Down feather non-destructive cleaning method

A down and cleaning box technology, applied in the field of down processing, can solve the problems of poor cleaning effect of down, achieve the effects of saving manpower, avoiding leakage loss, and improving cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

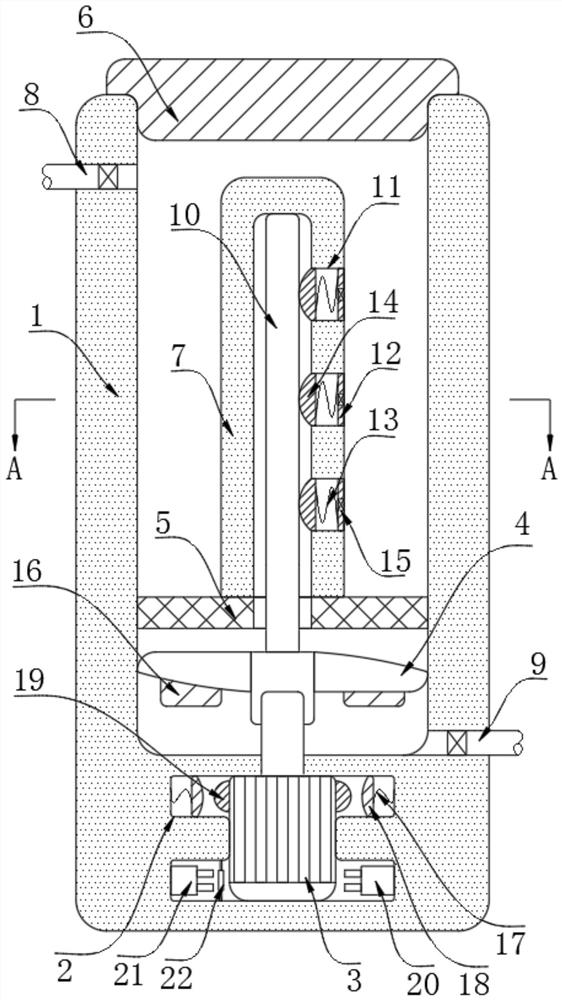

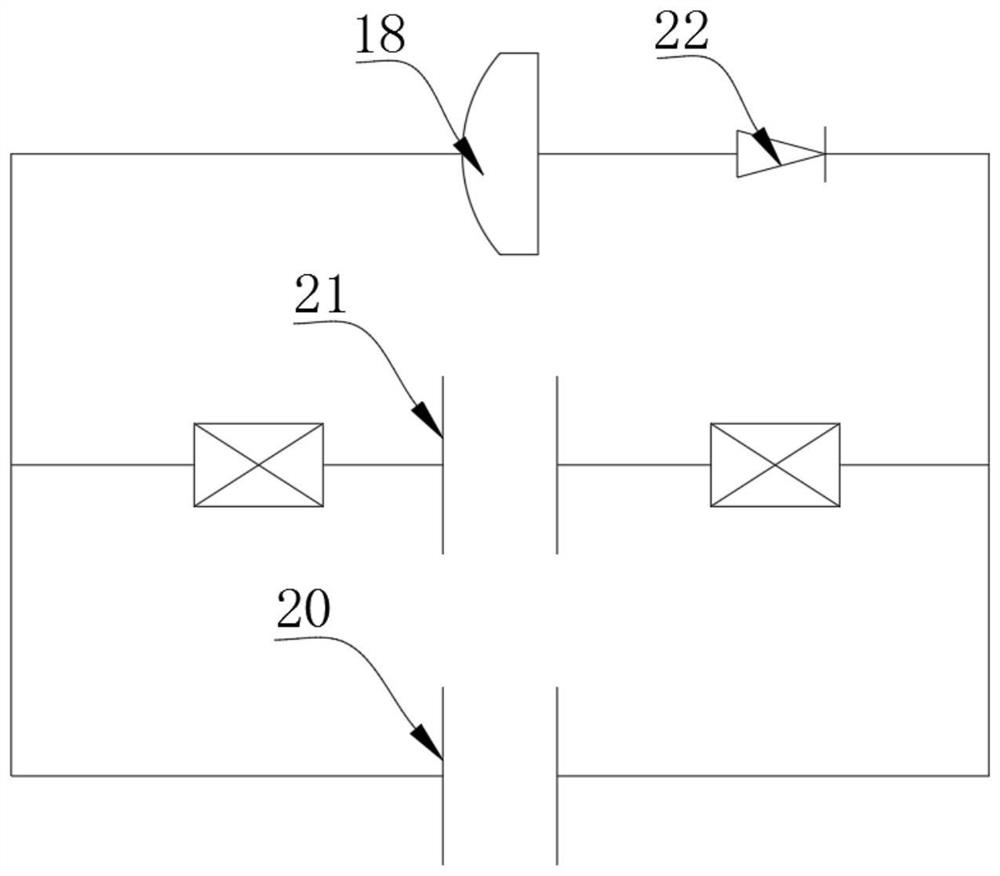

[0024] refer to Figure 1-3 , a non-destructive cleaning method for down, which mainly includes the following processing steps:

[0025] S1. Filling with water: pour the down to be cleaned into the cleaning box 1, so that it is located on the upper part of the partition 5 and does not directly contact the spiral leaf 4, then manually open the solenoid valve inside the water inlet pipe 8, and pour water into the cleaning box 1, and finally pass the The cover plate 6 closes the cleaning box 1;

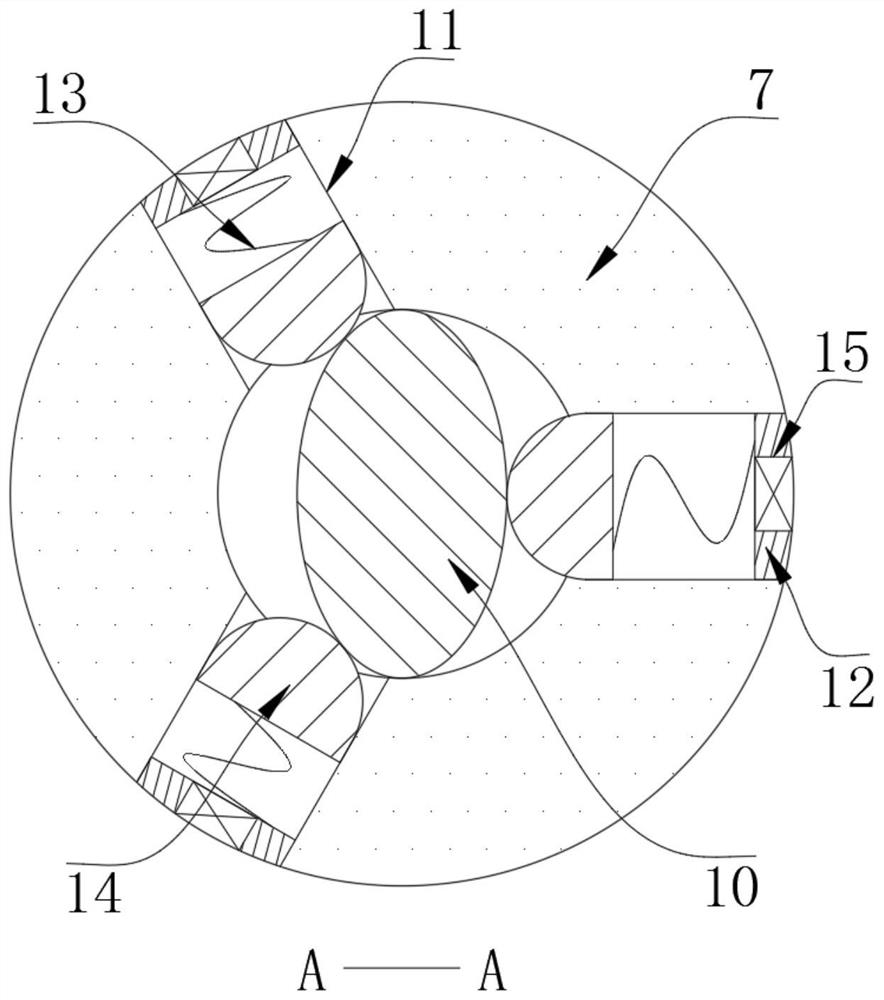

[0026] S2. Spiral water flow cleaning: start the motor 3 to drive the spiral blade 4 to rotate, thereby driving the water flow inside the cleaning box 1 to rotate, so that the beam inside the cleaning box 1 moves in a spiral shape, and at the same time, the rotation of the rotating shaft 10 drives the push block 14 to reciprocate. The water spray tank 11 is caused to spray water intermittently outward, and the water column is formed to impact the down spirally moving with the water flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com