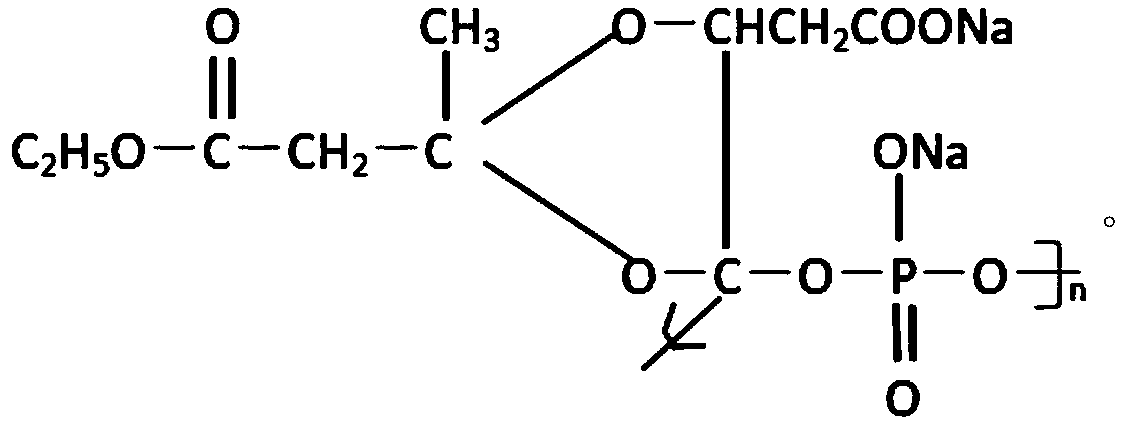

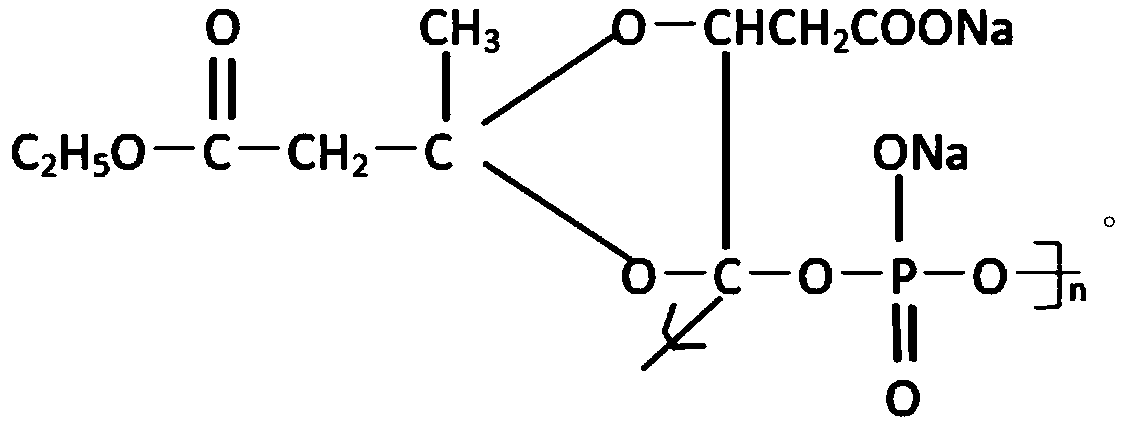

Nano-plugging agent modified ketal, preparation method thereof and oilfield drilling fluid

A nano-sealing agent and oilfield drilling technology, applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problem of effective sealing of nano-scale micro-fractures, inability to effectively block and prevent collapse, poor plugging effect, etc. problems, achieve the effect of preventing collapse, stabilizing well wall and improving mud cake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

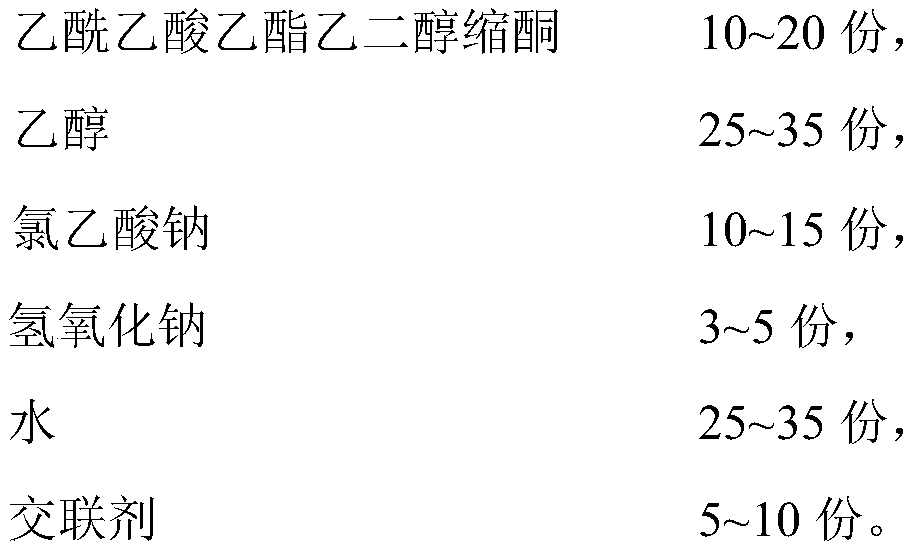

[0026] Take 30 parts of industrial superior grade absolute ethanol according to the weight ratio and add it to the reaction kettle, add 10 parts of industrial superior grade ethyl acetoacetate ethylene glycol ketal, 12 parts of industrial superior grade sodium chloroacetate, 3 parts of industrial High-grade sodium hydroxide, 25 parts of water, slowly heat up to 90°C, react for 3 hours, then add 5 parts of disodium hydrogen phosphate, raise the temperature to 95°C, and keep stirring at 95°C for 3 hours, cool , that is to obtain the nano-blocking agent modified ketal of this embodiment.

Embodiment 2

[0028] Take 32 parts of industrial superior grade absolute ethanol according to the weight ratio and add it to the reaction kettle, add 18 parts of industrial superior grade ethyl acetoacetate ethylene glycol ketal, 12 parts of industrial superior grade sodium chloroacetate, 3 parts of industrial High-grade sodium hydroxide, 30 parts of water, slowly heat up to 90°C, react for 3 hours, then add 5 parts of disodium hydrogen phosphate, raise the temperature to 95°C, and keep stirring at 95°C for 3.5 hours, cool , that is to obtain the nano-blocking agent modified ketal of this embodiment.

Embodiment 3

[0030] Take 32 parts of industrial superior grade anhydrous ethanol according to the weight ratio and add it to the reaction kettle, add 18 parts of industrial superior grade ethyl acetoacetate ethylene glycol ketal, 12 parts of industrial superior grade sodium chloroacetate, 4 parts of industrial High-grade sodium hydroxide, 35 parts of water, slowly heat up to 90°C, react for 3 hours, then add 6 parts of disodium hydrogen phosphate, raise the temperature to 92°C, and keep stirring at 92°C for 4 hours, cool , that is to obtain the nano-blocking agent modified ketal of this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com