Digital servo hydraulic cylinder

A technology of hydraulic cylinders and cylinder blocks, which is applied in the direction of fluid pressure actuators, etc., can solve the problems of high counterfeiting of servo valves and sensor servo controllers, cost and high technical thresholds hindering the popularization of servo hydraulic cylinders, high control technology, etc. Achieve the effects of improving anti-pollution ability, avoiding leakage loss, and simplifying the hydraulic system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

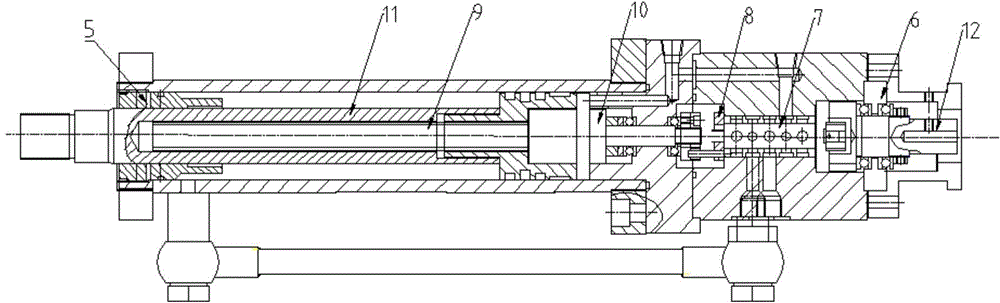

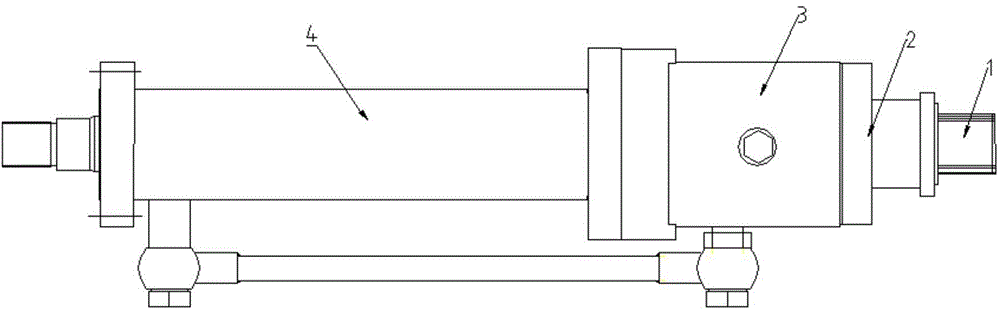

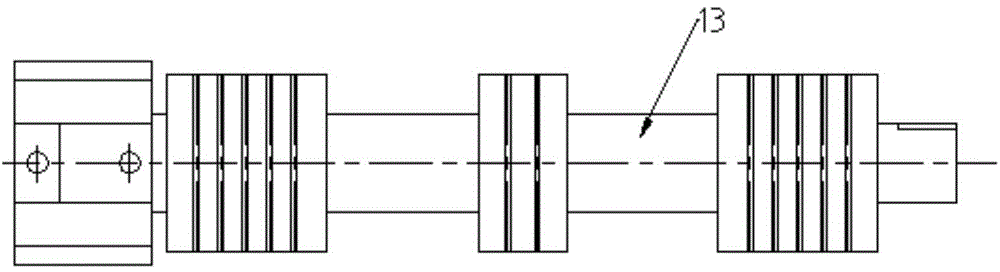

[0041] Such as Figure 1-Figure 3 As shown, the present invention provides a digital servo hydraulic cylinder, which includes a stepper motor 1, a rear end cover 2, a digital valve block 3, a cylinder body 4, and a front end cover 5 connected in sequence, a plane thrust bearing 6, a hydraulic slide valve 7, a valve The core nut 8, the ball screw 9, the screw nut 10, and the hollow piston rod 11 are designed and combined in the hydraulic cylinder. The stepper motor 1 generates rotational motion by receiving the digital pulse signal sent by the external dedicated digital controller, computer or PLC programmable controller, and the spool valve core 13 in the hydraulic spool valve 7 passes through the flat key 12 and the plane thrust bearing 6 connected to drive the spool 13 of the spool to rotate. Further, such as figure 1 As shown, the plane thrust bearing 6 is installed at the rear end of the hydraulic spool valve 7 and in the rear end cover 2 to bear the axial load, ensure t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com