A kind of high temperature resistant Pickering emulsion drilling fluid and preparation method thereof

A technology of Pickering emulsion and high temperature resistance, which is applied in the field of drilling fluid, can solve the problems that the pore size cannot be effectively measured or judged, the contribution is limited, and the resealing effect is probabilistic, etc., so as to improve the spatial structure and gel strength, The emulsion has good stability and the effect of solving difficult removal problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

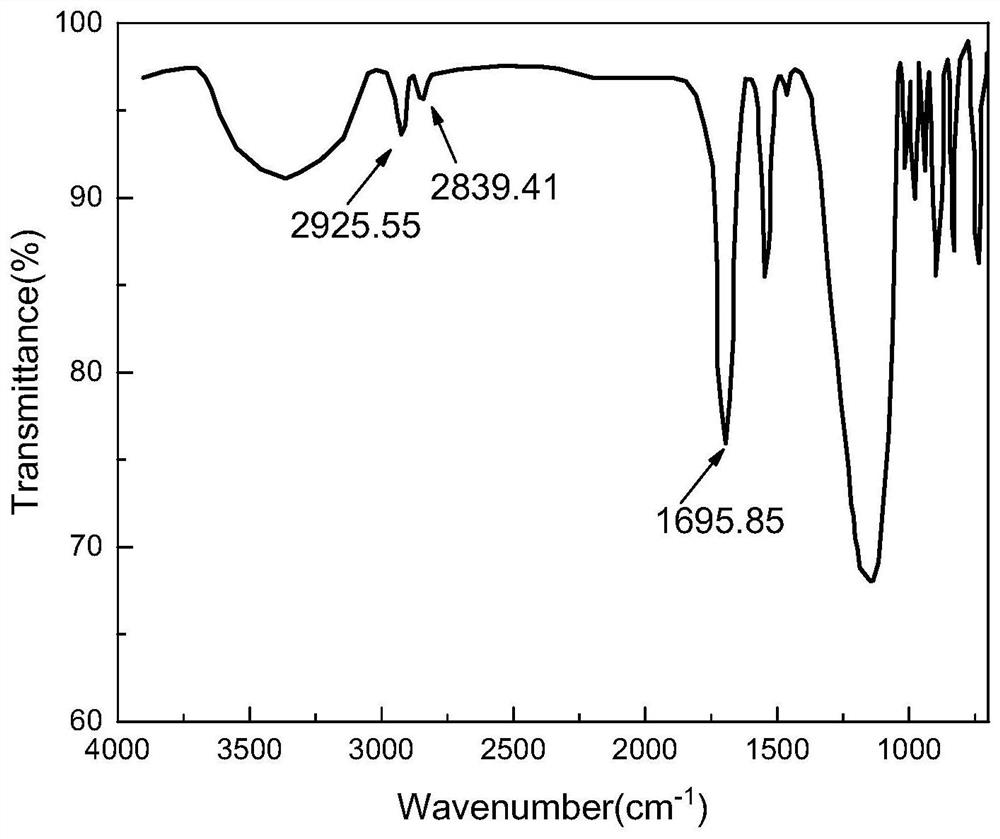

[0059] The present embodiment provides a preparation method of modified organic soil, and the steps are as follows:

[0060] Stir 1 part of sodium bentonite in 20 parts of deionized water for 1 hour, add 0.5 part of dioctadecyl amidopropyl trimethyl ammonium chloride, stir at 1000 rpm for 1 hour at a temperature of 40 ° C, and spin at 8000 rpm for centrifugation 30min. Then add 1 part of dioctadecyl amidopropyl trimethyl ammonium chloride, under the condition of temperature of 40 ℃, stir at 1000 rpm for 1 h, centrifuge at 10000 rpm for 20 min; Dry for 24 hours, grind, and sieve with a 200-mesh sieve to obtain modified organic soil.

Embodiment 2

[0062] The present embodiment provides a preparation method of modified organic soil, and the steps are as follows:

[0063] Stir 1 part of sepiolite in 20 parts of deionized water for 30 minutes, add 1 part of octadecyltrimethylammonium bromide, stir at 1000 rpm for 30 minutes at a temperature of 45°C, and centrifuge at 5000 rpm for 30 minutes. Then, 2 parts of dioctadecyltrimethylammonium bromide were added, and at a temperature of 45° C., the mixture was stirred at 1000 rpm for 6 h, and centrifuged at 5000 rpm for 30 min. The lower layer of sediment was taken out, ground and dispersed on a ball mill for 6 hours, dried at 100° C. for 24 hours, ground, and sieved with a 200-mesh sieve to obtain modified organic soil.

Embodiment 3

[0065] The present embodiment provides a preparation method of modified organic soil, and the steps are as follows:

[0066] Stir 1 part of attapulgite in 30 parts of deionized water for 2 hours, add 0.5 part of cetyl amidopropyl trimethyl ammonium bromide, stir at 800 rpm for 1 hour at a temperature of 45 ° C, and spin at 8000 rpm for centrifugation 15min. Then add 0.5 part of bis-dodecyl amidopropyl trimethyl ammonium bromide, stir at 800 rpm for 3 hours at a temperature of 45 ℃, spin at 8000 rpm for 10 min, take the lower layer of modified sediment and grind and disperse it on a ball mill for 0.5 h , dried at 90°C for 12 hours, ground, and sieved with a 200-mesh sieve to obtain modified organic soil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com