Mg-Zn-Y-Nd alloy for novel biodegradable vascular stents and preparation method thereof

A mg-zn-y-nd, biodegradable technology, applied in stents, prostheses, medical science, etc., can solve the problems of fast corrosion rate and low plasticity, achieve the goal of reducing corrosion rate, uniform corrosion and improving mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

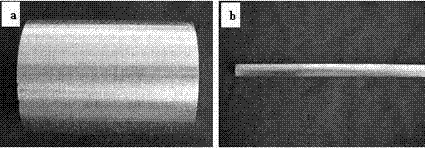

[0047] The method for preparing extruded Mg-1Zn-0.23Y-0.5Nd magnesium alloy comprises the following steps:

[0048] (1) Determine the alloy composition and prepare materials:

[0049] Before smelting, calculate the quality of each alloy element required in advance; then use the pallet balance to weigh and prepare according to the calculated results; the content of each element (percentage by weight) in the Mg-1Zn-0.23Y-0.5Nd alloy is: Zn 1 %, Y 0.23%, Nd 0.5%, and the balance is Mg. Among them, Zn and Nd elements have a burning loss rate, and the excess is 20%; Y and Nd are added by Mg-25wt%Y and Mg-25wt%Nd master alloys respectively ; The charge required for smelting 1000g Mg-1Zn-0.23Y-0.5Nd alloy is as follows:

[0050] High-purity magnesium ingot: 954.8g

[0051] High-purity zinc ingot: 12g

[0052] Mg-25wt%Y master alloy: 9.2g

[0053] Mg-25wt%Nd master alloy: 24g;

[0054] (2) Preparation of ordinary solidified Mg-1Zn-0.23Y-0.5Nd magnesium alloy:

[0055] a. Put the...

Embodiment 2

[0071] The method for preparing extruded Mg-2Zn-0.46Y-0.5Nd magnesium alloy comprises the following steps:

[0072] (1) Determine the alloy composition and prepare materials:

[0073] Before smelting, calculate the mass of each alloy element required in advance; then use the tray balance to weigh and prepare according to the calculated result; the content (weight percentage) of each element in the Mg-2Zn-0.46Y-0.5Nd alloy is: Zn 2 %, Y 0.46%, Nd 0.5%, and the balance is Mg. Among them, Zn and Nd elements have an excessive burning loss rate of 20%; Y and Nd are added with Mg-25wt%Y and Mg-25wt%Nd master alloys respectively; The charge required for smelting 1000g Mg-2Zn-0.46Y-0.5Nd magnesium alloy is as follows:

[0074] High-purity magnesium ingot: 933.6g

[0075] High-purity zinc ingot: 24g

[0076] Mg-25wt%Y master alloy: 18.4g

[0077] Mg-25wt%Nd master alloy: 24g;

[0078] (2) Preparation of ordinary solidified Mg-2Zn-0.46Y-0.5Nd magnesium alloy:

[0079] Basically th...

Embodiment 3

[0087] The method for preparing subrapidly solidified Mg-2Zn-0.46Y-0.5Nd magnesium alloy comprises the following steps:

[0088] (1) Determine the alloy composition and prepare materials:

[0089] With embodiment 2 step (1);

[0090] (2) Preparation of ordinary solidified Mg-2Zn-0.46Y-0.5Nd magnesium alloy:

[0091] With embodiment 2 step (2);

[0092] (3) Preparation of sub-rapid solidification Mg-2Zn-0.46Y-0.5Nd magnesium alloy:

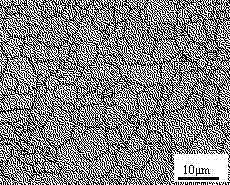

[0093] The preparation of the sub-rapid solidification alloy sample adopts the method of water-cooled copper mold injection; during the preparation process, the heating equipment used is: GP30-CW7 induction heating equipment, copper mold (wall thickness 25mm and internal hollow diameter 2mm), SP009 Strip machine, quartz tube (the diameter of the melt spraying port at the bottom of the quartz tube is Φ1mm); firstly, the common solidified Mg-2Zn-0.46Y-0.5Nd magnesium alloy prepared in step (2) is made into small pieces, And polish the surface of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com