Patents

Literature

181results about How to "Improve fermentation performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

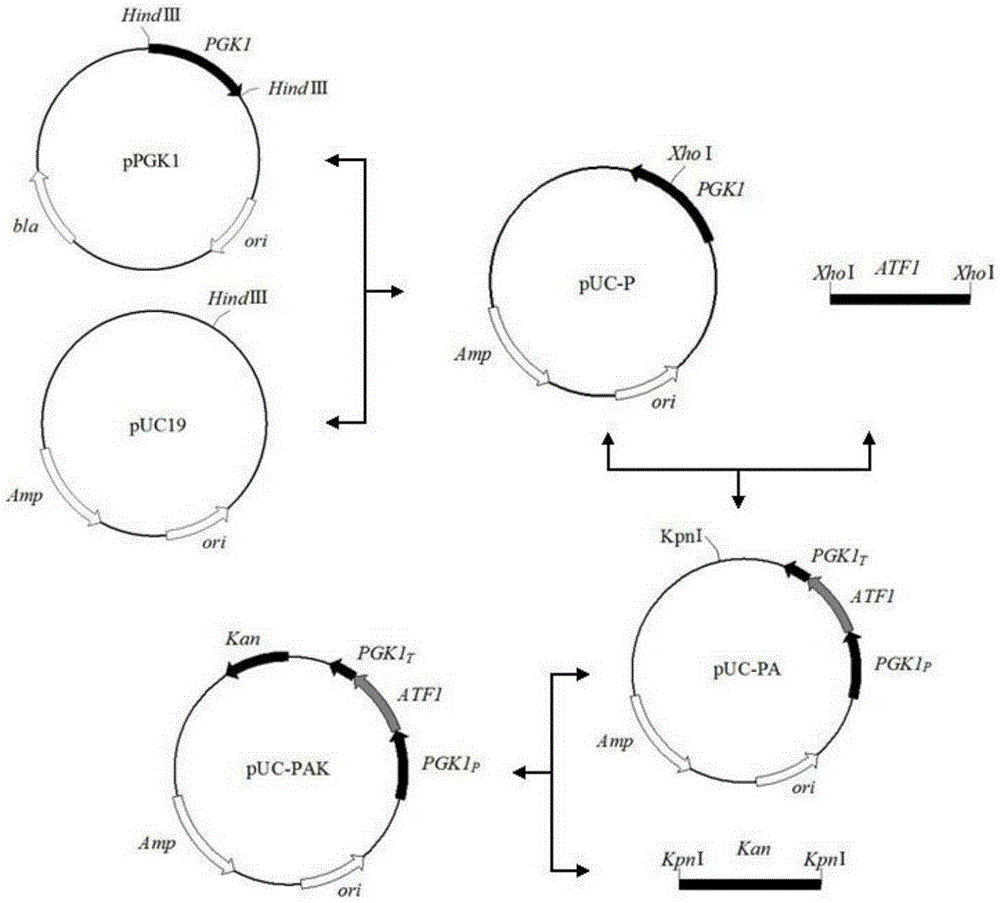

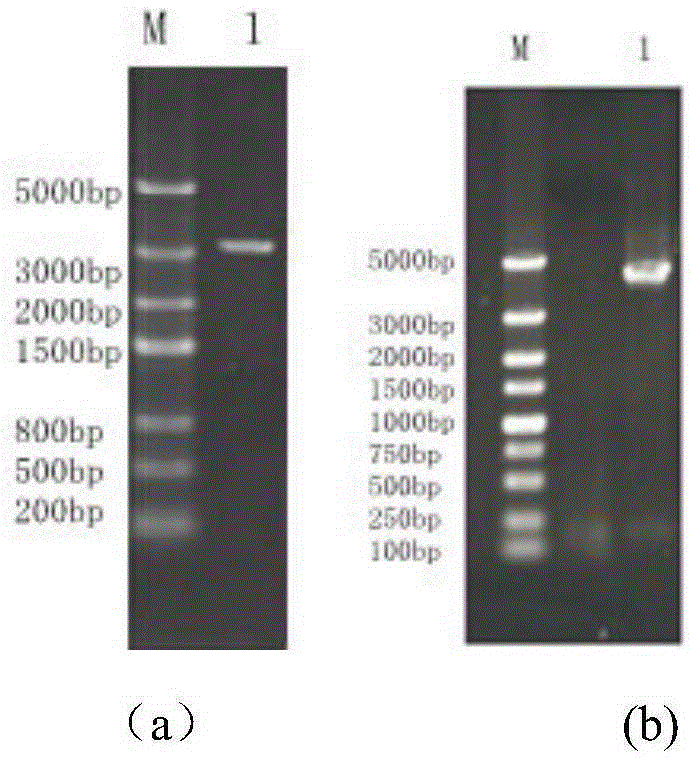

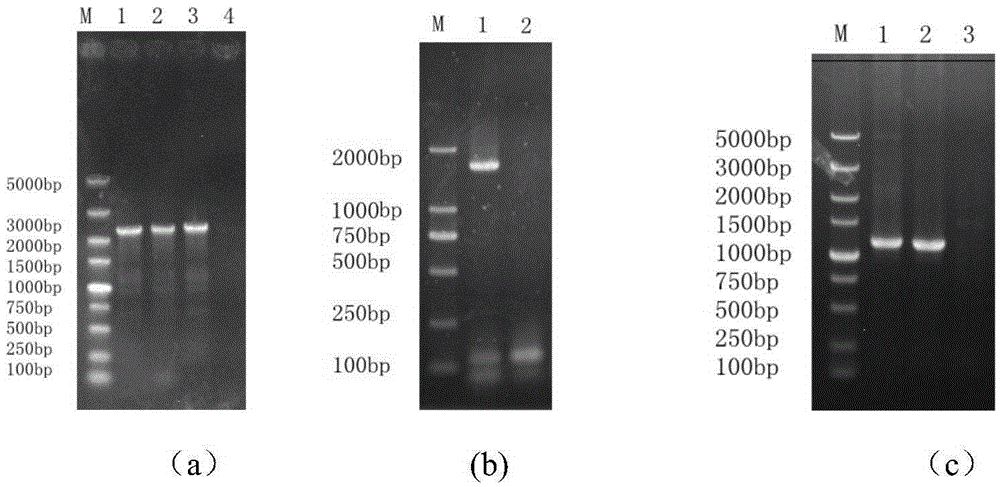

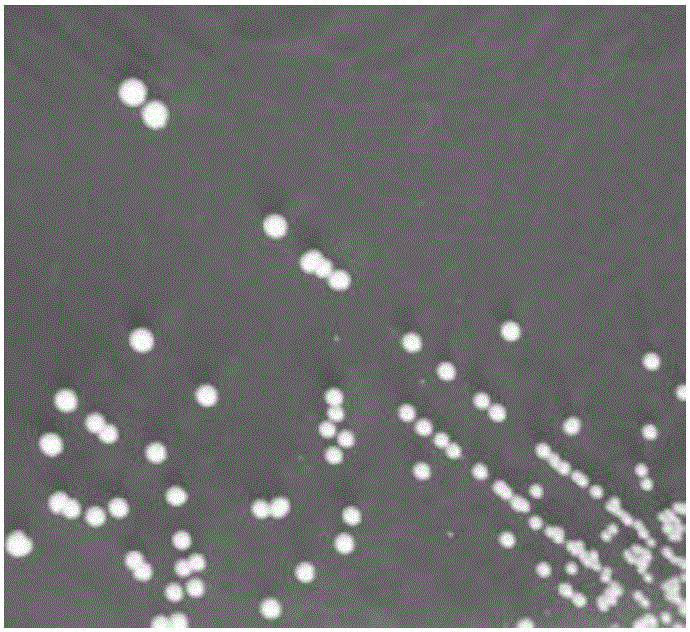

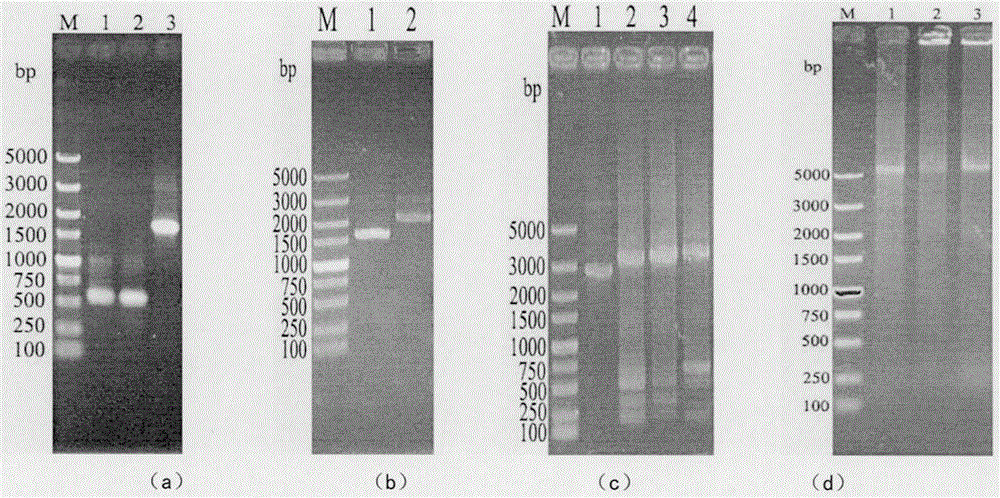

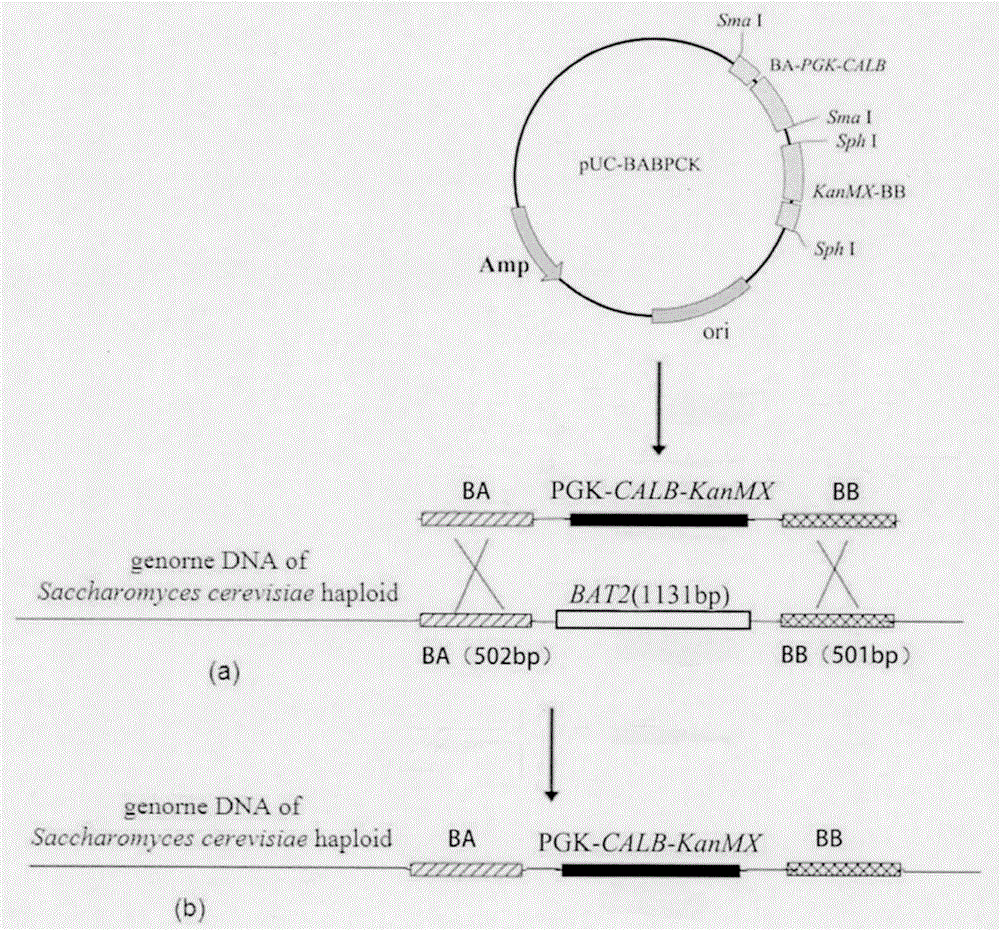

Saccharomyces cerevisiae strain with high yield of ester and low yield of higher alcohol as well as building and application of saccharomyces cerevisiae strain

PendingCN105385615AReduce outputOvercome flavor incongruityFungiHydrolasesEster hydrolaseBio engineering

The invention discloses a saccharomyces cerevisiae strain with high yield of ester and low yield of higher alcohol as well as a building method of the saccharomyces cerevisiae strain, and belongs to the technical field of bioengineering. According to the building method provided by the invention, through completely knocking out an amino acid transaminase gene BAT2 and an ester hydrolase gene IAH1 in an original strain, and selecting a strong promoter PGK1 over-expression alcohol acetyltransferase I gene ATF1 at the same time, the saccharomyces cerevisiae strain with high yield of ester and low yield of higher alcohol is obtained. Compared with a parent strain, other fermentation performances of built recombinant bacteria are not affected, the total quantity of acetic acid ester is obviously increased and reaches 1303.6mg / L, wherein the content of ethyl acetate is 52 times that of the original strain, isoamyl acetate is increased to 73.7mg / L, the content of main higher alcohol is 151.8mg / L and is reduced by 61.4 percent in comparison with that of the original strain. By using the saccharomyces cerevisiae, ester yield is significantly increased while the higher alcohol yield is reduced, the higher requirements of white spirit related fields on yeast are met and the application prospect is wide.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Preparation method of methane dry fermentation compound bacterial preparation

InactiveCN102559499AReduce volumeLow costBacteriaMicroorganism based processesBiotechnologyCellulose

The invention discloses a preparation method of a methane dry fermentation compound bacterial preparation, which comprises the following steps: mixing fermentation substrate with an inoculum which is compound bacteria composed of cellulose decomposing bacteria, proteolytic bacteria, fat decomposing bacteria, hydrogen-producing aceogenic bacteria, sulfate reducing bacteria and methanogenic archaea, adjusting the water content and pH of the mixed materials to 70-80% and 7.0 respectively, performing anaerobic fermentation under the condition of 35 DEG C plus or minus 2 DEG C for 60-90 days to obtain methane dry fermentation compound bacterial preparation. The preparation method of the invention can prepare compound bacterial preparation with a relatively complete methane fermentation function, and the total number of microbial cells and methanogenic archaea cells in the bacterial preparation are at least 10*10<10> / g and 1.0*10<8> / g respectively. Using the compound bacterial preparation as an inoculum of methane dry fermentation can reduce the starting time, and the fermentation process is stable and easy to control.

Owner:BIOGAS SCI RES INST MIN OF AGRI

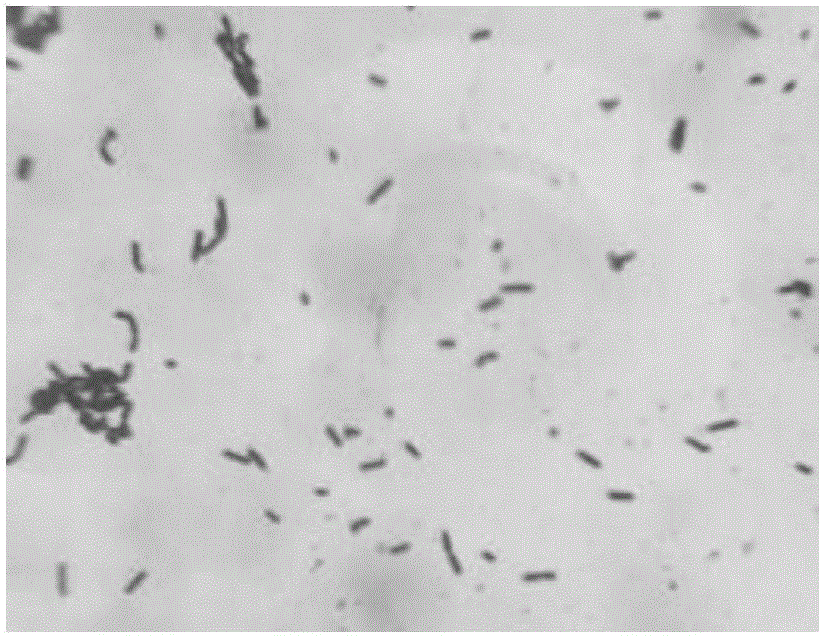

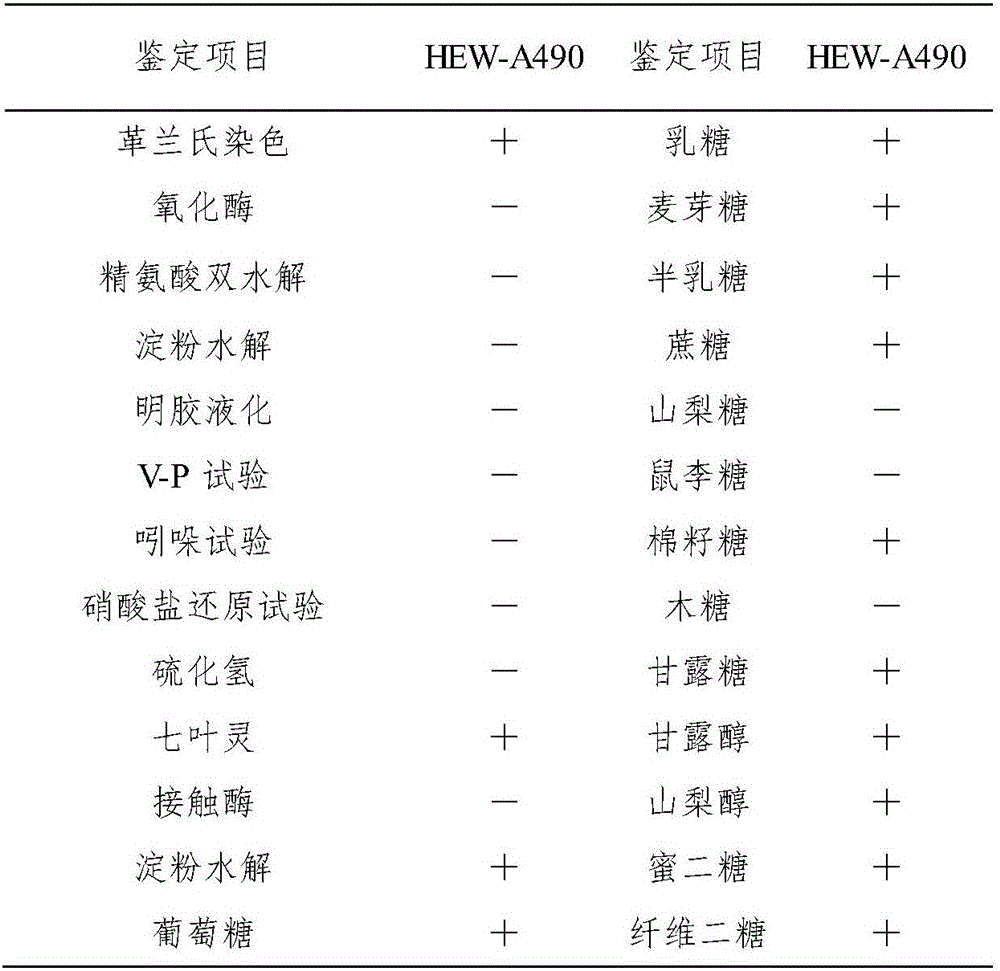

Lactobacillus plantarum HEW-A490 and application thereof

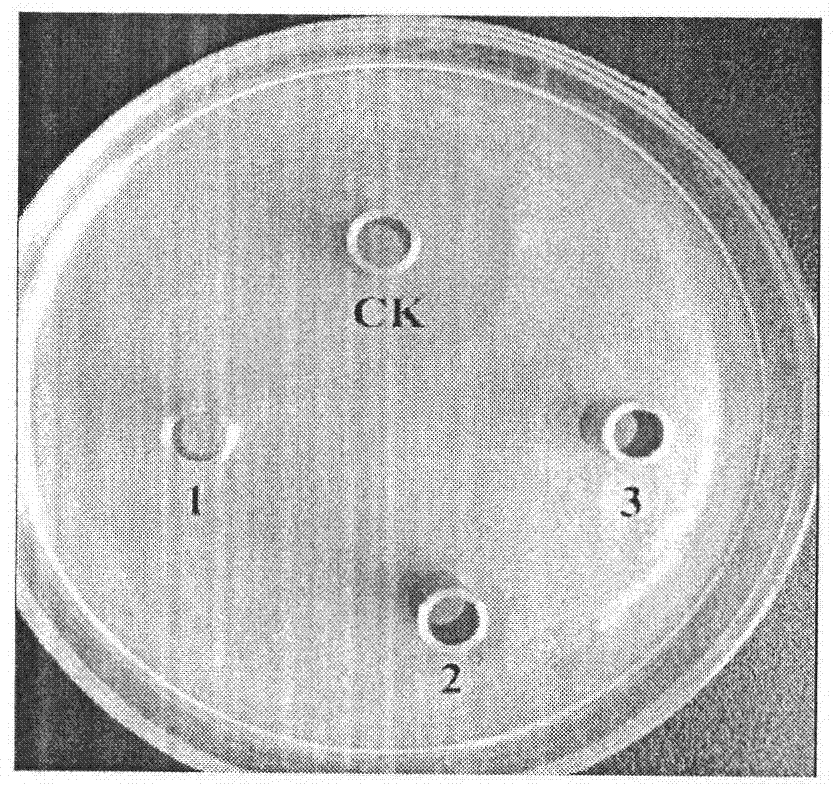

ActiveCN106399196AGood antibacterial effectInhibition of growth and reproductionBacteriaAnimal feeding stuffEconomic benefitsBiology

The invention provides newly-separated Lactobacillus plantarum HEW-A490. The Lactobacillus plantarum HEW-A490 has the advantages that the Lactobacillus plantarum HEW-A490 is evident in probiotic performance and stress resistance, the probiotics prepared by the Lactobacillus plantarum HEW-A490 can fast activate and proliferate after entering the intestines of animals and can form a beneficial dominant bacterial community to maintain intestinal track balance, animal feed utilization efficiency can be increased, cost can be saved, the steady state of the digestive tract internal environments in the animals is improved, nutrition absorption is promoted, animal growth is promoted, economic benefits are increased, the Lactobacillus plantarum HEW-A490 is promising in application prospect, and the like.

Owner:BEIJING HESWOF BIOTECH CO LTD

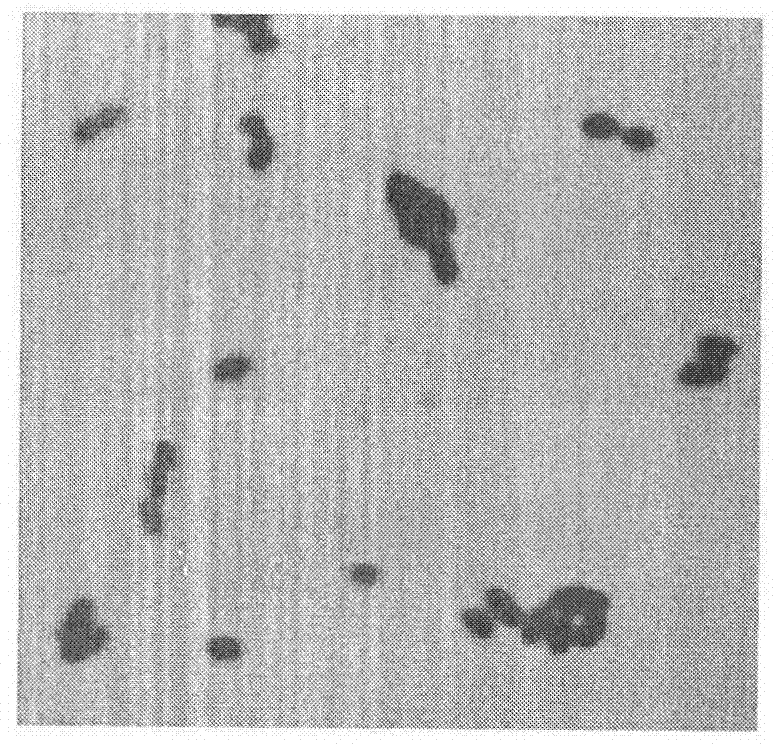

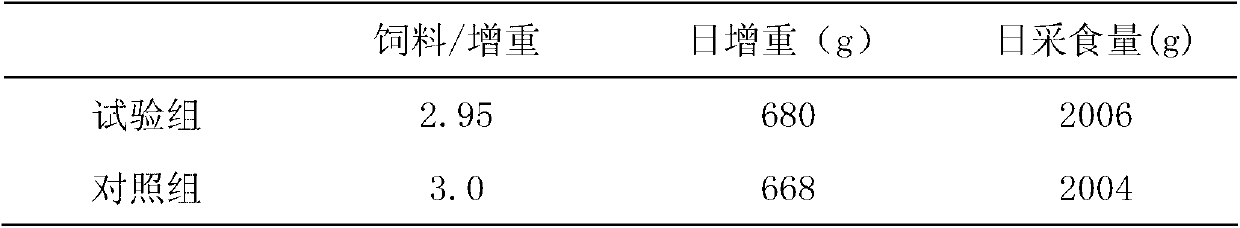

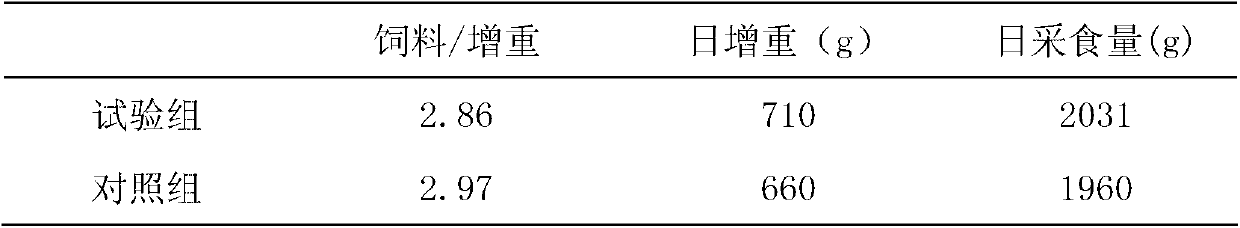

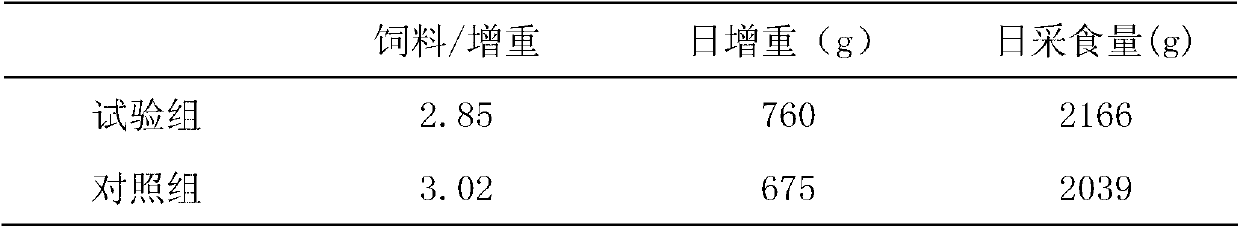

Enterococcus faecalis HEW-A131 and application thereof

ActiveCN104293696ASignificant probioticInhibition of growth and reproductionBacteriaMicroorganism based processesMicroorganismEconomic benefits

The invention discloses enterococcus faecalis HEW-A131 which is high in thermal resistance, wide in acid-alkali resistance range, high in stress resistance and relatively high in probiotic property. The strain is preserved in the China General Microbiological Culture Collection Center on June 17th, 2014, the preservation serial number is CGMCC NO.9353, and the classification name is enterococcus faecalis. The enterococcus faecalis HEW-A131 has excellent microorganism characteristics, remarkable probiotic property and stress resistance and super high fermentation property, not only is the utilization efficiency of feed of animals increased, but also the cost is reduced, moreover the stability of the environment inside the alimentary canals of animals is greatly improved, the adsorption and utilization of nutrition are promoted, the animal growth is promoted, the production performance, immunity and breeding property of the animals are remarkably improved, the production cost is lowered, and the economic benefits are increased.

Owner:江西好实沃生物技术有限公司

Preparation method for high-temperature delay type organic zirconium cross-linking agent

InactiveCN102040995AIncrease oil production rateHigh temperature and shear resistanceDrilling compositionPrepolymerOrganic acid

The invention discloses a preparation method for a high-temperature delay type organic zirconium cross-linking agent. The preparation method comprises the following steps of: sufficiently dissolving inorganic zirconium salt in water and adding a proper amount of organic acid; under the catalytic action of NaOH, controlling the pH value of the system and raising the temperature and reacting to obtain organic acid-zirconium prepolymer; keeping the temperature constant, adding a ligand and a cross-linking shielding agent into the organic acid-zirconium-prepolymer to perform reaction; continuously keeping the temperature constant, adding polyalcohol and a high-temperature stabilizing agent, adjusting the pH value and reacting at constant temperature; removing the high-temperature stabilizing agent residue after reaction is finished so as to obtain the modified clarified transparent high-temperature delay type cross-linking agent. The aqueous fracturing fluid prepared by the invention has good shear resistance, good sand carrying property and wide application prospect, greatly enhances the heat resistance property, reduces the use cost and relieves damage to the stratum environment.

Owner:SHAANXI UNIV OF SCI & TECH

Resource utilization method for combined production of biogas and cultivation matrix through utilizing tobacco stalk fermentation

InactiveCN102851318AModerate granularityQuality improvementBio-organic fraction processingInternal combustion piston enginesSocial benefitsResource utilization

The invention provides a resource utilization method for the combined production of a biogas and a cultivation matrix through utilizing tobacco stalk fermentation. The method comprises the following steps: carrying out anaerobic fermentation of a main fermentation raw material which is waste tobacco stalks generated in the tobacco threshing redrying line to produce the biogas; carrying out solid-liquid separation of a biogas slurry and the tobacco stalks to obtain a tobacco stalk biogas residue and a biogas slurry; purifying the biogas to prepare clean fuels or to be used for electricity generation to provide partial energy for a plant area; and decomposing the tobacco stalk biogas residue, and carrying out dry molding to prepare the cultivation matrix, wherein the biogas slurry returns to a fermentation system to be recycled or to be used as a liquid organic fertilizer. The method provided by the invention has the advantages of simple production operation, concentrated and stable raw material, scale production benefiting, low production cost, realization of no pollution, zero discharge and cycle utilization of waste tobacco stalk resources of a threshing redrying plant, and generation of good economic, ecological and social benefits.

Owner:ZHENGZHOU UNIV

Beneficial microorganism antibiont-free feed and preparation method thereof

InactiveCN103098986AStrong activityInhibit bacteriaFood processingAnimal feeding stuffLactobacillus acidophilusLactobacillus acidipiscis

The invention discloses a beneficial microorganism antibiont-free feed and a preparation method of the beneficial microorganism antibiont-free feed. The preparation method comprises the following steps of: preparing a Lactobacillus acidophilus bacteria solution, a lactobacillus plantarum bacteria solution, a Saccharomyces cerevisiae bacteria solution and a Bacillus licheniformis bacteria solution respectively by carrying out secondary fermentation; then mixing the Bacillus licheniformis bacteria solution with cottonseed meal to carry out aerobic fermentation; mixing the fermented cottonseed meal, corn flour, beer slag and premixes uniformly, and adding a compound bacteria solution prepared from the Lactobacillus acidophilus bacteria solution, the lactobacillus plantarum bacteria solution and the Saccharomyces cerevisiae bacteria solution, mixing uniformly, carrying out constant temperature fermentation, thus obtaining the antibiont-free feed. The antibiont-free feed disclosed by the invention is not added with antibiotic medicines, is high in the content of the beneficial microorganism, has good attractant performance, palatability, and high nutrition digestion and absorption rate, increases the feed intake of animals, promotes the animal growth, enhances the level of animal health, and improves animal immune resistance to disease. The antibiont-free feed is applicable to breeding of antibiont-free livestock and poultry products, so that the breeding cost can be lowered, the economic efficiency is enhanced and the healthy development of aquaculture is promoted.

Owner:GUANGXI FULAIKANG FEED

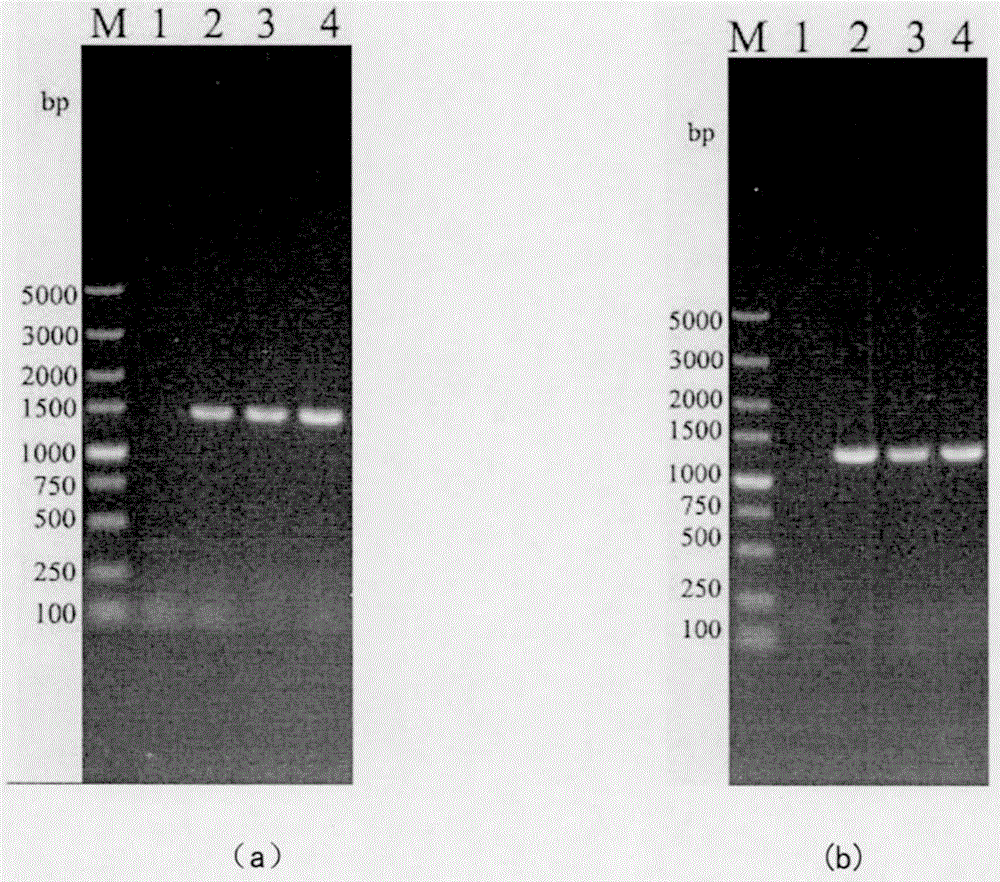

Low-yield high-grade alcohol high-yield ethyl lactate saccharomyces cerevisiae strain and construction method thereof

InactiveCN105969678AReduce productionOvercome flavor incongruityFungiHydrolasesHeterologousAlcohol production

The invention relates to a low-yield high-grade alcohol high-yield ethyl lactate saccharomyces cerevisiae strain and a construction method thereof. The method comprises acquisition of a target gene, construction of a chromosome integrated vector and fermented verification of the breeding bacterial strain. The selected bacterial strain performs heterogenous secrete expression on pseudonym antarctica lipase B, compared with parent strains, the fermentation performance of the constructed saccharomyces cerevisiae is not influenced, after fermentation by sorghum raw material semi-solid liquor for 6 days, ethyl lactate content of the breeding bacterial strain is increased by 57.4%-84.5%; the high-grade alcohol production amount is obviously reduced, isoamyl alcohol is reduced by 9.5%, isobutyl alcohol is reduced by about 50.0%, and active-amyl alcohol is reduced by about 44.0%. According to the breeding bacterial strain, the production amount of ethyl lactate is obviously increased, the high-grade alcohol production amount is obviously reduced, the problem of incompatibility of flavor of the wind can be solved at certain degree, and the method has wide application prospect in the wine-related filed.

Owner:TIANJIN UNIV OF SCI & TECH

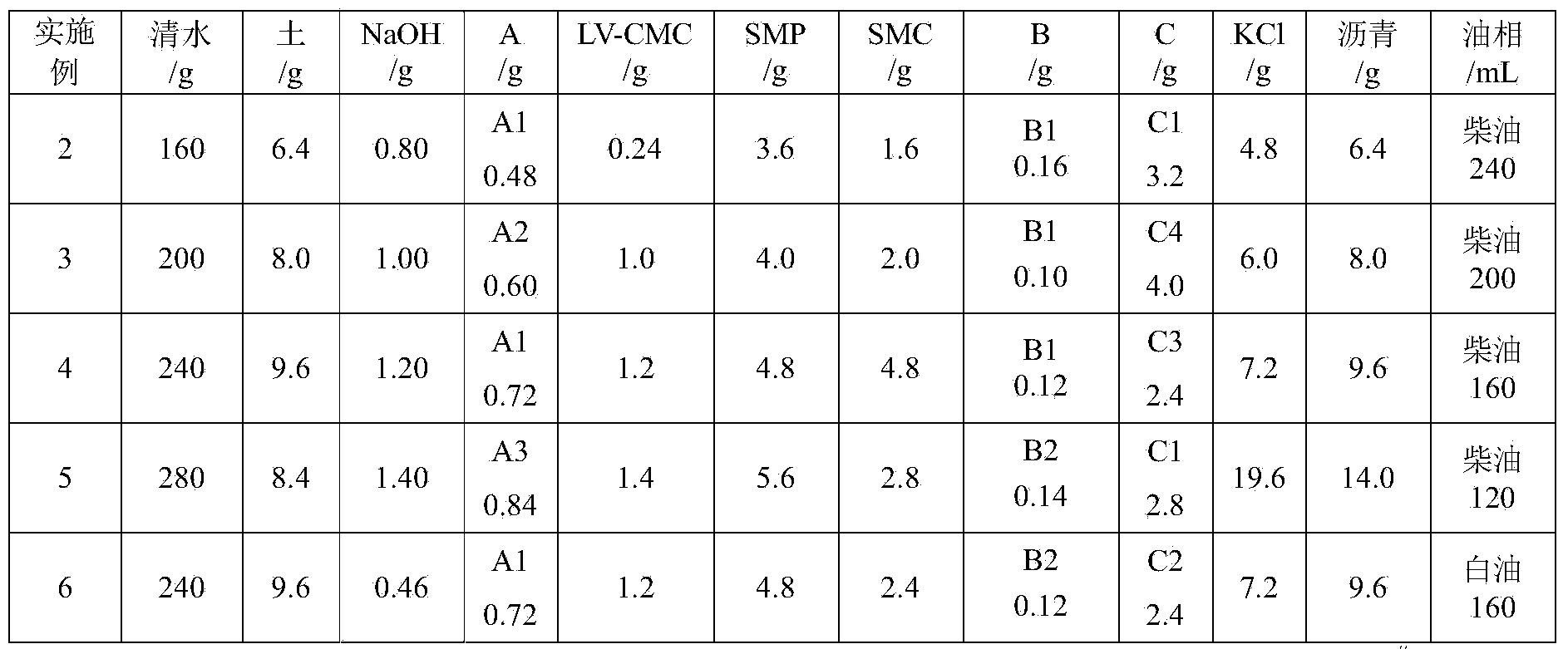

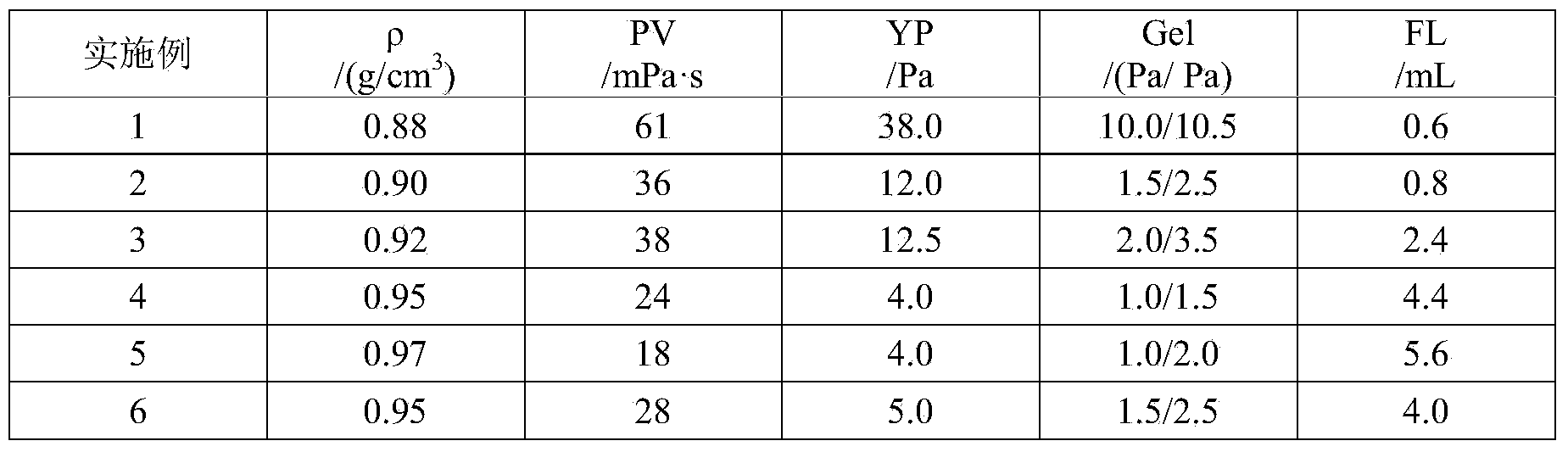

High temperature resistant oil-in-water drilling fluid

ActiveCN104140794AImprove rheologyImprove fermentation performanceDrilling compositionSodium BentonitePetroleum

The invention discloses a high temperature resistant oil-in-water drilling fluid, which is realized through the following technical scheme of: (1) by mass, mixing 3.0%-4.0% of sodium bentonite, 0.2%-0.5% of NaOH, 0.1%-0.3% of a temperature and salt resistant filtrate reducer A, 0.2%-0.5% of a carboxymethylcellulose sodium salt, 2.0%-3.0% of sulfonated phenolic resin, 0.8%-2.0% of sulfonated lignite, 0.05%-0.15% of a high temperature stabilizer B, 1.0%-3.0% of an anti-high temperature emulsifier C, 3%-7% of KCl, 2%-5% of asphalt, and the balance water to obtain an aqueous phase; (2) mixing the aqueous phase obtained in step (1) with diesel oil or white oil according to a volume percentage of 7:3, 6:4, 5:5, 4:6 and 3:7 and performing emulsification, and then carrying out high temperature aging to obtain the high temperature resistant oil-in-water drilling fluid. The formed high temperature resistant oil-in-water drilling fluid has temperature resistance up to 180DEG C and a lowest density of 0.88g / cm<3>, can effectively prevent formation leakage of low pressure depleted oil and gas zones, is conducive to enhancement of the productivity of oil-gas wells, and is suitable for the technical field of petroleum drilling and development of low pressure oil and gas reservoirs.

Owner:CHINA PETROLEUM & CHEM CORP +3

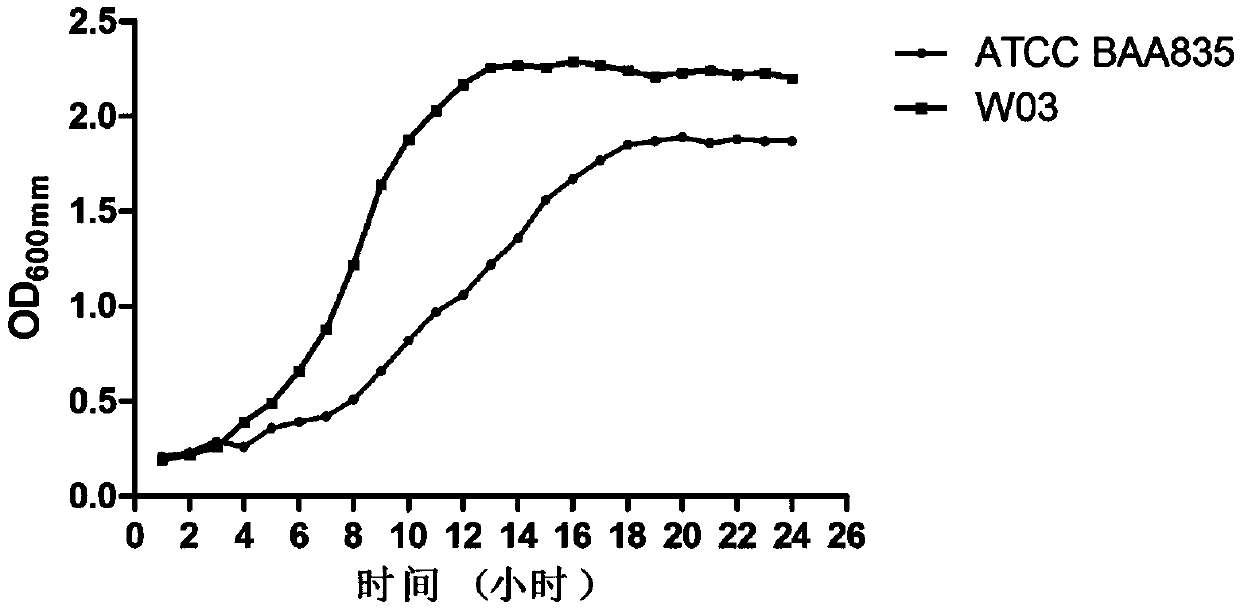

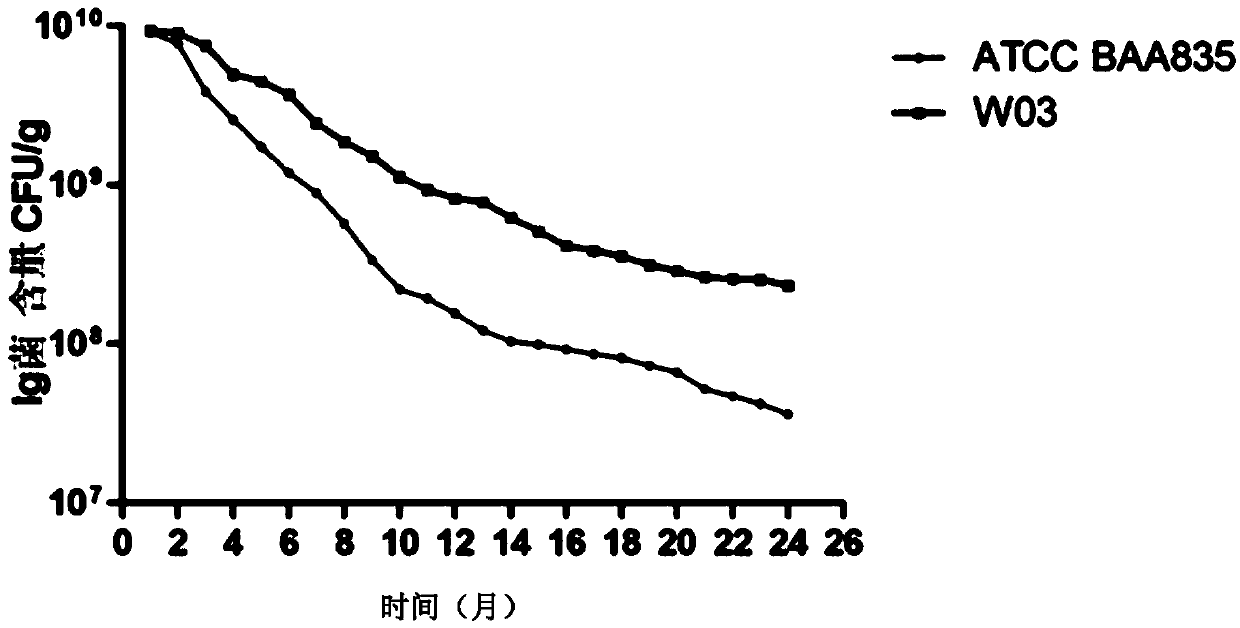

Strain for preventing and treating metabolic diseases and application for strain

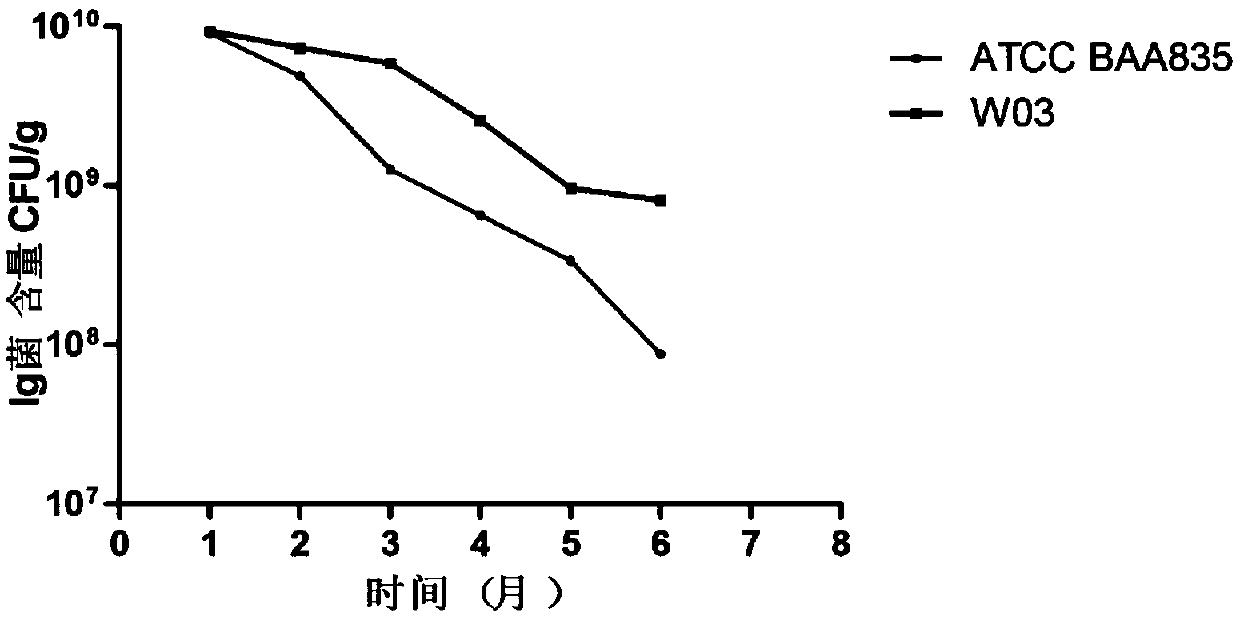

ActiveCN110964650AImprove fermentation performanceGood storage stabilityBacteriaMetabolism disorderBiotechnologyDisease

The invention discloses a strain for preventing and treating metabolic diseases and application for the strain. The strain is Akkermansia muiniphila strain which is named Akkermansia muciniphila SSYD-3 and has the preservation number being CGMCC No.14764. Compared with the existing Ackermann muiniphila strain ATCC BAA 835, the Akkermansia muiniphila strain provided by the invention is more ideal in fermentation performance, storage stability, acid resistance, bile salt tolerance and the effect of treating the metabolic diseases.

Owner:SHANGHAI SINE PHARMA LAB +1

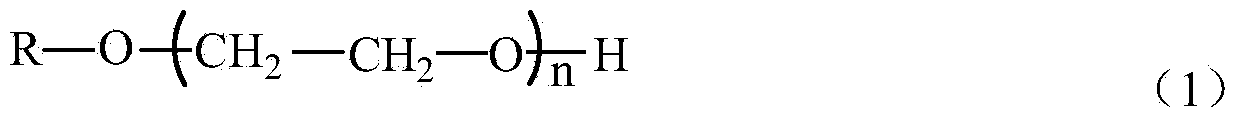

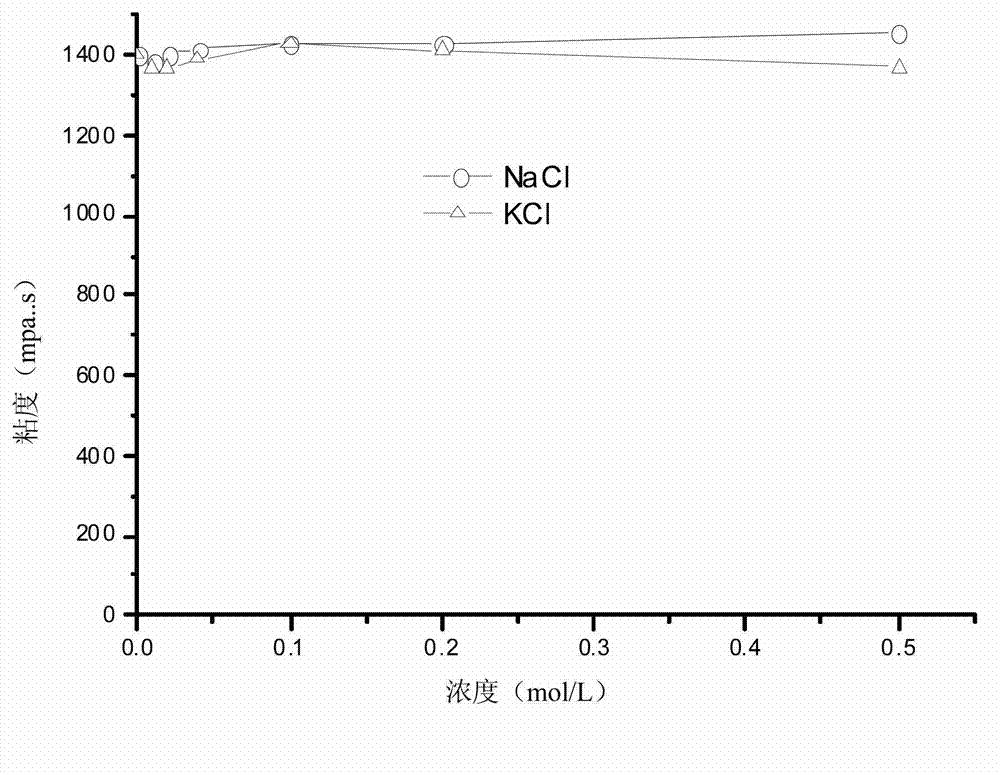

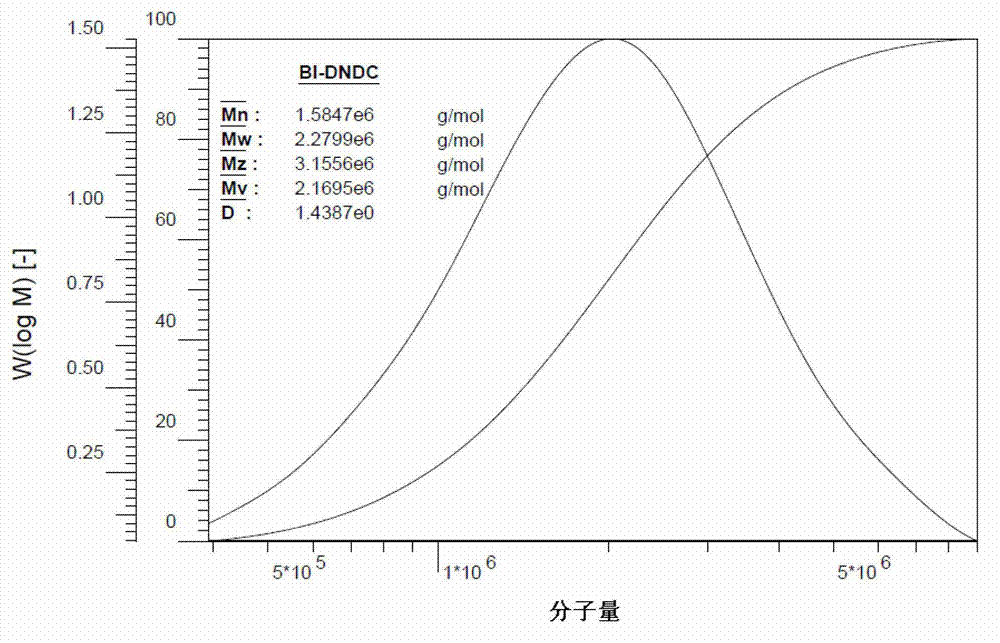

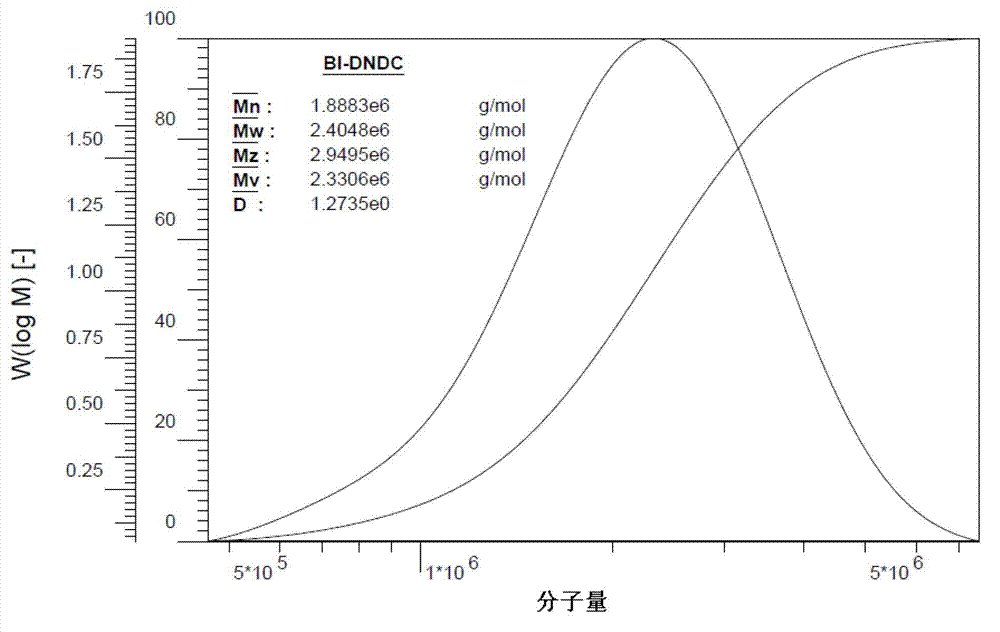

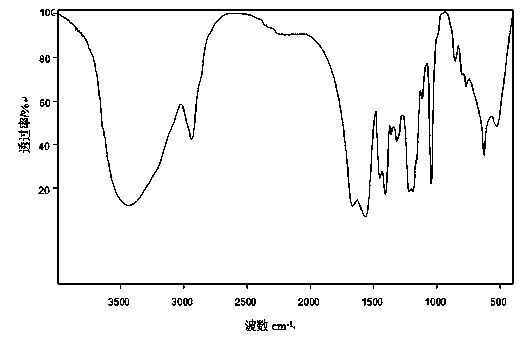

Sulfonic acid modified carboxymethyl hydroxypropyl guar gum, and preparation method and application thereof

ActiveCN103113486AImprove surface activityReduce surface activityDrilling compositionAlcoholAqueous sodium hydroxide

The invention relates to sulfonic acid modified carboxymethyl hydroxypropyl guar gum, and a preparation method and application thereof. The structural formula of the sulfonic acid modified carboxymethyl hydroxypropyl guar gum is shown in the specification, wherein R is H, and n is 0, 1, 2 or 3; or R is OH, and n is 0-6. The preparation method comprises the following steps: adding carboxymethyl hydroxypropyl guar gum into a reaction vessel, and adding an alcohol water solution; in a nitrogen atmosphere, dropwisely adding a sodium hydroxide water solution, heating to 65-80 DEG C while stirring, dropwisely adding a sulfonating agent, and reacting for 3-10 hours; and regulating the pH value of the solution to 7 with acid, filtering, collecting solids, and drying to obtain light yellow powder, namely the sulfonic acid modified carboxymethyl hydroxypropyl guar gum. The prepared sulfonic acid modified carboxymethyl hydroxypropyl guar gum is high in thickening efficiency, low in surface / interface tension, easy to realize viscosity break and beneficial to flowback.

Owner:PETROCHINA CO LTD

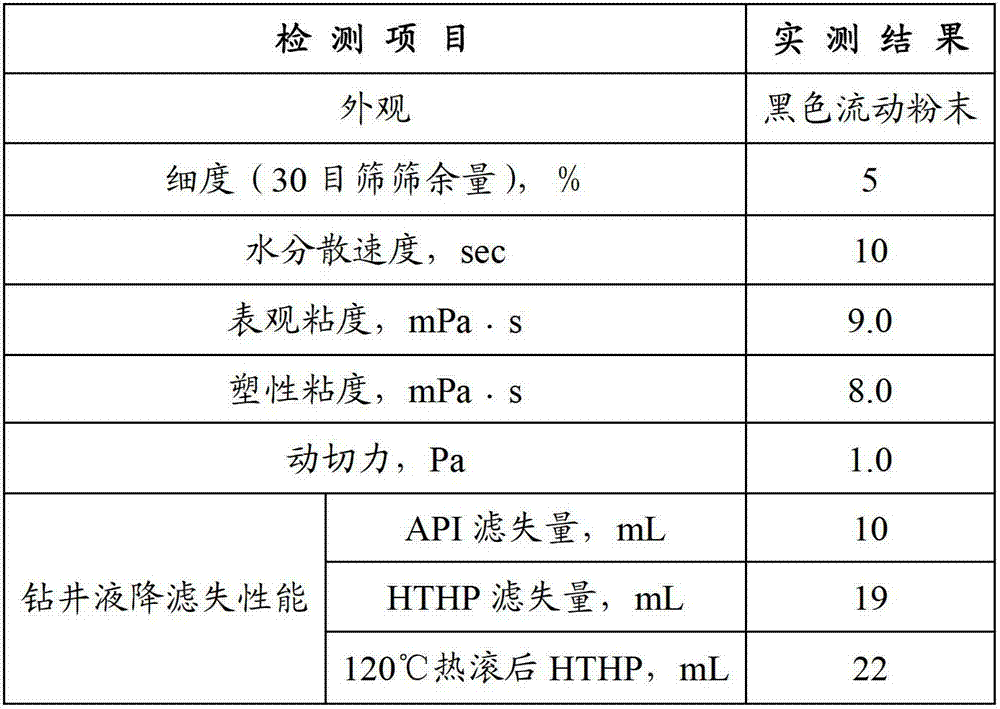

Plugging-type filtrate reducer for water-based drilling fluid and preparation method thereof

InactiveCN103045188AImprove fermentation performanceNothing producedDrilling compositionWater basedPolymer modified

The invention relates to a plugging-type filtrate reducer for water-based drilling fluid and a preparation method thereof. The filtrate reducer can be selected in accordance with different well section temperatures and strata characteristics, and comprises polymer modified oxidized asphalt (PMA), a modifying agent and an auxiliary filtrate reducer; and the filtrate reducer series samples can be prepared by a simple surface modification and dry-blending process. The sample disclosed by the invention is excellent in performance of reducing filtrate of the drilling liquid with the reducing rate of 80%, a dense and tough mud cake is formed, and the crack and fracture of the strata can be plugged in real time based on high-temperature softening and deforming characteristic of the asphalt; an appropriate product formula can be selected depending on the applied strata characteristics and well section temperatures; and the plugging-type filtrate reducer for the water-based drilling fluid is flexile to use, simple in production process, moderate in condition, high in production efficiency, low in cost, free from waste and dust, and low in harm on the body of an operator.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

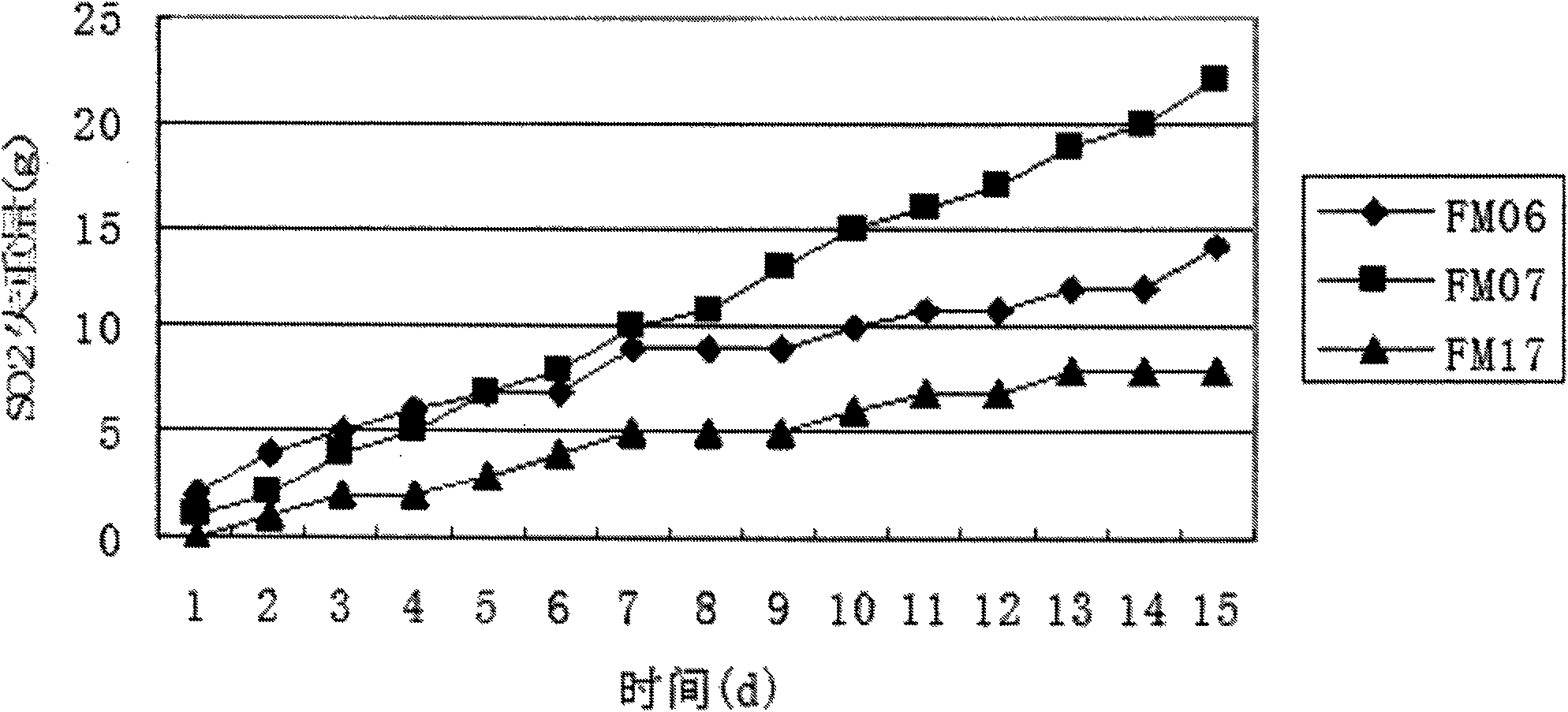

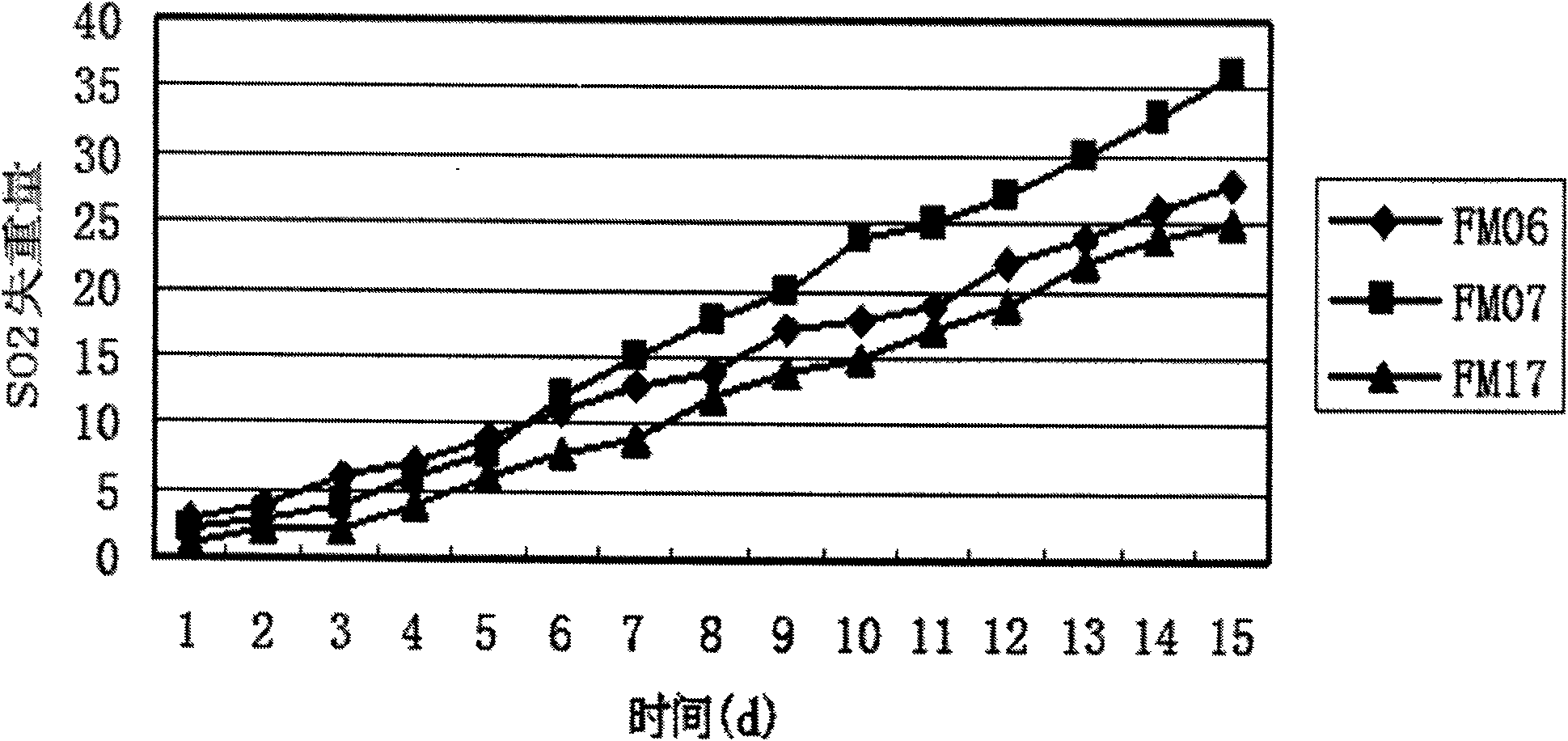

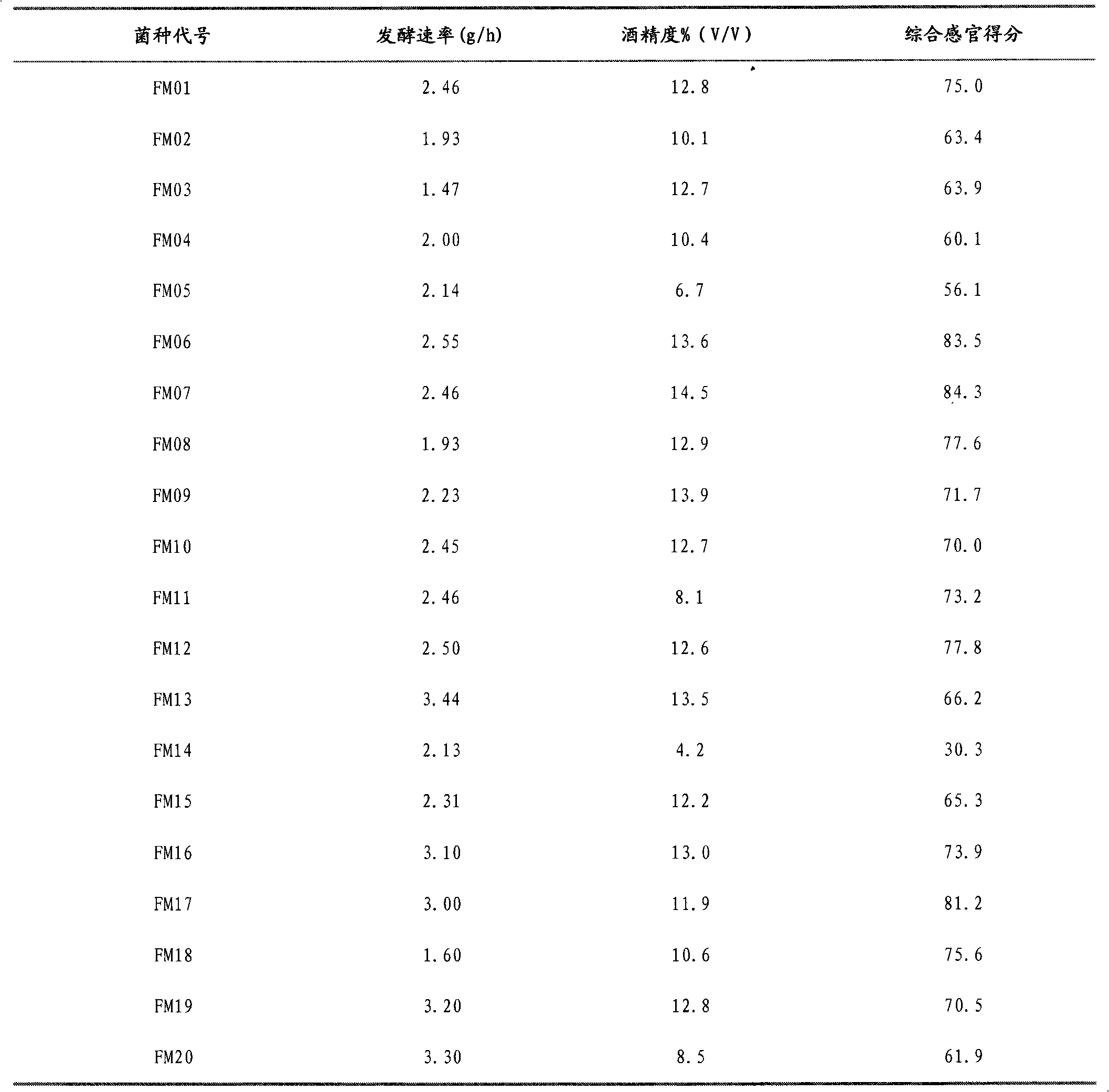

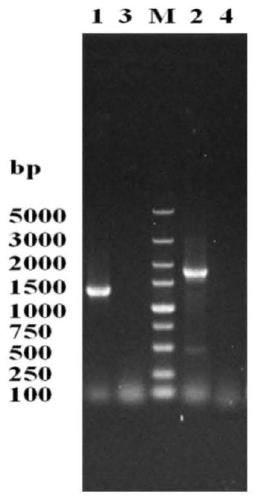

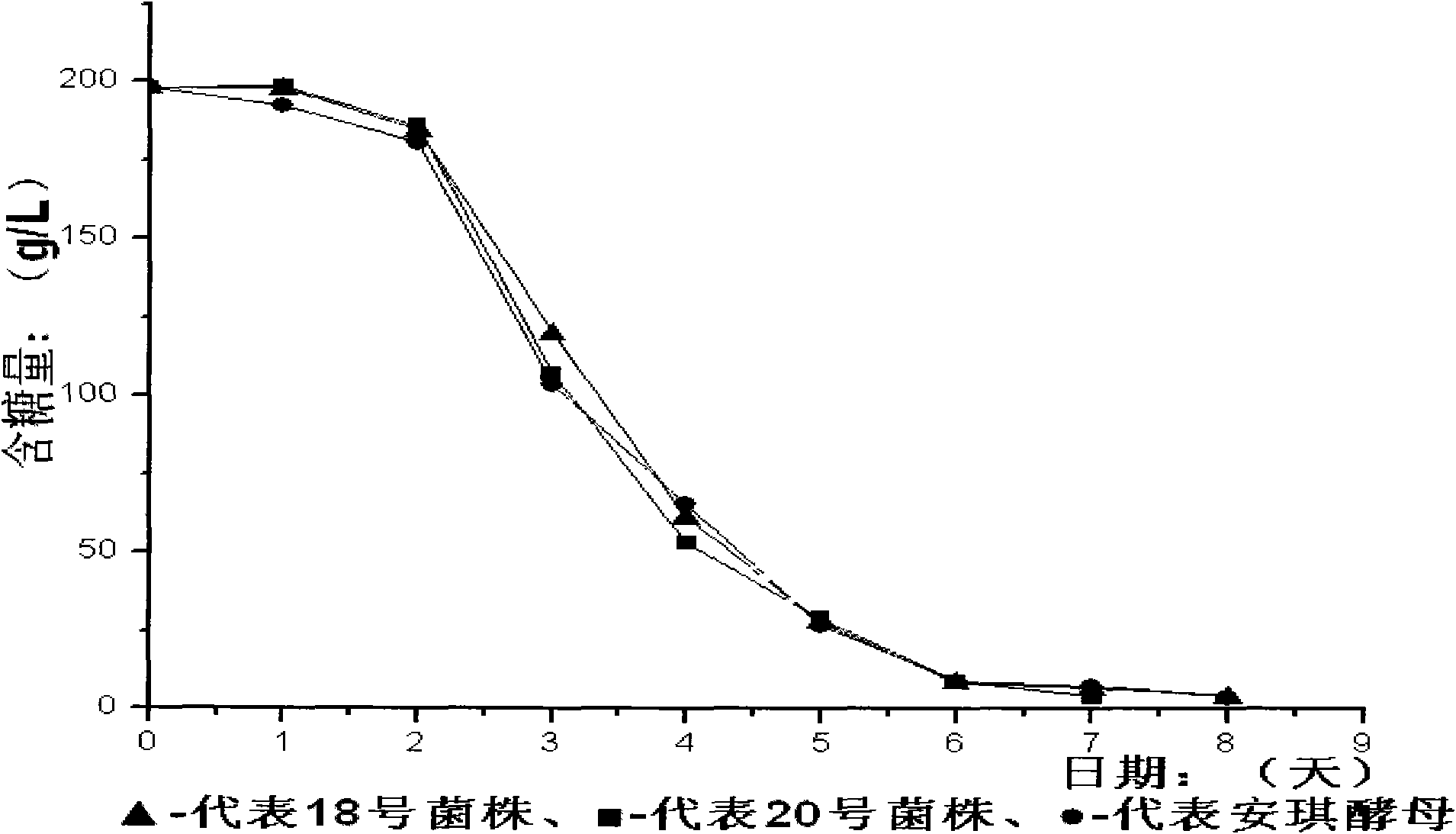

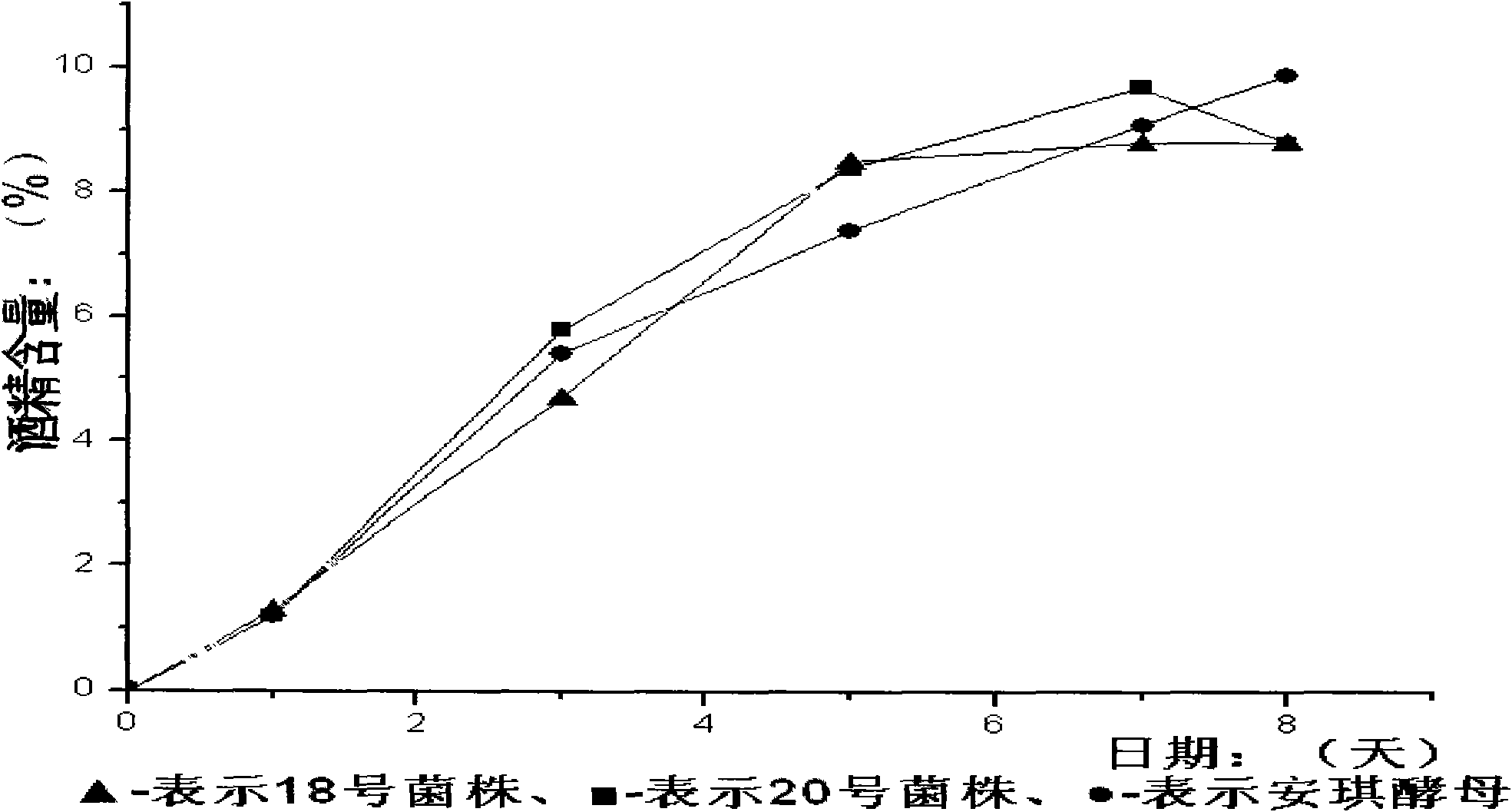

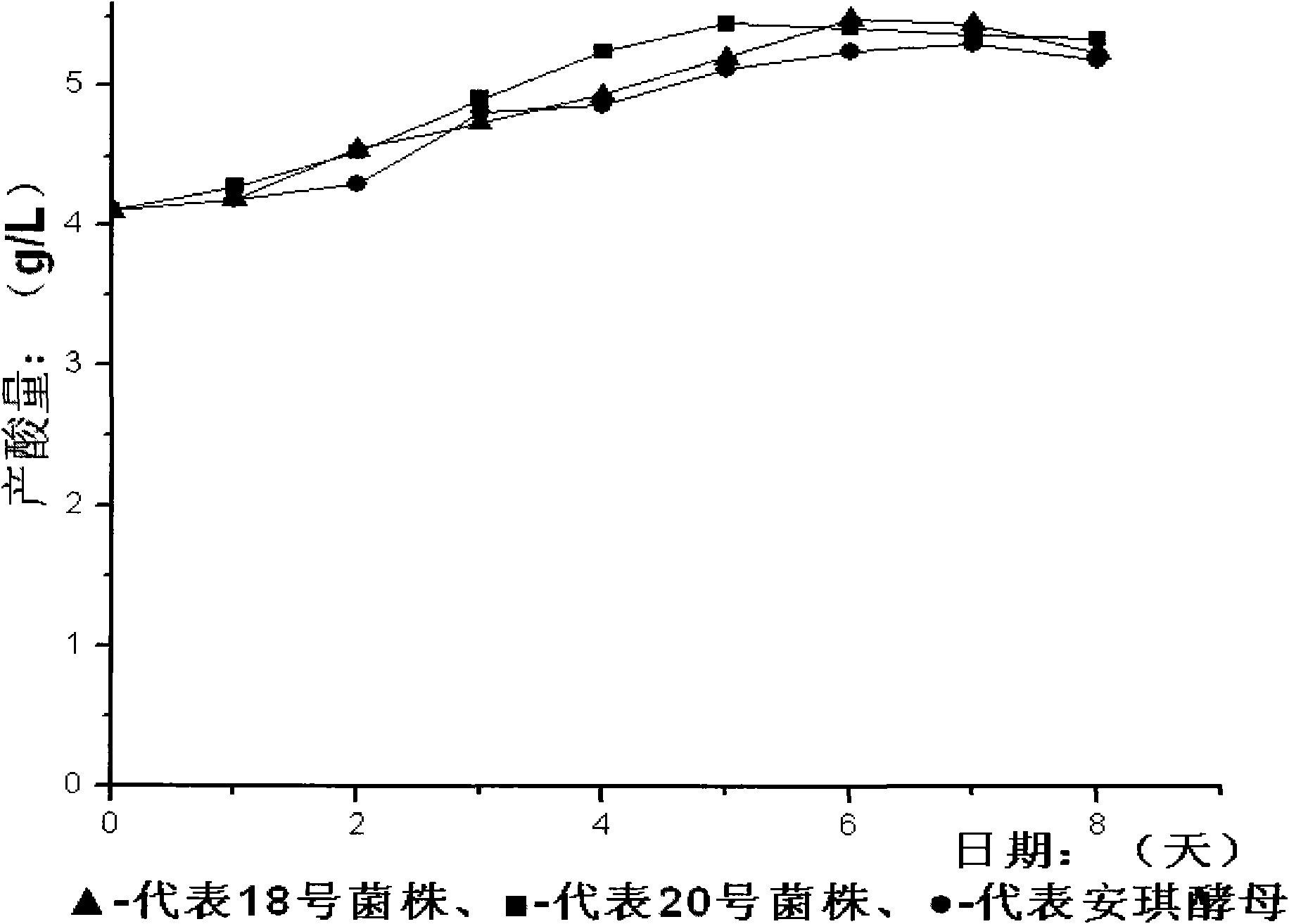

Saccharomycetes for brewing abricotine, preparation method and abricotine obtained by same

InactiveCN101603014AImprove fermentation performanceNormal growthFungiMicroorganism based processesAlcoholSaccharomyces

The invention discloses saccharomyces cerevisiae CGMCC No.2927 for producing abricotine, a preparation method for fermenting the abricotine by using saccharomyces cerevisiae strains, and the brewed abricotine. By separating and purifying a plurality of strains of saccharomyces by different paths and alcohol, SO2, high-low temperature, high-sugar tolerance experiment and abricotine fermentation experiment, a strain of abricotine saccharomyces with good brewing performance is screened; and an abricotine fermentation process is determined, and then the abricotine with golden and clear color, intense fruit taste and wine taste, and full and comfortable mouth feel is brewed. The preparation method is widely applied in the field of light industrial production, and the like.

Owner:XINJIANG AGRI UNIV

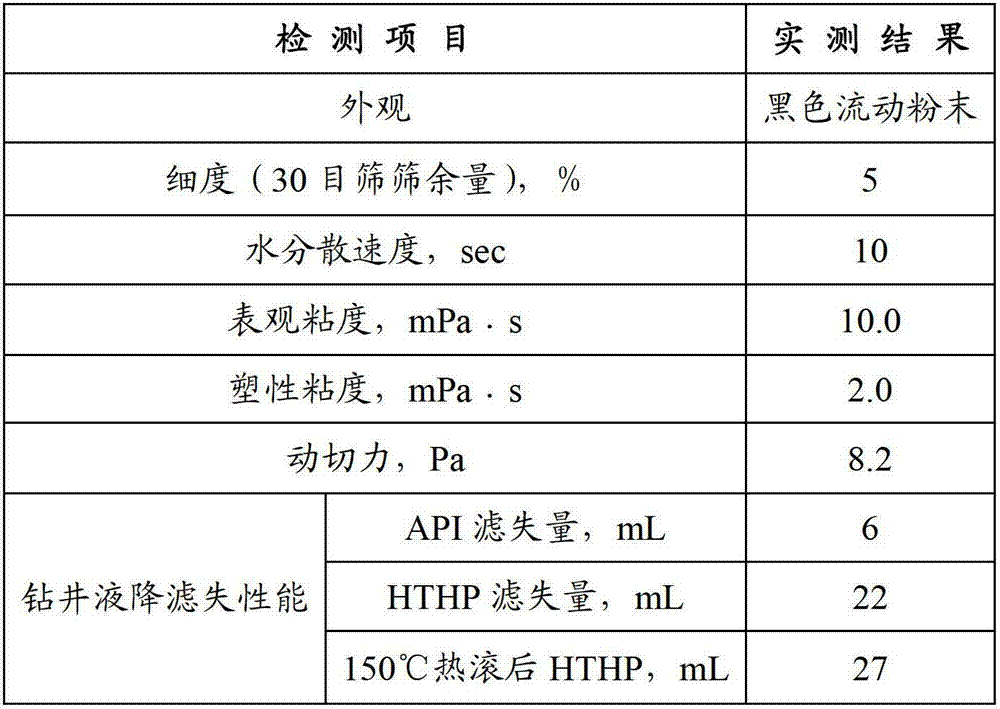

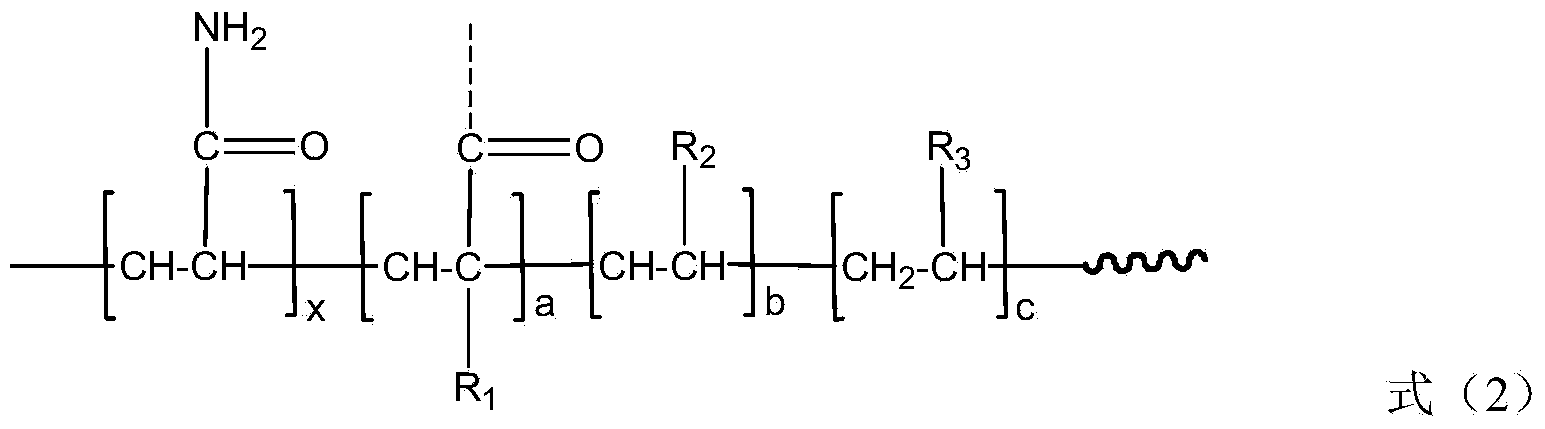

Micro-crosslinking polymer fluid loss additive for drilling fluid and preparation method of micro-crosslinking polymer fluid loss additive

ActiveCN104388063AImprove temperature resistanceIncrease steric hindranceDrilling compositionOrganic acidPolymer science

The invention relates to a micro-crosslinking polymer fluid loss additive for drilling fluid and a preparation method of the micro-crosslinking polymer fluid loss additive and belongs to the technical field of a preparation method of chemical high-molecular polymers of oil drilling fields. The micro-crosslinking polymer fluid loss additive is prepared from an organic acid monomer A with carboxyl, acrylamide, a monomer B for inhibiting acylamino hydrolysis, a temperature-resistant monomer C with a large side group, and a crosslinking agent by adopting aqueous solution copolymerization reaction under the initiation of an oxidation-reduction initiator system; and the obtained gel product is pelletized, baked and crushed, so as to obtain the micro-crosslinking polymer fluid loss additive for drilling fluid. The micro-crosslinking polymer fluid loss additive disclosed by the invention has good high-temperature fluid loss resistance; after the micro-crosslinking polymer fluid loss additive is added to 4% base slurry and is aged for 16 hours at 270 DEG C, the filter loss is reduced along with the increase of the micro-crosslinking polymer fluid loss additive disclosed by the invention; and when the addition amount of the micro-crosslinking polymer fluid loss additive is 0.01g / mL, the filter loss is reduced to 8.2mL from 46.0mL so that good performance of the drilling fluid is kept at 270 DEG C.

Owner:CHINA PETROCHEMICAL CORP +1

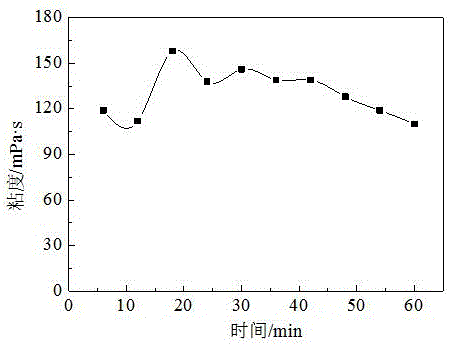

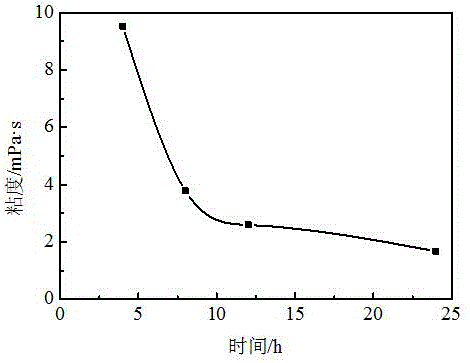

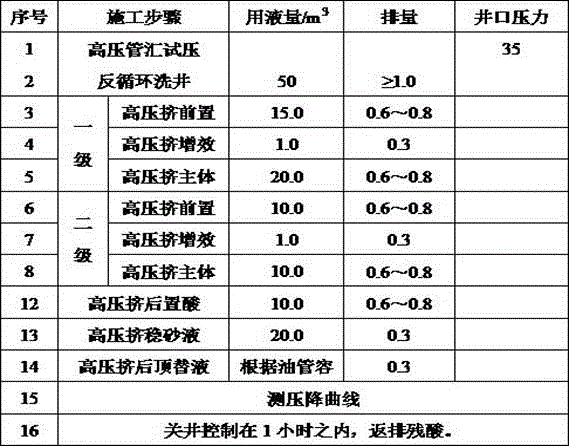

Temporary plugging steering acidification method applicable to sandstone reservoir

ActiveCN106382113ATo achieve preliminary temporary blockingHigh viscosityFluid removalDrilling compositionEngineering

Owner:CHINA PETROLEUM & CHEM CORP +1

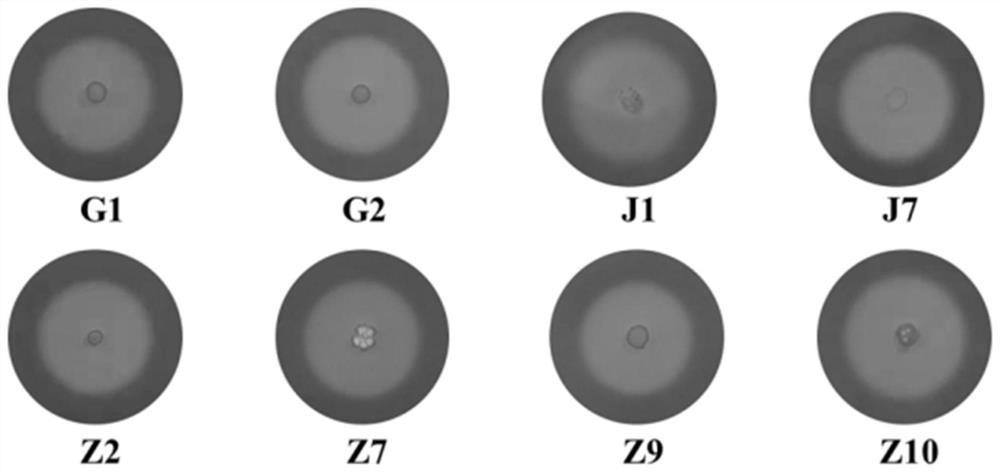

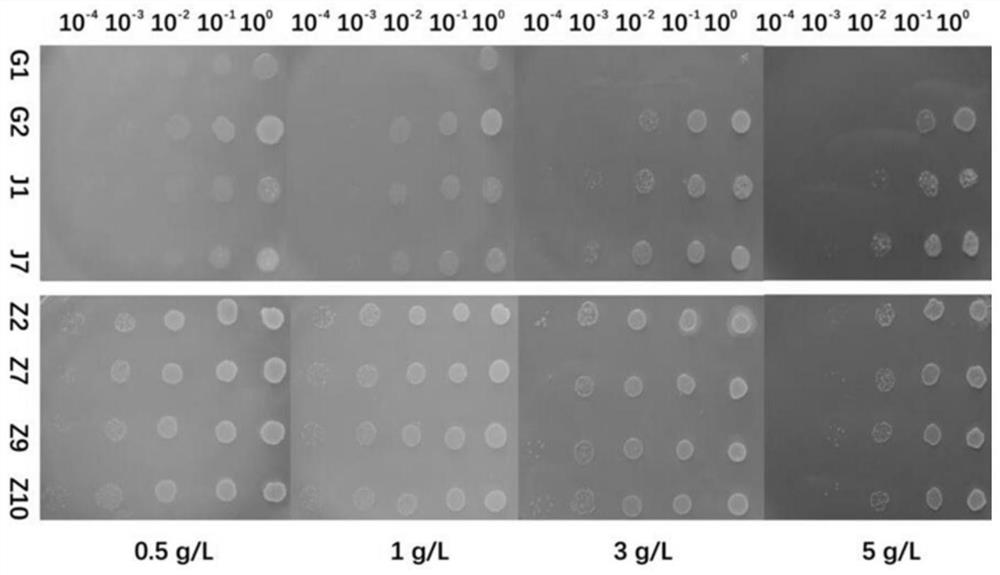

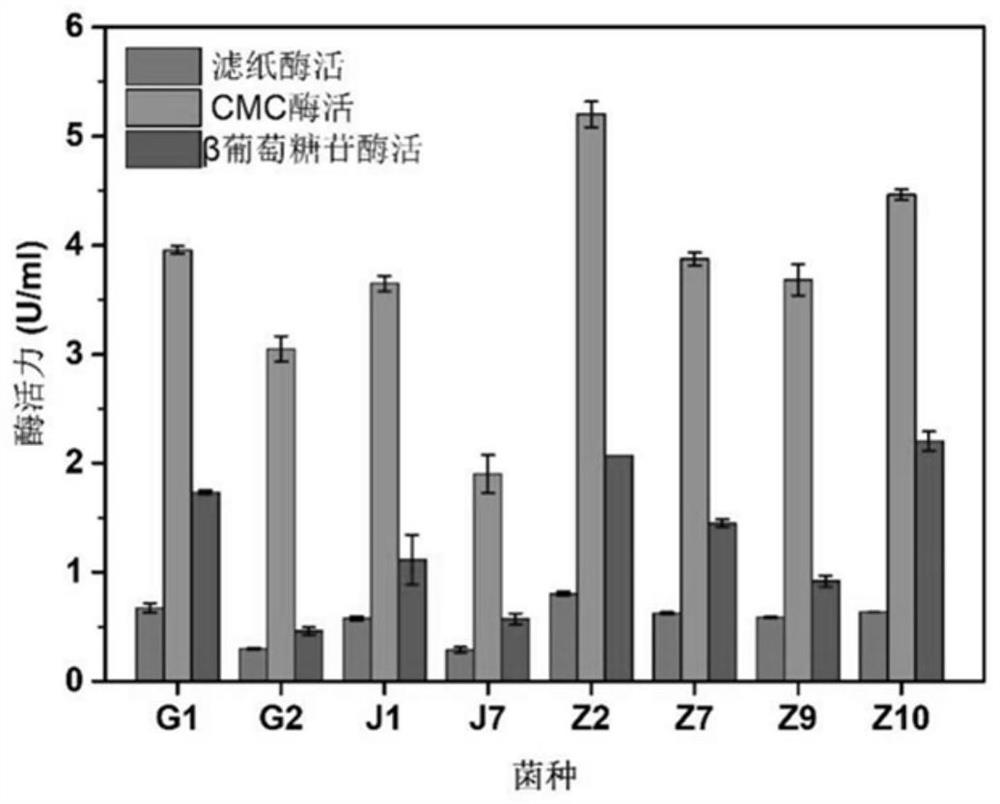

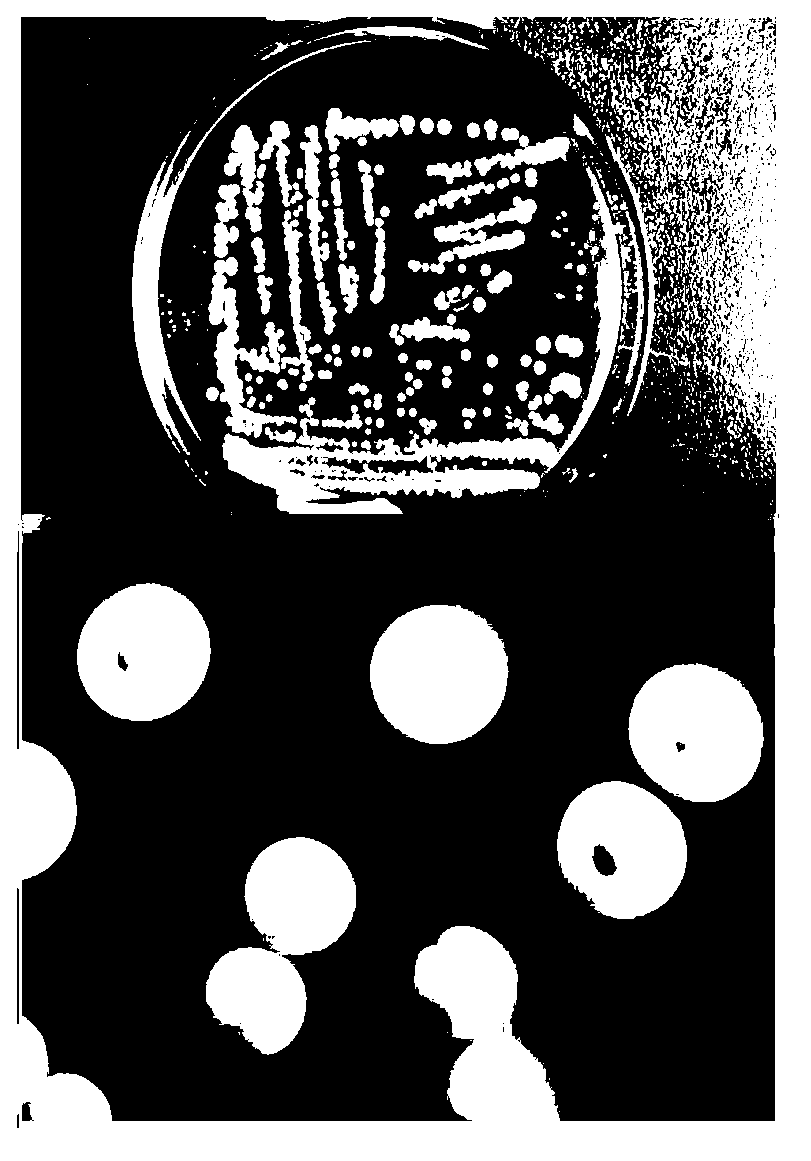

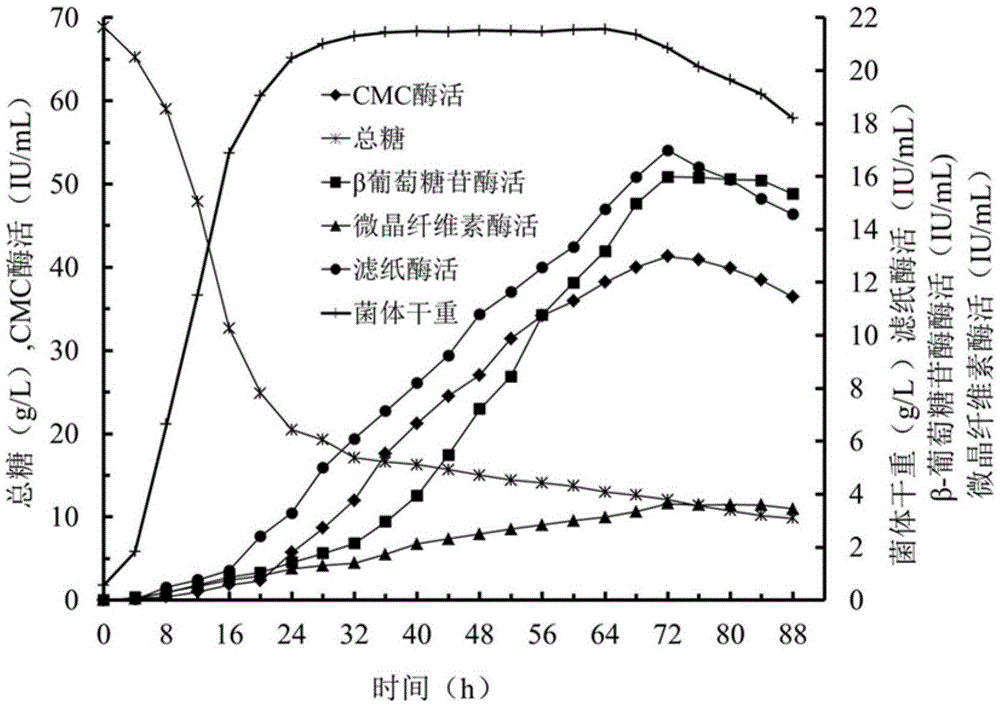

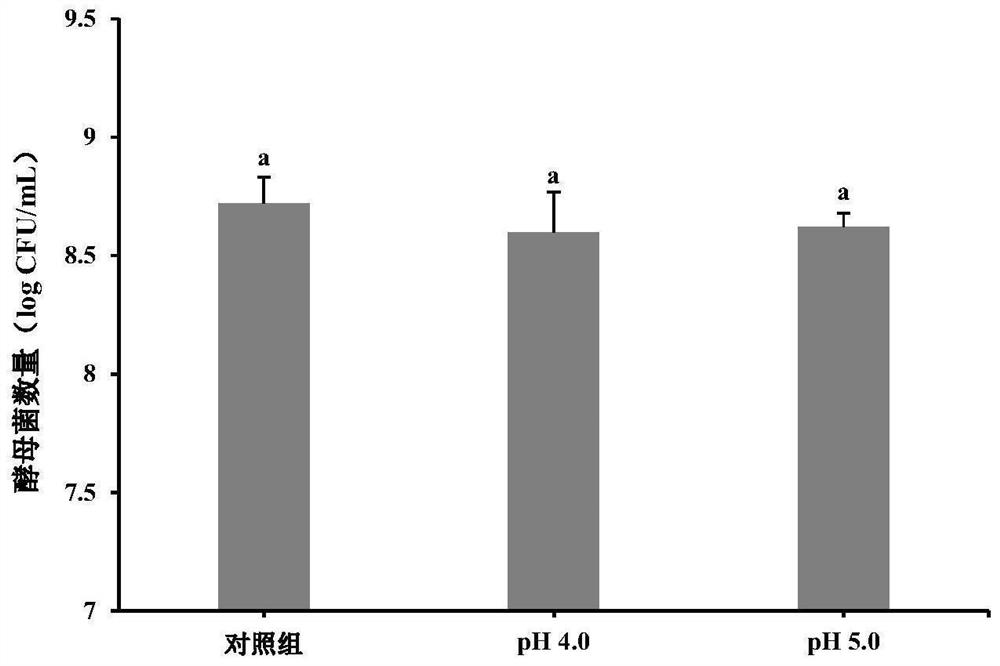

High-temperature-resistant high-yield cellulase bacillus subtilis and application thereof

InactiveCN112251374AFast growthImprove enzyme production efficiencyBacteriaMicroorganism based processesBiotechnologyXylanase

The invention discloses a high-temperature-resistant high-yield cellulase bacillus subtilis and application thereof. A cellulase production strain is separated from surface soil of a corn straw pile in a Jiangjin area of Chongqing, and the preservation number of the bacillus subtilis is CCTCC NO: M 2020002; a strain Z2 with the best enzyme production performance is finally obtained through enrichment culture, a CMC-Na plate experiment, a lignin plate experiment and an enzyme production experiment, and the obtained strain is subjected to 16S rRNA sequence comparison and identification to determine that the strain is bacillus subtilis Z2. By optimizing the culture medium and the culture conditions, the filter paper enzyme activity, the CMC enzyme activity and the beta-glucosidase activity under the optimal enzyme production conditions of 0.800 U / ml, 5.20 U / ml and 2.07 U / ml are obtained respectively. Cellulase produced by the strain has relatively high activity and stability under the conditions of a buffer solution with the pH value ranging from 4.0 to 10.0 and the temperature of 30 DEG C and 80 DEG C. Cellulase produced by the strain is mixed with commercial xylanase, then a saccharification experiment is carried out on pretreated straw stalks, and 84.27 mg / ml of total reducing sugar can be obtained.

Owner:CHONGQING UNIV

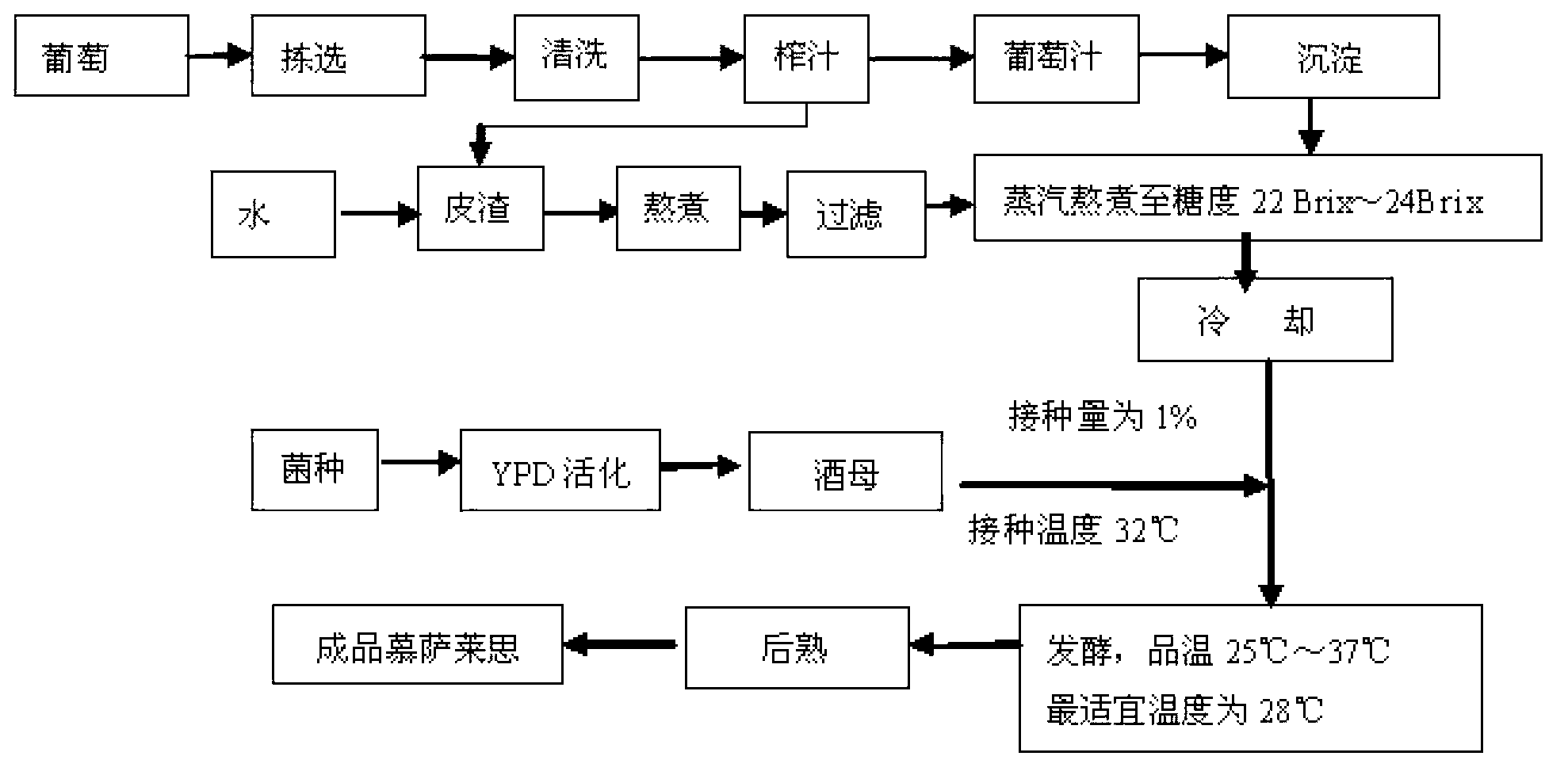

High temperature yeast for brewing msalais, preparation method thereof and brewed msalais

ActiveCN103243037AExcellent fermentation performanceImprove toleranceFungiMicroorganism based processesBiotechnologyAlcohol content

The invention discloses a high temperature yeast (Saccharomyces cerevisiae) CGMCC No.7513 for producing msalais through fermentation and msalais obtained by a preparation method through fermentation by utilizing the strain. By virtue of analysis at different temperatures, sugar degrees, alcohol contents and low nitrogen tolerances, metabolism property determination, detection of wine production capacity, flocculability, autolysis, H2S production capacity and biogenic amine production characteristic, determination of pectinase activity and determination test on activity of beta-glucosaccharase, the high temperature msalais yeast strain with excellent brewing performance is screened, and the high temperature msalais yeast strain is widely applied to the fields of light industry production and the like.

Owner:TARIM UNIV

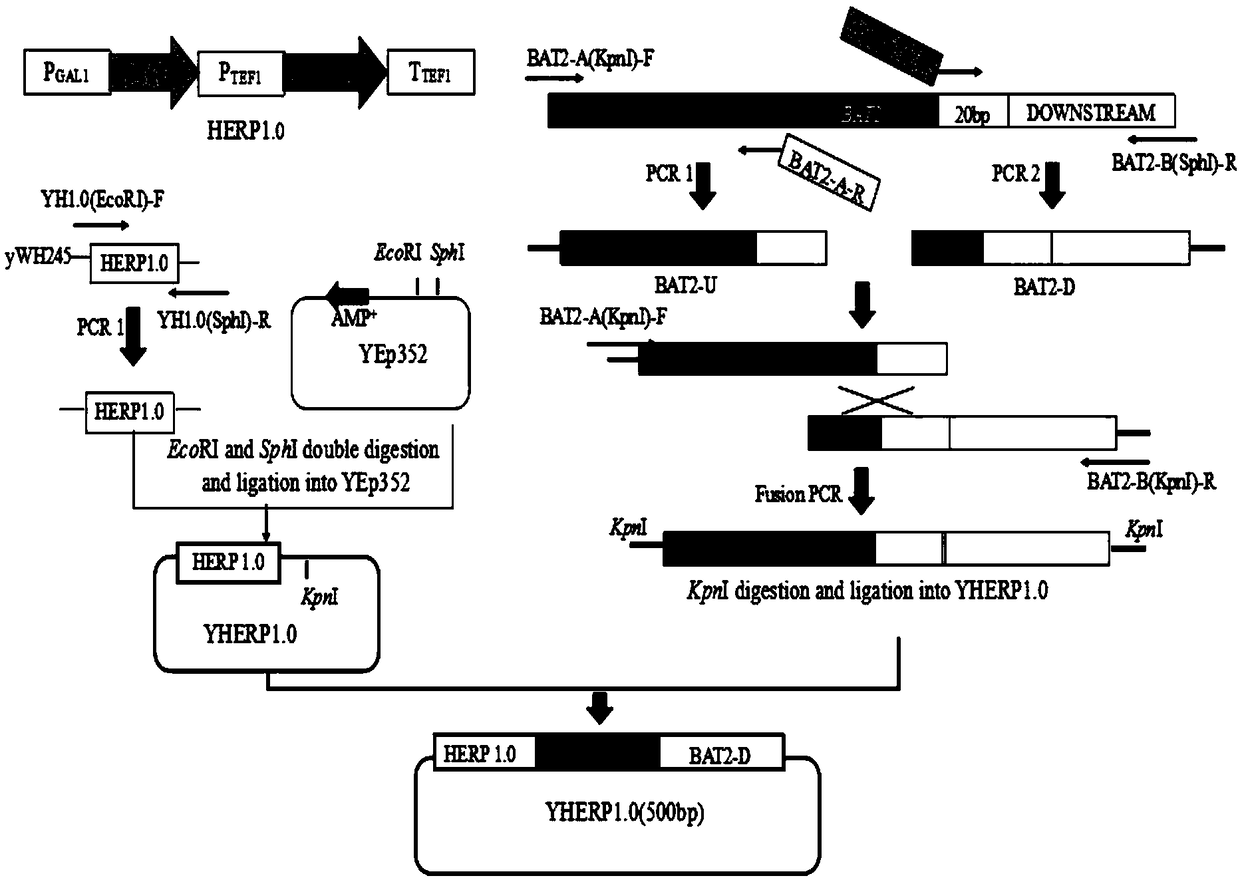

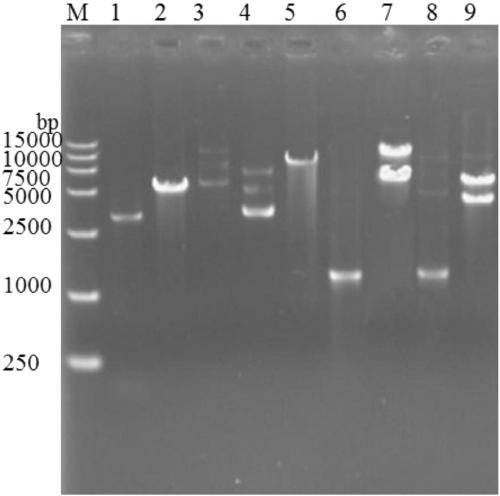

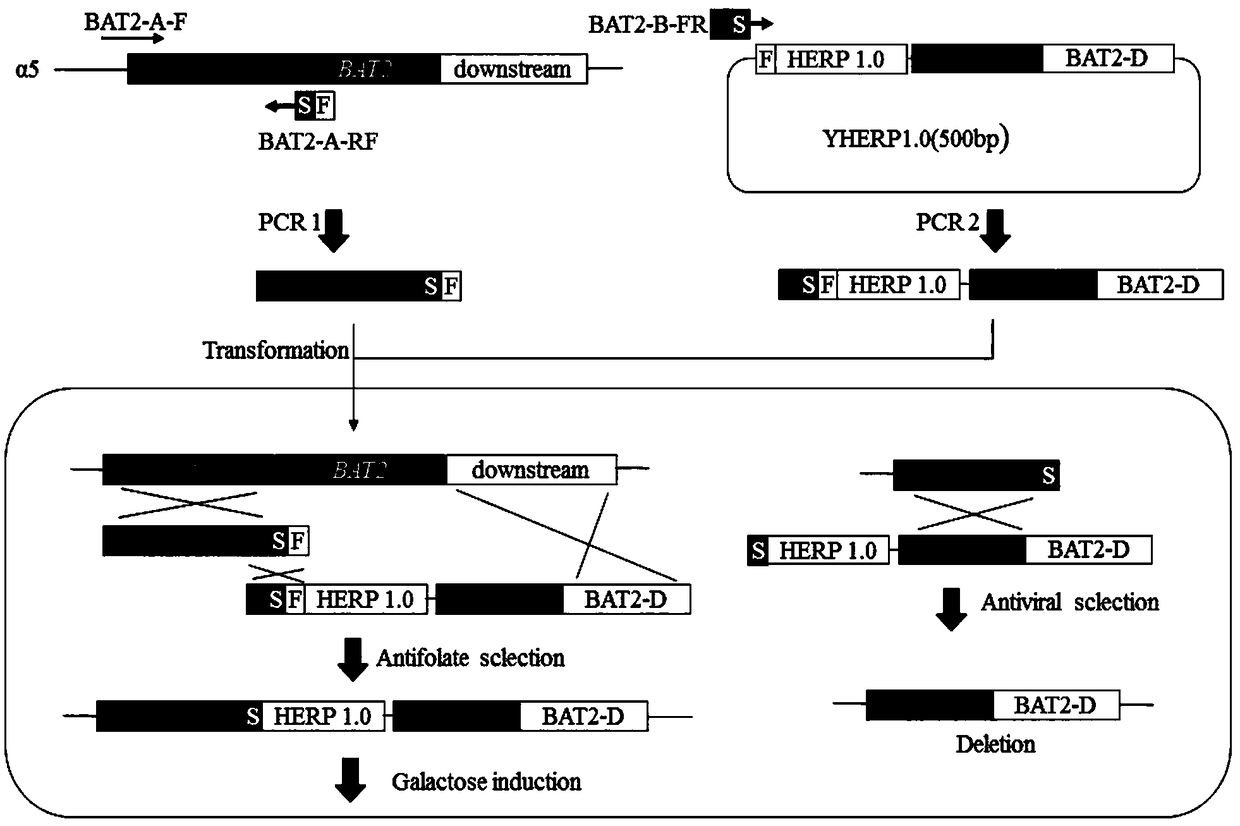

Efficient traceless gene knockout method for saccharomyces cerevisiae and application thereof

ActiveCN109136254AIsoamyl alcohol content decreasedGood flavorFungiMicroorganism based processesLactoseIsobutanol

The invention discloses an efficient traceless gene knockout method for saccharomyces cerevisiae. By optimizing the forward homologous sequence, galactose concentration and galactose induction time ina traceless gene knockout system, the probability of homologous recombination of the second step reaches 6.86*10<-4>. Haploids alpha 5 of saccharomyces cerevisiae AY15 serves as starting strains, BAT2 genes serves as the target gene, efficient and traceless knockout of wild saccharomyces cerevisiae genes BAT2 is achieved, through a liquor fermentation experiment, the contents of n-propanol, isobutanol and isoamyl alcohol of the modified strains are reduced by 20.32%, 47.85% and 23.14% respectively compared with these of parent strains, and the aim of low yield of higher alcohols is achieved.The method can be widely used in genetic modification of yeast and other microorganisms, because obtained mutants have no exogenous genes left and thus can be safely used in industrial production, anda useful reference is provided for gene knockout directly conducted on industrial strains.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Flavouring method for low-salt solid-state fermentation sauce

A method for enhancing flavor of low-salt soy sauce obtained by solid state fermentation, which solves the problems of the prior low-salt soy sauce obtained by solid state fermentation, including poor flavor, low content of total esters and no ester flavor. The method comprises (1) immobilizing yeast cells with magnetic chitosan microspheres as a carrier to obtain immobilized yeast cells; and (2) inoculating the immobilized yeast cells in soy sauce mash, and fermenting to obtain low-salt soy sauce with enhanced flavor. In the obtained low-salt soy sauce with enhanced ester flavor, the content of total esters is increased by 15-20 wt%, the content of ethyl acetate is increased by 11-20 wt%, and the content of 4-ethyl guaiacol is increased by 12-15 wt%.

Owner:哈尔滨正阳河调味食品有限公司

Preparation method of filtrate reducer for drilling fluid

ActiveCN105754564AStable rheologyImprove fermentation performanceDrilling compositionWater bathsWater based

The invention discloses a preparation method of a filtrate reducer for drilling fluid.The preparation method of the filtrate reducer for the drilling fluid is characterized by comprising the following steps: 1, dissolving 2.5-3.0 parts by weight of an alkaline substance A and 0.6-0.75 part by weight of metallic oxides in 100 parts by weight of water, and stirring until the alkaline substance and the metallic oxides are dissolved fully to obtain a solution a; b, adding 9-11 parts by weight of monomer C in the solution a, and stirring until the monomer C is dissolved fully to obtain a solution b; c, adding 18-22 parts by weight of monomer D into the solution, and stirring until the monomer D is dissolved fully to obtain a solution c; d, adding 0.9-1.0 part by weight of monomer E into the solution c, and stirring until the monomer E is dissolved fully to obtain a solution d; e, continuing stirring, and heating the solution d in water bath until the temperature reaches 70+ / - 5 DEG C; and f, maintaining the temperature to be 70+ / - 5 DEG C, slowly dropwise adding 0.08-0.1 part by weight of an initiator F into the solution d while stirring, and reacting for 4-5 hours to obtain a preliminary product.The filtrate reducer prepared by the method seldom affects the performance of the water-based drilling fluid, and resistance of the water-based drilling fluid to ultra-high calcium pollution can be enhanced effectively.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

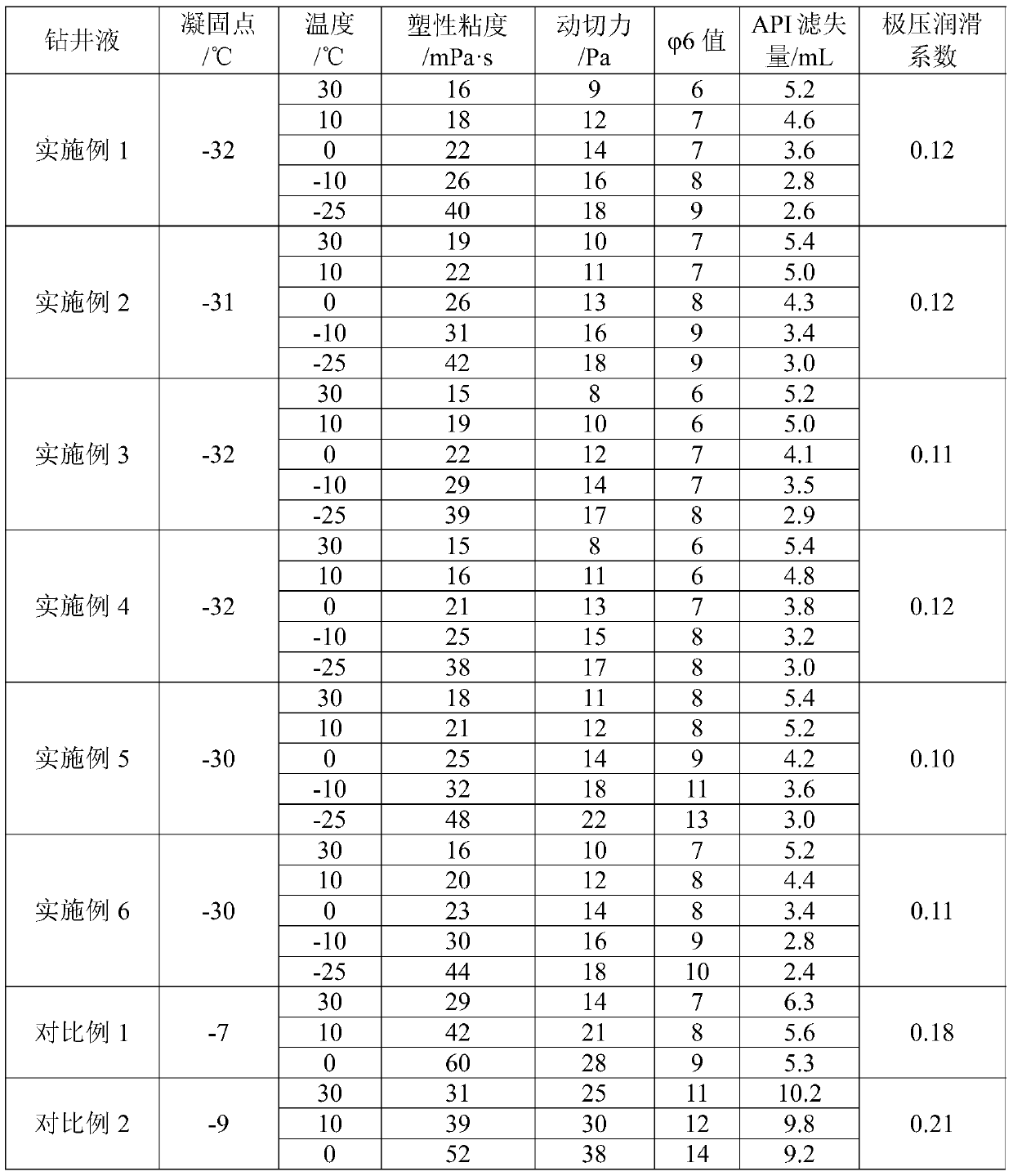

Water-based clay-free drilling fluid and application of drilling fluid to polar region frozen soil stratigraphical drilling

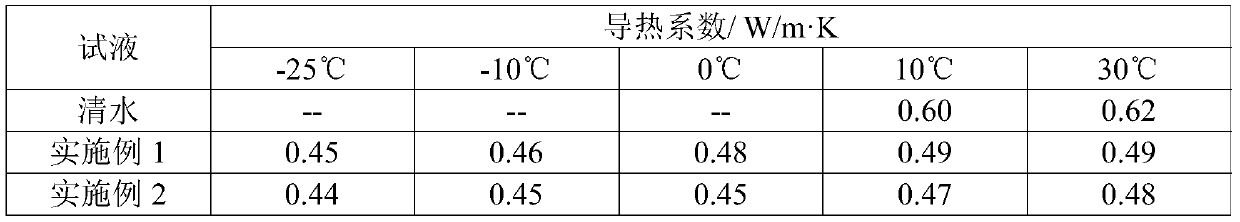

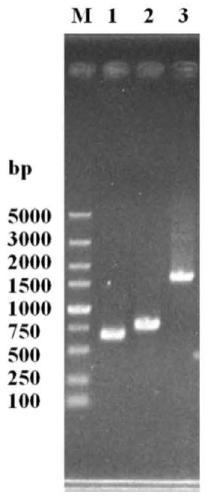

ActiveCN110804424AExcellent ultra-low temperature rheologyImprove fermentation performanceDrilling compositionInorganic saltsSoil science

The invention relates to the field of drilling fluids for petroleum, natural gas and natural gas hydrate drilling and discloses a water-based clay-free drilling fluid and application of the drilling fluid to polar region frozen soil stratigraphical drilling. The drilling fluid comprises an ultralow-temperature base liquid, a tackifier, a filtrate reducer, a blocking agent, a lubricating agent andwater, wherein the ultralow-temperature base liquid is composed of inorganic salt and alcohol, the solidifying point of the ultralow-temperature base liquid is lower than or equal to -28 DEG C, and the heat conduction coefficient is smaller than 0.5W / m.K. The water-based clay-free drilling fluid has good rheological properties, filtration properties, low heat conduction characteristics, well wallstability and environment-friendliness even under the condition of -25 DEG C and can be applied to polar region frozen soil stratigraphical drilling.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Method for producing erythritol by using broken rice

InactiveCN101979616AImprove conversion rateShort fermentation cycleMicroorganism based processesFermentationBroken riceGlycerol

The invention relates to a method for producing erythritol by using broken rice. In the method, moniliellaacetoabutans (ATCC18455) is used as a production strain and broken rice sugar liquid is used as a fermentation substrate for preparing the high-purity erythritol; and the method comprises three steps, namely preparation of the broken rice sugar liquid, preparation of erythritol fermentation liquid and refining of an erythritol product. The erythritol has high transformation rate, short fermentation period and stable fermentation performance, and has no byproducts such as glycerol and the like; the method reduces the production cost, and has the advantages of low operating cost, small equipment space, high product yield, few impurities and simple process; and the purity of the final product reaches over 98 percent.

Owner:HEFEI UNIV OF TECH

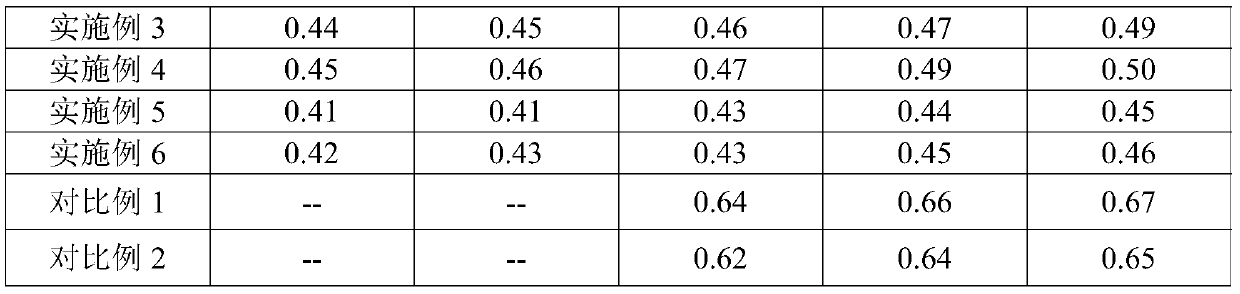

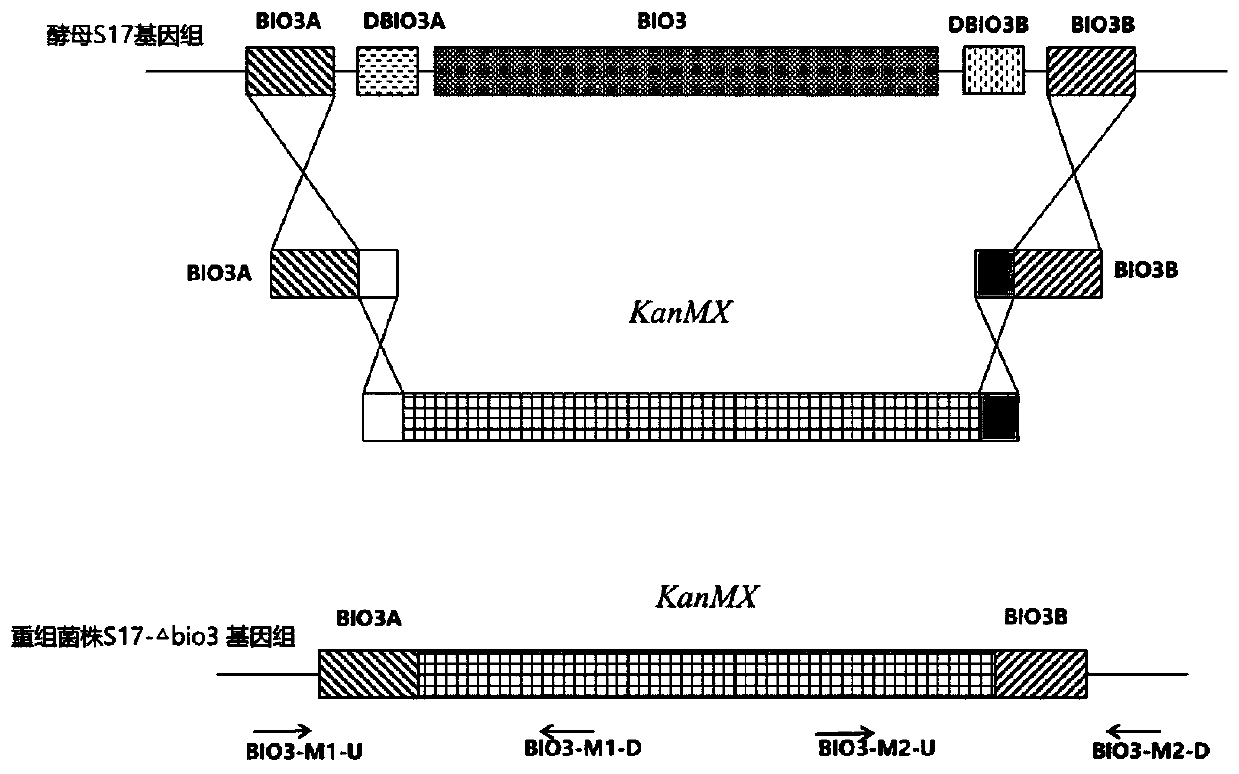

Saccharomyces cerevisiae strain low in higher alcohol yield and building method thereof

ActiveCN110373341AUnique tasteExcellent fermentation performanceFungiStable introduction of DNACarrier proteinBioengineerings

The invention discloses a Saccharomyces cerevisiae strain low in higher alcohol yield and a building method thereof and belongs to the technical field of bioengineering. The Saccharomyces cerevisiae strain is built by regulating the biotin synthesis route of Saccharomyces cerevisiae and knocking out the gene complete sequence of precursor substances, capable of promoting Saccharomyces cerevisiae biotin synthesis, in an original Saccharomyces cerevisiae strain, and the specific genes are a BIO3 gene for encoding 7,8-diamino-pelargonic acid aminotransferase and a BIO5 gene for encoding 8-amino-7-ethyl oxopelargonate carrier protein. After the Saccharomyces cerevisiae strain is fermented in a fermentation culture medium using wheat as the raw material, and the total higher alcohol generationquantity of the Saccharomyces cerevisiae strain is lowered by 16.85% and 23.55% as compared with that of the parent strain; the strain is good in fermentation performance and growth performance, and the condition that the growth performance of the recombinant strain is affected or other conditions can be avoided.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Saccharomyces cerevisiae for brewing pomegranate fruit wine and pomegranate wine prepared by fermentation

The invention discloses saccharomyces cerevisiae CGMCC No. 3027 for producing pomegranate fruit wine and the pomegranate fruit wine fermented and brewed by utilizing same. A plurality of strains of yeast are separated and purified through different approaches, saccharomyces cerevisiae with excellent wind-making performance of pomegranate fruit wine is selected out through tests of resistance against alcohol, SO2, high-low temperature as well as high glucose and an abricotine fermentation test, and the fermentation technology of pomegranate fruit wine is determined; and clear and transparent pomegranate fruit wine with cherry color, typical pomegranate fruit fragrance, alcohol degree of 6.6-9.7 percent by V / V, total sugar of 180g / L, total acid of 4g / L and good alcohol flavor is brewed through closed fermentation of main fermentation at the temperature of 25 DEG C and post fermentation at the control temperature of 18-22 DEG C. The pomegranate fruit wine has full body, fineness, mellowness, good harmony and moderate acidity, and the invention is widely applied to the field of the industrial production of the pomegranate fruit wine.

Owner:THE INST OF MICROBIOLOGY XINJIANG ACADEMY OF AGRI SCI

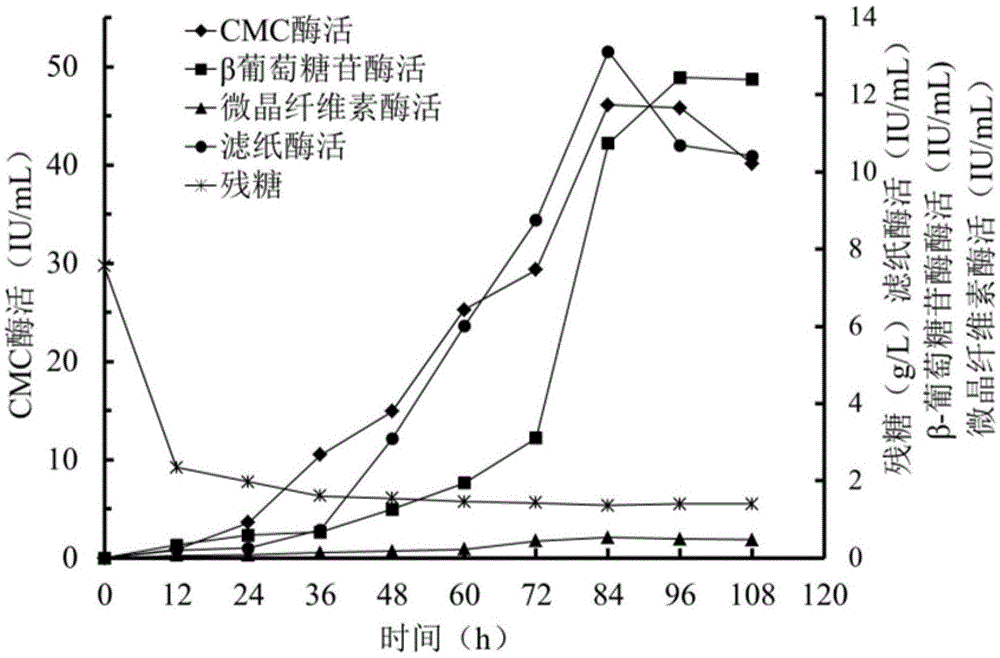

Method for screening cellulase producing strains and method for producing cellulase by means of fermentation

InactiveCN105647904AFast growthHigh enzyme production rateMutant preparationMicroorganism based processesBiotechnologyGlucan

The invention discloses a method for screening cellulase producing strains and a method for producing cellulase by means of fermentation. The cellulase producing strains which are named as TP-02 are acquired from rotten wood in ecological forest in the Huangshang Mountain by means of primary screening, protoplast preparation, ultraviolet-irradiation mutation breeding and secondary screening. The methods have the advantages that the cellulase producing strains are high in cellulase producing capacity, bean pulp, ammonium sulfate, urea or ammonium chloride can be used as nitrogen sources, bran juice, lactose, starch sugar, rice straw or corn straw can be used as carbon sources, the nitrogen sources and the carbon sources are subjected to liquid-state fermentation to obtain the cellulase producing strains, the enzyme activity of filter paper can reach 16.98 IU / mL after the cellulase producing strains are cultivated for 72-84 hours, the enzyme activity of incision enzymes can reach 41.33 IU / mL, the enzyme activity of excision enzymes can reach 3.65 IU / mL, and the enzyme activity of beta-glucanase can reach 15.98 IU / mL.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

Low fluid loss drilling fluid compositions comprising diblock copolymers

ActiveUS20150275065A1Improve fermentation performanceFlushingDrilling compositionPolystyreneIsoprene

The invention relates to a selectively hydrogenated isoprene-styrene diblock copolymer having a polystyrene content of at least 40 wt. %, which when added to an oil-based mud composition, substantially reduces fluid loss. The polystyrene in the diblock has a true molecular weight greater than 60 kg / mole and the total apparent molecular weight of the diblock copolymer is at least 160 kg / mole. The drilling mud that contains about 0.5 pounds per barrel to about 10 pounds per barrel of a selectively hydrogenated isoprene-styrene diblock copolymer and a weighting agent, resulting in a drilling fluid composition exhibiting good suspension of the weighting agent and improved fluid loss performance.

Owner:KRATON POLYMERS US LLC

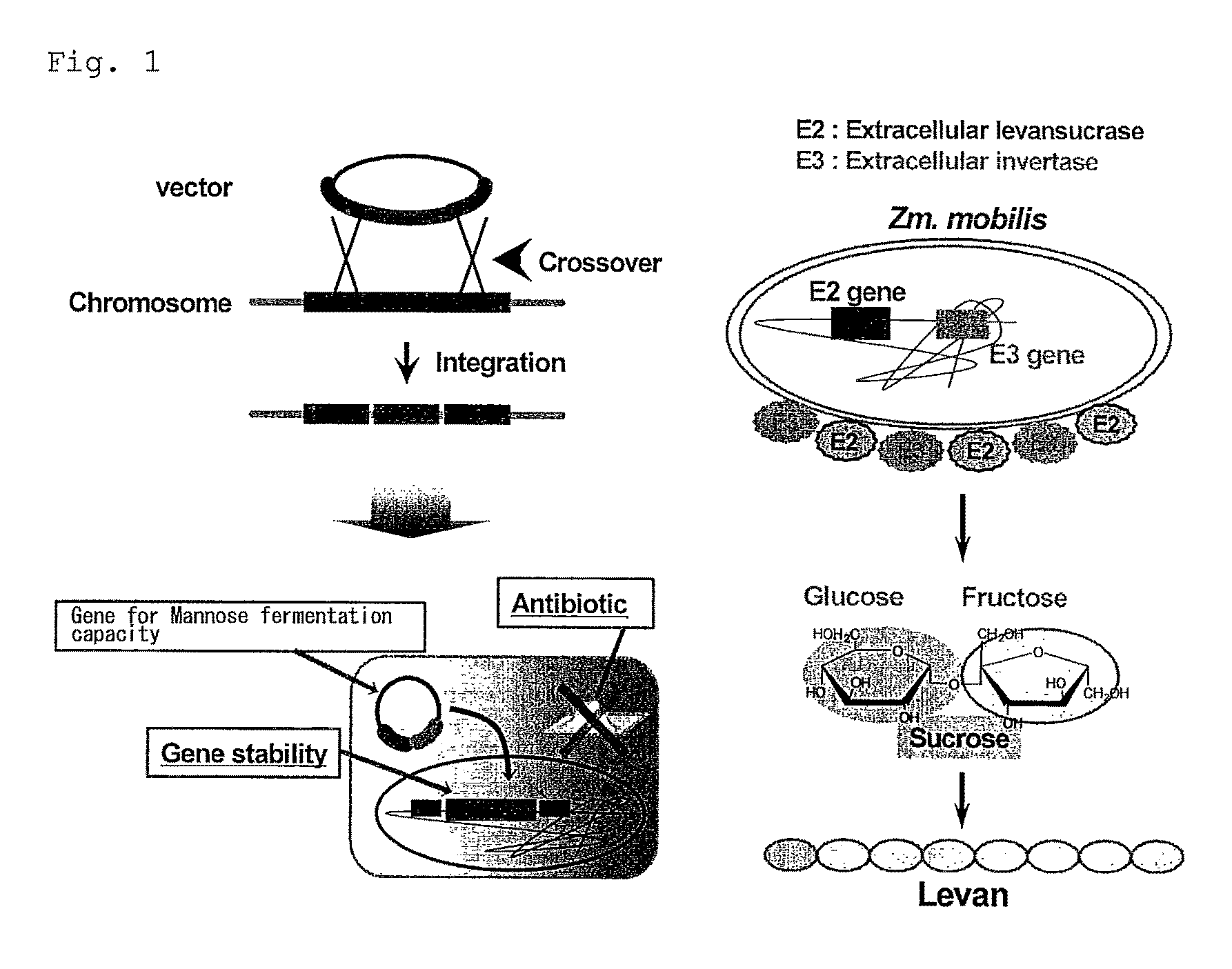

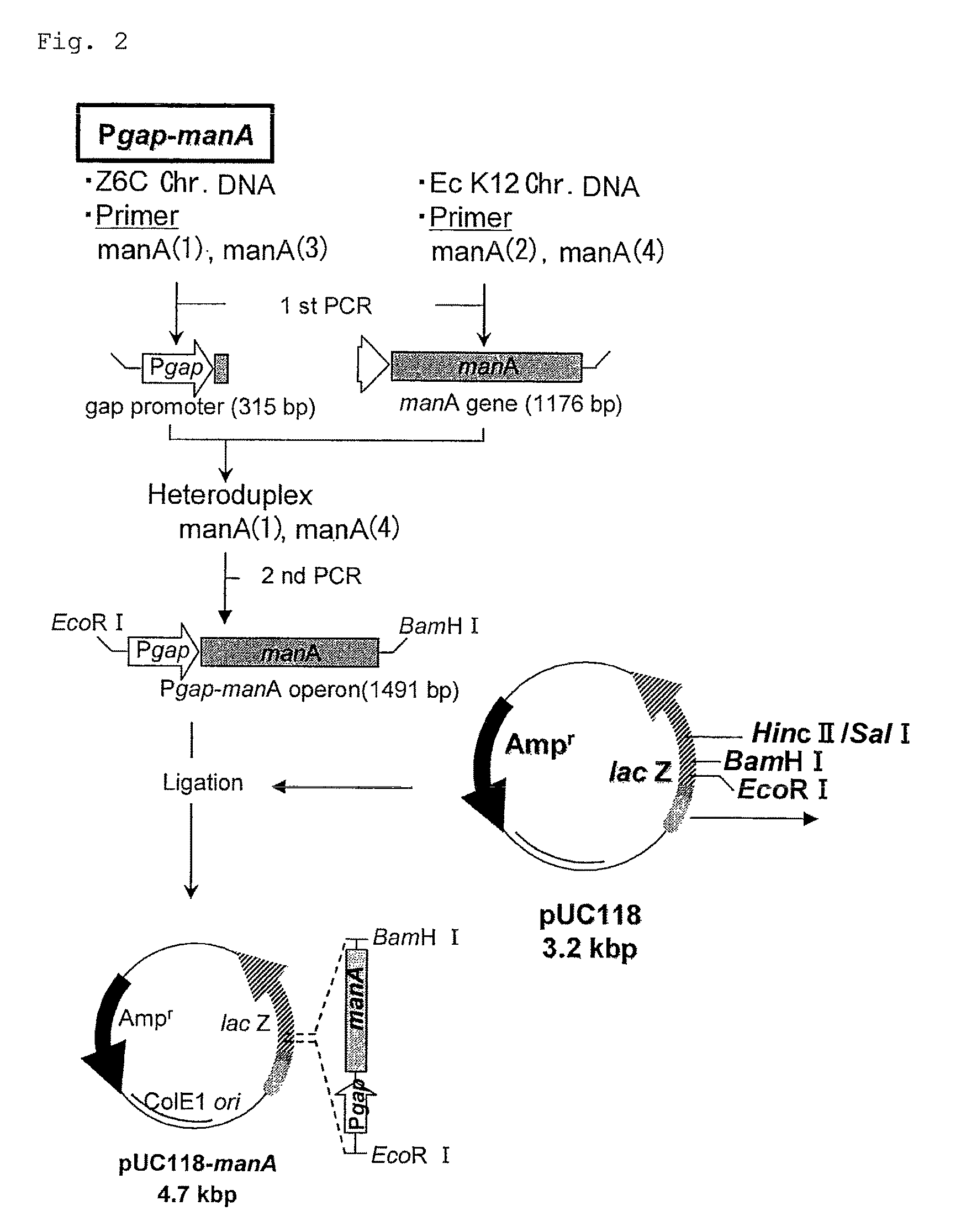

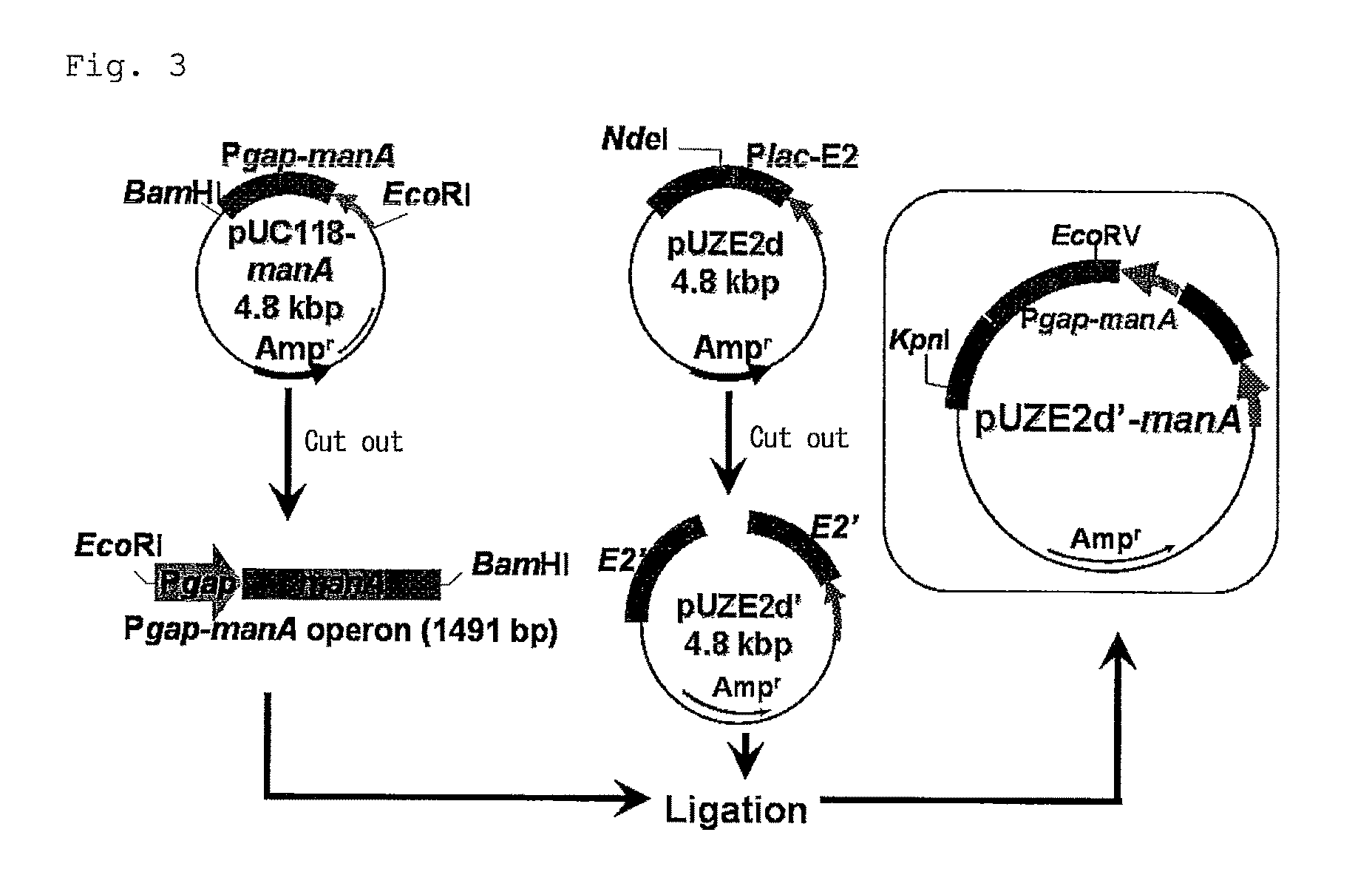

Bacterium capable of fermenting glucose, mannose and xylose simultaneously, and method for production of bioethanol using the bacterium

InactiveUS8383377B2Strong glucose fermentation capacityImprove fermentation performanceBacteriaBiofuelsTransketolaseEscherichia coli

The object is to develop a bacterium capable of fermenting glucose, mannose and xylose simultaneously, which can ferment a saccharified solution of a cellulose-type or lignocellulose-type biomass resource to produce ethanol, and to construct an energy-saving high-efficiency bioethanol conversion process. Thus, disclosed is Zymomonas mobilis bacterium which is prepared by integrating a gene encoding a phosphomannose isomerase derived from Escharichia coli into a levansucrase gene located on the chromosome by the double cross-over by means of a homologous recombsination method, and then introducing recombinant DNA prepared by binding a DNA fragment containing genes encoding a xylose isomerase, a xylulokinase, a transaldolase and a transketolase, respectively, all derived from Escherichia coli to a vector. Also disclosed is a method for producing ethanol by continuously fermenting a saccharified solution of a cellulose-type biomass resource in a system on which the Zymomonas mobilis bacterium is immobilized.

Owner:TOTTORI UNIVERSITY

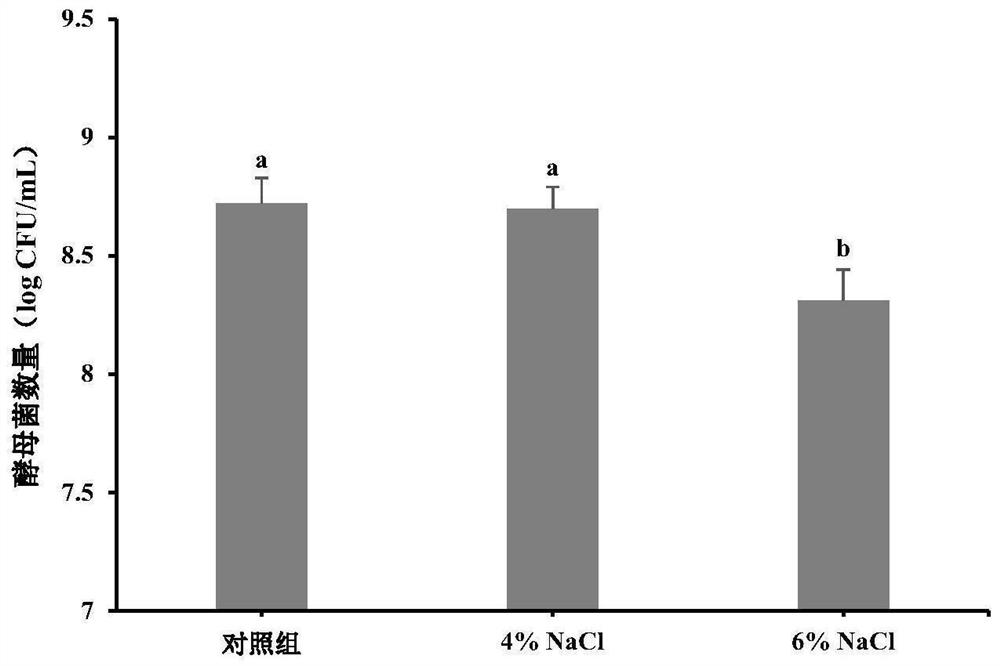

Debaryomyces hansenii with good fermentation performance and aroma production function and screening method thereof

ActiveCN113388533AStrong fermentation abilityRich in aroma substancesFungiYeast food ingredientsBiotechnologyMicroorganism

The invention belongs to the technical field of microorganisms, and particularly relates to debaryomyces hansenii with good fermentation performance and an aroma production function and a screening method thereof. The strain is named as Debaryomyces hansenii SH4, which is preserved in the China General Microbiological Culture Collection Center on May 12, 2021, and the preservation number of the Debaryomyces hansenii SH4 is CGMCC No.22507. After the debaryomyces hansenii SH4 is inoculated into a fermented sausage simulation system and fermented for 12 days, the contents of aldehydes, acids, alcohols and esters are obviously higher than those of an uninoculated control group (P is greater than 0.05). The fat taste of the simulation system is reduced, the fermentation taste, the wine fragrance, the fruit fragrance and the flower fragrance are increased, and good quality as an aroma production leavening agent is shown. The debaryomyces hansenii provided by the invention is applied to the air-dried sausages and has important significance in improving the fragrance of products and increasing the strength and complexity of the fragrance.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

High-density low-frictional-resistance drilling fluid

ActiveCN104312557AReduce contentLow viscosity coefficientDrilling compositionPolymer scienceFiltration

The invention relates to a high-density low-frictional-resistance drilling fluid, and belongs to the technical field of oil-field drilling fluids. The high-density low-frictional-resistance drilling fluid employs water as a base liquid, and is obtained by mixing 1%-3% by mass of sodium bentonite, sodium carbonate accounting for 5% by mass of sodium bentonite, 0.5%-1.0% by mass of sodium hydroxide, 0.05%-0.1% by mass of tackifier A, 0.2%-0.5% by mass of filtrate reducer B, 0.5%-1.0% by mass of carboxymethyl cellulose sodium salt, 3.0%-5.0% by mass of sulfonated phenolic resin, 3.0%-5.0% by mass of sulfonated lignite, 2.0%-3.0% by mass of polymeric alcohol, 100% by mass of an organic salt C and 29.1%-122.2% by mass of barite, and performing high-temperature ageing. The drilling fluid has the temperature resistance up to 135 DEG C and the controllable density scope of 1.50-1.80 g / cm<3>, has good rheological property and filtration property at a high temperature, and has relatively low barite content, mud cake sticking coefficient and cyclic pressure dissipation, and relatively high inhibition performance.

Owner:CHINA PETROCHEMICAL CORP +1

Filtration reducing agent for drilling fluid and preparation method thereof

ActiveCN104031621AEnhanced fluid loss control performanceGood filter loss reduction effectDrilling compositionChemistrySodium metabisulfite

The invention discloses a filtration reducing agent for a drilling fluid and a preparation method thereof. The filtration reducing agent comprises the components in parts by weight: 200-250 parts of phenol, 50-60 parts of sodium chloroacetate, 50-60 parts of epoxy chloropropane, 380-430 parts of formaldehyde, 80-100 parts of sodium metabisulfite, 80-90 parts of anhydrous sodium sulfate, 65-78 parts of sodium hydroxide, 60-70 parts of trimethylamine, 36-45 of sodium 2-chloroethanesulfonate, 25-35 parts of carboxymethyl cellulose, 30-40 parts of acrylic amine, 28-40 parts of vinyl acetate, 30-36 parts of dimethyl diallyl ammonium chloride, and 800-1000 parts of water. The preparation method comprises the steps of firstly dissolving sodium hydroxide in water, adding phenol and sodium chloroacetate, carrying out a reaction, then adding epoxy chloropropane and trimethylamine, continuing to carry out a reaction, after the reaction, adding other components, successively carrying out reactions, and carrying out spray drying on the finally-obtained mixture to obtain the filtration reducing agent product.

Owner:新疆中经宏泰石油技术服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com