Polycarboxylate flow regulator for water-based drilling fluid and completion fluid with ultra-high temperature and ultra-high density and preparation method of polycarboxylate flow regulator

A technology of flow regulator and water-based drilling fluid, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of poor temperature resistance and low temperature resistance, and achieve the purpose of reducing viscosity and increasing space The effect of resistance and inhibition of coalescence characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

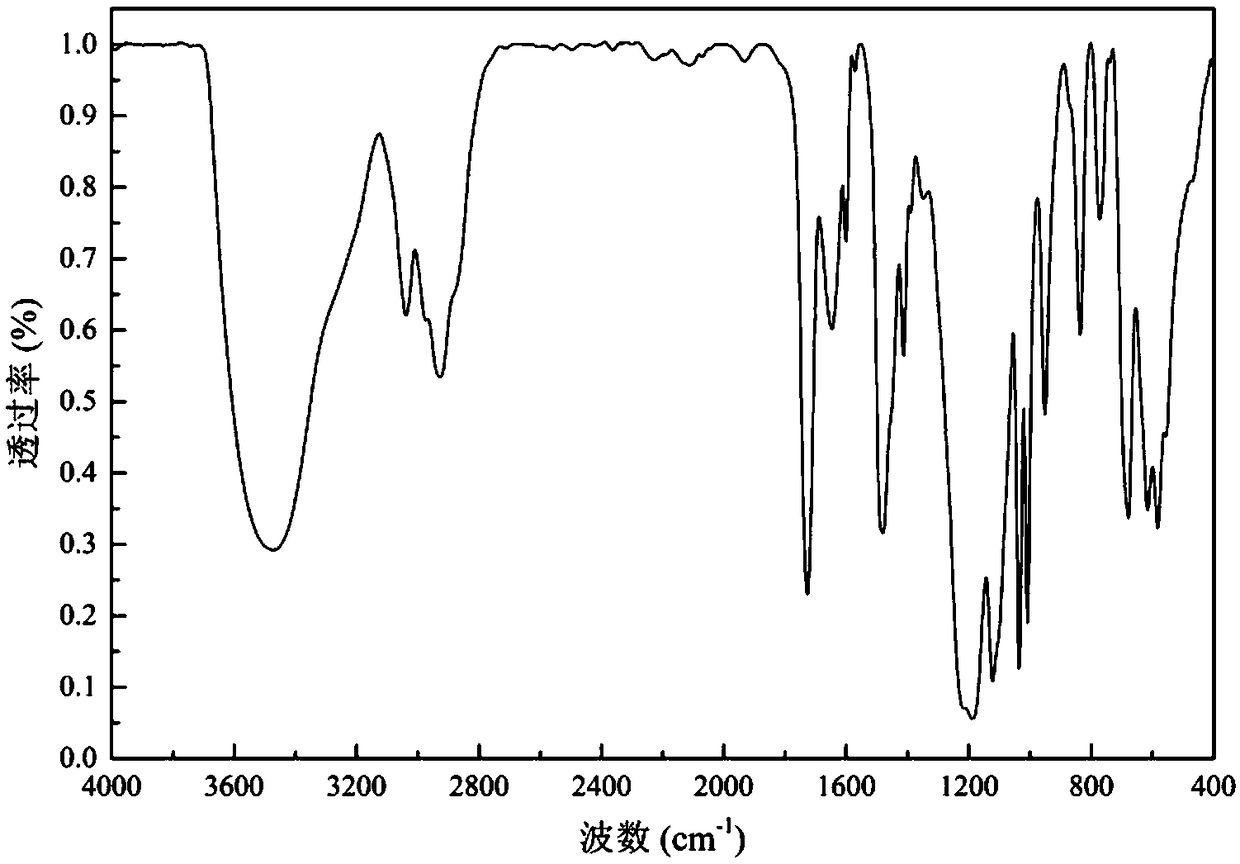

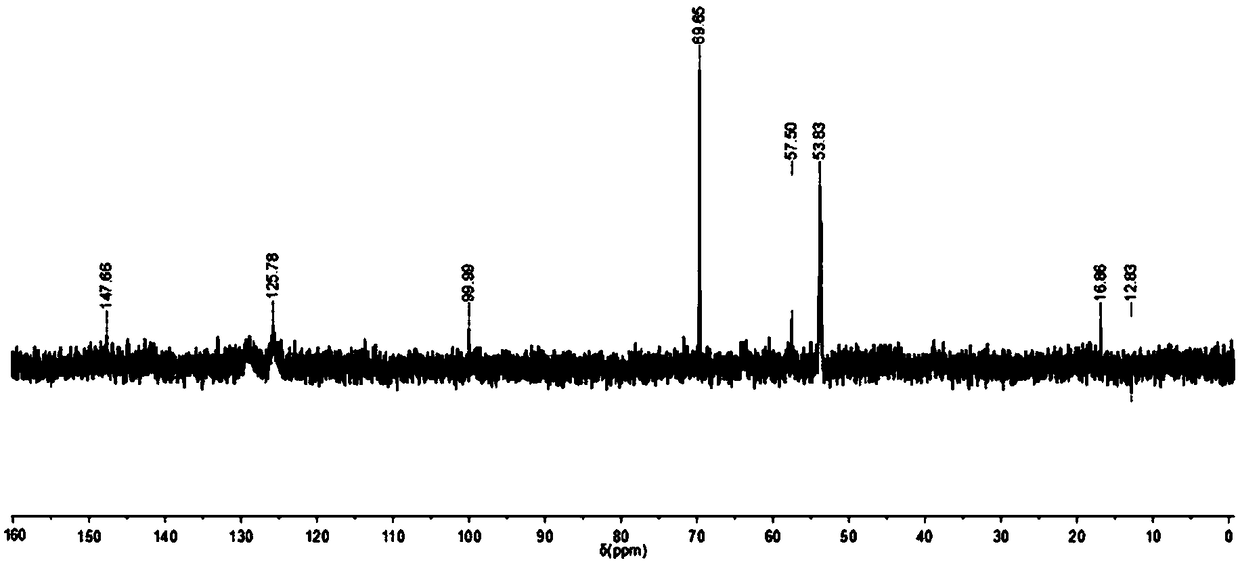

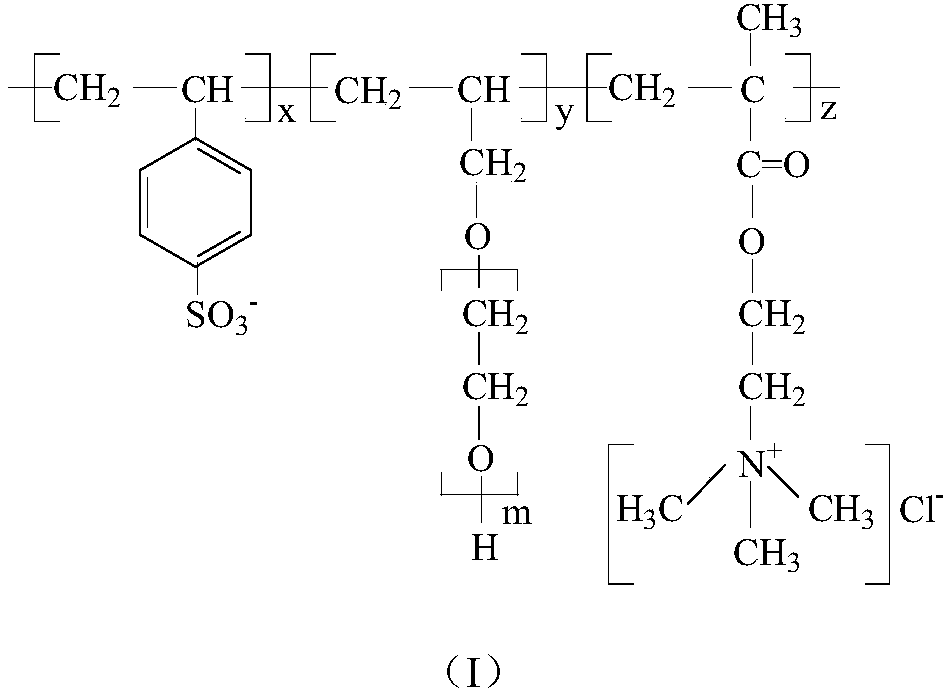

Embodiment 1

[0041] The sodium alkenylbenzene sulfonate that takes 56.68 grams is added in the capacity that agitator, reflux condenser, nitrogen protection device, temperature sensor and heating device are housed are in the reactor of 2.5 liters, add the tap water of 500 milliliters, open stirring device, Stir at high speed to make it fully dissolve; weigh 392 grams of allyl polyoxyethylene ether (the number of repeating chains of polyoxyalkyl groups m=12-15) and pour it into the reactor; weigh 22.43 grams of methacryl Oxyethyltrimethylammonium chloride was poured into the reactor and stirred at high speed for 10 minutes; 18.89 grams of ammonium persulfate was weighed and fully dissolved in 200 ml of tap water, poured into the reactor and stirred evenly at high speed, Then add tap water until the total amount of tap water reaches 1575 ml; pass nitrogen gas, stir at high speed for 5 minutes, then heat up to 78-83°C, react for 4 hours and cool to room temperature to obtain the ultra-high tem...

Embodiment 2

[0044] To the capacity that agitator, reflux condenser, nitrogen protection device, temperature sensor and heating device are equipped with is the reaction kettle of 1.5 liters to take by weighing 61.8 grams of sodium alkenyl benzene sulfonate, add 600 milliliters of tap water, open stirring device, Stir at a high speed to make it fully dissolve; weigh 216 grams of allyl polyoxyethylene ether (the number of repeating chains of the polyoxyalkyl group m=5-9) and pour it into the reactor; weigh 18.1 grams of methacryl Pour oxyethyltrimethylammonium chloride into the reaction kettle and stir at high speed for 10 minutes; weigh 3.55 grams of azobisisobutylamidine hydrochloride and fully dissolve it in 100 ml of tap water, and pour it into the reaction kettle Stir evenly at medium and high speed, then add tap water until the total amount of tap water reaches 850 ml, blow nitrogen, stir at high speed for 5 minutes, then heat up to 63-68°C, react for 4 hours, and cool to room temperatu...

Embodiment 3

[0047] Add 500 kg of tap water to a stainless steel corrosion-resistant reaction kettle with a capacity of 3-3.5 tons equipped with a stirrer, a reflux condenser, a nitrogen protection device, a thermometer and a heating device, and then turn on the stirrer at a rate of 25 kg / min. The sodium p-styrenesulfonate of 142 kilograms is added in the reactor, is stirred to dissolving evenly; With the speed of 50 kilograms / min, the allyl polyoxyethylene ether of 497 kilograms (number of repeated chains m=5 of polyoxyalkylene group) -9) Add it to the reaction kettle and stir for 10 minutes; then add 41.5 kg of methacryloyloxyethyltrimethylammonium chloride into the reaction kettle and stir at high speed for 10 minutes; weigh 8.166 kg of azobisiso Butyamidine hydrochloride is fully dissolved in 100 kg of tap water, poured into the reaction kettle, and stirred for 10 minutes; the total weight of tap water is added to 1950 kg, nitrogen gas is passed, and the temperature is raised to 65-70°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of unsaturation | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com