Double-membrane pressure-bearing water-based drilling fluid

A pressurized water and drilling fluid technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve problems such as leakage of the well wall, and achieve the effects of stable wellbore, good anti-pollution performance, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

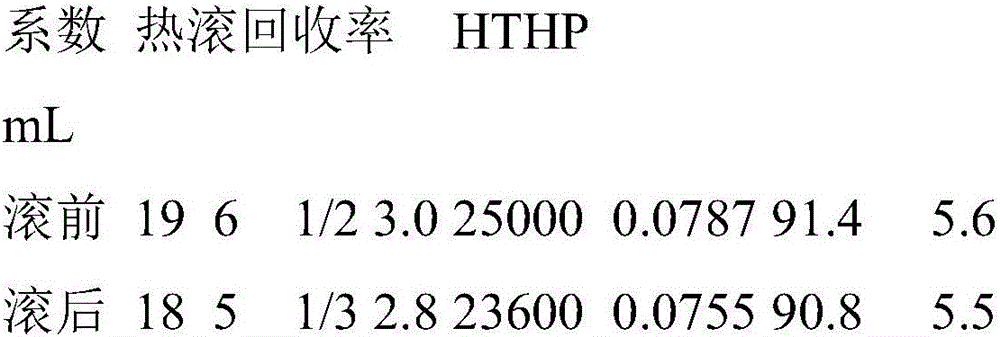

Embodiment 1

[0025] In parts by weight, add 1000 parts of water, 5 parts of soda ash and 10 parts of bentonite to the mud cup, pre-hydrate for 25 hours at 500r / min, and slowly add 10 parts of low A mixture of viscosity carboxymethyl cellulose and carboxymethyl starch (preferred mass ratio, low viscosity carboxymethyl cellulose: carboxymethyl starch = 1:10), 5 parts of xanthan gum and high viscosity carboxymethyl cellulose (preferred mass ratio, xanthan gum: high viscosity carboxymethyl cellulose = 1:10), 20 parts of well wall stabilizer HQ-1, 20 parts of plugging agent ZTC-1, 2 parts of hydrolysis degree of 30 % binary copolymer of polyacrylamide and polyacrylic acid sodium potassium salt (molecular weight is preferably 2 million), 30 parts of KCl and a mixture of polymeric alcohols (preferable polymeric alcohols are ethylene glycol, polyethylene glycol, polypropylene glycol, propane Fatty alcohol polyoxyethylene ether produced by triol and ethylene oxide, and the mass ratio, KCl: polymer ...

Embodiment 2

[0046] In parts by weight, add 1000 parts of water, 6 parts of soda ash and 10 parts of bentonite to the mud cup, pre-hydrate for 26 hours at 500r / min, and add 15 parts of low A mixture of viscosity carboxymethyl cellulose and carboxymethyl starch (preferred mass ratio, low viscosity carboxymethyl cellulose: carboxymethyl starch = 1:5), 10 parts of xanthan gum and high viscosity carboxymethyl cellulose (preferred mass ratio, xanthan gum: high-viscosity carboxymethyl cellulose = 1:8), 25 parts of well wall stabilizer HQ-1, 22 parts of plugging agent HTK-1, 4 parts of hydrolysis degree of 40 % binary copolymer of polyacrylamide and polyacrylic acid sodium potassium salt (molecular weight is preferably 4 million), 35 parts of KCl and a mixture of polymeric alcohols (preferable polymeric alcohols are ethylene glycol, polyethylene glycol, polypropylene glycol, propane Fatty alcohol polyoxypropylene ether produced by triol and propylene oxide, and the mass ratio, KCl: polymer alcoho...

Embodiment 3

[0056] In parts by weight, add 1000 parts of water, 7 parts of soda ash and 15 parts of bentonite to the mud cup, pre-hydrate for 26 hours at 500r / min, and add 20 parts of low A mixture of viscosity carboxymethyl cellulose and carboxymethyl starch (preferred mass ratio, low viscosity carboxymethyl cellulose: carboxymethyl starch = 1:3), 15 parts of xanthan gum and high viscosity carboxymethyl cellulose (preferred mass ratio, xanthan gum: high-viscosity carboxymethyl cellulose = 1:5), 20 parts of well wall stabilizer HQ-1, 25 parts of plugging agent YHS-1, 5 parts of hydrolysis degree of 50 % of polyacrylamide and polyacrylic acid sodium potassium salt binary copolymer (molecular weight is preferably 5 million), 40 parts of KCl and a mixture of polymeric alcohols (preferred polymeric alcohols are ethylene glycol, polyethylene glycol, polypropylene glycol, propane Fatty alcohol polyoxypropylene ether generated by triol and propylene oxide, and the mass ratio, KCl: polymer alcoho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com