Micro-crosslinking polymer fluid loss additive for drilling fluid and preparation method of micro-crosslinking polymer fluid loss additive

A fluid loss control agent and micro-crosslinking technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve problems such as easy degradation, achieve good performance, good high-temperature resistance to fluid loss, improve resistance The effect of thermal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Dissolve NaOH in 75.4mL water to make a solution, add 58.0g fumaric acid under stirring, then add 5.0g CaO, continue stirring until the mixture is uniform; add 31.1g 2-acrylamido-2-methanol to the mixture propanesulfonic acid, 7.1g acrylamide, 9.9g N,N-dimethylacrylamide, 7.1g N-acryloylmorpholine, stir to dissolve, adjust the pH to 8 with NaOH aqueous solution, and adjust the temperature to 25°C Finally, add 0.2g of ammonium persulfate and 0.3g of sodium sulfite aqueous solution, and react under stirring to obtain a gel-like product, which is granulated, dried and pulverized at 80°C to obtain the drilling fluid micro-crosslinking polymerization Fluid loss reducer HRJ-1.

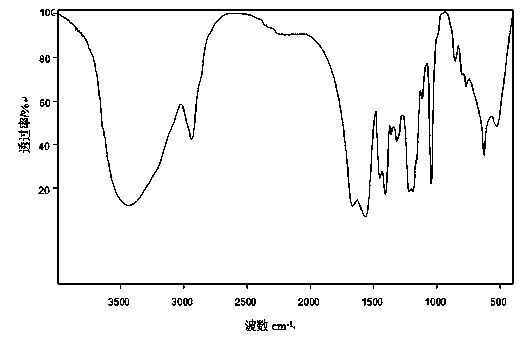

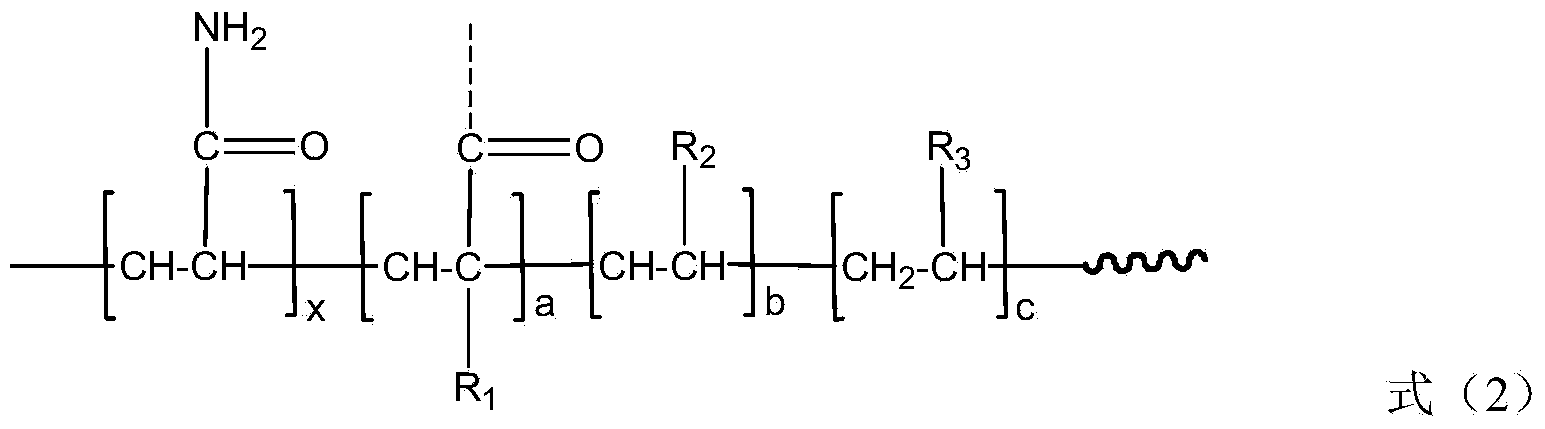

[0027] Its structural formula is:

[0028]

Embodiment 2

[0030] Dissolve KOH in 73.0mL of water to make a solution, add 28.8g of acrylic acid under stirring, then add 6.0g of CaO, continue stirring until the mixture is uniform; add 31.0g of 2-acrylamido-2-methylpropane to the mixture Sulfonic acid, 10.7g acrylamide, 5.5g N-vinyl-2-pyrrolidone, 12.7g N,N-diethylacrylamide, stir to dissolve, adjust the pH to 9 with KOH aqueous solution, and adjust the temperature to 30°C Finally, add 0.4g of potassium persulfate and 0.3g of sodium bisulfite aqueous solution, and react under stirring to obtain a gel-like product, which is granulated, dried and pulverized at 120°C to obtain the drilling fluid. Cross-linked polymer fluid loss additive HRJ-2.

[0031] Its structural formula is:

[0032]

Embodiment 3

[0034] Dissolve NaOH in 54.0mL water to make a solution, add 43.0g methacrylic acid under stirring, then add 3.0g CaO, continue stirring until the mixture is uniform; add 41.4g 2-acrylamido-2-methyl Propanesulfonic acid, 10.7g acrylamide, 11.1g N-vinyl-2-pyrrolidone, 5.0g N,N-dimethylacrylamide, 14.1g N-acryloylmorpholine, stirred to dissolve, adjusted with NaOH aqueous solution The pH is 10. After the temperature is adjusted to 35°C, add 0.3g of ammonium persulfate and 0.3g of sodium bisulfite aqueous solution and react under stirring to obtain a gel-like product, which is granulated and dried at 100°C Pulverize to obtain the micro-crosslinked polymer fluid loss reducer HRJ-3 for drilling fluid.

[0035] Its structural formula is:

[0036]

PUM

| Property | Measurement | Unit |

|---|---|---|

| filtration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com