Patents

Literature

50results about How to "Low plastic viscosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Complete-oil synthetic base drilling fluid

InactiveCN101215461AGood water loss wall building performanceStrong anti-pollutionDrilling compositionReducerHigh pressure

The invention discloses whole-oil synthetic base drilling fluid which mainly comprises following components: base liquid 100 parts, histosol 2-5 parts, viscosity increaser 0.5-3 parts, filtrate reducer 2-5 parts, wetting agent 0.5-2 parts, emulsifier 1-3 parts, calcium oxide 0.5 part and weighting agent 27-180 parts. The invention has the advantages that firstly, the rheological property is good and the plastic viscosity is low, secondly, the anti-temperature performance is good and anti-temperature can reach 150 DEG C, thirdly, the invention is provided with good water loss wall building performance with API filter loss content<5ml and high temperature and high pressure filter loss content <= 10 ml, fourthly, the anti-pollution ability is strong and the anti-poor soil ability and the anti-water invasion ability respectively reach 20%, and fifthly, reservoir has good protective effects and the permeability recovery value is over 85%.

Owner:CHINA NAT OFFSHORE OIL CORP +1

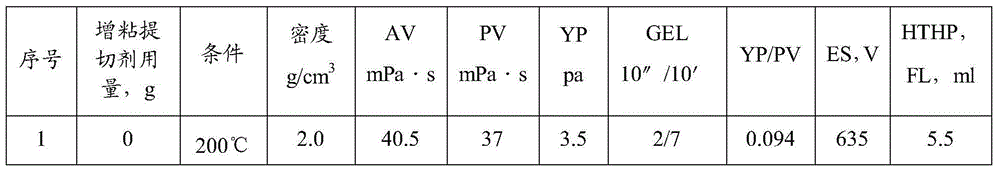

Tackifying and shear strength improving agent as well as preparation method and application of tackifying and shear strength improving agent

The invention relates to a tackifying and shear strength improving agent and a preparation method thereof. The tackifying and shear strength improving agent disclosed by the invention is prepared through the steps of reacting dimeric fatty acid and polyethylene polyamine according to the molar ratio, namely 1: (0.4-1.6) of carboxyl to amino in the existence of triethylene glycol monobuthyl ether, wherein the reaction temperature is 140-160 DEG C; keeping the temperature until no water comes off, and then, further reacting for 10-20 minutes to finish the reaction; and removing water generated by the reaction while reacting. A soilless oil-based drilling fluid system with the tackifying and shear strength improving agent is good in suspension property, enhanced in solid-phase and stratum water pollution resistance, little in reservoir damage, increased in system permeability recovery value, stable in performance, strong in inhibiting property, good in lubricating property, low in plastic viscosity and high in temperature resistance up to 260 DEG C.

Owner:CHINA NAT OFFSHORE OIL CORP +1

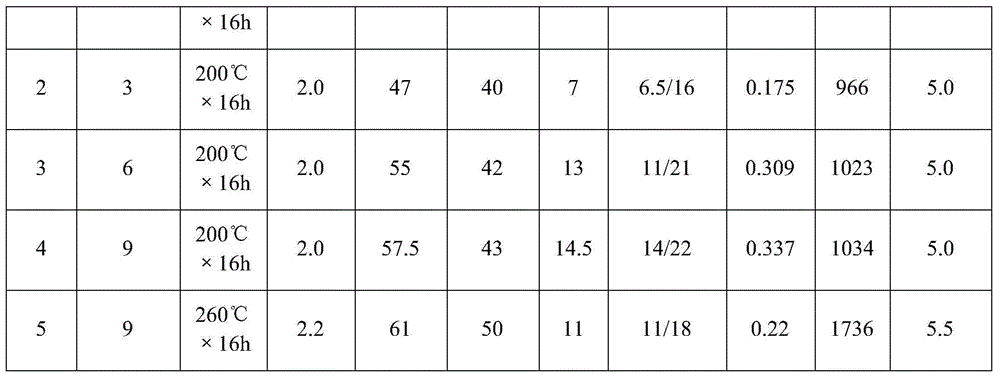

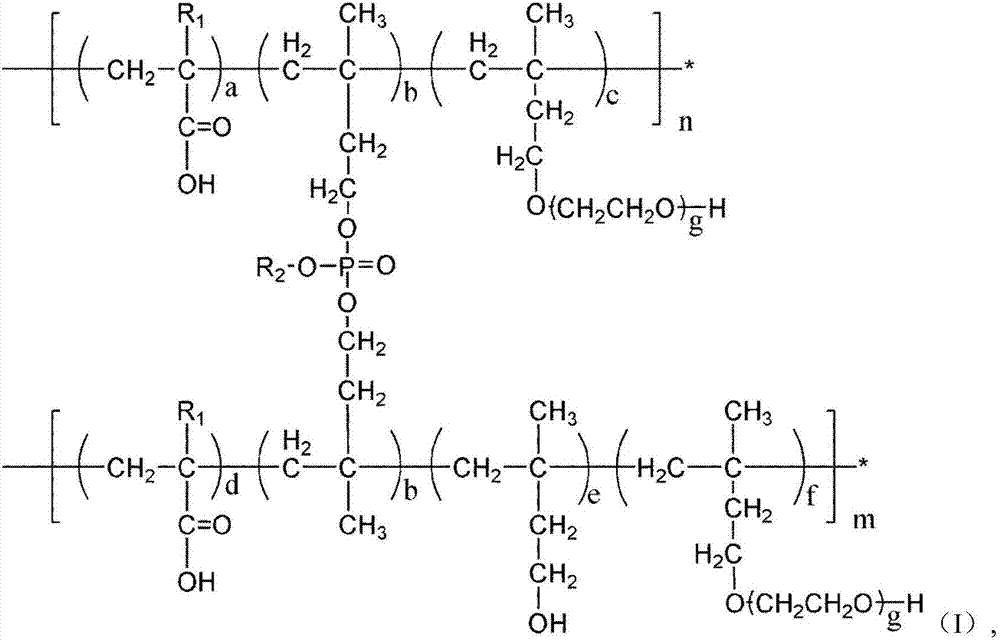

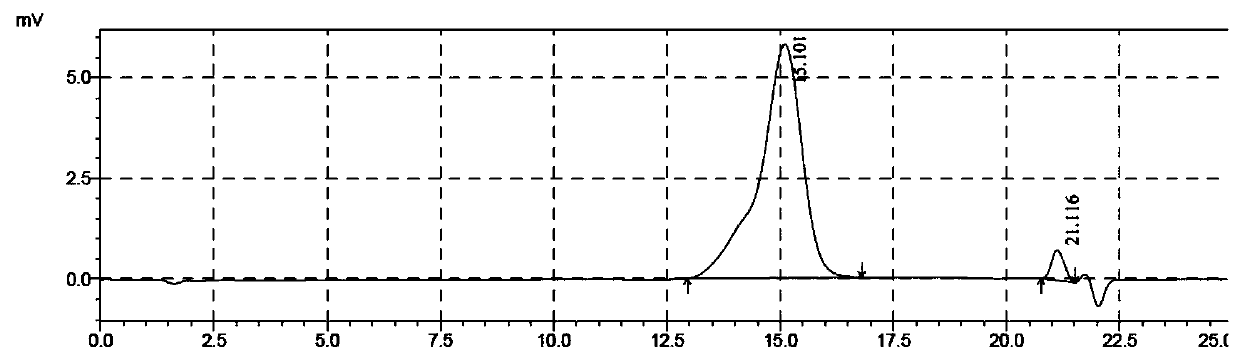

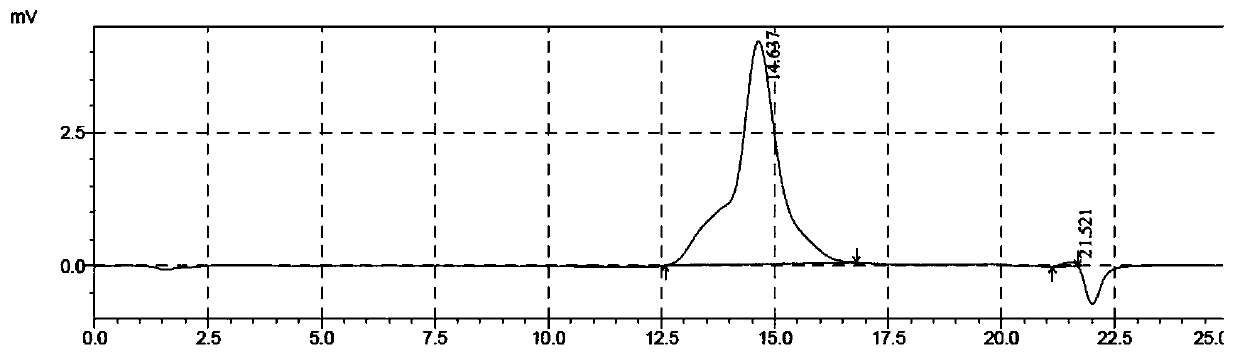

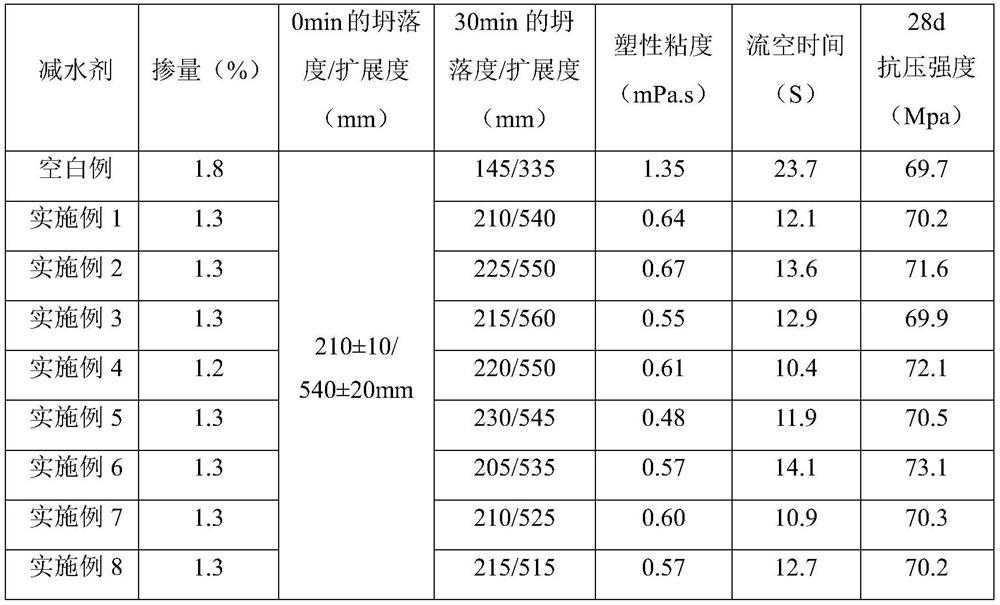

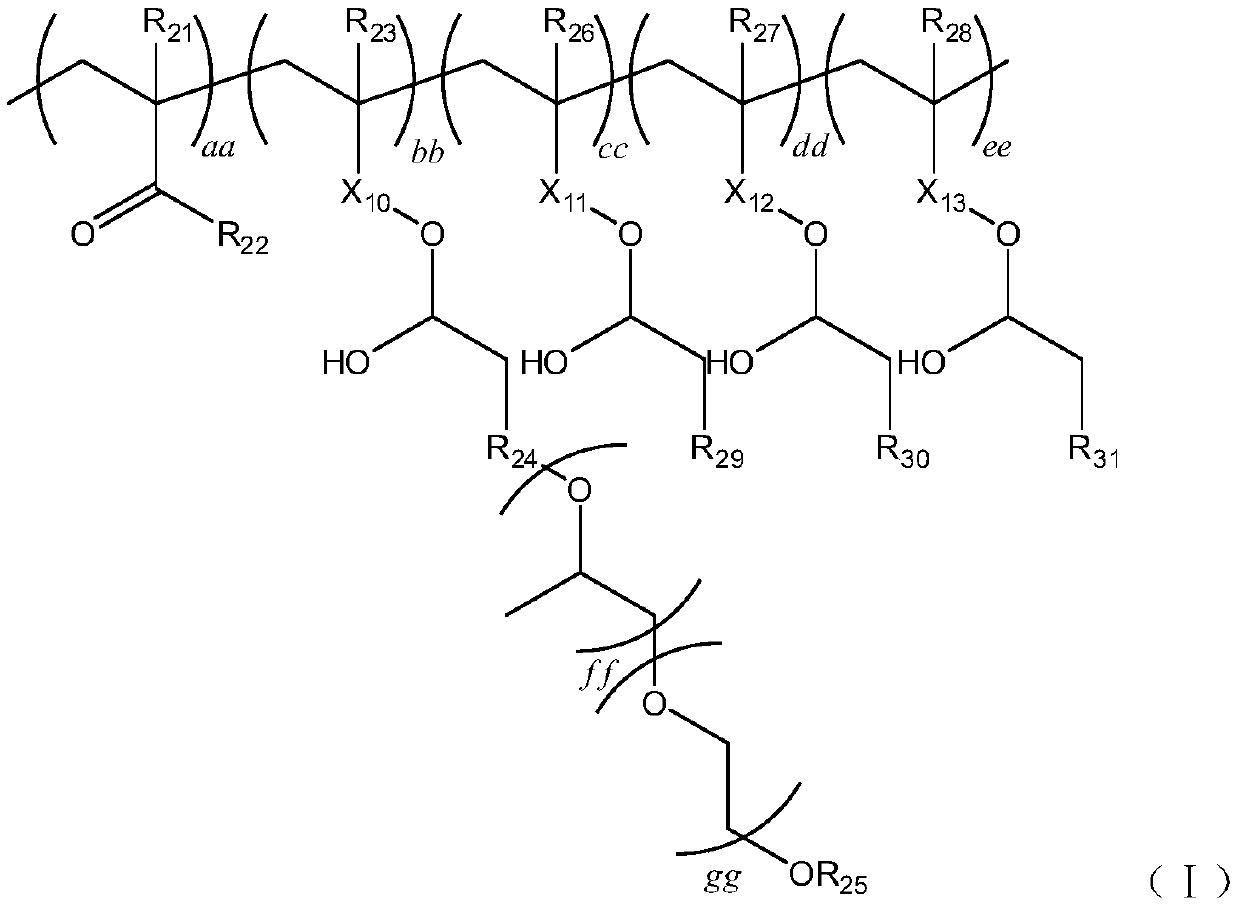

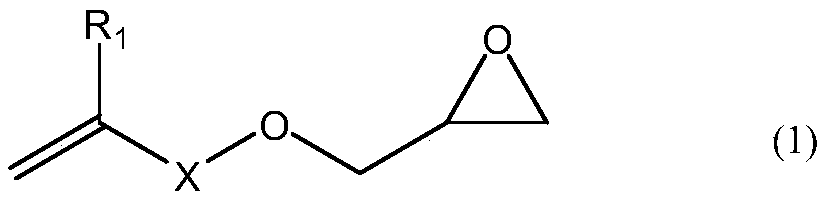

Low air-entraining viscosity reducing polycarboxylic water reducer and preparation method thereof

The invention discloses a low air-entraining viscosity reducing polycarboxylic water reducer which is formed by free radical polymerization of an alkyl phosphotriester mixture, TPEG and unsaturated carboxylic acid under the action of an initiator and a chain transfer agent. By introducing an alkyl phosphotriester monomer containing two double bonds to a main chain, molecules of the obtained polycarboxylic water reducer are of heterocyclic multibranched structures, so that the thickness of a polycarboxylic water reducer adsorption layer is increased, the plastic viscosity of concrete can be remarkably reduced, and meanwhile, by introducing the phosphotriester structure into the molecules of the polycarboxylic water reducer, the foaming property of the obtained polycarboxylic water reducer can be effectively improved and the air entraining property thereof can be reduced. The low air-entraining viscosity reducing polycarboxylic water reducer prepared by the invention is low in dosage and high in water reducer rate, the air entraining property of the low air-entraining viscosity reducing polycarboxylic water reducer can be reduced, the strength and durability of the concrete are improved while the viscosity of high grade concrete is remarkably reduced, and the raw materials are low in cost, the reaction condition is mild, and the low air-entraining viscosity reducing polycarboxylic water reducer is suitable for being popularized and applied.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD +1

High water phase oil-based drilling fluid applicable to long horizontal section of shale gas and preparation method of high water phase oil-based drilling fluid

InactiveCN106634888ALow oil-to-water ratioReduce oil phase contentDrilling compositionAlkalinityFiltration

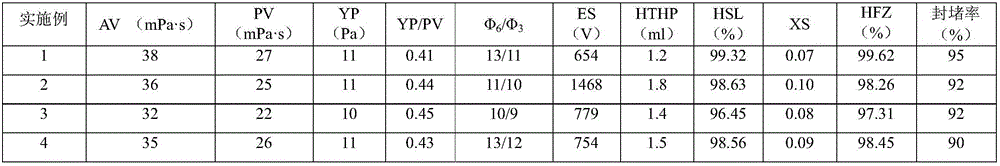

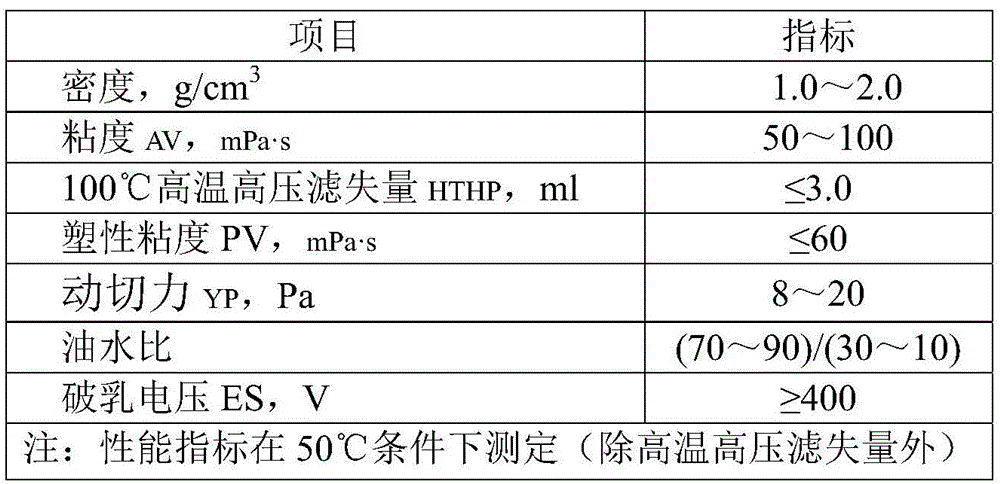

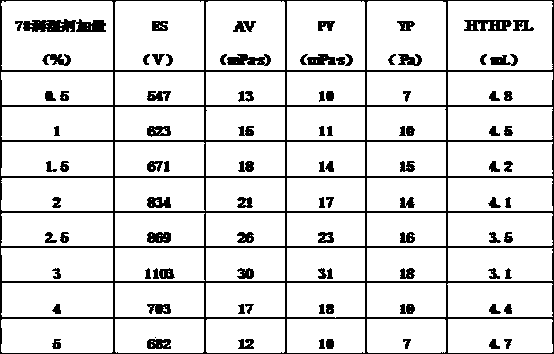

The invention provides a high water phase oil-based drilling fluid applicable to a long horizontal section of shale gas and a preparation method of the high water phase oil-based drilling fluid. The drilling fluid is prepared from oil, water, a high-efficiency emulsifier, a nanometer plugging agent, a tackifying and shear strength improving agent, a filtrate reducer, an activity control agent, an alkalinity regulator and a weighting agent, wherein a volume ratio of oil to clear water is 40:60-70:30, 3-5 g of the high-efficiency emulsifier, 2-4 g of the nanometer plugging agent, 1-3 g of the tackifying and shear strength improving agent, 3-5 g of the filtrate reducer, 15-20 g of the activity control agent, 2-5 g of the alkalinity regulator and 20-200 g of the weighting agent are added to every 100 mL of an oil and clear water mixed solution. A product of the drilling fluid has the characteristics of low oil-water ratio, high inhibition property, low shear rate, high viscosity, high electrical stability, high sealing property, good lubricity, low filtration loss, simple formula composition, and has the advantages of being environment-friendly, efficient, low in cost and the like.

Owner:中石化石油工程技术服务有限公司 +1

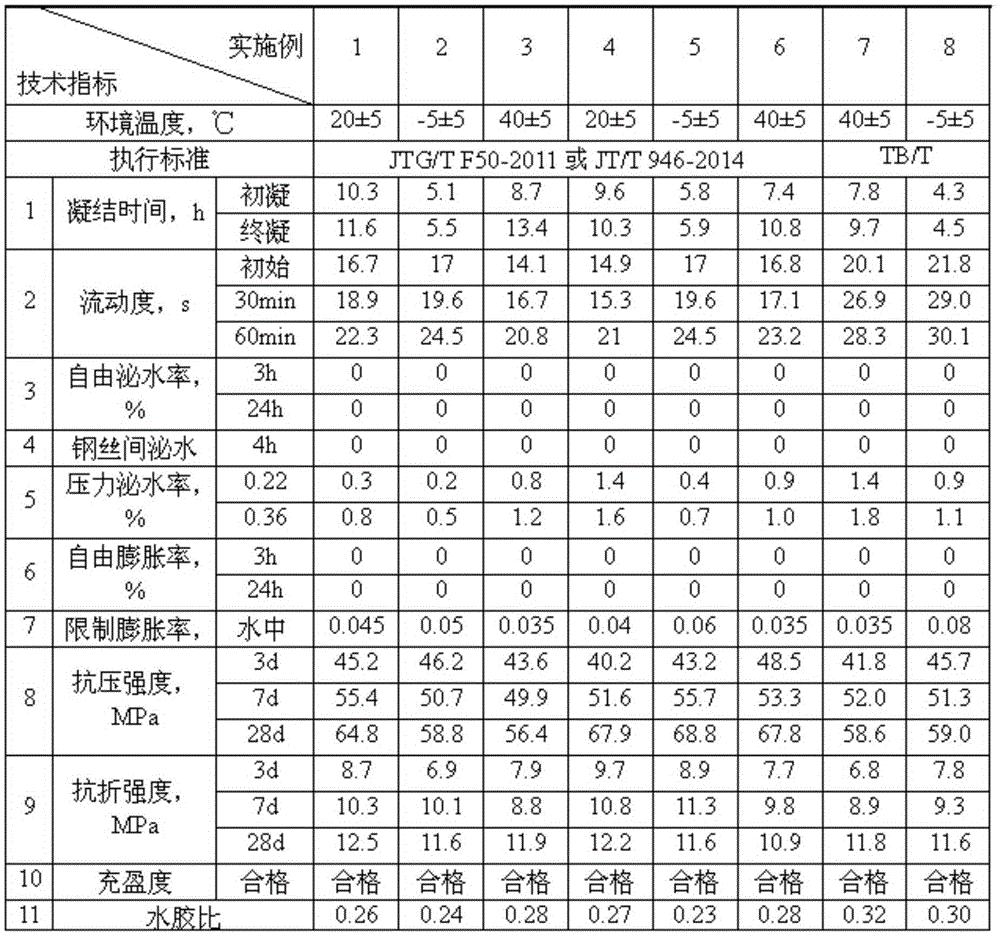

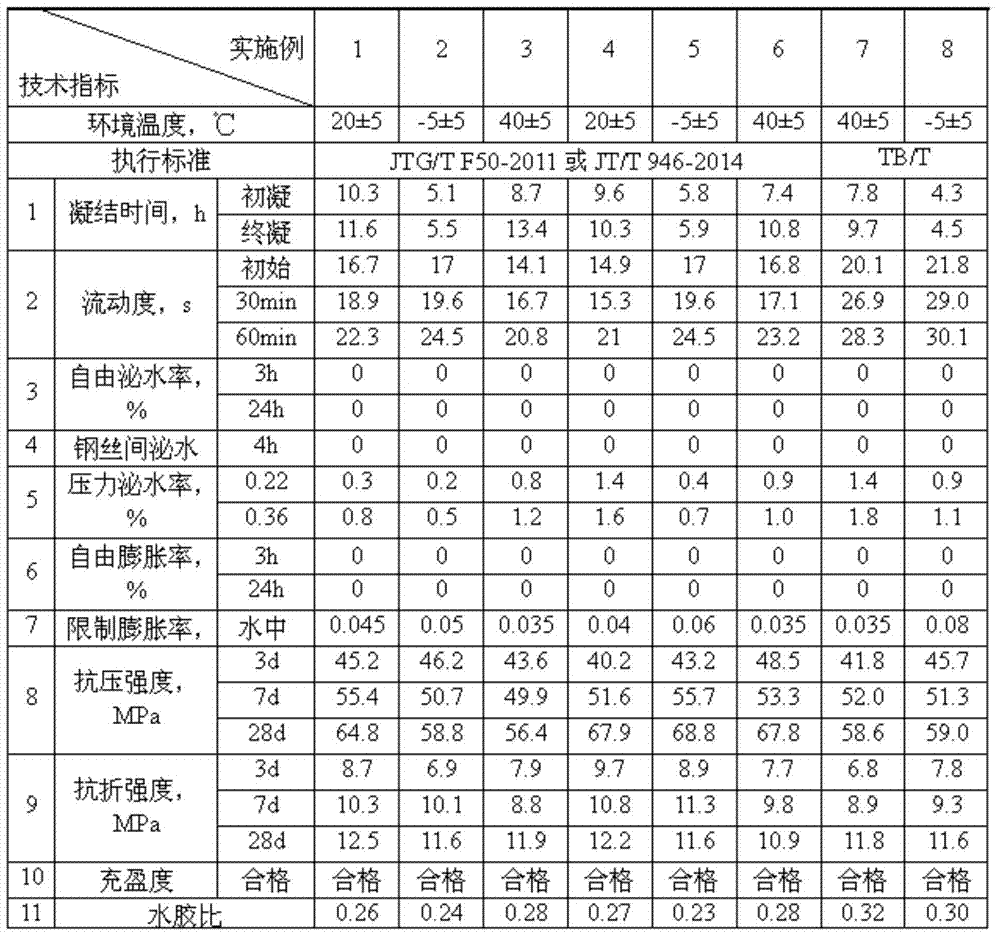

Pre-stressed duct grouting agent, and preparation and application methods thereof

The invention provides a pre-stressed duct grouting agent which has the characteristics of high fluidity, bleeding prevention and the like. The pre-stressed duct grouting agent comprises the following components: 2 to 10 percent of a water reducing agent, 0.1 to 10 percent of a viscosity modifying agent, 0 to 1 percent of a defoaming agent, and 35 to 78 percent of a coagulation time regulating agent; the coagulation time regulating agent comprises the following components: 28 to 52 percent of clinker, 42 to 68 percent of plaster, 4 to 30 percent of fillers, and 0 to 3 percent of a coagulation accelerator. The invention further provides a preparation method and an application method of the pre-stressed duct grouting agent. The invention has the advantages that the pre-stressed duct grouting agent contains the cement coagulation time regulating agent, so that the coagulation time of a cement-based composite material can be regulated based on external temperature changes to guarantee the normal use and normal strength growth of the cement-based composite material; meanwhile, the cement-based composite material achieves micro-expansion at the later stage due to the addition of the cement coagulation time regulating agent.

Owner:WUHAN BILLION TECH DEV CO LTD

Double-membrane pressure-bearing water-based drilling fluid

The invention discloses a double-membrane pressure-bearing water-based drilling fluid comprising the following materials by mass: 1000 parts of water, 10-30 parts of bentonite, 5-10 parts of soda ash, 20-30 parts of a plugging agent, 30-50 parts of a film-forming agent, 2-5 parts of a coating agent, 30-50 parts of a mud shale inhibitor, 5-10 parts of a pH adjusting agent, 5-20 parts of a flow type regulator, 10-40 parts of a filtration loss reducing agent and 20-30 parts of a borehole wall stabilizer; salt and barite can be appropriately adjusted according to needs, and the double-membrane pressure-bearing water-based drilling fluid solves the special requirements of shale gas well drilling for drilling fluids, especially solves the problems of well leakage and borehole wall stability, and is suitable for well drilling requirements of a two-opening large borehole of a shale gas well.

Owner:中石化石油工程技术服务有限公司 +1

Anti-radiation concrete and preparation method thereof

The invention belongs to the technical field of preparation of building materials, and concretely relates to an anti-radiation concrete and a preparation method thereof. The preparation method comprises the following steps: mixing and crushing graphite and barite, carrying out sealed fermentation on the obtained crushed mixture and biogas slurry to obtain a fermentation product, centrifuging and sterilizing the fermentation product to obtain a modified filler, mixing and heating methylallyl alcohol, boric acid and anhydrous ether, reacting the obtained heated mixture with a sulfuric acid solution to obtain a product, distilling the product to obtain a methyallyl borate mixture, reacting and distilling the methyallyl borate mixture, N-hydroxymethylacrylamide and toluene to obtain an anti-segregation agent, mixing cement, the modified filler and fibers, stirring the obtained mixture, the anti-segregation agent, a water reducer and water, injecting the finally obtained mixture into a die, carrying out vibration molding, and demolding and curing the molded mixture to obtain the anti-radiation concrete. The anti-radiation concrete obtained in the invention has the advantages of good anti-segregation and anti-radiation performances, effective improvement of the construction performances of concrete, high mechanical strength, and effective prolongation of the service life of concrete buildings.

Owner:湖州三中混凝土有限公司

Low-toxicity oil base microbubble drilling fluid for protecting hydrocarbon reservoir

InactiveCN105086964ALow densityImprove rheologyDrilling compositionEnvironmental resistanceCarbonate

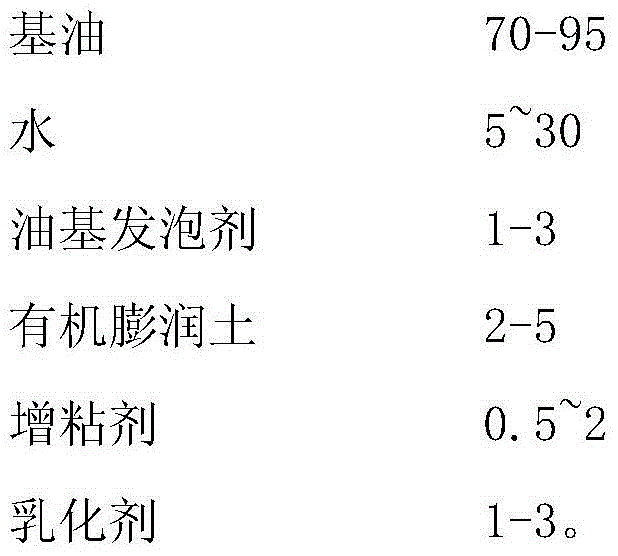

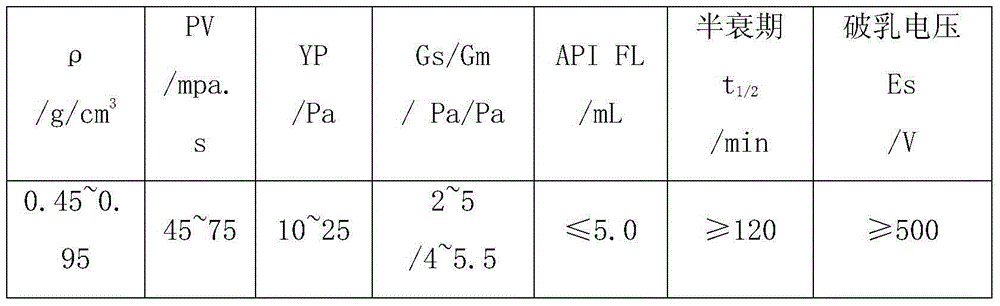

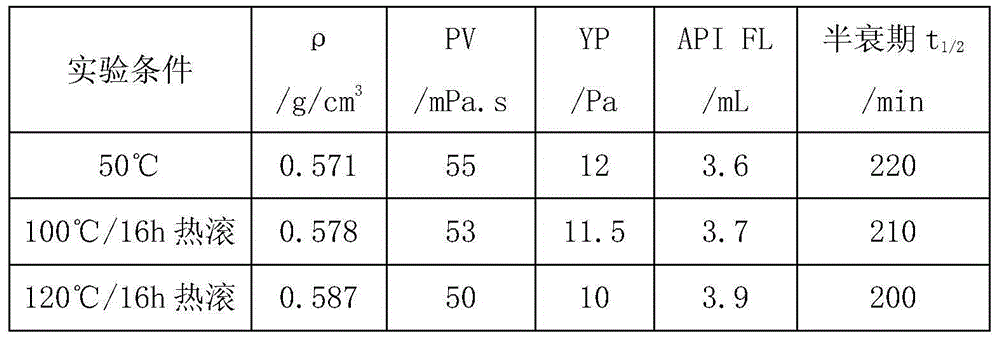

The present invention discloses a low-toxicity oil base microbubble drilling fluid for protecting a hydrocarbon reservoir. The drilling fluid mainly comprises the following components in parts by weight: 70-95 parts of base oil, 5-30 parts of water, 1-3 parts of an oil base blowing agent, 2-5 parts of organic bentonite, 0.5-2 parts of a tackifier and 1-3 parts of an emulsifier. By adopting a technical solution of using a mixture of the oil base blowing agent, organic bentonite, the tackifier, the base oil, water and air to form oil base microbubbles, the existing problems in the prior art that lower density, limited degree, insufficient temperature and salt resistance capacity in an aqueous foaming system, and complex underground problems of leakage, hole shrinkage and tool jamming easily caused can be solved. The drilling fluid provided by the present invention can be applied to a drilling operation in a special and complex reservoir such as a low-pressure carbonate reservoir, a mud shale reservoir and the like, and has the advantages of low-toxicity and environmental protection.

Owner:CHINA PETROCHEMICAL CORP +1

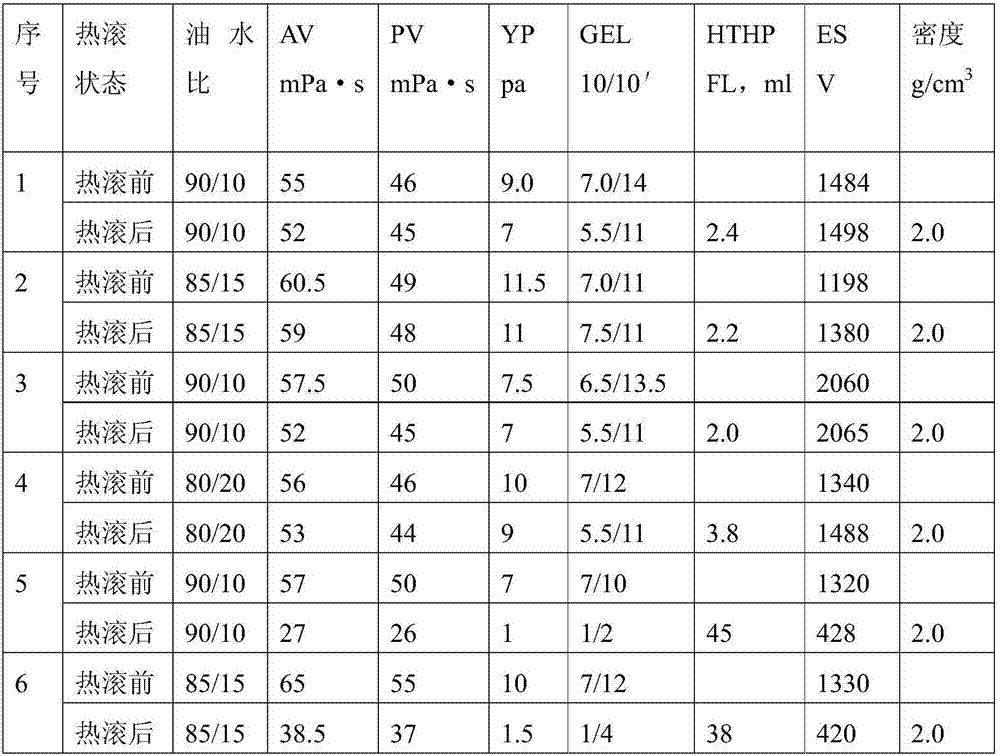

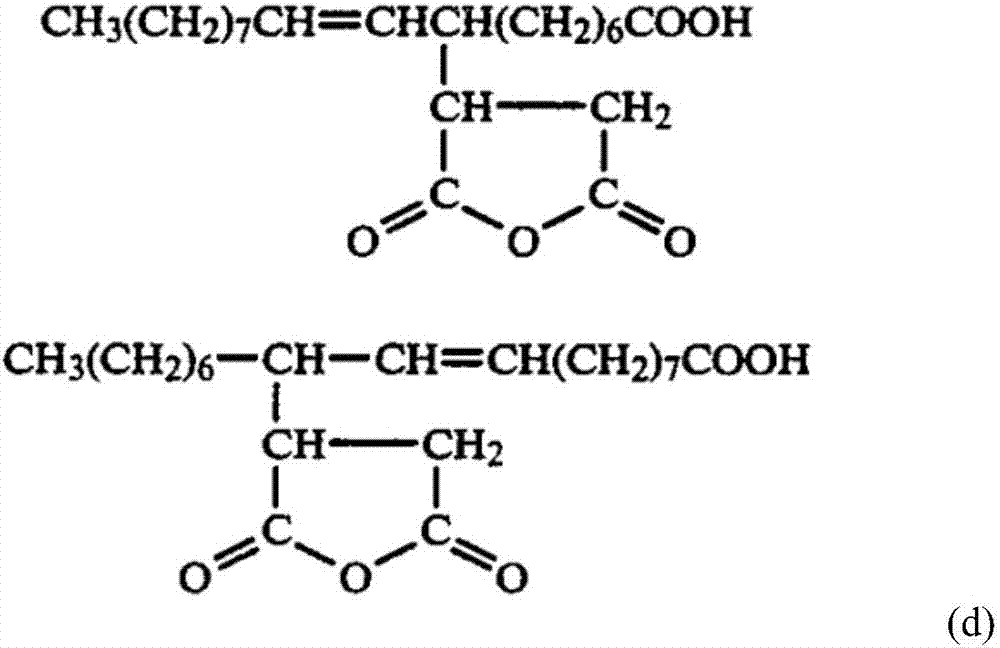

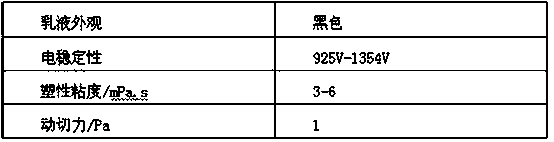

Preparation method of wetting agent used for oil-based drilling fluid, and oil-based drilling fluid using the same

ActiveCN106947441APlay the role of high temperature stabilityImprove performanceDrilling compositionVegetable oilDiethylenetriamine

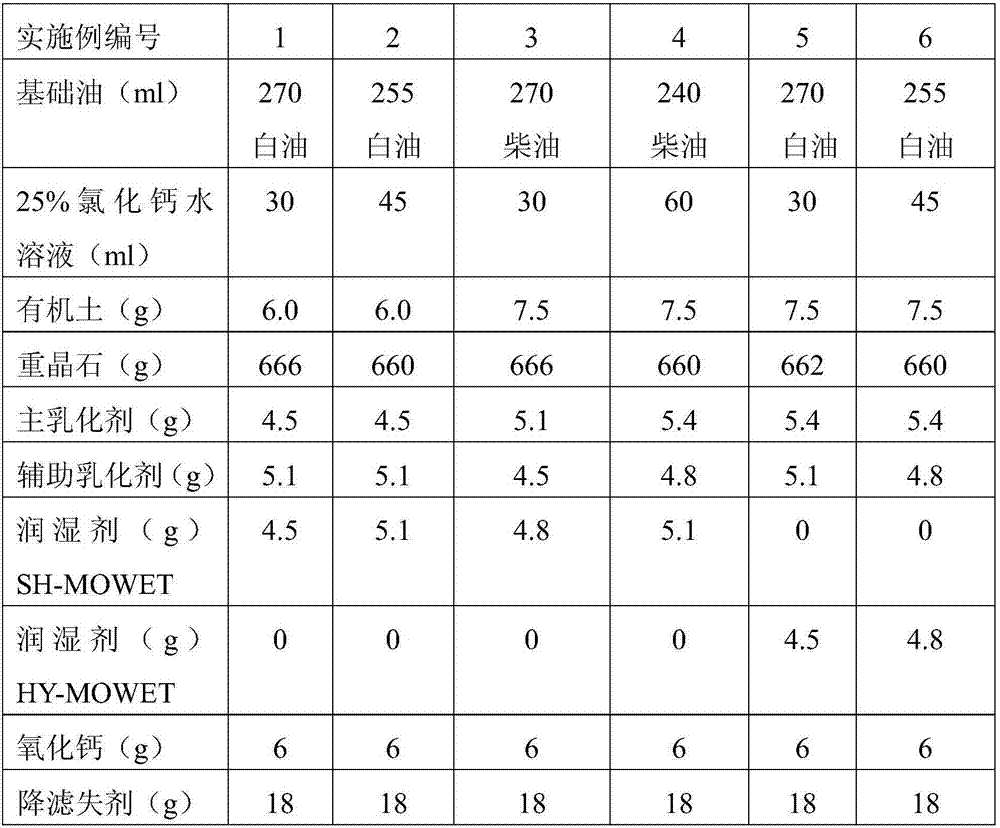

The invention discloses a preparation method of a wetting agent used for an oil-based drilling fluid. The method comprises the following steps: mixing and stirring vegetable oil fatty acid and maleic anhydride or fumaric acid or acrylic acid, heating the obtained mixture to 200-220 DEG C, carrying out a reaction for 2-4 h, and cooling the obtained reaction product to 130 DEG C; adding diethylenetriamine, and carrying out heating dehydration until no water is separated out at 260 DEG C; adding the vegetable oil fatty acid with the amount being 1.1-1.25 times the first-time addition amount of the vegetable oil fatty acid, heating the obtained mixture to 220 DEG C, and separating out water until no water can be separated out; and cooling the obtained material to 130 DEG C, adding xylene with the amount being 0.7 times the weight of the first-time addition amount of the vegetable oil fatty acid in order to realize dilution, and carrying out uniform stirring. The high-temperature and high-pressure filter loss of the oil-based drilling fluid using the wetting agent after 260 DEG C high temperature hot rolling for 16 h is 2.2-4.0 ml, the change of the apparent viscosity and the plastic viscosity before and after the hot rolling is small, the oil-based drilling fluid using the wetting agent has good rheological property and low plastic viscosity, facilitates the improvement of the mechanical drilling speed, and after the hot rolling, the emulsification stability is good, and the demulsification voltage is 1000 V or above.

Owner:北京石大胡杨石油科技发展有限公司 +1

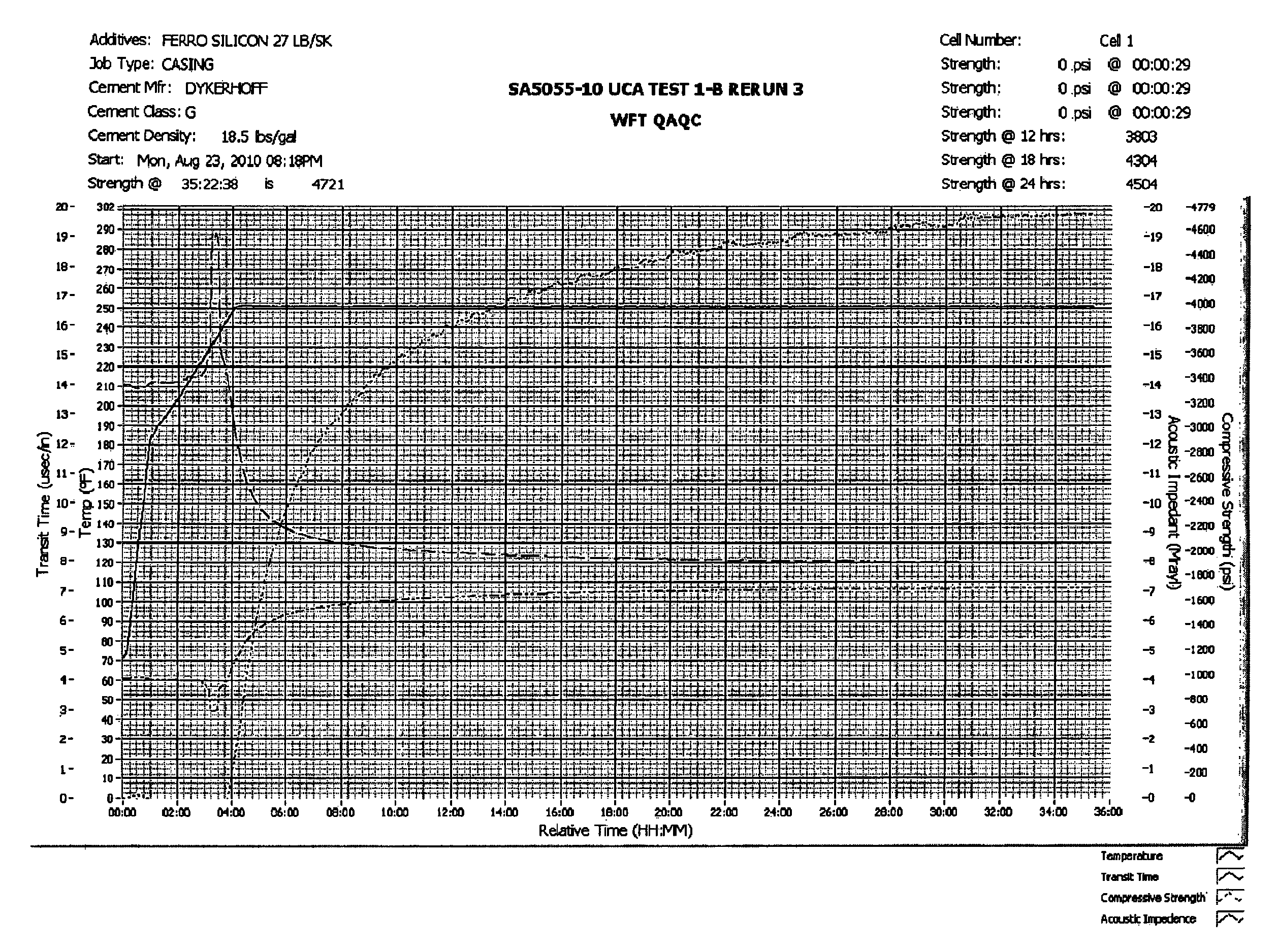

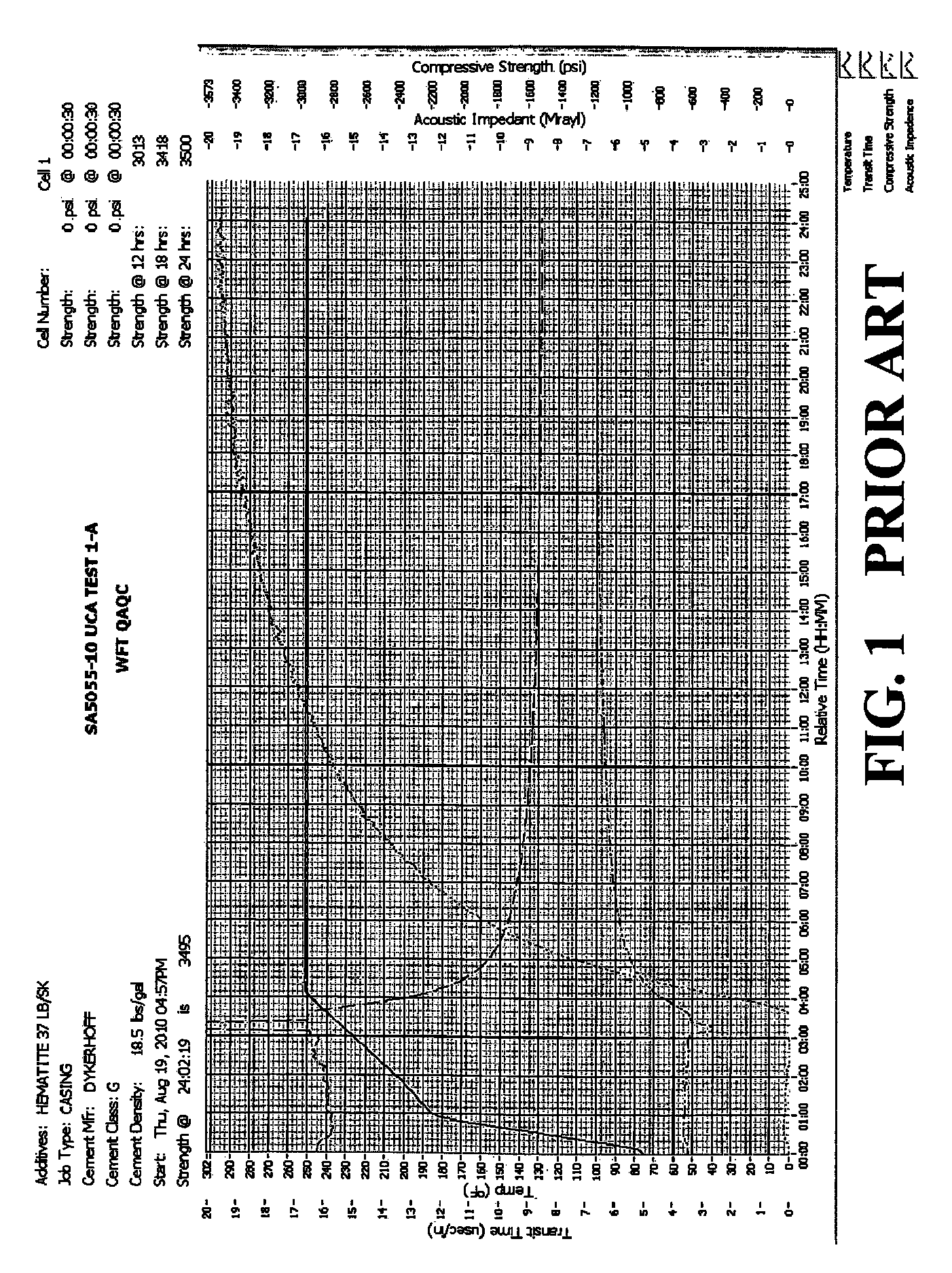

Weight materials for use in cement, spacer and drilling fluids

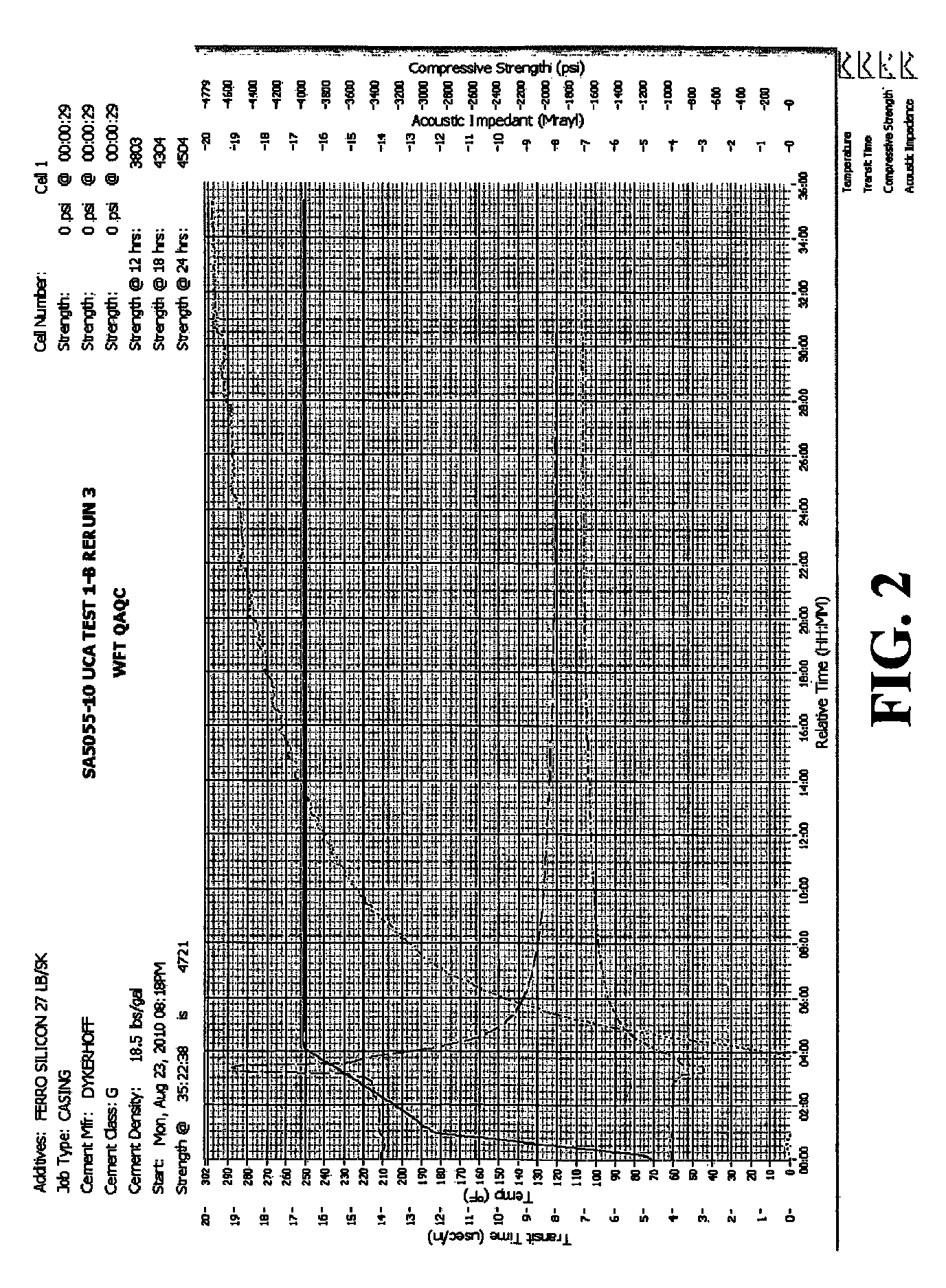

InactiveUS9062241B2Low plastic viscosityFast curingSolid waste managementFlushingHigh densitySilicon alloy

A drilling fluid, spacer fluid and cementing compositions for use in subterranean wells are disclosed along with methods for making using same, where the compositions include a weighting system having an effective amount of a metal silicon alloy, mixtures of metal silicon alloys, or mixtures of metal silicon alloys and conventional weighting agents, to produce compositions having a desired high density, while retaining other fluid properties such as pumpability, gas tight sealing, low tendency to segregate, and reduced high temperature cement strength retrogression.

Owner:WEATHERFORD TECH HLDG LLC

Drilling fluid completion fluid for increasing drilling speed and preparation method of drilling fluid completion fluid

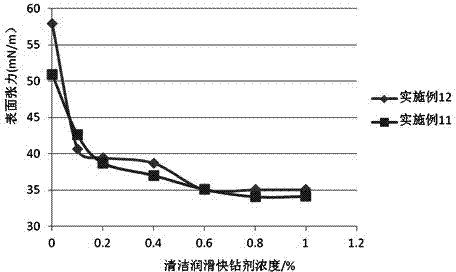

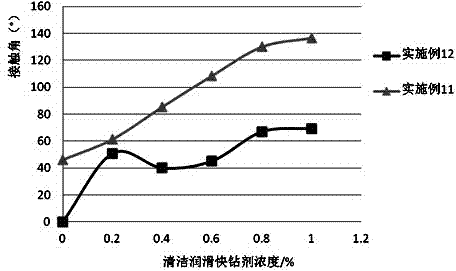

InactiveCN103897675AGood suspension rock carrying capacityGood shear thinningDrilling compositionSodium BentoniteSurface-active agents

The invention relates to a drilling fluid completion fluid for increasing drilling speed and a preparation method of the drilling fluid completion fluid. The drilling fluid completion fluid is prepared from the following components in parts by weight: a continuous liquid phase, 0.2-1 part of a cleaning and lubrication fast drilling agent, 0.1-1 part of anhydrous sodium carbonate, 2-3 parts of clay, a tackifier, a filtrate reducer, 0-10 parts of an inhibitor, 0-1 part of a surfactant, 1-3 parts of a plugging agent and 0.1-10 parts of a weighting agent, wherein fresh water is used as the continuous liquid phase; sodium bentonite is used as the clay; lignite resin, or a sulfonate copolymer filtrate reducer, or sulfomethyl phenol formaldehyde resin is used as the filtrate reducer; super-fine calcium carbonate or expanded graphite is used as the plugging agent; barite or manganese tetraoxide is used as the weighting agent. The drilling fluid completion fluid disclosed by the invention has the advantages that the drilling fluid completion fluid can keep a low solid-phase content under the high density conditions, has excellent capacities of cleaning and wetting a mud-proof drum, preventing water blocking damage, resisting temperature and salt, lubricating to reduce frictional resistance, inhibiting and preventing collapse, and plugging, and can be used for stabilizing the wall of a well, increasing initial water loss of the drilling fluid, reducing a chip hold-down effect and increasing the drilling speed.

Owner:CHINA PETROCHEMICAL CORP +1

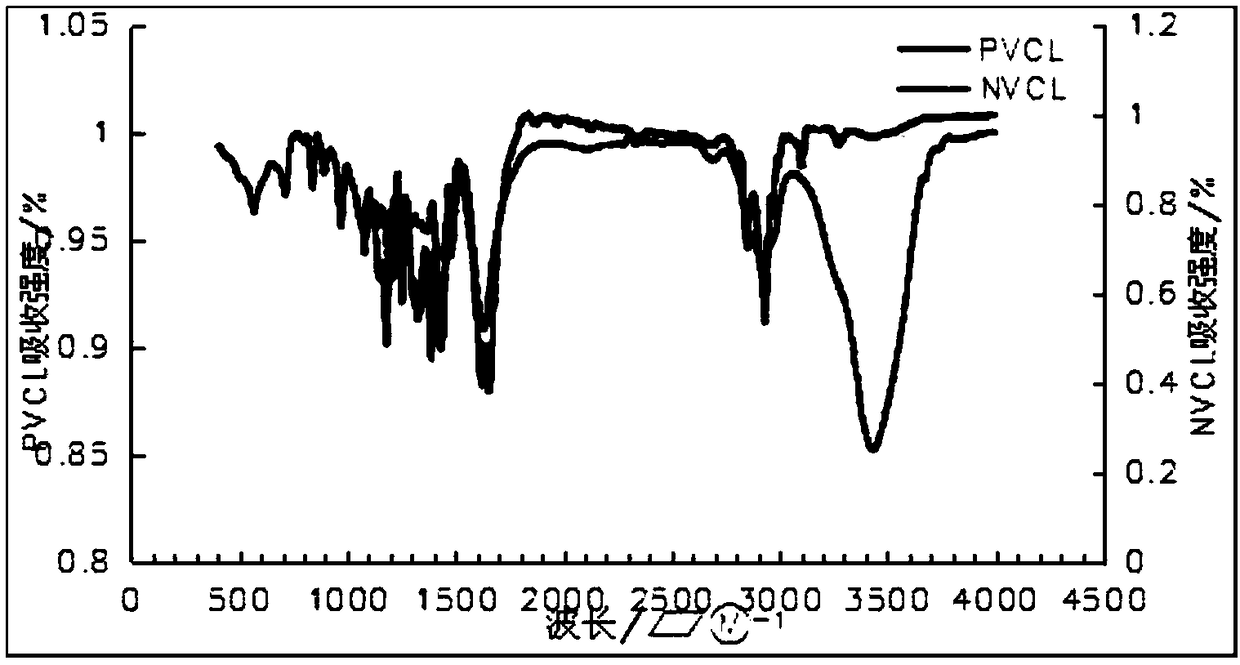

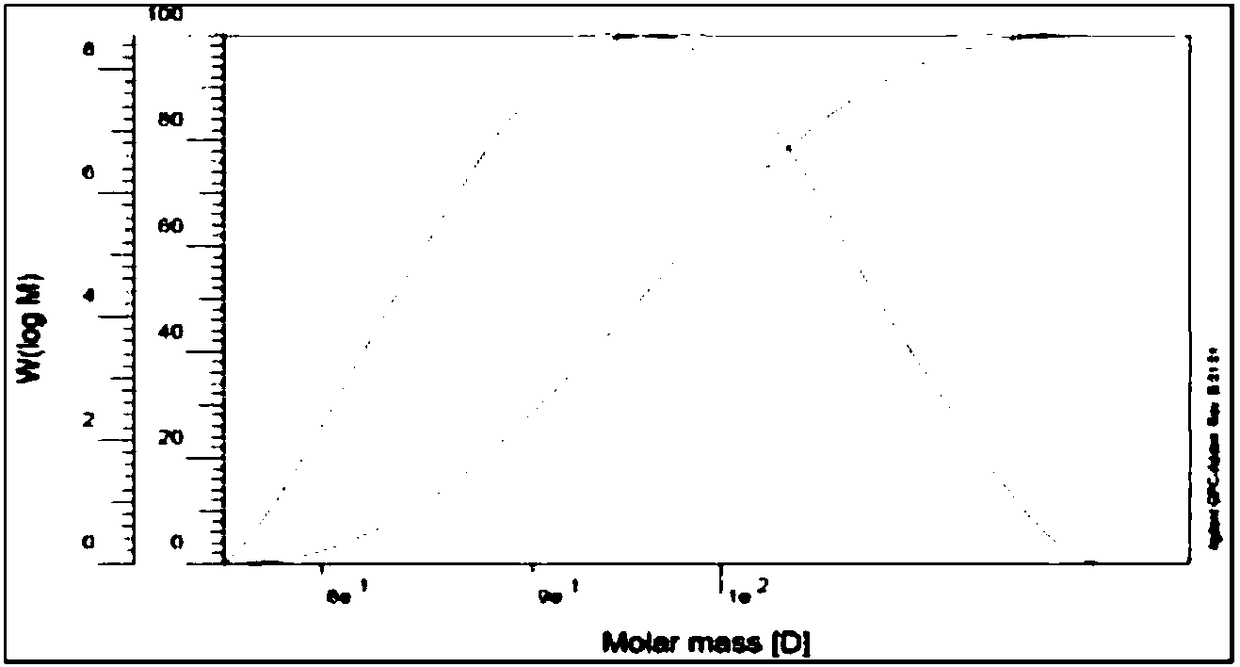

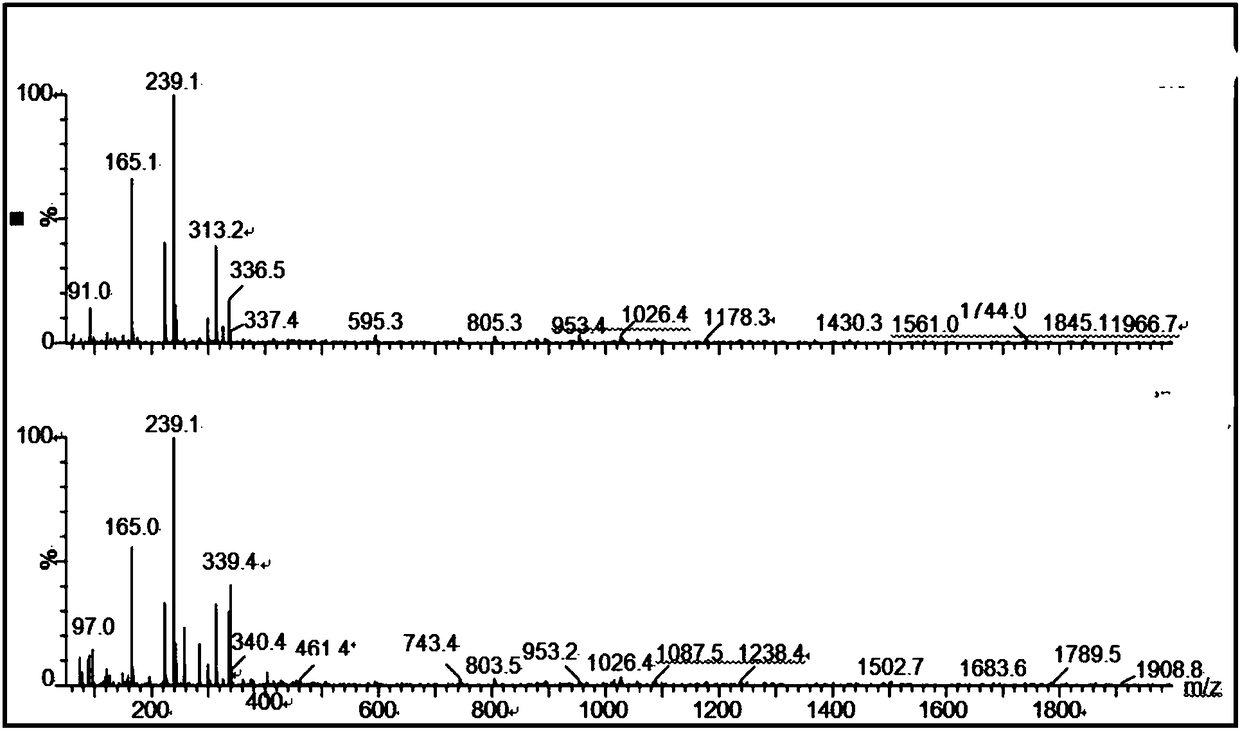

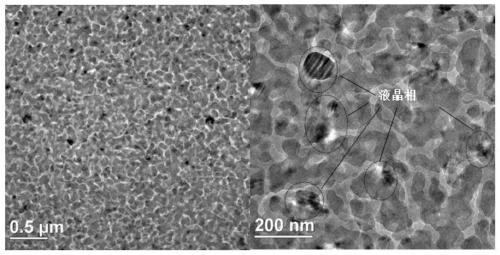

Temperature-sensitive type polymer and preparation method thereof

InactiveCN108276512ALow plastic viscosityThe change in apparent viscosity is reducedDrilling compositionWater basedPolymer science

The invention discloses a temperature-sensitive type polymer and a preparation method thereof. According to the preparation method of the polymer, reaction temperature is controlled and salt concentration, pH (Potential of Hydrogen) value and polymer concentration of a polymerization reaction solution are controlled to prepare the temperature-sensitive type polymer with different lower critical solution temperatures (LCST). The temperature-sensitive type polymer is used as a drilling fluid additive and can improve the low-temperature rheological property of water-based drilling fluid; the changes of the plastic viscosity and the apparent viscosity within a range of 0 to 60 DEG C are reduced by 50 percent. A preparation process of the temperature-sensitive type polymer is simple and feasible and the preparation efficiency is high; the temperature-sensitive type polymer has an excellent temperature-sensitive behavior in the deep-water water-based drilling fluid; the low-temperature rheological property of the water-based drilling fluid can be extremely improved, so that the preparation method of the temperature-sensitive type polymer and the temperature-sensitive type polymer prepared by the preparation method have actual application value in a petroleum industry, especially a deep-water well drilling field.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Bicontinuous phase micro-emulsion, preparation method thereof, drilling fluid containing micro-emulsion and preparation method thereof

ActiveCN109971441AImprove drilling performanceSimplify drilling proceduresOrganic compound preparationCarboxylic acid amides preparationEmulsionOil phase

The invention provides a bicontinuous phase micro-emulsion which comprises an emulsifier, a water soluble acid, an oil phase and a water phase. The emulsifier is an amine nonionic emulsifier. The invention further discloses a drilling fluid containing the micro-emulsion. The drilling fluid comprises the micro-emulsion, an oil base stabilizer, organic soil and a weighing material. The invention further discloses a preparation method of the micro-emulsion and the drilling fluid. The method comprises the steps that other raw materials are mixed, the water soluble acid is added for induction to obtain the bicontinuous phase micro-emulsion and the drilling fluid, or the other raw materials and the water soluble acid are mixed at first to obtain the bicontinuous phase micro-emulsion, a drillingfluid additive is added, and the bicontinuous drilling fluid is obtained. The bicontinuous phase micro-emulsion has the advantages that the unique oil phase and water phase bicontinuous characteristics, high shearing force, low plastic viscosity and viscoelasticity rheologic characteristics are achieved, the advantages of the oil phase and water phase drilling fluids can be shown at the same timewhen the micro-emulsion is used for the drilling fluid, and the water power transmission, suspension, rock debris carrying and well cleaning capability of the drilling fluid are enhanced.

Owner:SOUTHWEST PETROLEUM UNIV

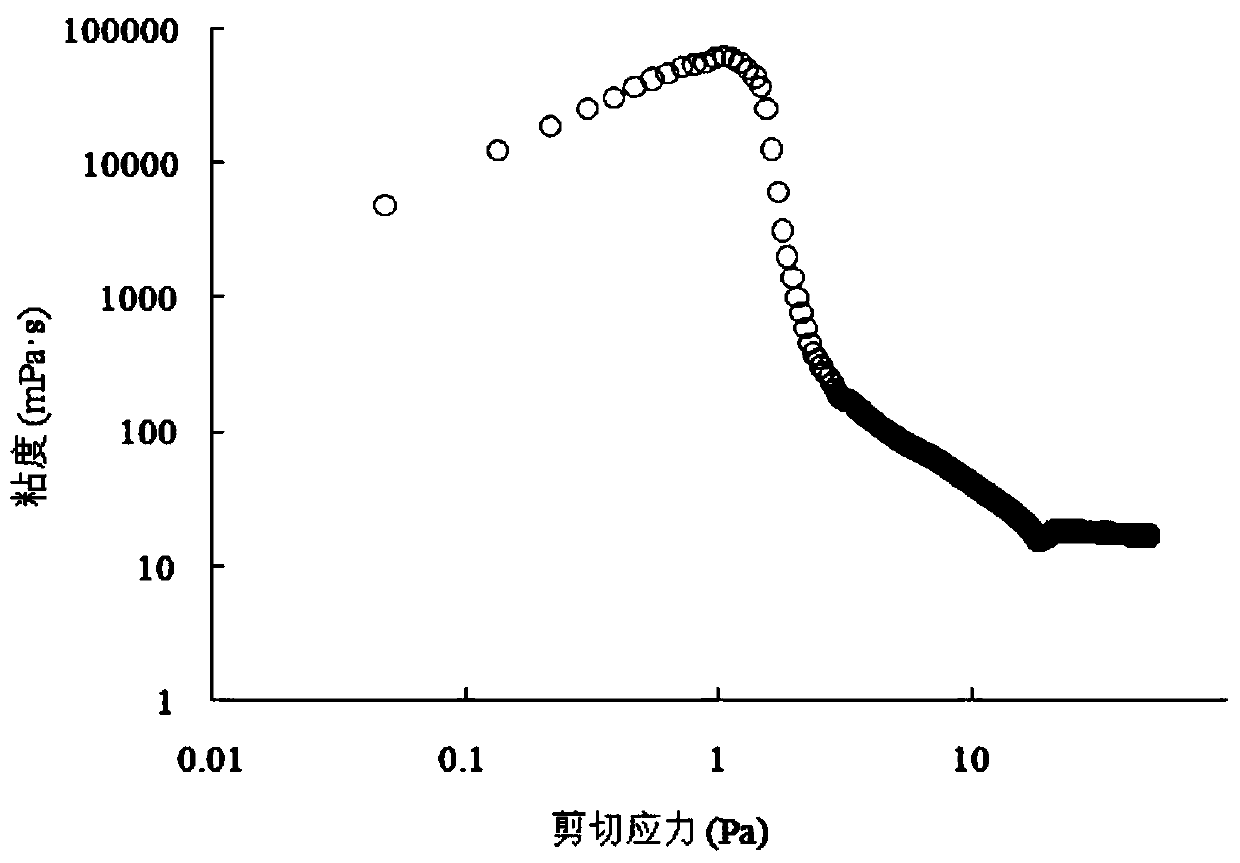

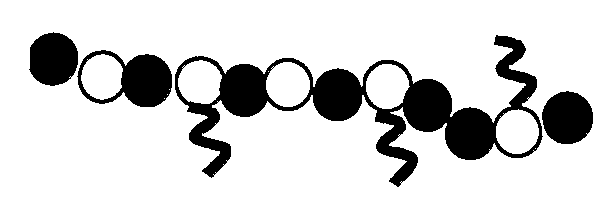

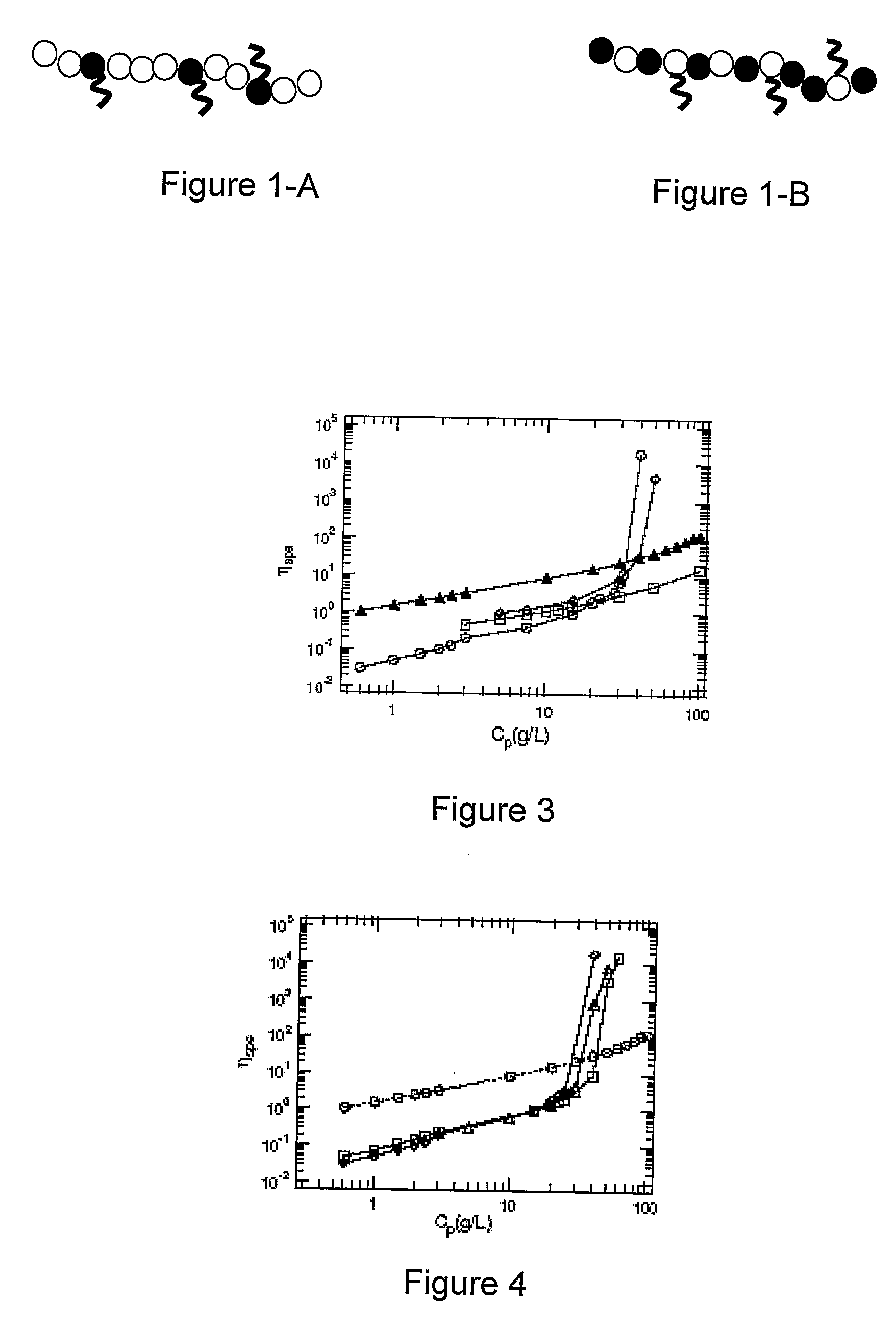

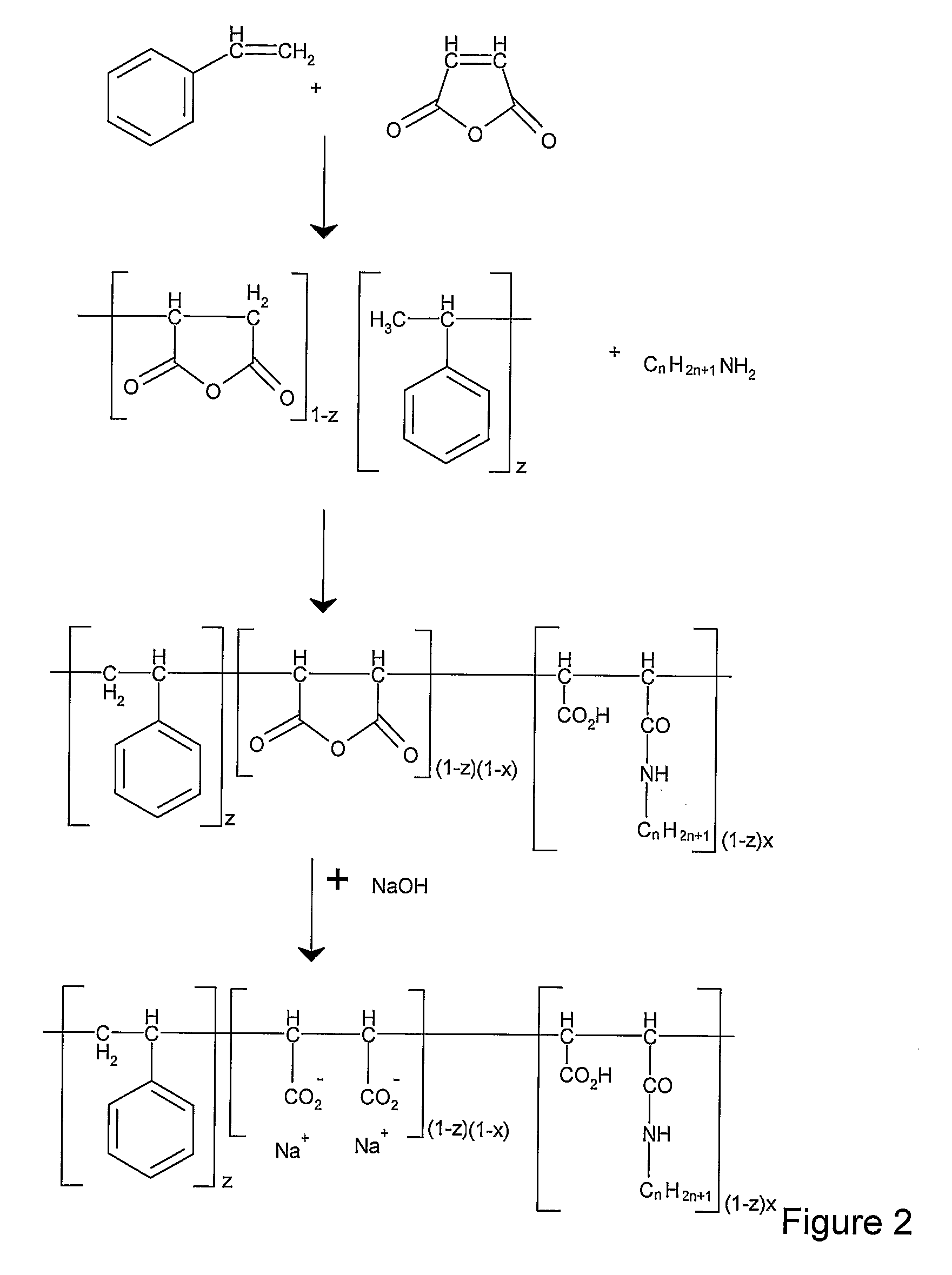

Anionic Amphiphilic Copolymers And Solutions Comprising Thereof

InactiveUS20080032899A1Yield point is highLow plastic viscosityFlushingDrilling compositionRepeat unitAqueous solution

It is proposed a new family of terpolymers based on repeating units of two different types of hydrophobic moieties modified with anionic charged groups. In a preferred embodiment, the first hydrophobic moiety is an aromatic compound such as styrene and the second hydrophobic moiety is a fatty acid. Depending on the modification rate, and on the neutralization degree, the aqueous solutions of the terpolymers have different rheological behavior, ranging from yield point fluid, shear-thickening and polysoaps.

Owner:SCHLUMBERGER TECH CORP

Lightweight high-strength concrete and preparation method thereof

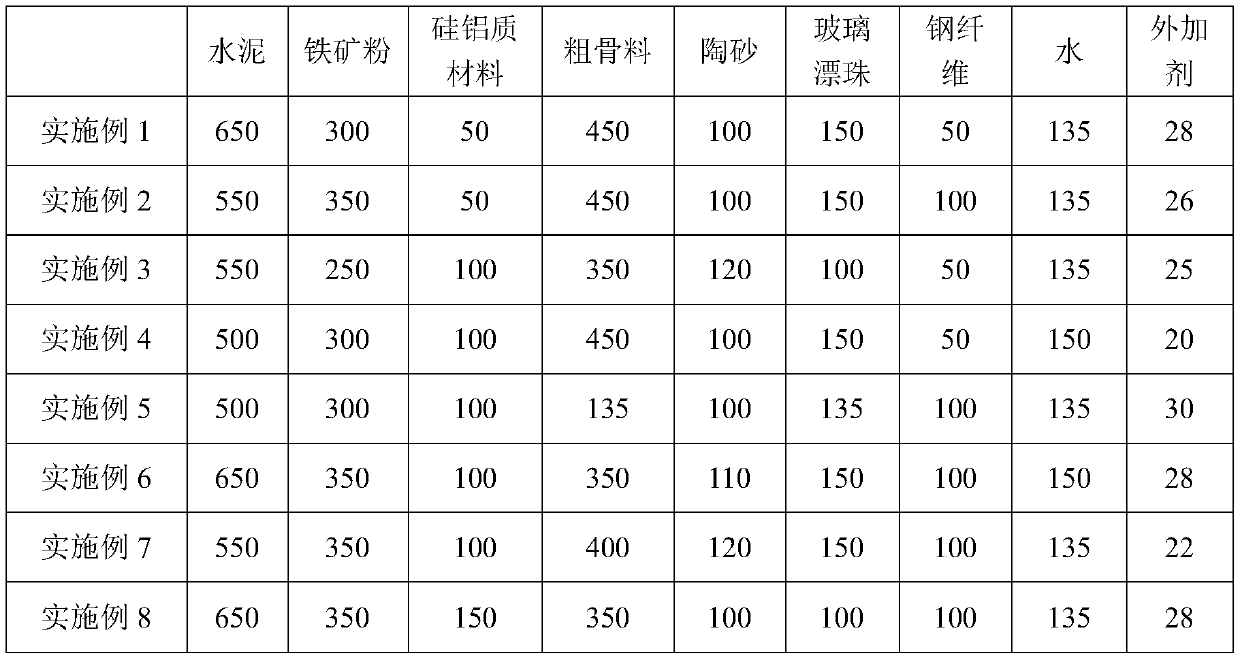

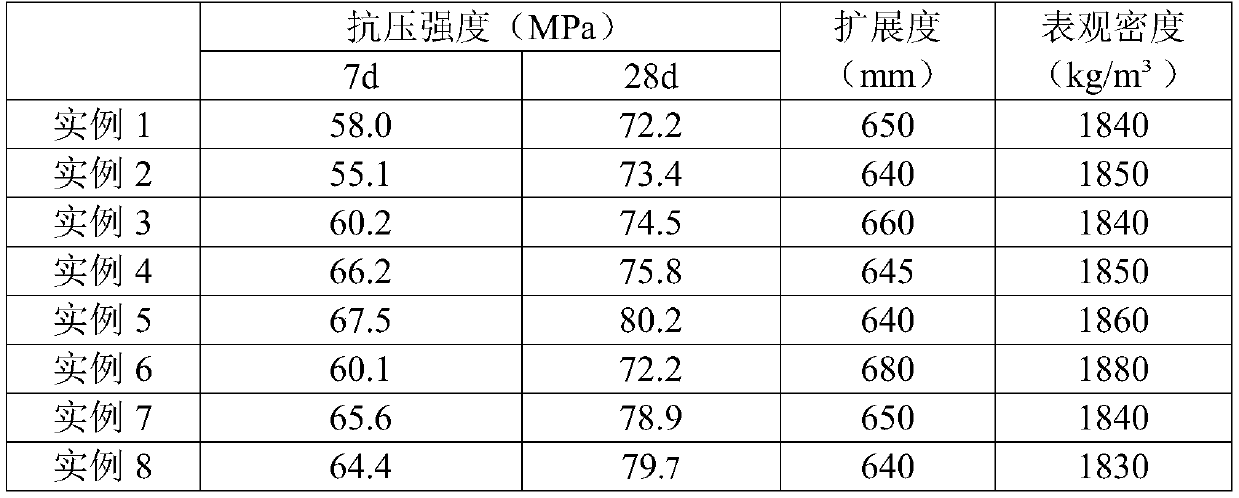

The invention discloses lightweight high-strength concrete and a preparation method thereof. The lightweight high-strength concrete comprises 550-650 parts of cement, 50 to 150 parts of a high-activity spherical silica-alumina material, 250 to 350 kg / m<3> of a low-activity alkaline calcareous material, 100 to 150 kg / m<3> of a light spherical fine material, 100 to 120 kg / m<3> of a light fine aggregate, 350 to 450 kg / m<3> of a light spherical coarse aggregate, 135 to 150 kg / m<3> of water, 20 to 30 kg / m<3> of an additive and 50 to 100 kg / m<3> of high-toughness fibers. According to the prepared lightweight aggregate concrete, due to matching of the cementing material and adding of the high-toughness fibers, the 28d compressive strength is 70 MPa or above, meanwhile, due to the ball effect of the cementing material and blending of the additive, the concrete is good in fluidity and the expansion degree ranges from 640 mm to 680 mm. The steel fiber is added into the lightweight aggregate high-strength concrete, so that the concrete is good in toughness, not easy to shrink and good in durability.

Owner:中建西部建设贵州有限公司

Concrete super plasticizer and preparation method thereof

The invention discloses a concrete super plasticizer and a preparation method thereof. The preparation method of the super plasticizer comprises the following steps that polymerizable monomers are added into a solvent and an initiator, the mixture is stirred, and reaction is carried out to obtain an intermediate polymer; a catalyst, two kinds of functional monomers I and the intermediate polymer obtained in the previous step are added into polyether G, and an intermediate mixture is obtained after stirring; the catalyst and the intermediate mixture obtained in the previous step are added intopolyether H, the mixture is stirred, and reaction is carried out to obtain a sample taking the product super plasticizer polymer as a main component. Compared with a common commercial super plasticizer, the concrete super plasticizer is applied to common commercial concrete, and the dosage of the concrete super plasticizer is correspondingly lower than that of the common commercial polycarboxylicacid super plasticizer; the concrete super plasticizer is applied to high-strength concrete above C50, the dosage can be reduced by 4-19% when the concrete super plasticizer reaches the same mobility;and when the concrete super plasticizer is applied to ultra-high strength concrete above C100, the advantages are more prominent, the dosage can be reduced by greater than 6-27%, and viscosity is effectively reduced.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

Oil-based drilling fluid for protecting shale gas reservoir

InactiveCN106520088AStabilize the wellboreImprove the lubrication effectDrilling compositionFiltrationBase oil

The invention discloses an oil-based drilling fluid for protecting a shale gas reservoir, wherein the oil-based drilling fluid includes, in parts by volume, 70-90 parts of base oil and 10-30 parts of an aqueous phase; based on the total volume of the base oil and the aqueous phase, the oil-based drilling fluid further includes the components by the mass / volume ratio: 1-3% of a main emulsifier, 0.5-1.5% of an auxiliary emulsifier, 1-3% of lime, 1-3% of organic soil, 1-3% of a tackifier, 1-5% of a filtration loss reduction agent, 1-3% of a plugging agent, 3-8% of a reservoir protective agent, and 0-100% of a weighting agent, wherein the reservoir protective agent is a compound mixture of calcium carbonate, magnesium oxide and magnesium carbonate. The drilling fluid has relatively good inhibition and lubrication performance, and can protect the shale gas reservoir.

Owner:中石化石油工程技术服务有限公司 +1

Oil base drilling fluid wetting agent and application thereof

The invention discloses an oil base drilling fluid wetting agent and application thereof, belonging to the technical field of oil and gas filed chemical engineering. The wetting agent comprises the following components by weight percent: 60%-90% of pine tar and 10%-40% of oleic acid, wherein the pine tar is vegetable pine tar, oleic acid is vegetable oleic acid, and the adding amount of the wetting agent accounts for 1%-3% of the weight of the oil base drilling fluid. The components of the wetting agent have wide source of feed and are cheap; the wetting agent is easy to prepare, has good wetting effect on multiple weighting materials, and can be widely used for the base oil of the oil base drilling fluid; the oil base drilling fluid prepared by using the wetting agent can meet the well drilling and construction requirements of unconventionality oil and gas reservoirs.

Owner:CNPC SICHUAN GASOLINEEUM GEOPHYSICAL PROSPECTING ENG TECH RES INST

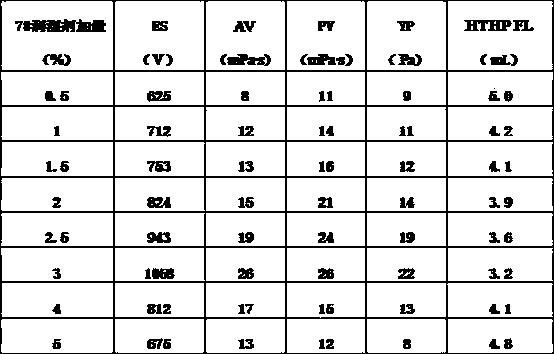

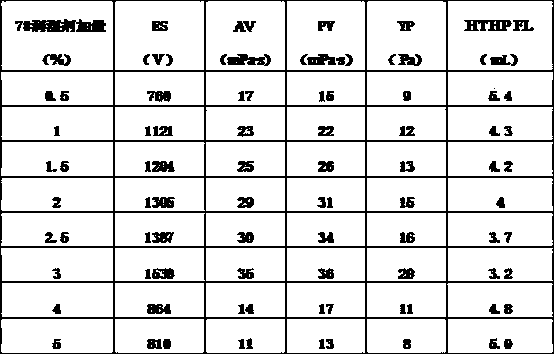

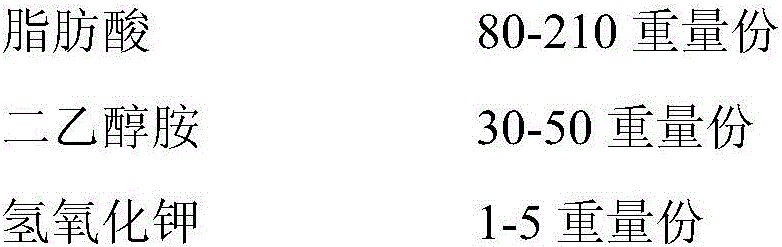

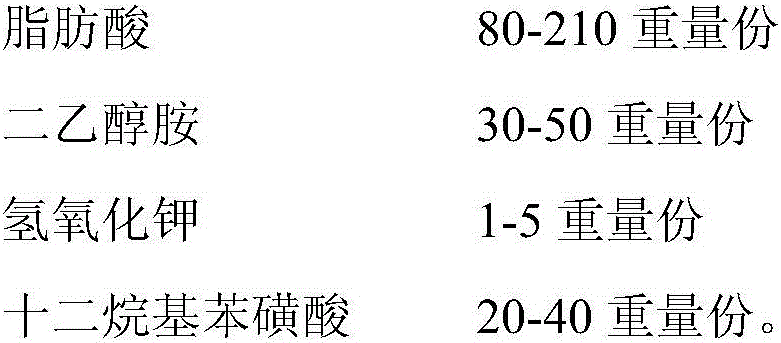

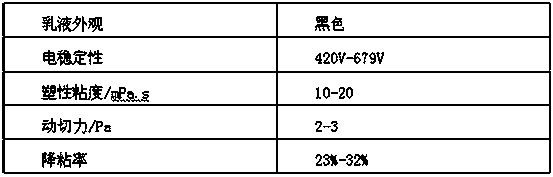

Diluent for oil-based drilling fluid, preparation method and application thereof

ActiveCN105950124ALow viscosityReduce apparent viscosityDrilling compositionPotassium hydroxideSlurry

The invention provides a diluent for oil-based drilling fluid and a preparation method thereof. The raw materials for preparation of the diluent consist of: 80-210 parts by weight of fatty acid, 30-50 parts by weight of diethanolamine, 1-5 parts by weight of potassium hydroxide and 15-45 parts by weight of dodecyl benzenesulfonic acid. The diluent for oil-based drilling fluid provided by the invention can have good compatibility with the oil base, and accordingly can be well dispersed in oil-based drilling fluid so as to reduce the viscosity of the oil-based drilling fluid, and under a high temperature condition, the diluent also has good performance. The invention also provides application of the diluent in high density oil-based drilling fluid. The diluent can effectively reduce the apparent viscosity, plastic viscosity and yield value of drilling fluid in high density oil-based drilling fluid base slurry, thereby better realizing reuse of oil-based drilling fluid, and reducing the use cost of oil-based drilling fluid.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

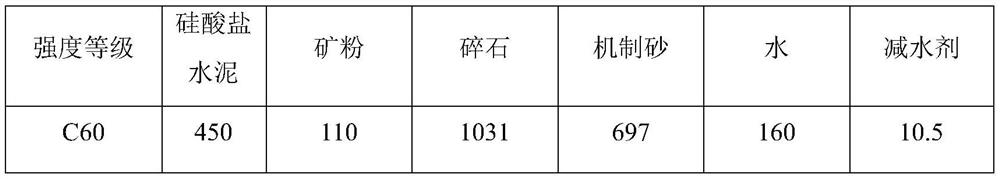

Inorganic dispersing agent for improving rheological property of geopolymer slurry as well as preparation method and application of inorganic dispersing agent

ActiveCN108218274AImproved rheological propertiesHelp promote the applicationSurface energyBuilding material

The invention provides an inorganic dispersing agent for improving the rheological property of geopolymer slurry as well as a preparation method and application of the inorganic dispersing agent, andrelates to the field of production and preparation of building materials. The preparation method of the inorganic dispersing agent comprises the following steps: mixing coal ash particles and alkalineliquor, stirring for 1-6 hours at the temperature of 50-80 DEG C, then mixing the coal ash particles and solution containing low-surface-energy substances, and dipping for 0.5-1.5 hours at the temperature of 55-65 DEG C. The inorganic dispersing agent prepared by the method has a hydrophobic surface and also has the beneficial effects that a ball effect can be exerted in high-alkalinity and high-viscosity geopolymer slurry, the plastic viscosity can be reduced and the rheological property of the geopolymer slurry can be improved.

Owner:YANCHENG INST OF TECH

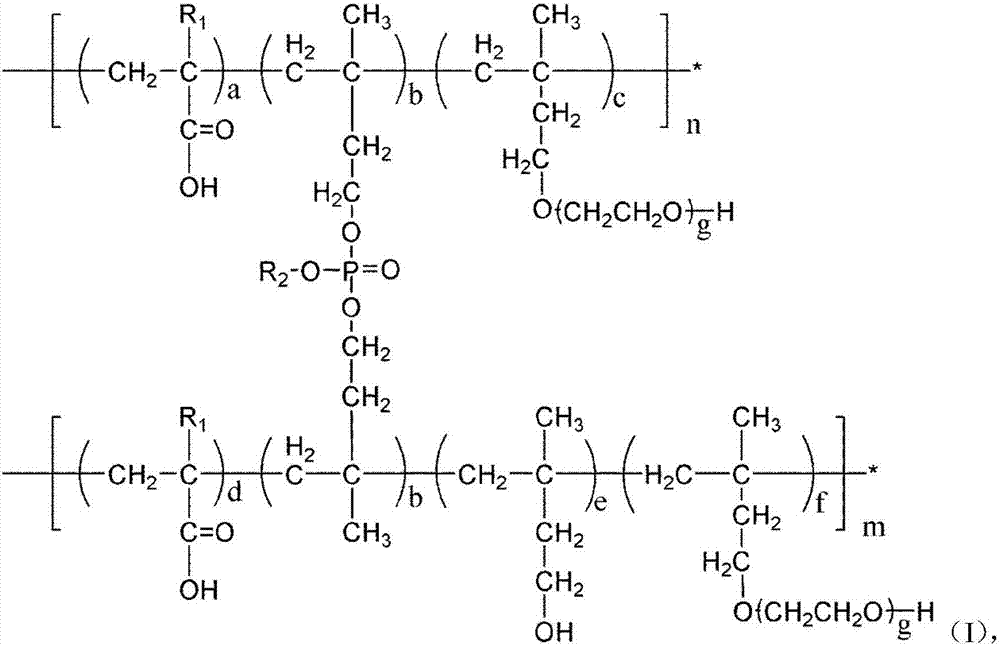

Preparation method of viscosity-reducing mud-resistant polycarboxylic acid water reducing agent

ActiveCN113372510AReduce dosageProlong the slump timeSolid waste managementFunctional monomerPtru catalyst

The invention belongs to the field of concrete water reducing agents, and particularly relates to a preparation method of a viscosity-reducing mud-resistant type polycarboxylic acid water reducing agent, which comprises the following steps: uniformly mixing trifluoroacetic acid and a catalyst, adding an enol compound into a mixed solution, carrying out reflux reaction, and after the reaction is completed, distilling and collecting a product to prepare a viscosity-reducing functional monomer I; dissolving a polyether monomer and a benzylidene nitrile compound in water to form a water phase system, dissolving a reducing agent and a chain transfer agent in water to serve as a solution A, and dissolving a carboxyl small monomer and a viscosity-reducing functional monomer I in water to serve as a solution B; and adding an initiator into the water-phase system, then dropwise adding thesolution A and the solution B into the water-phase system, completely reacting at a certain temperature, preserving heat and curing for 2-4 hours, and finally adjusting the pH value to be neutral, thereby obtaining the viscosity-reducing and mud-resistant polycarboxylate superplasticizer. The viscosity-reducingmud-resistant type water reducing agent prepared by the invention can obviously reduce the use dosage of the water reducing agent and prolong the slump retaining time of concrete. The viscosity-reducingmud-resistant type water reducing agent has an excellent viscosity reduction effect, reduces the plastic viscosity of concrete and improves the construction performance of concrete.

Owner:HUZHOU FENGSHENG NEW MATERIAL

Low-viscosity high-shear high-density oil-base drilling fluid

InactiveCN105733530ARheology is easy to adjustHigh viscosityDrilling compositionCalcium hydroxideHigh density

The invention provides a low-viscosity high-shear high-density oil-base drilling fluid which is prepared from the following raw materials in percentage by weight: 30-80% of base oil, 10-30% of CaCl2 salt water, 3-6% of composite emulsifier G326-HEM, 2-5% of fluid loss additive G328, 1-5% of calcium hydroxide, 0.5-1% of tackifier G336-VIS, 1.5-5% of shear strength improving agent and the balance of barite. The low-viscosity high-shear high-density oil-base drilling fluid solves the problem of overhigh thickness of the high-density oil-base drilling fluid since the viscosity of the system greatly increases as the shear force of the high-density oil-base drilling fluid increases in the past, has the advantages of higher movable shear force, lower plastic viscosity and favorable rheological properties, and is suitable for requirements of the horizontal segment construction of the shale gas horizontal well for the solid-carrying behavior of the oil-base drilling fluid.

Owner:CNPC SICHUAN GASOLINEEUM GEOPHYSICAL PROSPECTING ENG TECH RES INST

A prestressed channel grouting agent and its preparation and use method

The invention provides a prestressed channel grouting agent with the characteristics of high fluidity and no bleeding, which comprises the following components: 2-10% of water reducing agent, 0.1-10% of viscosity modifier, and 0.0% of defoaming agent ~1%, setting time regulator 35~78%; the setting time regulator includes the following components: clinker 28~52%; gypsum 42~68%; filler 4~30%; %; The present invention also provides a preparation method and a use method of the above-mentioned prestressed channel grouting agent. Because the present invention contains the cement setting time regulator, it can adjust the setting time of the cement-based composite material according to the change of external air temperature, so as to ensure the normal use and normal growth of the strength of the cement-based composite material. At the same time, the addition of the cement setting time regulator makes the Cement-based composites produce micro-expansion in the later stage.

Owner:WUHAN BILLION TECH DEV CO LTD

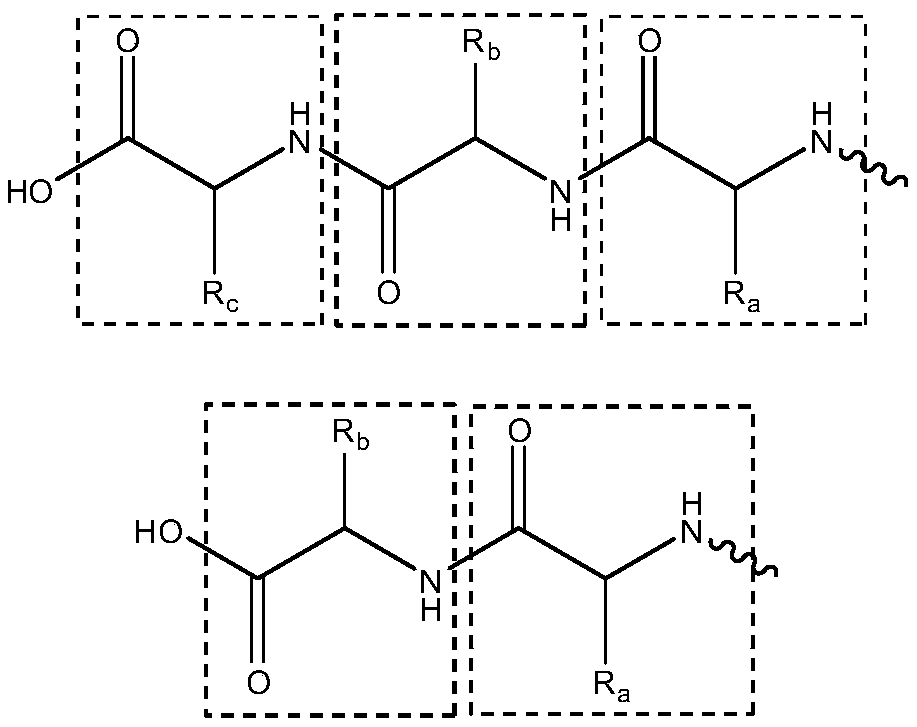

Special superplasticizer used for concrete with high and ultrahigh strength and preparation method thereof

The invention discloses a special superplasticizer used for concrete with high and ultrahigh strength and a preparation method thereof. The preparation method for the superplasticizer provided by theinvention comprises the following steps: initiating a solvent, a polymerizable monomer A, a chain transfer agent B, a polymerizable monomer I and an initiator to polymerize so as to obtain an intermediate solution; then adding polyether C, amino acid D and micromolecular peptide E, and simultaneously adding an auxiliary reaction reagent F so as to obtain an intermediate mixed solution; and addingthe intermediate mixed solution into a mixed solution of water and a phosphoric acid composition G which is dissolved in a solvent so as to obtain a solution of the superplasticizer. Compared with a commercially-available ordinary superplasticizer, the superplasticizer provided by the invention has the following advantages: when the superplasticizer is applied to high-strength concrete with a strength grade of C50 or above, the usage amount of the superplasticizer can be significantly reduced to achieve a same fluidity; the workability is significantly improved under same fluidity conditions;the inverted slump cylinder emptying time is shortened; the viscosity is reduced; and when the superplasticizer is applied to ultrahigh-strength concrete with a strength grade of C100 or above, the advantages of the superplasticizer are more prominent, and the usage amount and viscosity of the superplasticizer can be significantly reduced.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

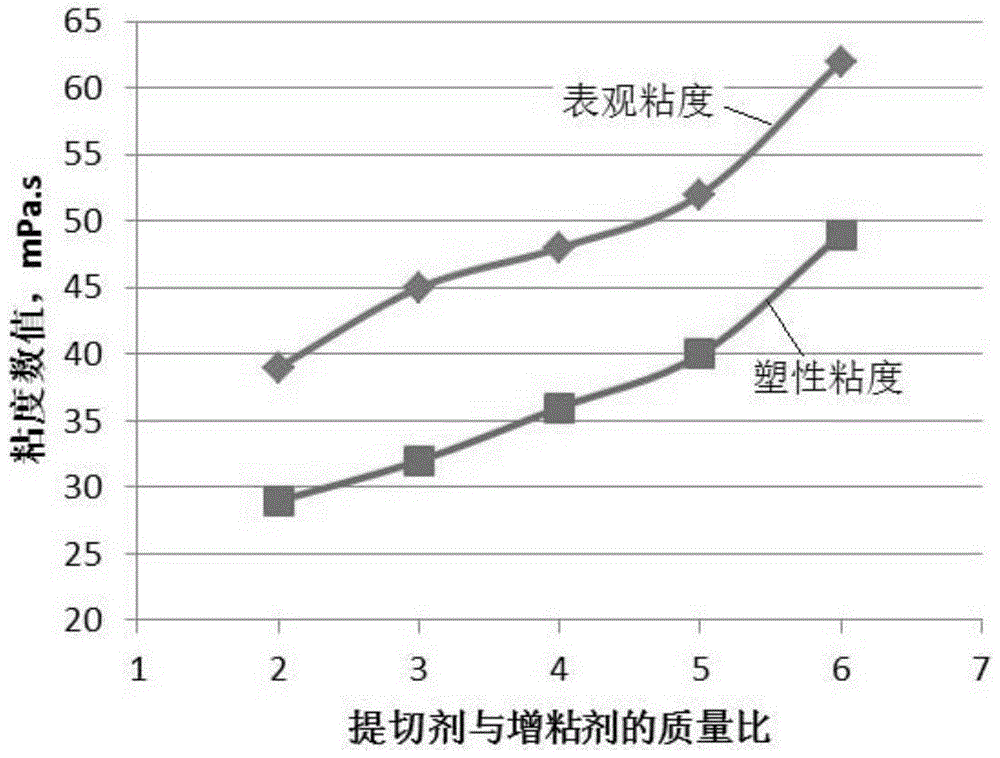

Cement-based composite material for trenchless centrifugal spraying repair of pipeline and preparation method of material

ActiveCN113307587ALow plastic viscosityHigh yield stressSolid waste managementUltimate tensile strengthMechanical engineering

The invention discloses a cement-based composite material for trenchless centrifugal spraying repair of a pipeline. The cement-based composite material is prepared from the following components in parts by weight: 900 to 940 parts of cement, 140 to 160 parts of viscosity reducer, 370 to 390 parts of thickener, 1500 to 1600 parts of sand, 0.5 to 2 parts of thixotropic agent, 60 to 100 parts of setting-adjusting early strength agent, 6 to 12 parts of fiber, 30 to 40 parts of water reducing agent and 260 to 280 parts of mixing water. The invention further discloses a preparation method of the cement-based composite material for pipeline trenchless centrifugal spraying repair. According to the invention, the sprayability and early strength of the high-performance cement-based composite material can be effectively improved, so that the rebound rate is reduced, the one-time spraying thickness is increased, the compactness is improved, and continuous centrifugal spraying construction of the high-performance cement-based composite material is realized.

Owner:CHANGJIANG INT HYDRO ENG CO LTD

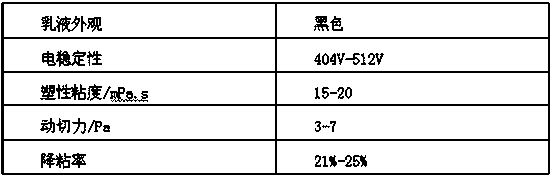

Preparation method of inert dilution agent for oil-based drilling fluid

The invention relates to a preparation method of an inert dilution agent for an oil-based drilling fluid. According to the technical scheme, the preparation method comprises the following steps that 1, low-viscosity synthetic base oil is added in a beaker with a stirrer and a thermometer, and a reaction is carried out at the 50-90 DEG C for 3-6 hours, and then heating is stopped; 2, an emulsifyingagent is added into the reactor in the step 1, and stirring is conducted 3-6 hours; 3, a filtrate reducer, a wetting agent, an alkalinity regulating agent and a calcium chloride water solution are mixed in a ratio and then added into the reactor in the step 1, and stirring is conducted for 6-8 hours; 4, the mixture in the reactor is stirred at a high speed, a reaction is carried out at the temperature of 50-90 DEG C for 3-6 hours, cooling is conducted until to the room temperature, an emulsion is formed, and the emulsion is the inert dilution agent for the oil-based drilling fluid. The preparation method has the advantages that under the condition that the inhibitive ability and the shear thinning performance of the oil-based drilling fluid are not changed, the plastic viscosity can be reduced, and the drilling fluid obtained before and after addition of the inert dilution agent cannot affect construction safety even in the construction process.

Owner:中石化石油工程技术服务有限公司 +2

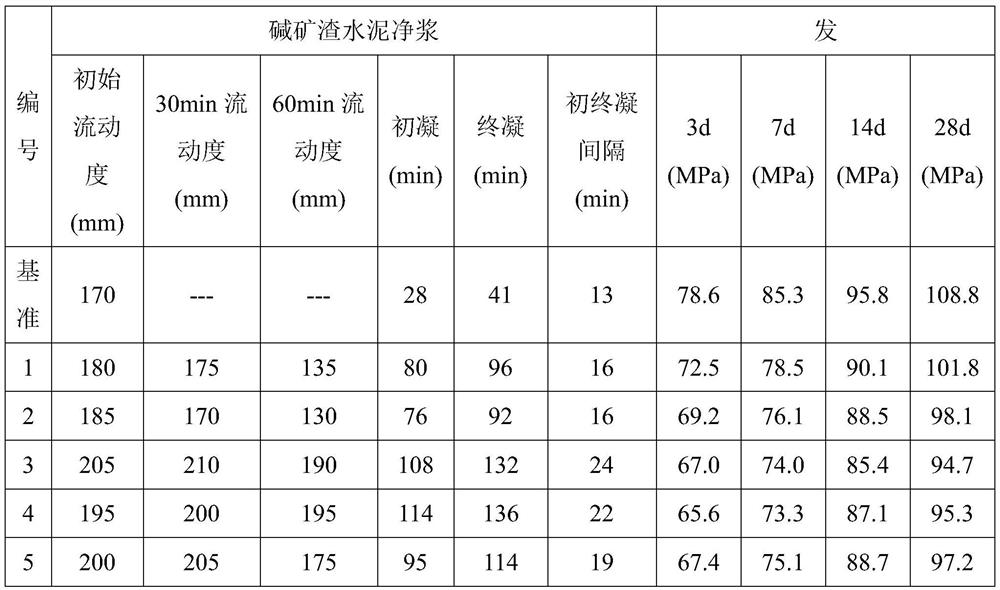

Method for adjusting fluidity and setting time of chemically activated cementing material system

ActiveCN113429134ARaise the absolute valueLow plastic viscosityCement productionInorganic saltsHydration reaction

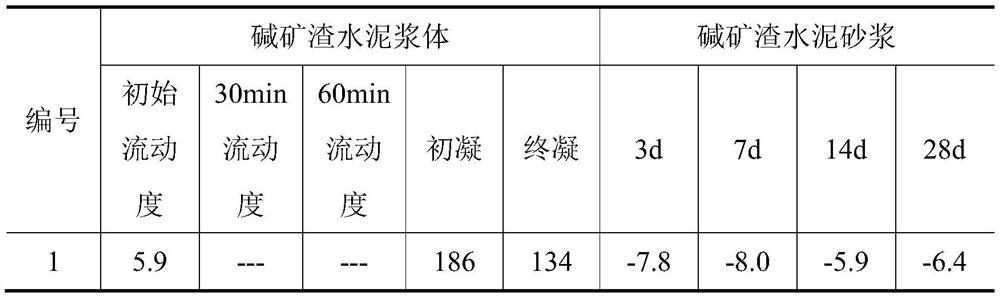

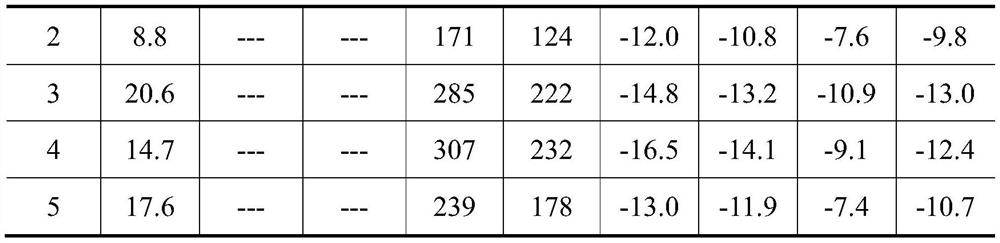

The invention discloses a method for adjusting fluidity and setting time of a chemically activated cementing material system, which comprises the steps of compounding and doping inorganic salt consisting of negative hydrated ions in the using process of a chemically activated cementing material, wherein the inorganic salt consisting of the negative hydrated ions adopts the inorganic salt formed by ions with different hydration properties and different chemical radiuses. The inorganic salt composed of the negative hydrated ions comprises one of KCl, KBr and KNO3 and Ba (NO3) 2. The content of KCl, KBr or KNO3 is 3%-5% of the mass of the chemically activated cementing material precursor material, and the content of Ba (NO3) 2 is 0.1%-0.2% of the mass of the chemically activated cementing material precursor material. According to the invention, the initial fluidity and fluidity retentivity of the chemically activated cementing material slurry can be improved, and the setting time can be prolonged. Compared with a chemically activated cementing material without being doped with inorganic salt, the initial fluidity of the slurry is improved by 5.9%-20.6%, the high fluidity is kept in 30 min and 60 min, the initial setting time is prolonged by 171%-307%, the final setting time is prolonged by 124%-232%, and the influence on the mechanical property of the chemically activated cementing material is small.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Thermosensitive resin inhibition plugging agent for drilling fluid and preparation method thereof

PendingCN110885669AChange affinityLow plastic viscosityDrilling compositionPolymer scienceFiltration

The invention discloses a thermosensitive resin inhibition plugging agent for drilling fluid and a preparation method thereof. The method comprises the steps of: performing modification treatment fororganic siloxane, and mixing treated bentonite to obtain an inhibition plugging agent for drilling fluid. The obtained inhibition plugging agent is high in sensitivity, good in temperature resistanceand high in strength, the affinity of the resin system is changed under the action of heat, the distance between fine liquid drops in the drilling fluid system and other oil-soluble dispersant particles is increased, the plastic viscosity of the drilling fluid is reduced, hydration expansion of clay is inhibited, the low-temperature low-pressure closed filtration loss and the high-temperature high-pressure permeation filtration loss are low, and the inhibition and plugging performance of the drilling fluid is improved.

Owner:四川巨力源能源科技有限公司

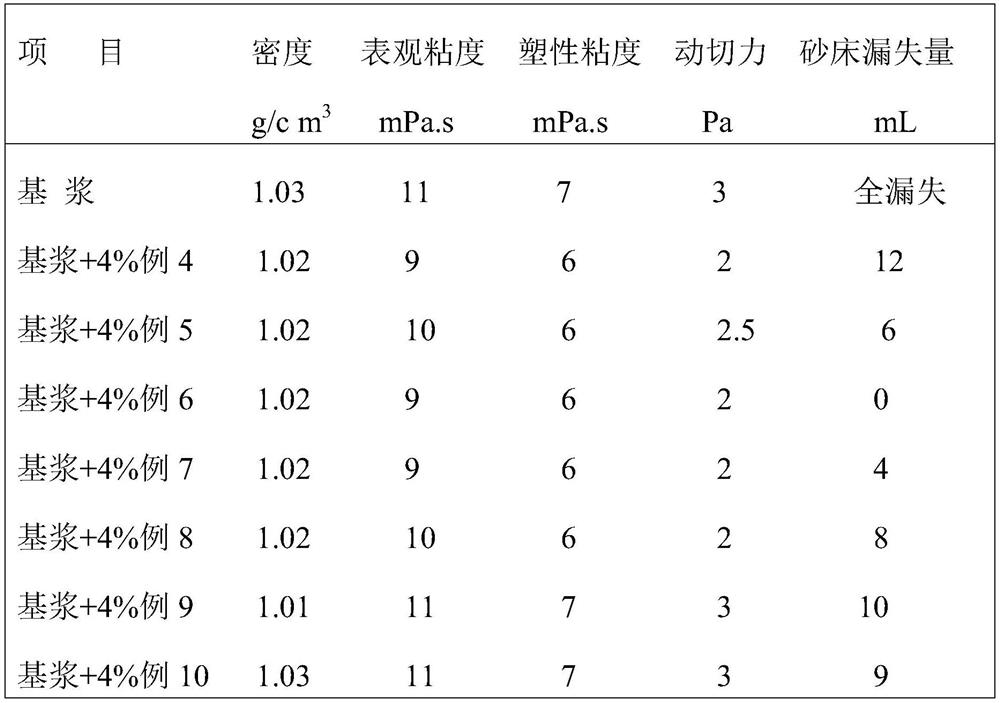

Modified plant fiber plugging-while-drilling agent for drilling fluid and preparation method of plugging-while-drilling agent

The invention relates to a plugging-while-drilling agent for drilling fluid and a preparation method of the plugging-while-drilling agent, in particular to a preparation method of a modified plant fiber plugging agent. The plugging-while-drilling agent is prepared from the following components in percentage by weight: 40 to 80 percent of plant fiber, 10 to 40 percent of humic acid and 5 to 10 percent of hydrolyzed polyacrylonitrile colloid, wherein the hydrolyzed polyacrylonitrile colloid is floccule obtained by cross-linking hydrolyzed polyacrylonitrile salt. The preparation method of the modified plant fiber plugging-while-drilling agent comprises the following steps: adding the prepared hydrolyzed polyacrylonitrile salt cross-linked floccule solution into a mixture of plant fiber and humic acid according to a corresponding ratio, fully and uniformly mixing, drying into a solid, and grinding into powder, thereby obtaining the modified plant fiber plugging-while-drilling agent. The plugging-while-drilling agent has little influence on the performance of the drilling fluid, can effectively plug stratum micro-cracks and high-permeability pore leakage, and has the advantages of accessible raw materials, low cost, simple production technique and favorable popularization and application values.

Owner:DAQING HEZHENG CHEM

Method for treating and recycling shale gas fracturing flow-back fluid

ActiveCN111423011AReduce fluid lossGood filter loss reduction effectWaste water treatment from quariesMultistage water/sewage treatmentPolymer adhesiveThermodynamics

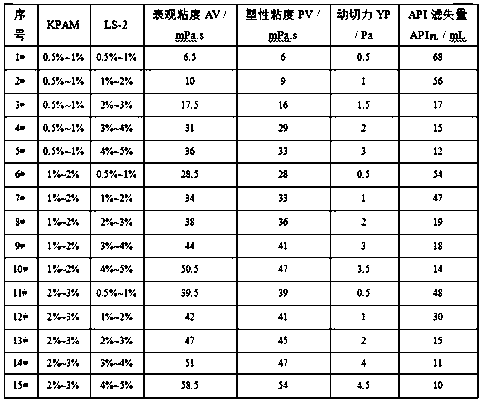

The invention discloses a method for treating and recycling shale gas fracturing flow-back fluid. The method comprises a step of treating the shale gas fracturing flow-back fluid and a step of preparing a polymer glue solution, wherein the polymer glue solution is prepared by the following steps: adding 0.5%-1.0% by mass of polyacrylamide potassium salt KPAM and 2.0%-3.0% by mass of a polymer filtrate reducer LS-2 into clear water, and hydrating to expand a polymer molecular chain, so as to obtain the polymer glue solution; mixing the polymer glue solution and the treated fracturing flow-backfluid according to the ratio of 7: 3, and the mixed fracturing flow-back fluid is used for preparing drilling fluid. According to the invention, mechanical equipment does not need to be added, operation is directly conducted in the on-site circulating tank, the method is simple, and extra cost is not increased; no secondary pollution waste is generated, and the treated fracturing flow-back fluid is completely recycled, so that the invention is more environment-friendly.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com