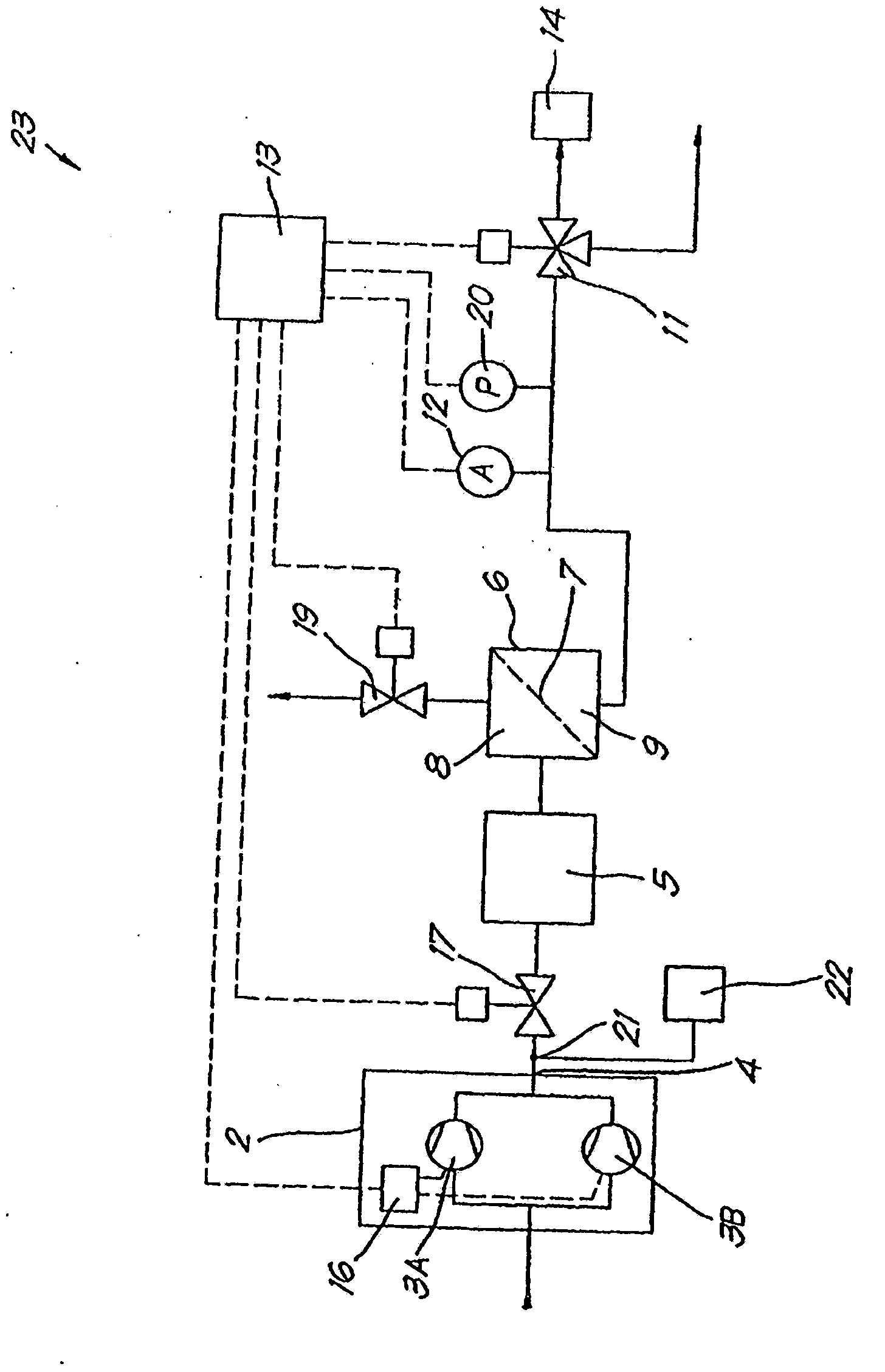

[0069] The plant 1 illustrated in Figure 1 is a plant for the production of nitrogen from air, whereby the nitrogen has a certain minimum purity.

[0070] The device 1 comprises a compressor unit 2 with a compressor 3, the outlet 4 of which is connected via a gas treatment unit 5 to a membrane unit 6 equipped with a membrane 7 whose permeability to oxygen higher than nitrogen. The membrane 7 separates the retentate side 8 from the permeate side 9 of the membrane unit 6 .

[0071] The compressor unit 2 may also include a gas dryer (not shown).

[0072] The stagnant side 8 is connected to a minimum pressure valve 10 and a three-way valve 11 . The oxygen sensor 12 is located between the minimum pressure valve 10 and the diaphragm unit 6 .

[0073] The oxygen sensor 12 is connected to the control unit 13 provided with an algorithm by means of signal transmission to adjust the capacity of the compressor in operation by means of a slide valve located at the inlet of the compresso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com