Device and method for transferring rod-shaped items for tobacco industry from storage bunker into conveyor pipe

A conveying pipeline and technology in the processing industry, which is applied in the field of devices and methods for transporting rod-shaped articles from storage bins to conveying pipelines in the tobacco processing industry, can solve the problems of high cost, achieve high conveying speed, alleviate sealing problems, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

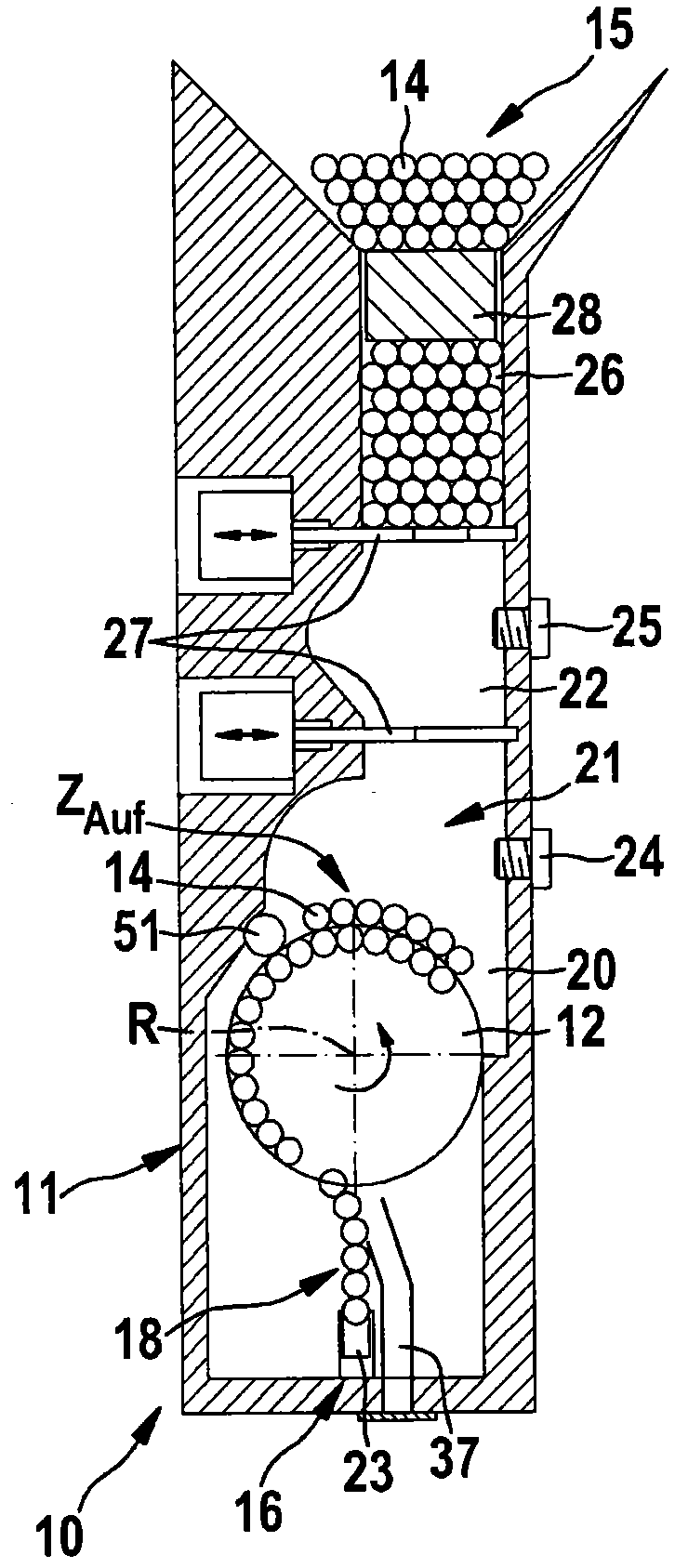

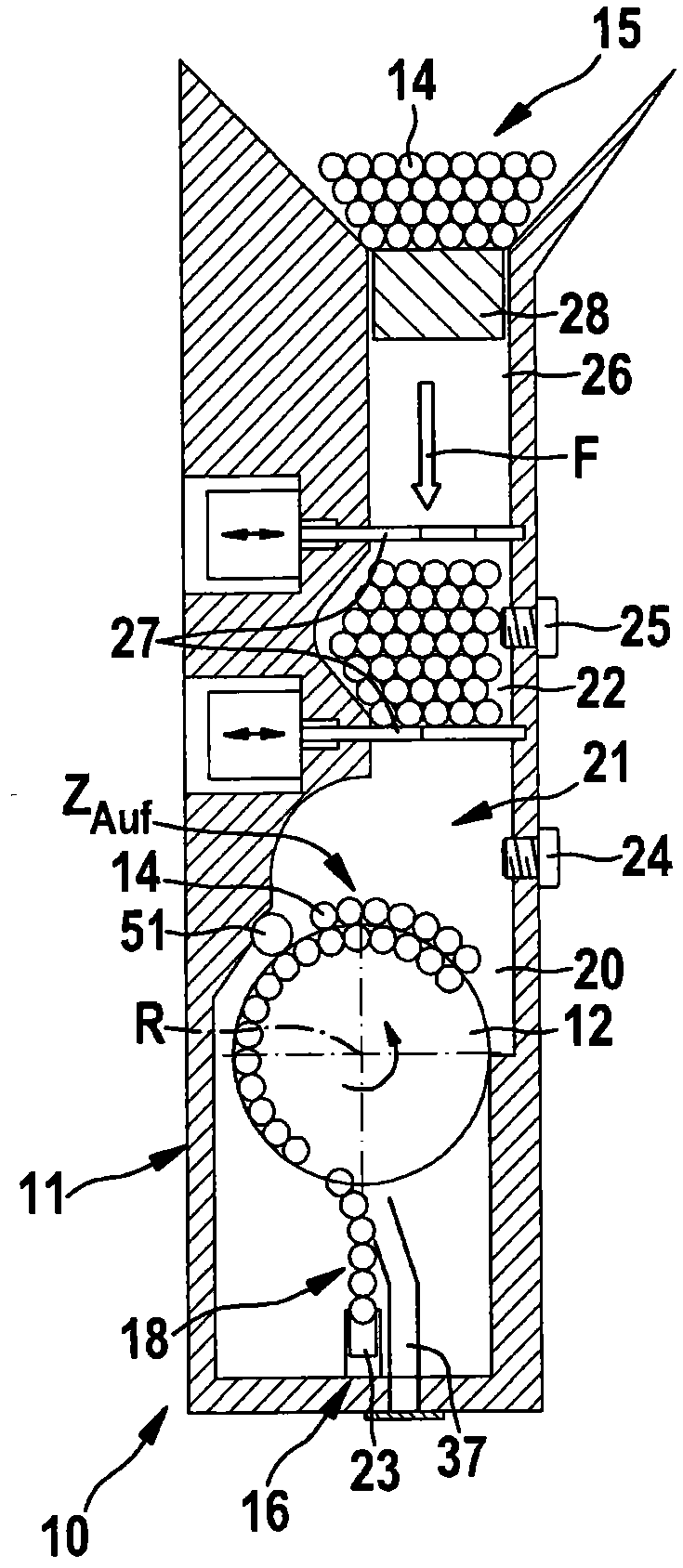

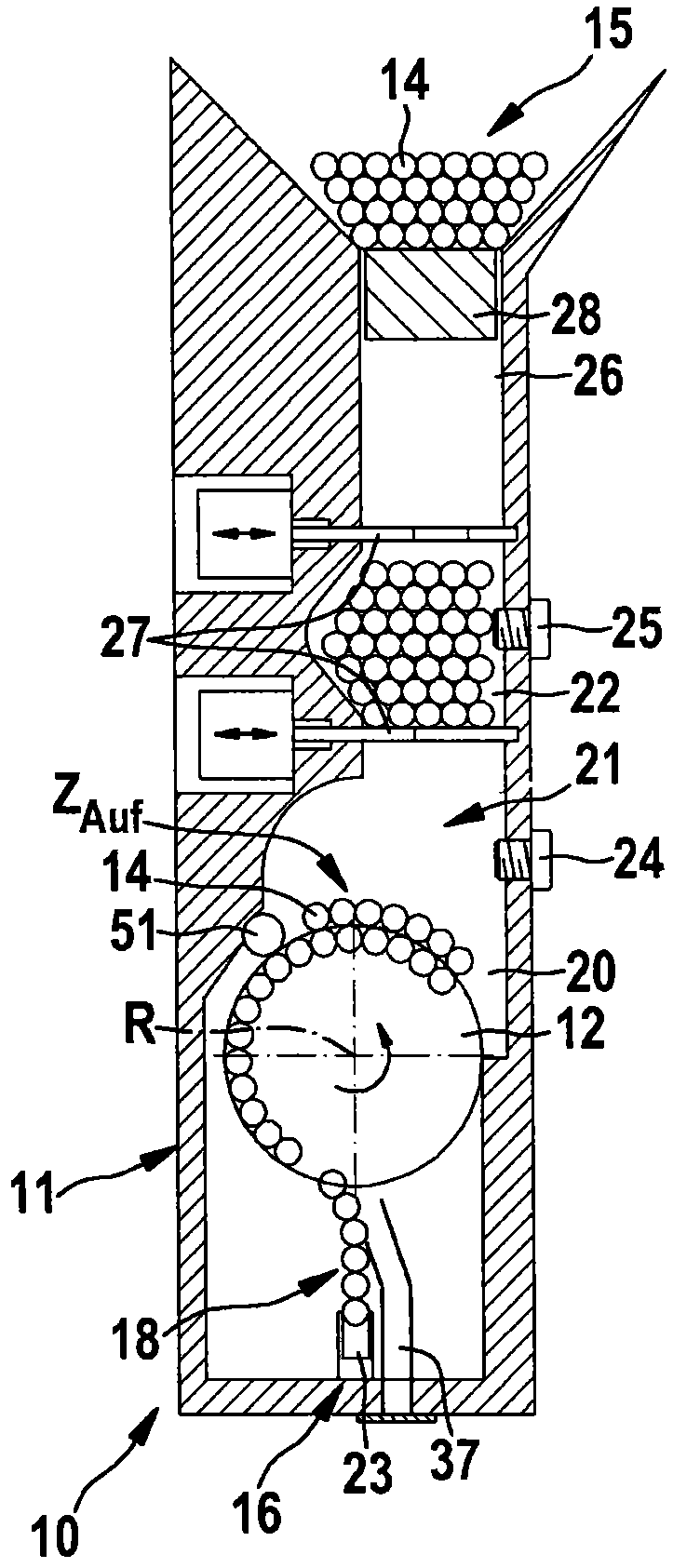

[0036] The device shown in the figures is used to transfer the filter plugs from the storage silo into a conveying line in order to launch the filter plugs to a receiving station. Of course, the device is also suitable and designed and provided for transporting other rod-shaped and in particular cylindrical objects of the tobacco processing industry.

[0037] The device 10 comprises a transmitter unit 11 having a conveying element designed as a rotatably driven roller 12 . The drum 12 is provided with recesses 13 for receiving stick-shaped objects 14 . Through the rotation of the drum 12 about the axis of rotation R, the goods 14 can be conveyed transversely and axially, preferably from the storage bin 15 into the region of the exhaust area 16 . The articles 14 can however also be conveyed directly to the drum 12 . In the embodiment described according to FIGS. 1 to 12 , the drum 12 has no openings for applying suction air or the like. In other words, the item 14 inside the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com