External pressure pillar type hollow fiber films subassemblies capable of air blast

A fiber membrane and membrane module technology, applied in the field of membrane bioreactor and sewage treatment and reuse, can solve the problems of high membrane cleaning cost, low membrane flux, inconvenient membrane cleaning, etc., and achieve good anti-pollution performance, increased Turbulence, the effect of improving the anti-pollution performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

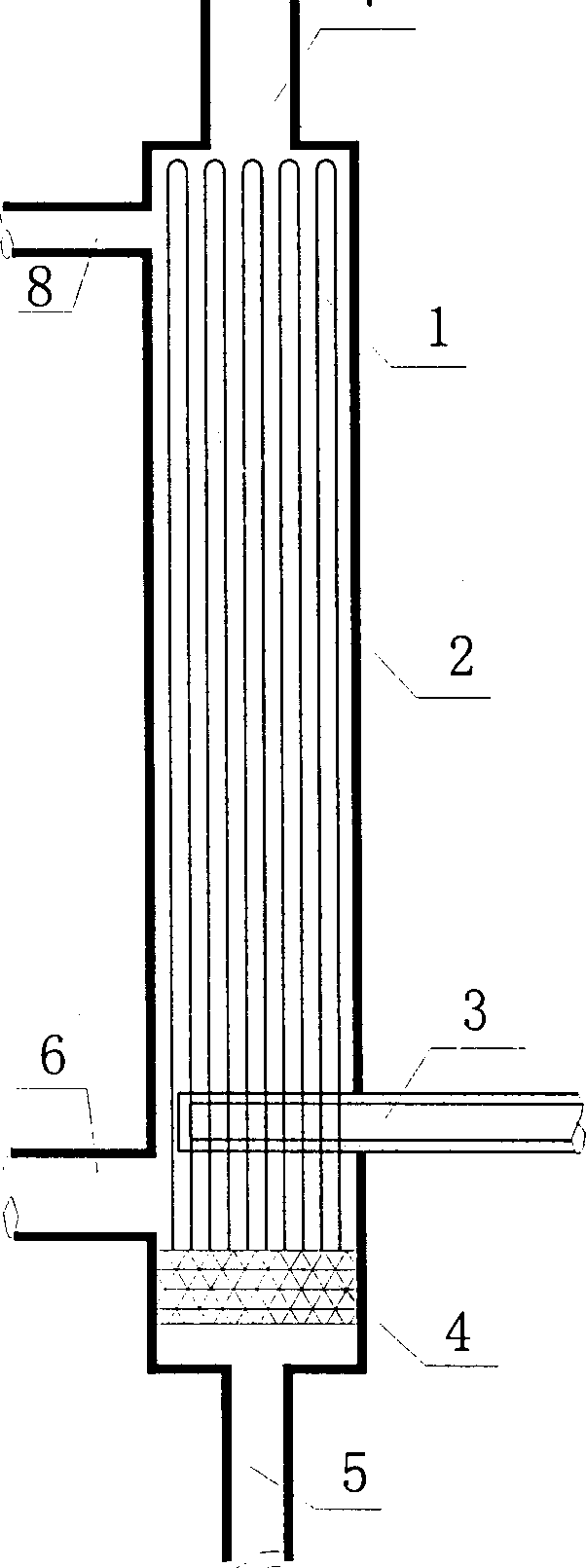

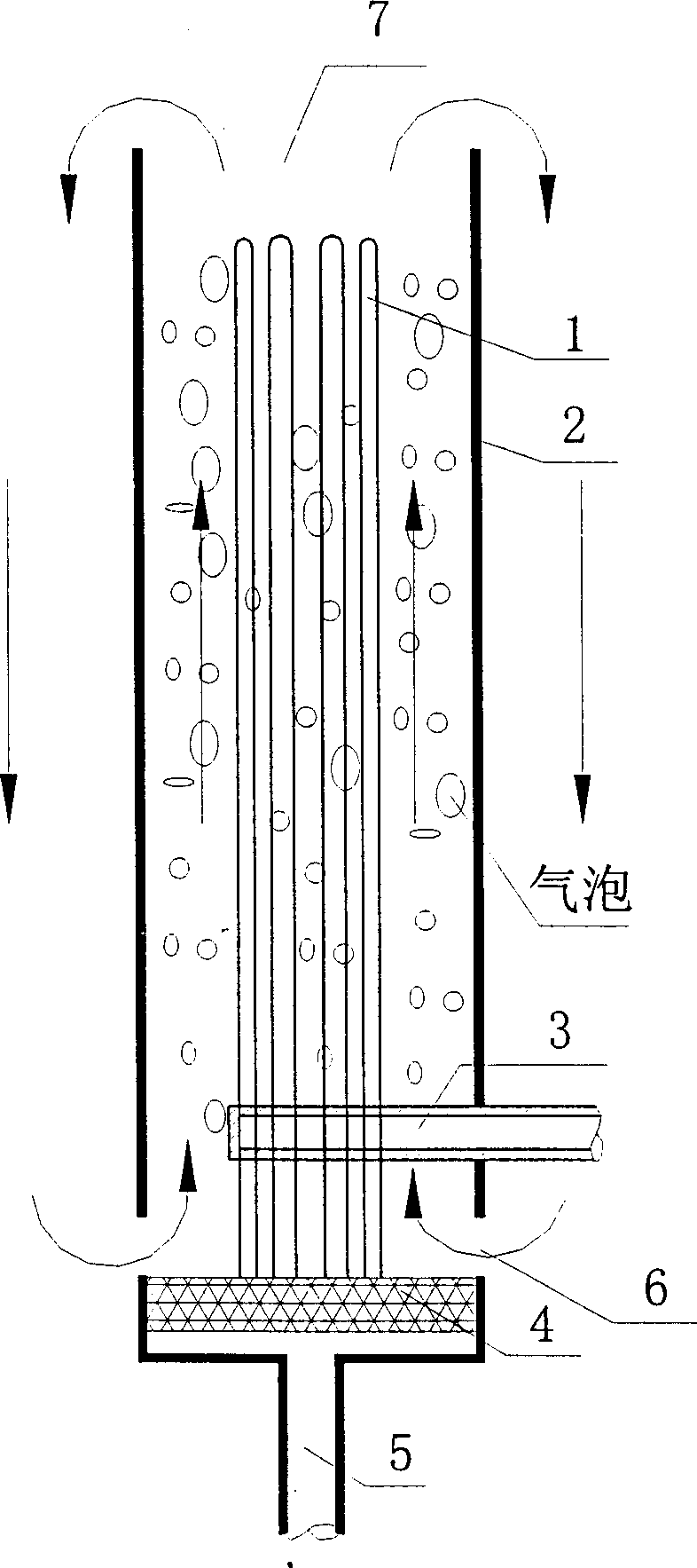

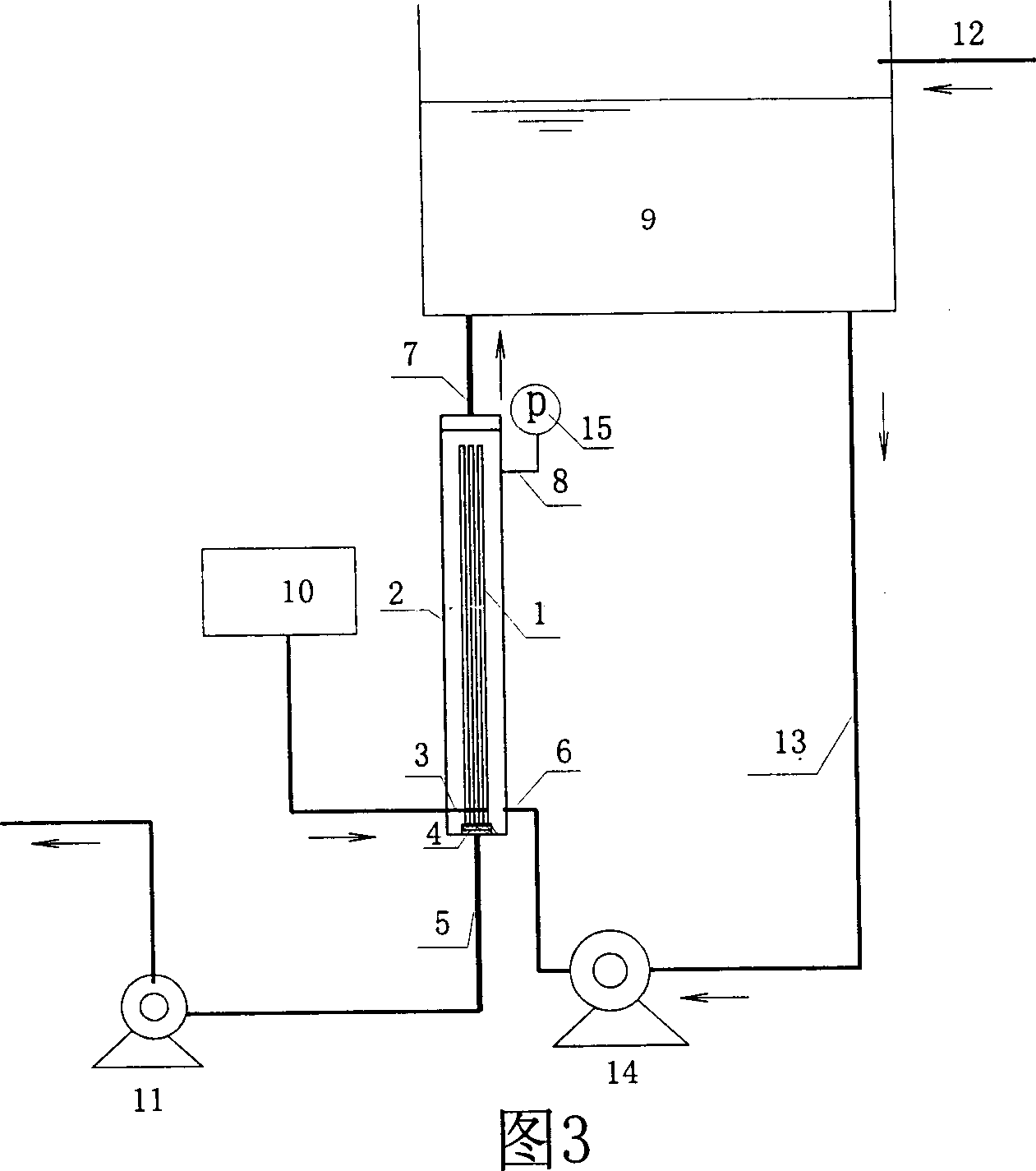

[0038] Please refer to Figure 3 for the process installation diagram of the external pressure column hollow fiber membrane module used in a separate membrane bioreactor. The height-to-diameter ratio of the outer pressure-column hollow fiber membrane module is 11:1, the length-to-diameter ratio of the hollow fiber membrane is 200:1, and the packing density of the membrane is 829m 2 / m 3 , Membrane area 0.5m 2 . When the mixed liquid sludge concentration in the reactor is 3-10g / L, the membrane flux can reach 20L / m 2 h, the circulating water volume of the circulating pump is 200L / h, the head is 2.0m, and the total efficiency of the unit is 0.49, so the energy consumption of the circulating water pump per unit water treatment is 0.21kw h / m 3 . The cross-flow velocity on the membrane surface can be controlled at 0.04-0.06m / s, which is much lower than the 3-4m / s cross-flow velocity of the known split-type membrane bioreactor process. The aeration rate is 250L / h, the boost press...

Embodiment 2

[0041] Please refer to Figure 4 for a process device diagram of an external pressure column hollow fiber membrane module used in an integrated membrane bioreactor. The height-to-diameter ratio of the outer pressure-column hollow fiber membrane module is 6:1, the length-to-diameter ratio of the hollow fiber membrane is 100:1, and the packing density of the membrane is 702m 2 / m 3 , membrane area 1.0m 2 . When the mixed liquor sludge concentration in the reactor is 3-10g / L, the membrane flux can reach 15L / m 2 h, the aeration rate is 390L / h, the boost pressure is 20kPa, and the blower efficiency is 0.44, so the energy consumption of the blower per unit water treatment is 0.49kw h / m 3 . The gas-water ratio is only 26:1, which is much smaller than the gas-water ratio (40-60:1) of the known integrated membrane bioreactor. The flow rate of the suction pump is 15L / h, the head is 10m, and the total efficiency of the unit is 0.49, so the energy consumption of the suction pump per u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com