External-pressure type charged hollow fiber nano-filtration membrane and preparation method therefor

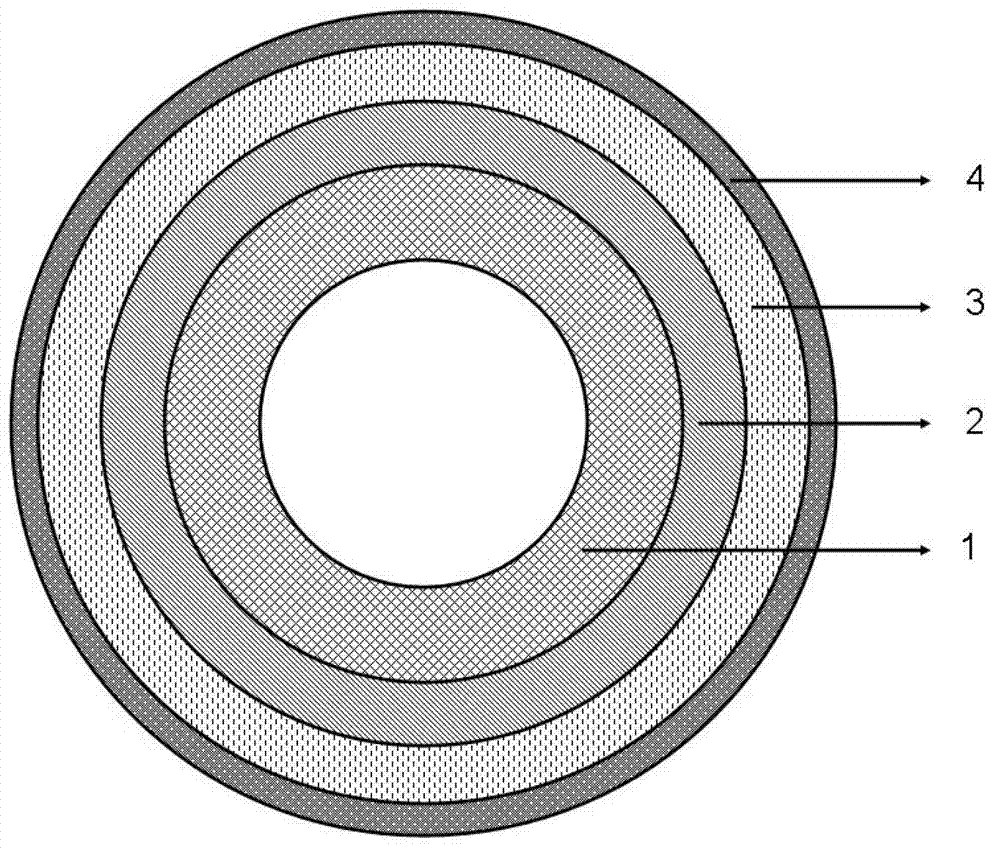

A nanofiltration membrane and external pressure technology, applied in the field of multi-layered tubular nanofiltration membrane and its preparation, can solve the problem of easy separation and the like, and achieve the effects of improving connection fastness, ensuring fastness and not falling off easily.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0096] 1. Form the ultrafiltration layer 2 outside the support tube 1

[0097]1.1 Surface treatment of inorganic nanoparticles: add 5 grams of silica nanoparticles with a particle size of 20 nm to 100 ml of 50% methanol solution by mass percentage, and add 1 gram of 3-aminopropyl- Triethoxysilane, stirred at 50°C for 1 hour, then filtered, washed with absolute ethanol and then vacuum-dried at 50°C for 48 hours to obtain surface-treated silica nanoparticles;

[0098] 1.2 Preparation of carboxyl-containing polyacrylate derivative copolymer:

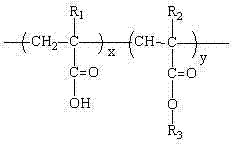

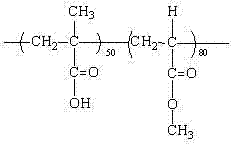

[0099] Mix 30g of acrylic acid and 100g of methyl acrylate, add 0.87g of initiator azobisbutyronitrile (AIBN), and react at 70°C for 6 hours to obtain a carboxyl-containing polyacrylate derivative copolymer with the following structural formula:

[0100]

[0101] 1.3 Preparation of film-forming solution: Dissolve 10 g of polyethersulfone, 2 g of the above-prepared carboxyl-containing polyacrylate derivative copolymer, 1 g of the above-p...

Embodiment 2

[0111] 1. Form the ultrafiltration layer 2 outside the support tube 1

[0112] 1.1 Surface treatment of inorganic nanoparticles: 30 grams of titanium dioxide nanoparticles with a particle size of 40nm were added to 100 ml of absolute ethanol solution, and 10 grams of γ-(2,3-glycidyloxy) was added after ultrasonic dispersion for 30 minutes Propyltrimethoxysilane was stirred at 80°C for 4 hours, then filtered, washed with absolute ethanol and then vacuum-dried at 80°C for 12 hours to obtain surface-treated titanium dioxide nanoparticles;

[0113] 1.2 Preparation of carboxyl-containing polyacrylate derivative copolymer:

[0114] Mix 50g of methacrylic acid and 100g of ethyl methacrylate, add 0.47g of initiator azobisbutyronitrile (AIBN), and react at 65°C for 10 hours to obtain a carboxyl-containing polyacrylate derivative copolymer with the following structural formula :

[0115]

[0116] 1.3 Preparation of film-forming solution: 30 g of polysulfone, 10 g of the above-prepa...

Embodiment 3

[0126] 1. Form the ultrafiltration layer 2 outside the support tube 1

[0127] 1.1 Surface treatment of inorganic nanoparticles: add 15 grams of silica nanoparticles with a particle size of 30 nm to 100 ml of 50% ethanol solution by mass percentage, and add 5 grams of 3-aminopropyl-tri Ethoxysilane, stirred at 60°C for 3 hours, then filtered, washed with absolute ethanol and then vacuum-dried at 60°C for 36 hours to obtain surface-treated silica nanoparticles;

[0128] 1.2 Preparation of carboxyl-containing polyacrylate derivative copolymer:

[0129] Mix 80g of methacrylic acid and 100g of methyl methacrylate, add 0.77g of initiator azobisbutyronitrile (AIBN), and react at 60°C for 8 hours to obtain a carboxyl-containing polyacrylate derivative copolymer with the following structural formula :

[0130]

[0131] 1.3 Preparation of film-making solution: dissolve 15g of polyvinyl chloride, 6g of the above-prepared carboxyl-containing polyacrylate derivative copolymer, 3g of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com