High water phase oil-based drilling fluid applicable to long horizontal section of shale gas and preparation method of high water phase oil-based drilling fluid

An oil-based drilling fluid and horizontal section technology, which is applied in the directions of chemical instruments and methods, drilling compositions, etc., can solve the instability of shale wellbore in long horizontal sections, the rising cost of oil-based drilling fluid, and the loss of oil-based drilling fluid. and other problems, to achieve the effect of shale wellbore stability, strong shale stability, and reduction of oil phase content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The present invention provides a high water-phase oil-based drilling fluid suitable for long horizontal sections of shale gas and a preparation method thereof:

[0025] Measure 200mL of No.0 diesel oil, add 12g of alkyl primary amine under high-speed stirring (10000r / min), stir for 20min, then add 200mL of clear water, stir for 40min; then add 8g of asphalt emulsion, stir for 20min; then add 4g of organic Add 12g of oxidized pitch and stir for 20min; then add 60g of calcium chloride and stir for 20min; then add 8g of lime and stir for 10min; finally add 320g of barite (density 1.50g / cm 3 ) and stirred for 20min to obtain the product.

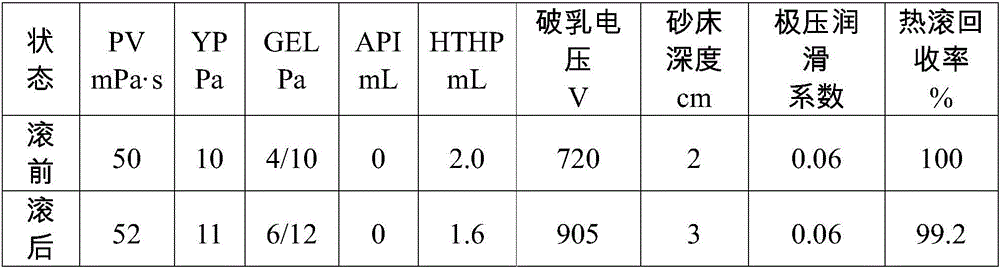

[0026] The performance of the product in this example is shown in Table 1, and all parameters are measured at room temperature. Among them, the pre-rolling state is to measure the performance after preparation, and the post-rolling state is to heat the prepared drilling fluid at 120 ° C. 16h, then cooled to room temperature to measure pe...

Embodiment 2

[0035] The present invention provides a high water-phase oil-based drilling fluid suitable for long horizontal sections of shale gas and a preparation method thereof:

[0036] Measure 200mL of No.0 diesel oil, add 6g of alkanolamide and 6g of polyester amide under high-speed stirring (10000r / min), stir for 20min, then add 200mL of clear water, stir for 40min; then add 10g of nanopolymer, stir for 20min; Then add the mixture of phosphoric acid ester of 6g and aluminum chloride, stir 20min; Add 16g superfine asphalt powder again, stir 20min; Then add 60g sodium formate, stir 20min; Add 8g lime again, stir 10min; Finally add 320g barite ( Density 1.50g / cm 3 ) and stirred for 20min to obtain the product.

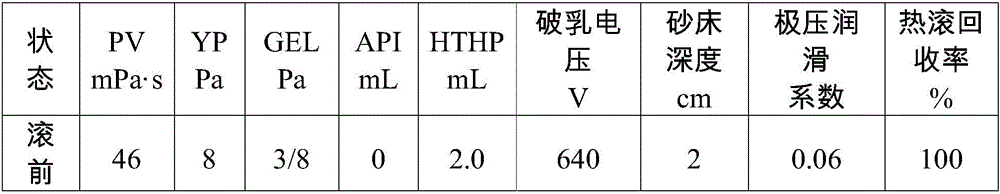

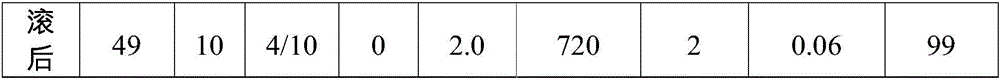

[0037] The performance of the product of this embodiment is as shown in Table 2, and the meaning of each parameter and the test method are the same as in Example 1.

[0038] Table 2 embodiment 2 product performance experiment data

[0039]

[0040]

[0041] Note: Hot ro...

Embodiment 3

[0043] The present invention provides a high water-phase oil-based drilling fluid suitable for long horizontal sections of shale gas and a preparation method thereof:

[0044] Measure 200mL No. 0 diesel oil, under high-speed stirring (10000r / min), add 6g carboxylic acid polyamide and 6g polyamide fatty acid soap, stir for 20min, then add 200mL clear water, stir for 40min; then add 4g nano-graphite, 4g Superfine calcium carbonate, 4g superfine calcined kaolin, stir for 20min; then add 6g of coumarone resin, stir for 20min; then add 16g of oxidized pitch, stir for 20min; then add 60g of potassium formate, stir for 20min; add 8g of lime, stir for 10min ; Finally add 320g barite (density 1.50g / cm 3 ) and stirred for 20min to obtain the product.

[0045] The product performance of this embodiment is as shown in Table 3, and the meaning of each parameter and test method are identical with embodiment 1.

[0046]Table 3 embodiment 3 product performance experiment data

[0047]

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com