Hollow fiber ultrafiltration composite membrane, preparation method and application thereof

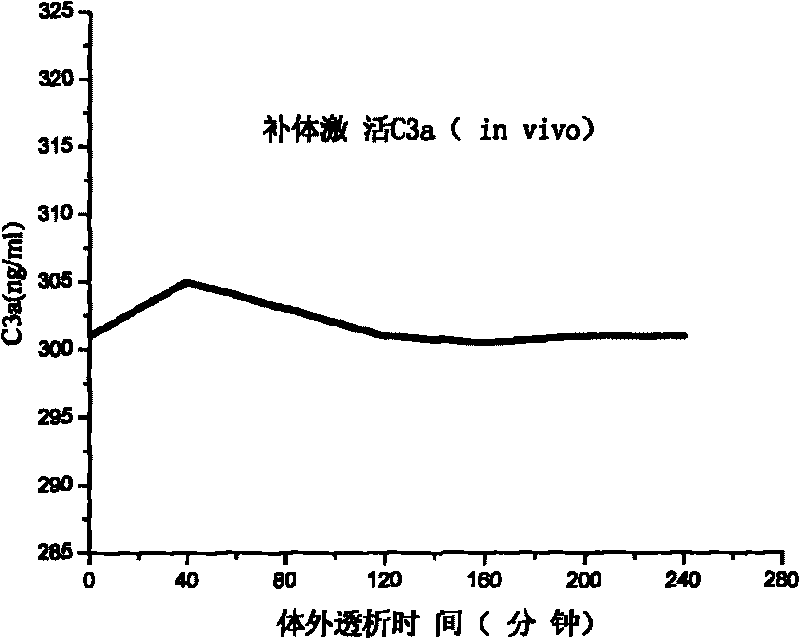

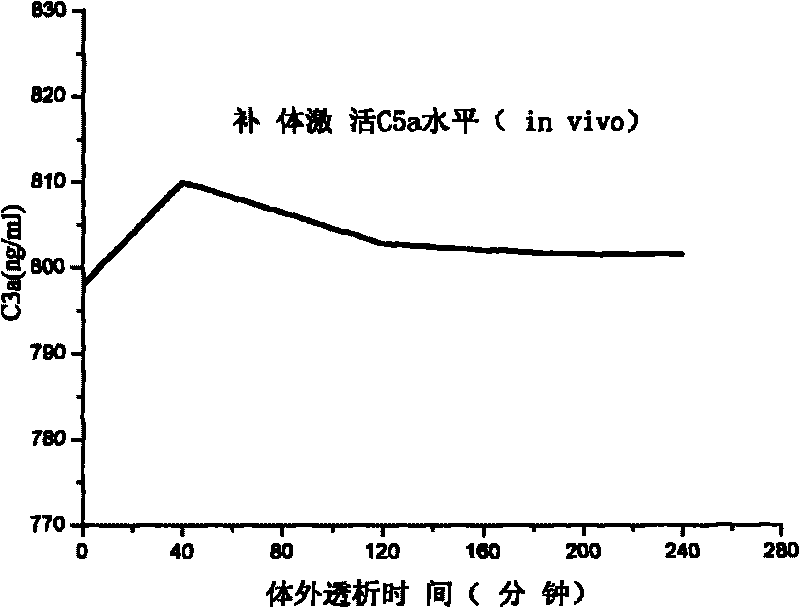

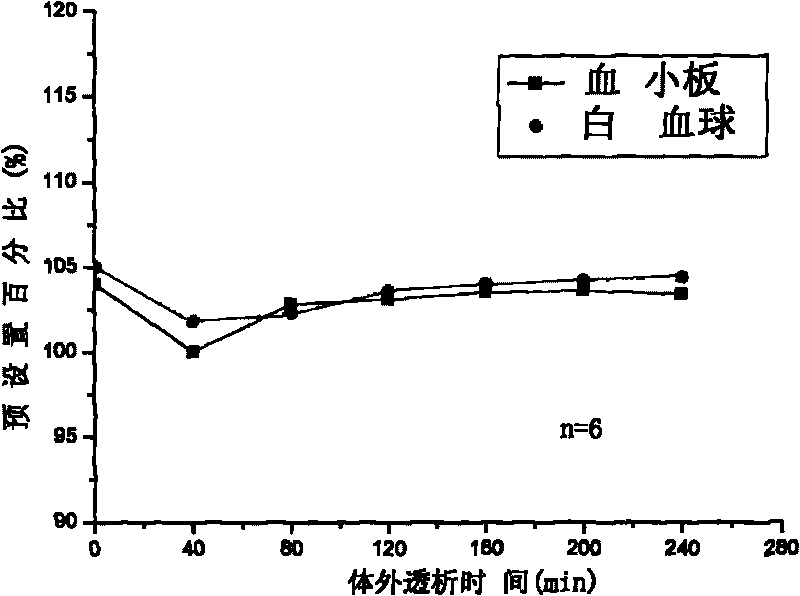

A technology of ultrafiltration composite membrane and hollow fiber, which is applied in the direction of chemical instruments and methods, membrane technology, semipermeable membrane separation, etc., can solve the problems of increasing activation degree and affecting the biocompatibility of polysulfone membrane materials, and achieve reduction Stimulation, improved blood compatibility, low complement activating factor effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The hollow fiber ultrafiltration composite membrane of the present invention, its raw material is made up of the component that has following percentage by weight, the membrane material of 15-25%, the porogen of 5-15%, the organic solvent of 55-75% and 5-10% % lithium chloride, and the membrane material is a mixture of one of polysulfone, polyethersulfone, polyacrylonitrile, polymethyl methacrylate or cellulose triacetate and 1-5% chitosan. The chitosan viscosity average molecular weight of the present invention is 300000-1000000, and the chitosan viscosity average molecular weight is preferably controlled between 500000-800000, and the chitosan N-deacetylation degree is 60%~100%. The organic solvent of the present invention It is one of N-methyl-2-pyrrolidone, dimethylacetamide or dimethyl sulfoxide, and the porogen is one of polyvinylpyrrolidone, polyethylene glycol and polyvinyl alcohol or a mixture of any two of them , above-mentioned each raw material is commercial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com