Preparation method of filtrate reducer for drilling fluid

A fluid loss control agent and drilling fluid technology, applied in drilling compositions, chemical instruments and methods, etc., can solve the problem that the water-based drilling fluid cannot be effectively strengthened to resist ultra-high calcium pollution, and the performance of the water-based drilling fluid is greatly affected. , The effect of calcium resistance and fluid loss reduction is not obvious, and the effect of good compatibility, stable rheology and fluid loss performance, and good temperature resistance is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] a. At 25°C, dissolve 2.8g of sodium hydroxide A and 0.7g of calcium oxide B in 100mL of distilled water, stir at 3000r / min for 10min, fully dissolve, and obtain solution a;

[0033] b. Add 10 g of acetic anhydride into solution a, stir at a high speed of 3000 r / min for 5 minutes, fully dissolve, and obtain solution b;

[0034] c. Continue to add 20g of 2-hydroxy-3-allyloxysulfonic acid into solution b, stir at a high speed of 3000r / min for 5min, fully dissolve, and obtain solution c;

[0035] d. Continue to add 1.0 g of nano-zinc oxide into solution c, stir at a high speed of 3000 r / min for 10 min, fully dissolve, and obtain solution d;

[0036] e. While stirring at a high speed of 3000r / min, heat the solution d in a water bath to 70±5°C;

[0037] f. Maintain 70±5°C, slowly add 0.2g ammonium persulfate dropwise to solution d while stirring, and react for 4 hours to obtain the preliminary product;

[0038] g. Washing of the product: wash the resultant with ethanol to r...

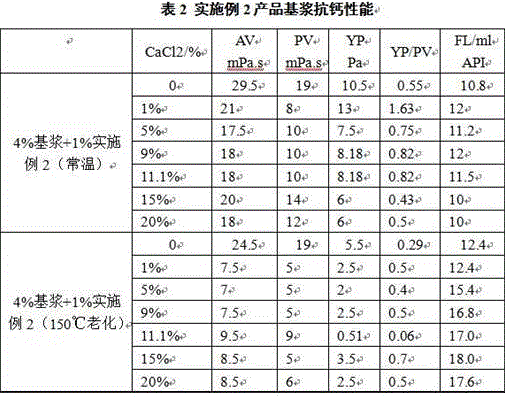

Embodiment 2

[0041] a. Under the condition of 25°C, dissolve 2.6g of potassium hydroxide A and 0.65g of magnesium oxide B in 100mL of distilled water, stir at 3000r / min for 10min, fully dissolve, and obtain solution a;

[0042] b. Add 8g of maleic anhydride into solution a, stir at 3000r / min for 5min at a high speed, fully dissolve, and obtain solution b;

[0043] c. Continue to add 22g of 2-acrylamide-2-methylpropanesulfonic acid into solution b, stir at a high speed of 3000r / min for 5min, fully dissolve, and obtain solution c;

[0044] d. Continue to add 1.0 g of nano-titanium oxide into solution c, stir at a high speed of 3000 r / min for 10 min, fully dissolve, and obtain solution d;

[0045] e. While stirring at a high speed of 3000r / min, heat the above solution d in a water bath to 70±5°C;

[0046] f. Keep at 70±5°C, slowly add 0.1g of potassium persulfate dropwise to solution d while stirring, and react for 4 hours to obtain the preliminary product;

[0047] g. Washing of the produc...

Embodiment 3

[0050] a. Dissolve 3.0g of potassium hydroxide A and 0.75g of calcium oxide in 100mL of distilled water at 25°C, and stir at 3000r / min for 10min to fully dissolve.

[0051] b. Add 15g of maleic anhydride to a, and stir at 3000r / min for 5min to fully dissolve.

[0052] c. Continue to add 15g of 2-acrylamide-2-methylpropanesulfonic acid into b, and stir at a high speed of 3000r / min for 5min to fully dissolve.

[0053] d. Continue to add 1.0 g of nano-titanium oxide into c, and stir at a high speed of 3000 r / min for 10 min to fully dissolve.

[0054] e. While stirring at a high speed of 3000r / min, heat the above homogeneously mixed liquid in a water bath to 70±5°C.

[0055] f. Keeping at 50±5°C, slowly add 0.15 g of ammonium persulfate dropwise to e while stirring, and react for 4 hours to obtain the preliminary product.

[0056] g. Product washing: wash the product with methanol to remove excess impurities.

[0057] h. After vacuum drying, the product is crushed into white po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com