Oil-based drilling fluid for protecting shale gas reservoir

An oil-based drilling fluid and shale gas technology, applied in the field of oil drilling engineering, can solve the problems of filtrate entry, reservoir damage, and poor sealing performance, and achieve the effect of preventing damage and stabilizing the well wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

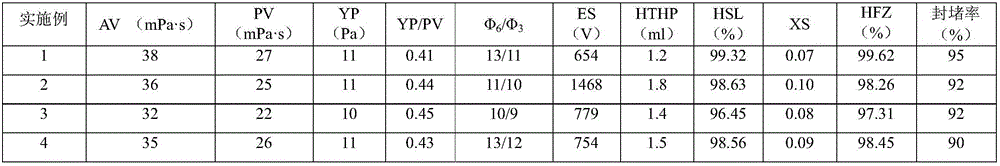

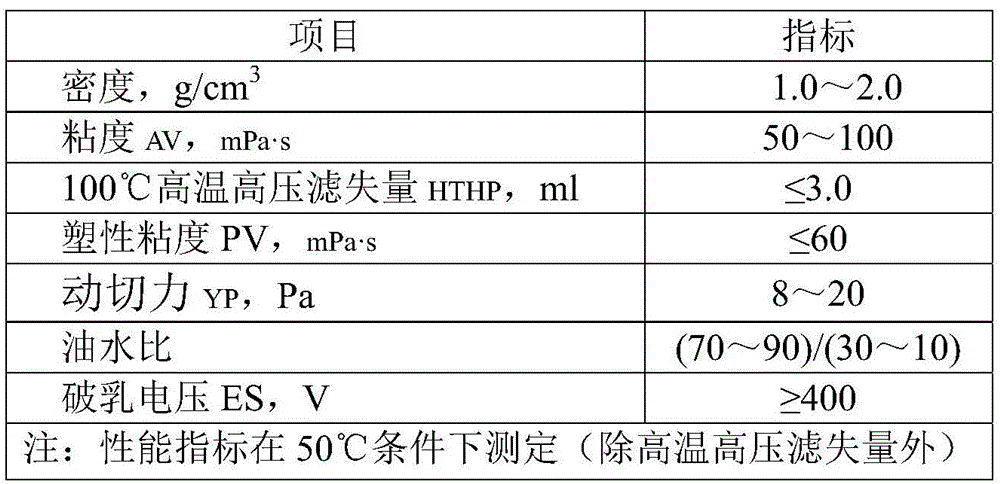

Examples

Embodiment 1

[0029] An oil-based drilling fluid for protecting shale gas reservoirs includes 70 parts of 3# white oil and 30 parts of 26% calcium chloride aqueous solution in parts by volume; and

[0030] Based on the total volume of 3# white oil and 26% calcium chloride aqueous solution, by mass volume ratio (g / ml), also include 2.0% main emulsifier, 1.0% secondary emulsifier, 1.5% lime, 2.5% Organoclay, 2% viscosifier, 3.0% fluid loss control agent, 2.0% plugging agent, 2.0% reservoir protection agent, 30% weighting agent;

[0031] The reservoir protection agent is in parts by weight, and the particle size is 200 mesh calcium carbonate: 300 mesh magnesium oxide: 500 mesh magnesium carbonate: 800 mesh calcium carbonate: 1200 mesh magnesium carbonate: 2000 mesh magnesium oxide is 1:3:2.5: 5:5:2 compound mixture;

[0032] The main emulsifier is a compound mixture of long-chain alkyl fatty alcohol amide nonionic surfactant and modified benzene sulfonate at a ratio of 65:35 by volume;

[00...

Embodiment 2

[0042] An oil-based drilling fluid for protecting shale gas reservoirs, in parts by volume, comprising 90 parts of gas oil, 10 parts of 35% calcium chloride aqueous solution; and

[0043] Based on the total volume of gaseous oil and 35% calcium chloride aqueous solution, by mass volume ratio (g / ml), it also includes 1.0% main emulsifier, 0.5% secondary emulsifier, 1.0% lime, 1.0% organic Soil, 1.0% viscosifier, 1.0% fluid loss control agent, 1.0% plugging agent, 3.0% reservoir protection agent, 70% weighting agent;

[0044] According to the ratio of parts by weight, the reservoir protection agent has a particle size of 500 mesh calcium carbonate: 500 mesh magnesium oxide: 500 mesh magnesium carbonate: 800 mesh calcium carbonate: 800 mesh magnesium carbonate: 1000 mesh magnesium oxide: 1:1:1:5 :5:7 compound mixture;

[0045] The main emulsifier is a compound mixture of long-chain alkyl fatty alcohol amide nonionic surfactant and modified benzene sulfonate at a ratio of 50:50 b...

Embodiment 3

[0055] An oil-based drilling fluid for protecting shale gas reservoirs includes 80 parts of 0# diesel oil and 20 parts of 25% calcium chloride aqueous solution in parts by volume; and

[0056] Based on the total volume of 0# diesel oil and 25% calcium chloride aqueous solution, by mass volume ratio (g / ml), also include 3.0% main emulsifier, 1.5% auxiliary emulsifier, 3.0% lime, 3.0% Organic clay, 3.0% viscosifier, 5.0% fluid loss control agent, 3.0% plugging agent, 8.0% reservoir protection agent, 85% weighting agent;

[0057] According to the ratio of parts by weight, the reservoir protection agent has a particle size of 800 mesh calcium carbonate: 800 mesh magnesium oxide: 1000 mesh magnesium carbonate: 1000 mesh calcium carbonate: 1000 mesh magnesium carbonate: 1500 mesh magnesium oxide is 1:1:2:2 :2:4 compound mixture;

[0058] The main emulsifier is a compound mixture of long-chain alkyl fatty alcohol amide nonionic surfactant and modified benzene sulfonate at a ratio of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com