Patents

Literature

66results about How to "Stable rheology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

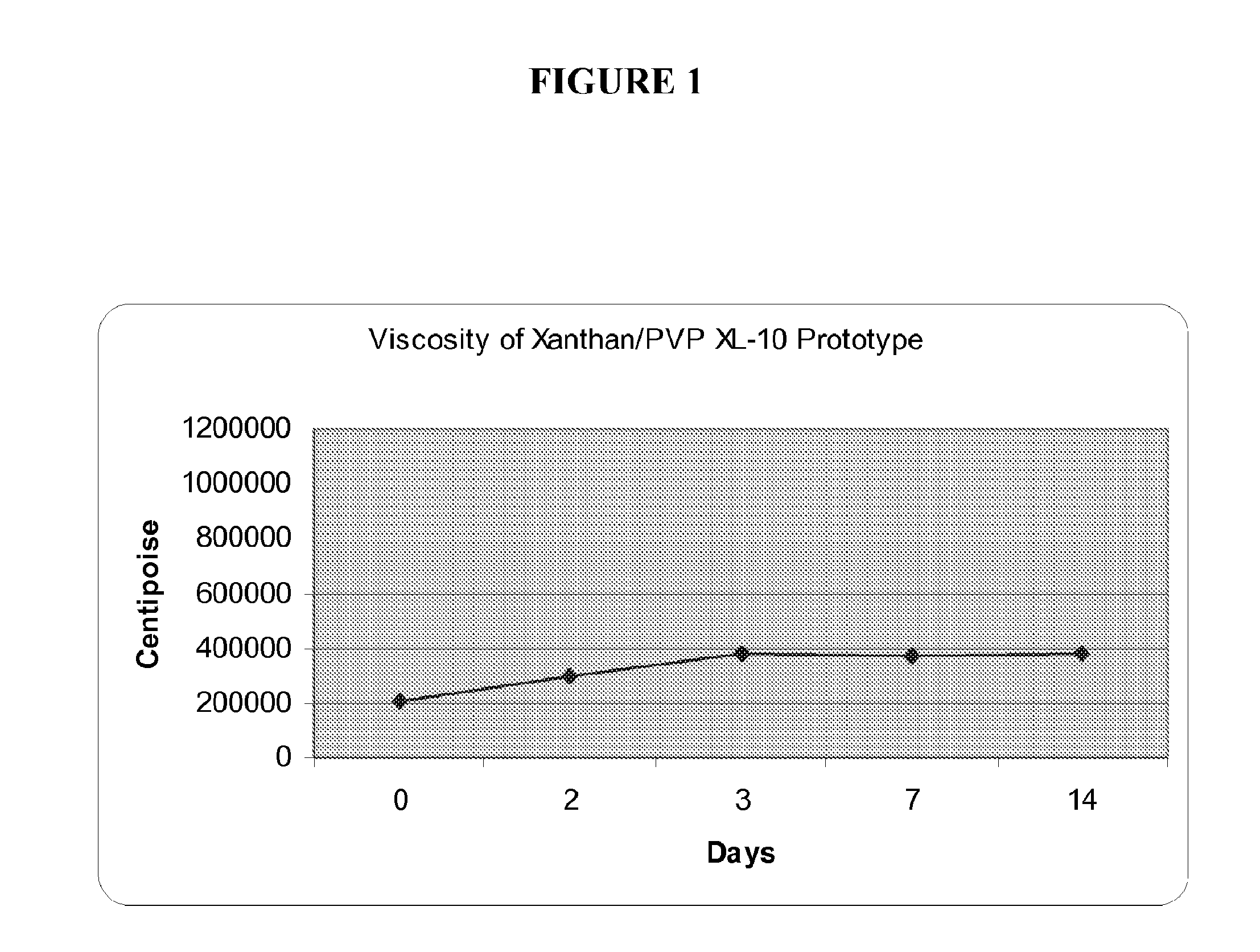

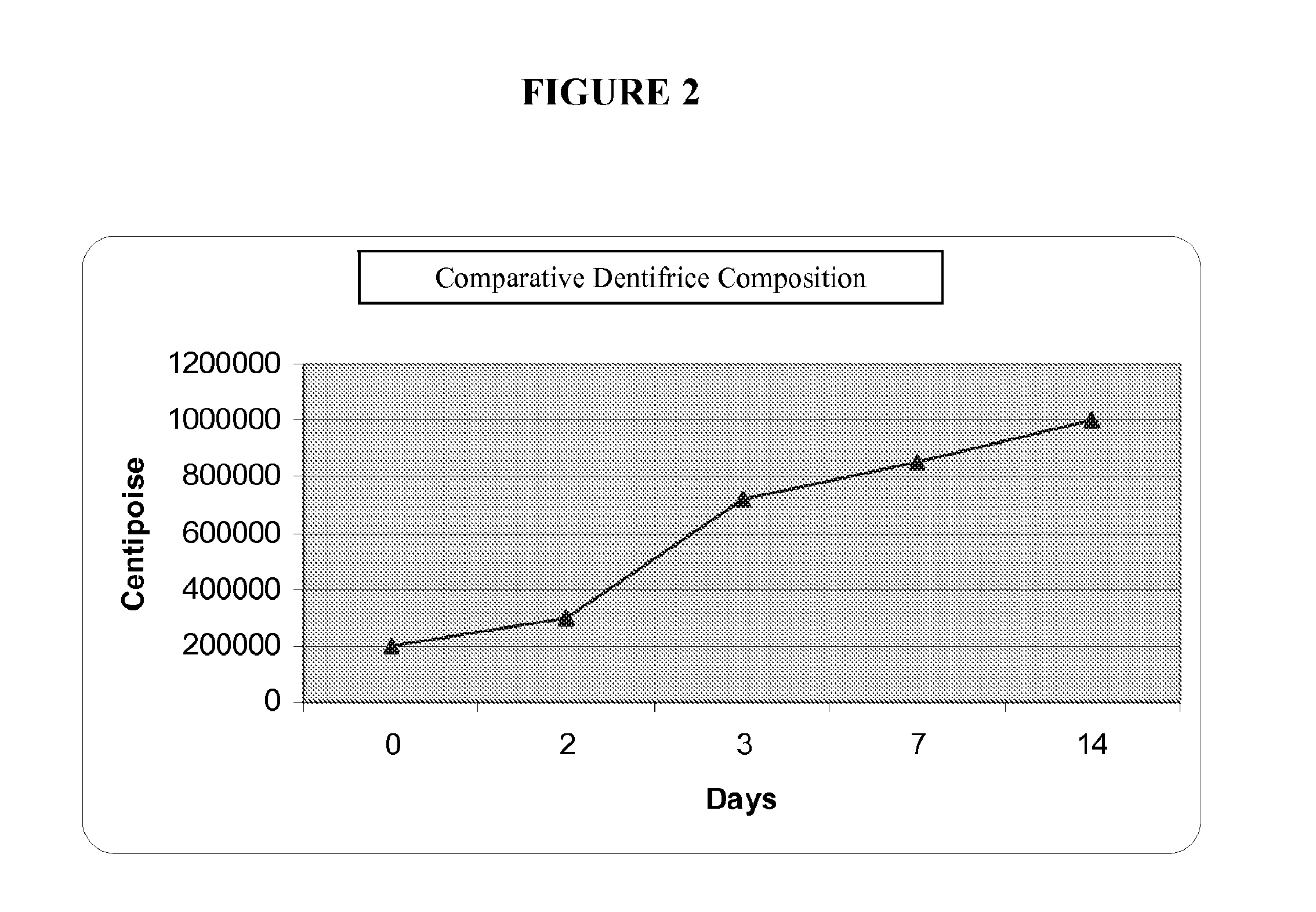

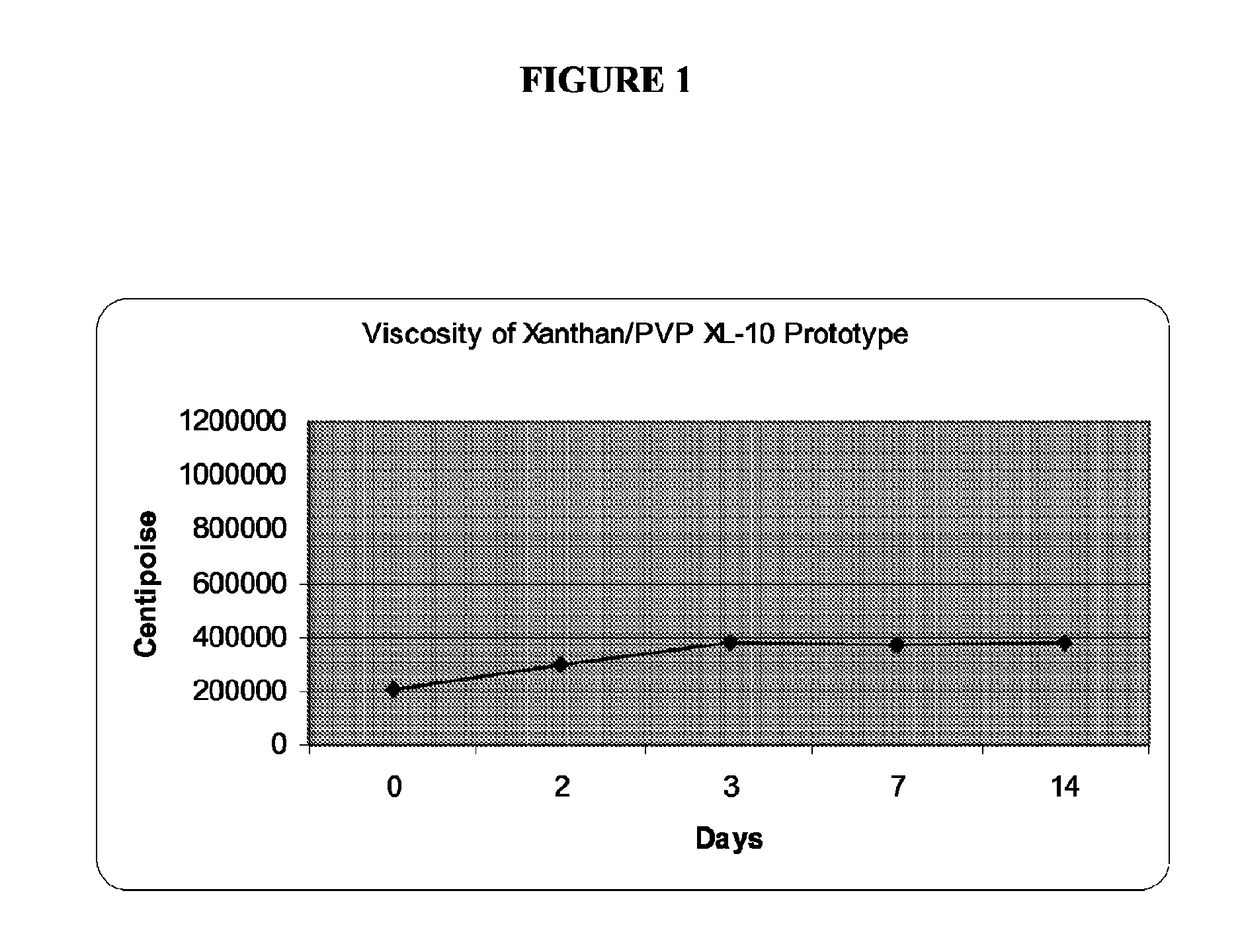

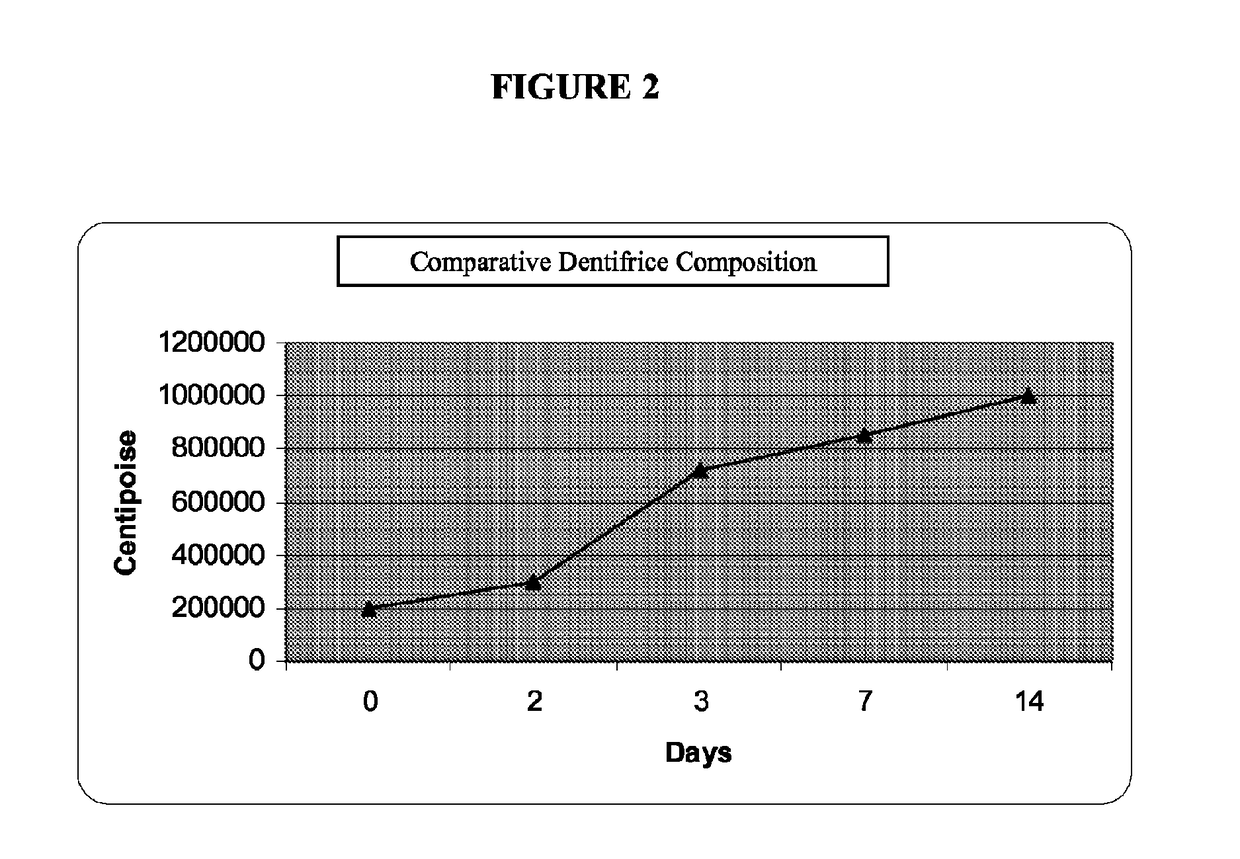

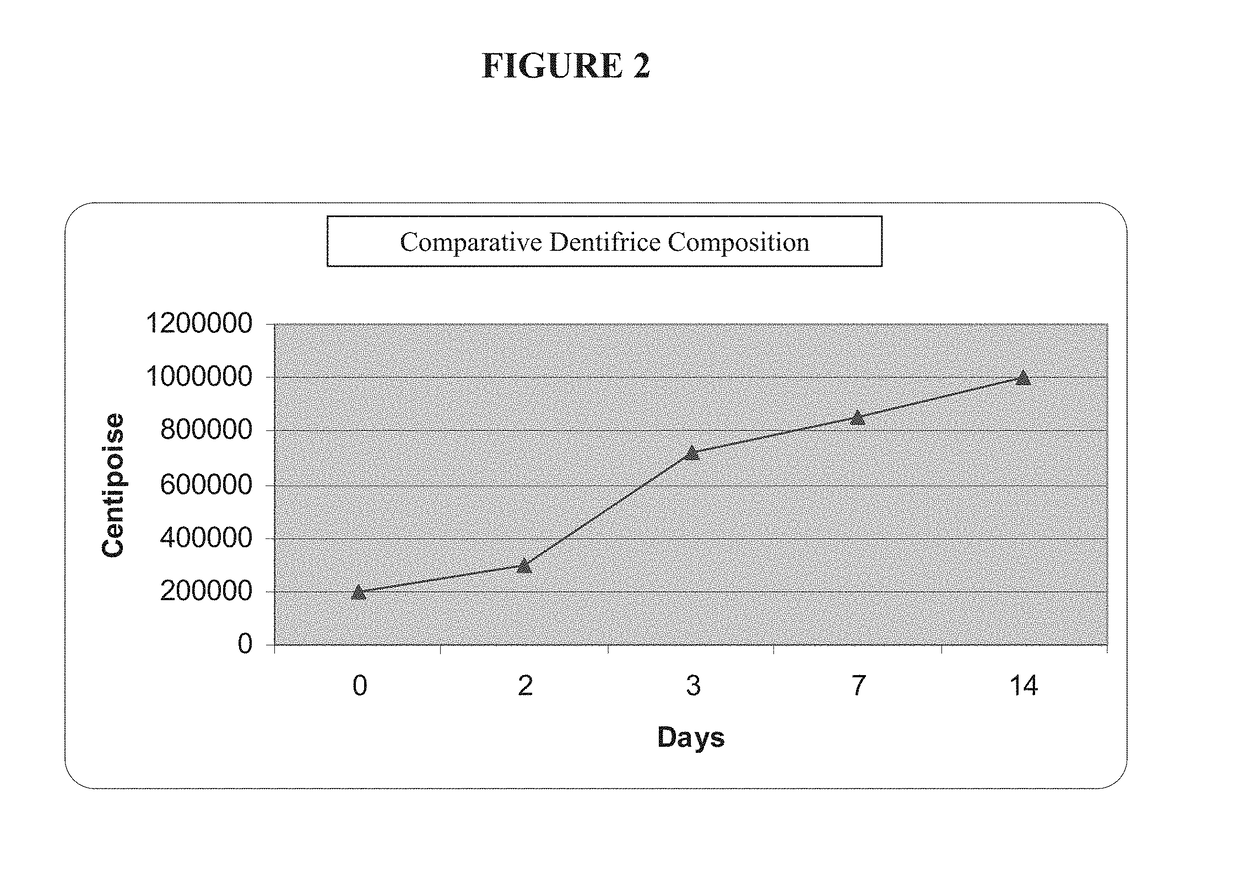

Low water stannous fluoride plus zinc citrate dentifrice with improved stability, rheology, and efficacy

ActiveUS20120207686A1Stable rheologyHigh viscosityAntibacterial agentsCosmetic preparationsBULK ACTIVE INGREDIENTActive ingredient

A dentifrice composition having a low water phase comprising effective amounts of polyphosphate and ionic active ingredients.

Owner:COLGATE PALMOLIVE CO

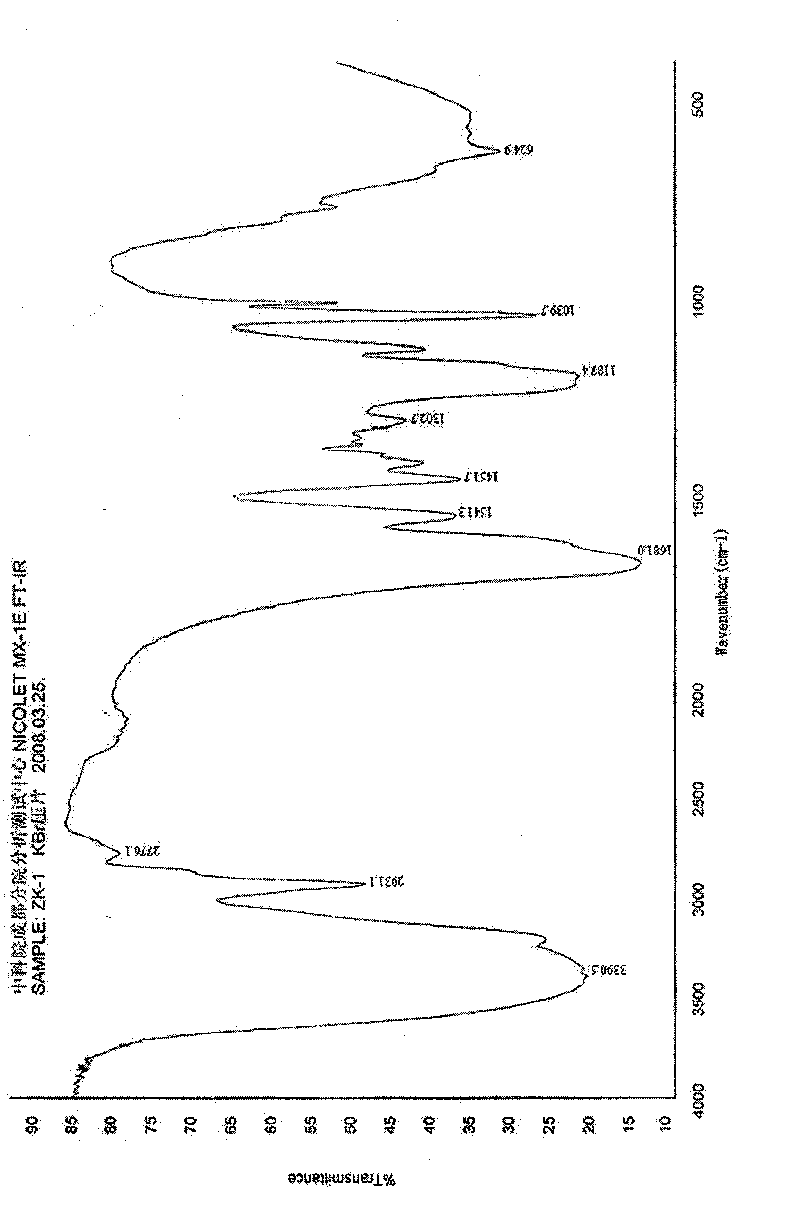

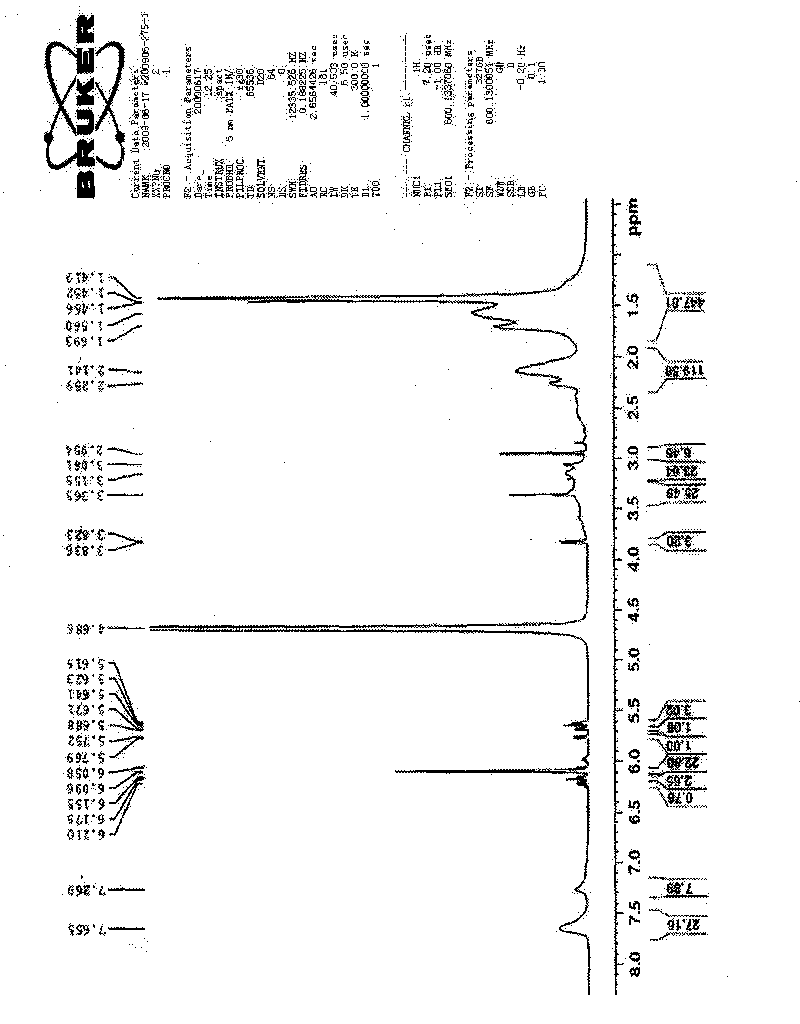

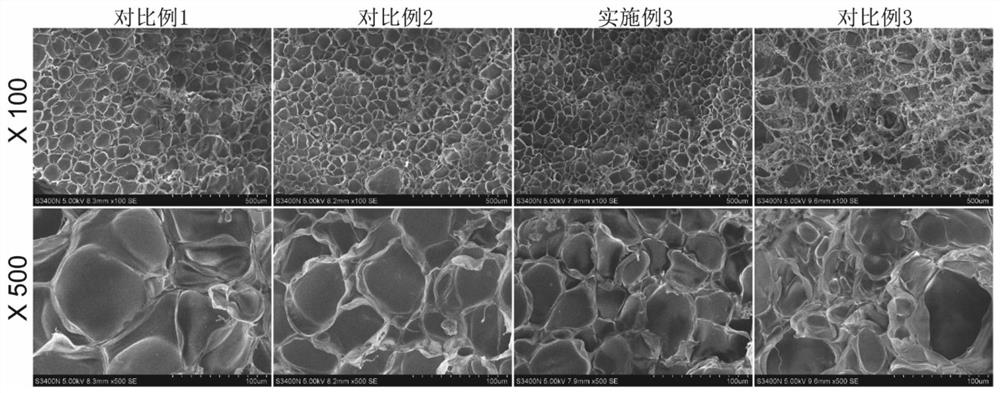

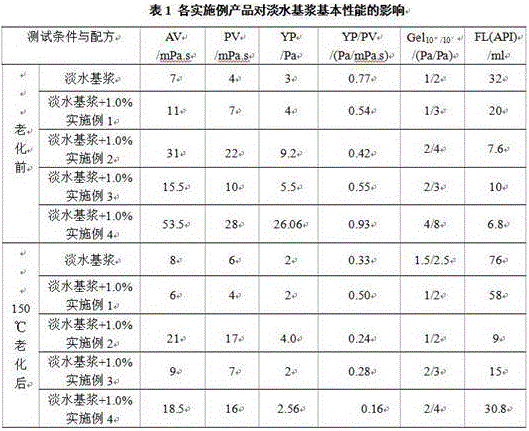

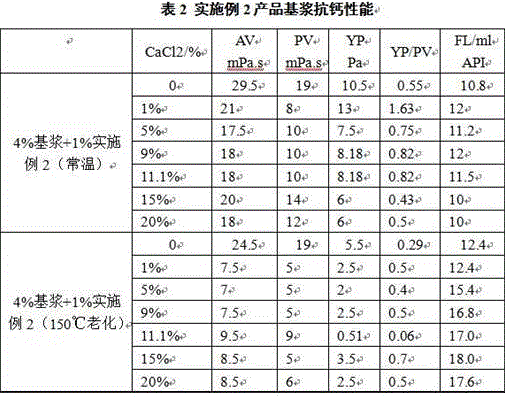

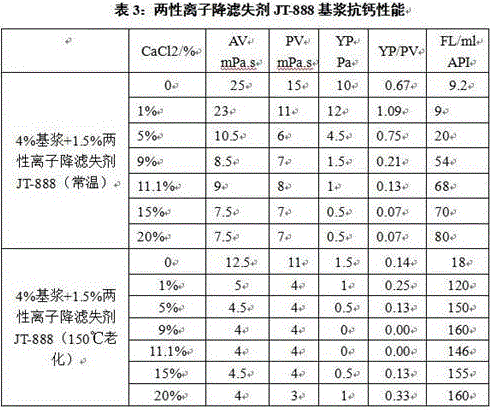

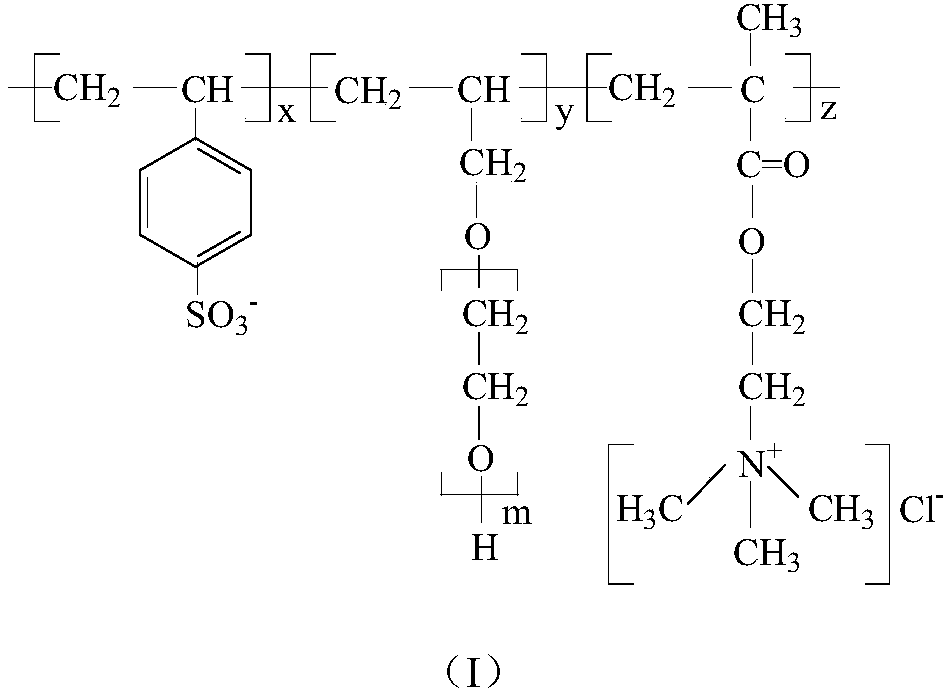

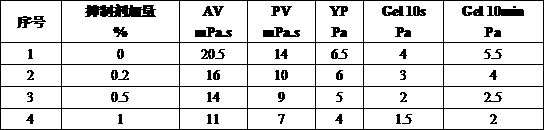

High temperature resistant amphoteric ion polymer fluid loss agent used for drilling fluid and preparation method thereof

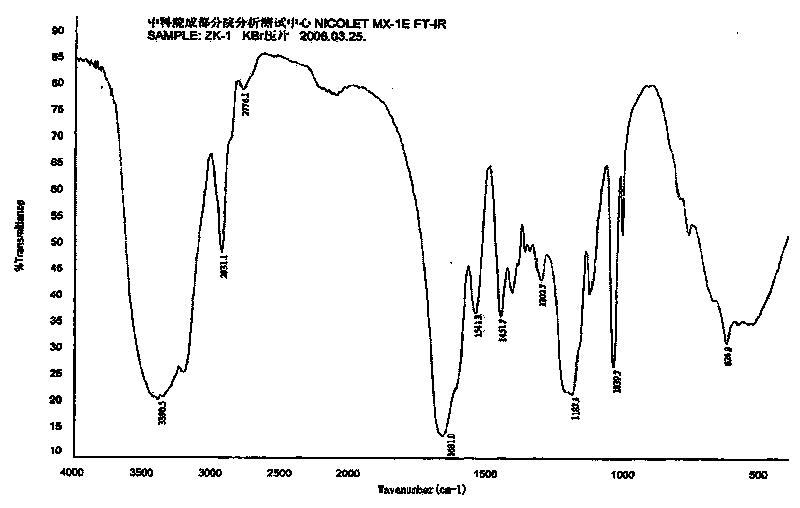

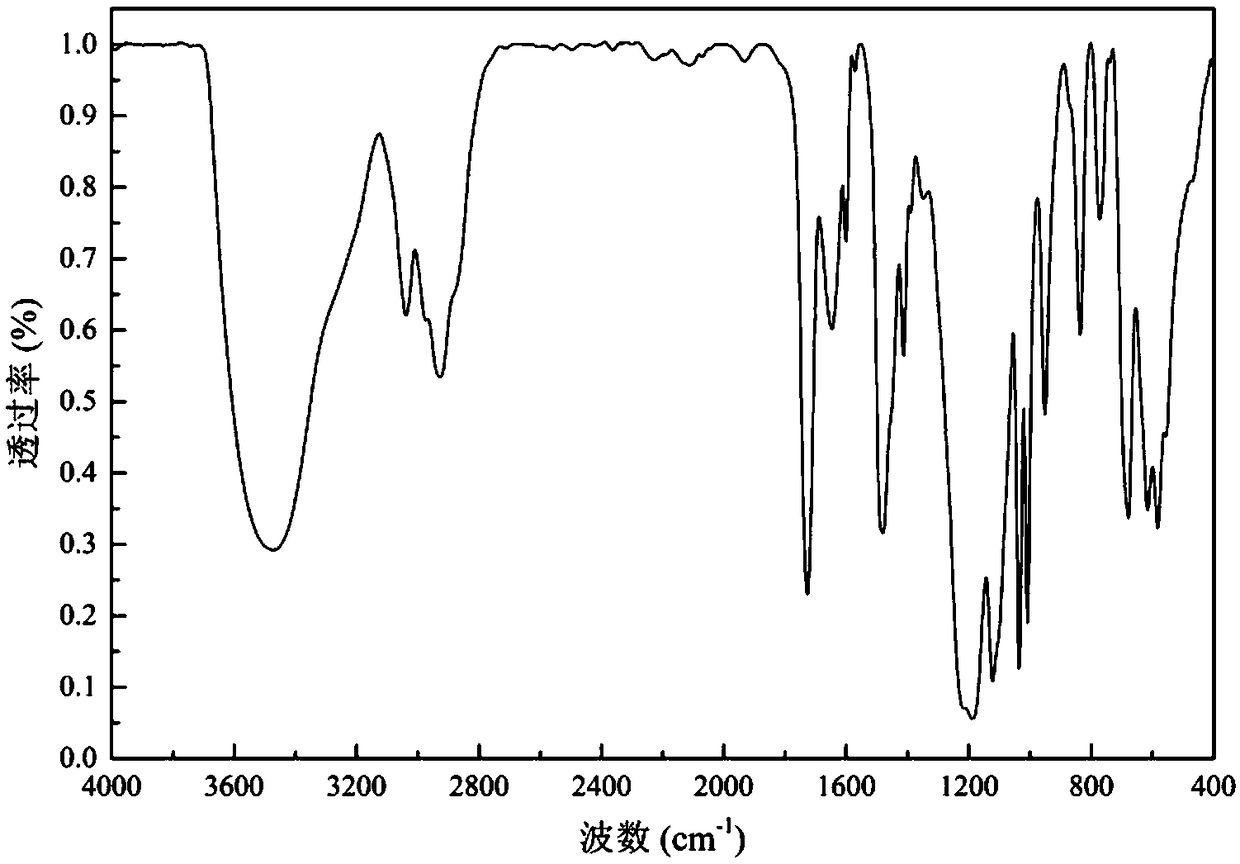

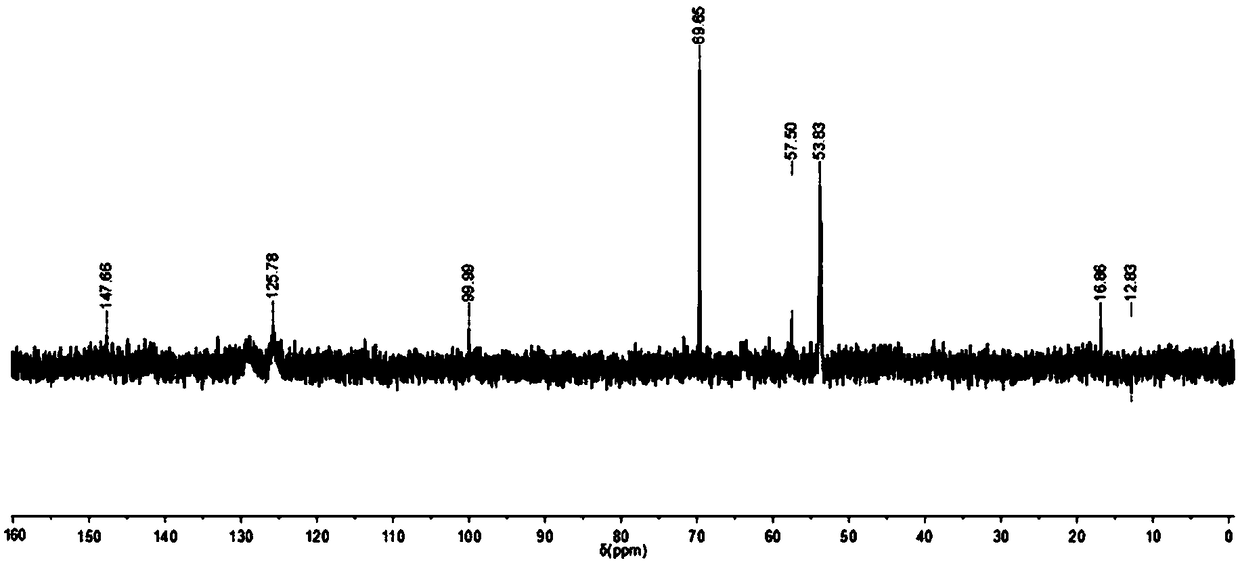

The invention relates to high temperature resistant amphoteric ion polymer fluid loss agent used for drilling fluid of a high temperature and high pressure drilling and a preparation method thereof. Four monomers, namely, acrylamide (AM), 2-acrylamide-2-methyl propane sulfonic acid (AMPS), dimethyl diallylammonium chloride (DMDAAC) and styrenesulfonate (SSS) are used as raw materials, wherein the mole ratio of AM:AMPS:DMDAAC:SSS is (9-11):(3-4):(0.5-1.5):(1.0-1.5); ammoniumpersulfate-sodium bisulfite as an initiator is added and solution is copolymerized through a polymerization method to compose the fluid loss agent. The fluid loss agent provided by the invention has the advantages of ideal high temperature resistant (more than 220 DEG C) reducing filtrate performance, shale inhibition performance and stable fluid rheology performance and simple preparation method, convenient operation and higher yield.

Owner:SOUTHWEST PETROLEUM UNIV

Magnesium aluminate spinel foamed ceramic filter as well as preparation method thereof

ActiveCN103553686APrevent plastic crackingImprove high temperature stabilityCeramicwareMg alloysSlurry

The invention relates to a magnesium aluminate spinel foamed ceramic filter which is excellent in high-temperature chemical stability and thermal shock resistance. A preparation method of the magnesium aluminate spinel foamed ceramic filter comprises the following steps: firstly, using water-base resin, a dispersing agent and water as a solvent, forming ceramic powder by using magnesium aluminate spinel powder, aluminum oxide powder and magnesium hydroxide powder, and mechanically stirring to prepare slurry; soaking polyurethane porous sponge serving as a carrier in slurry, pressing to remove excessive slurry to prepare a preform body, drying and sintering to obtain the magnesium aluminate spinel foamed ceramic filter. The foamed ceramic filter disclosed by the invention can satisfy rigorous requirements of filtering of molten magnesium alloy, has good high-temperature stability, does not pollute the alloy, has good filtering and adsorbing effect on inorganic impurities in the molten magnesium alloy, and is good in filtering and purifying effect, small in fluid resistance, and large in filtration yield; and good using effect is obtained through trial in casting production of metal magnesium and magnesium alloy.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

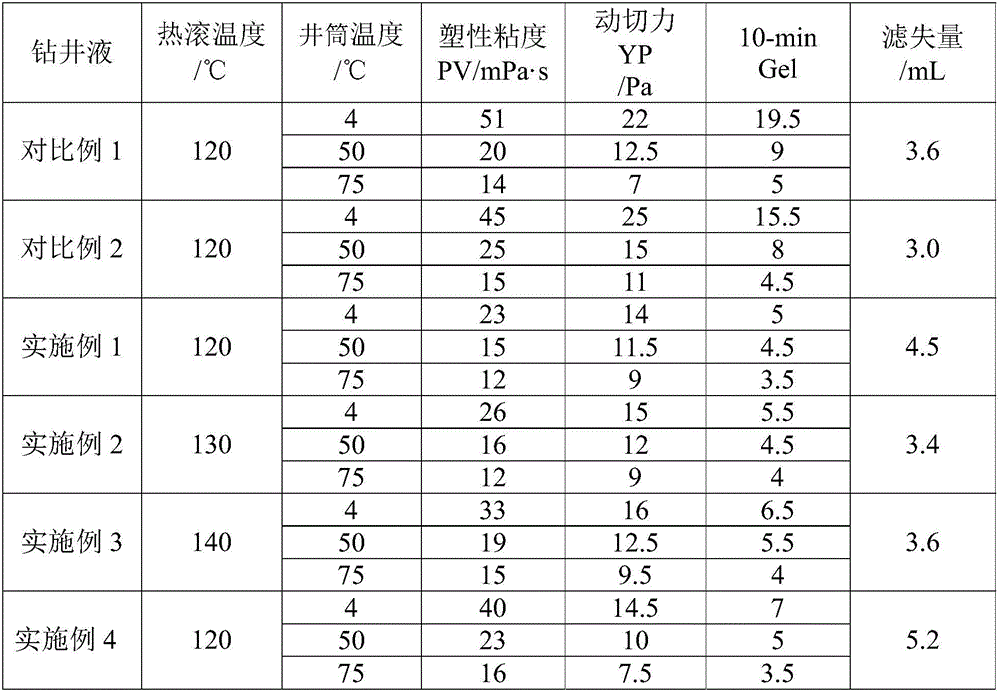

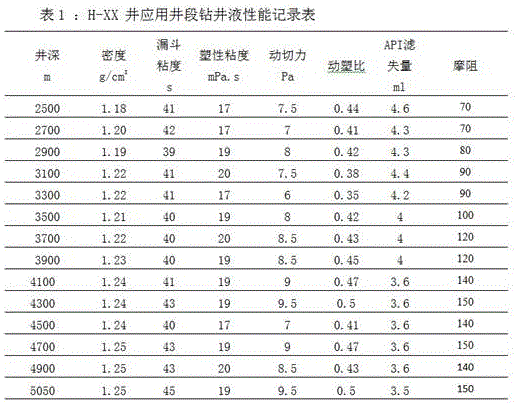

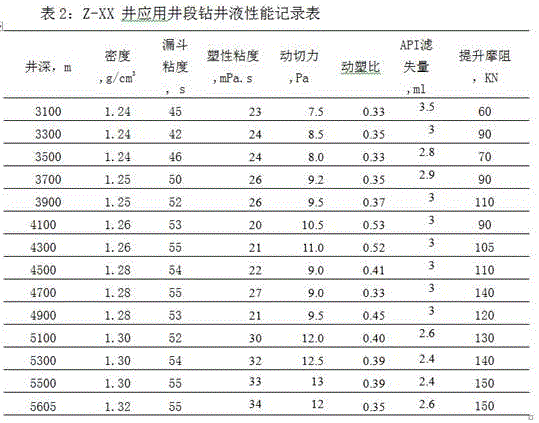

Water-based drilling fluid suitable for shale gas development

InactiveCN105255460AIncreased shale stabilityStable rheologyDrilling compositionShale gasDrilling fluid

The invention provides a water-based drilling fluid suitable for shale gas development. The water-based drilling fluid is prepared from the following raw materials in volume on the basis of water: 100 percent of water, 2 to 6 percent of lubricating agents, 1 to 5 percent of inhibitors, 1 to 5 percent of blocking anti-collapse agents, 1 to 5 percent of shale blocking agents, 1 to 5 percent of nanometer blocking agents, 1 to 3 percent of fluid loss additives, 1 to 3 percent of additives, 0 to 0.4 percent of shearing potentiator, 0.1 to 0.6 percent of pH regulator and 0 to 300 percent of weighting agents. The water-based drilling fluid has low filter loss, shale cracks can be effectively blocked, and the stability of a well wall is increased; the lubricating performance is good, and the problems of friction and torque caused by a shale gas horizontal well are preferably solved; the rheological property is excellent.

Owner:SINOPEC JIANGHAN OILFIELD SERVICE CORP +1

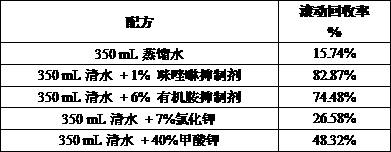

Low-molecular environmentally-friendly fracturing fluid and use of recovery liquid thereof

The invention relates to a low-molecular environmentally-friendly fracturing fluid and use of recovery liquid, wherein the fracturing fluid comprises low molecular thickening agent, cross linking agent, water, pH regulator, crude oil demulsification agent, surface active agent, clay stabilizer and bactericidal agent, thus no glue-breaking agent is needed, and very good rheological property can be achieved.

Owner:CHANGQING GASOLINEEUM EXPLORATION BUREAU

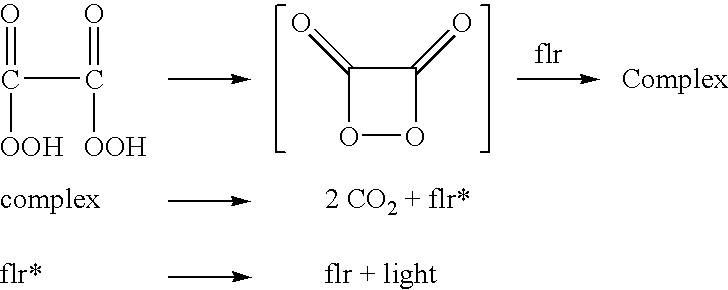

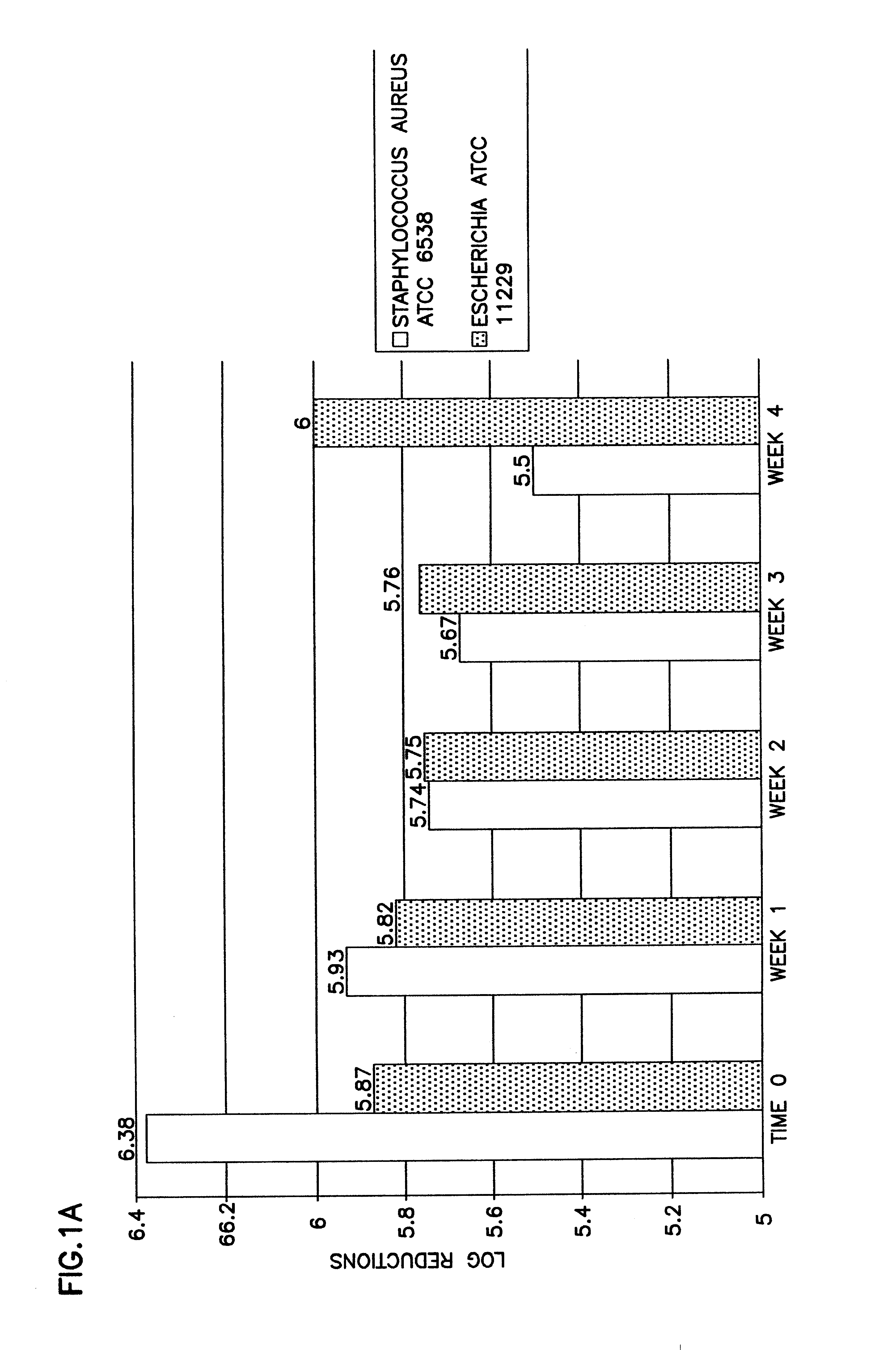

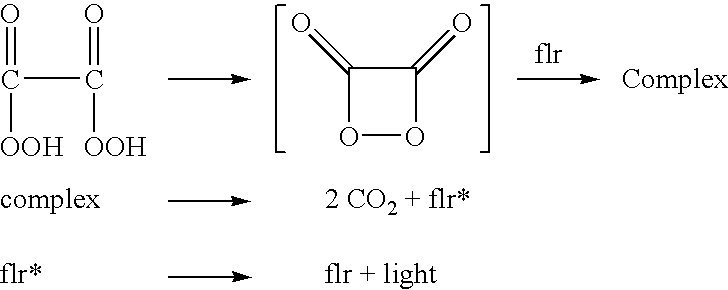

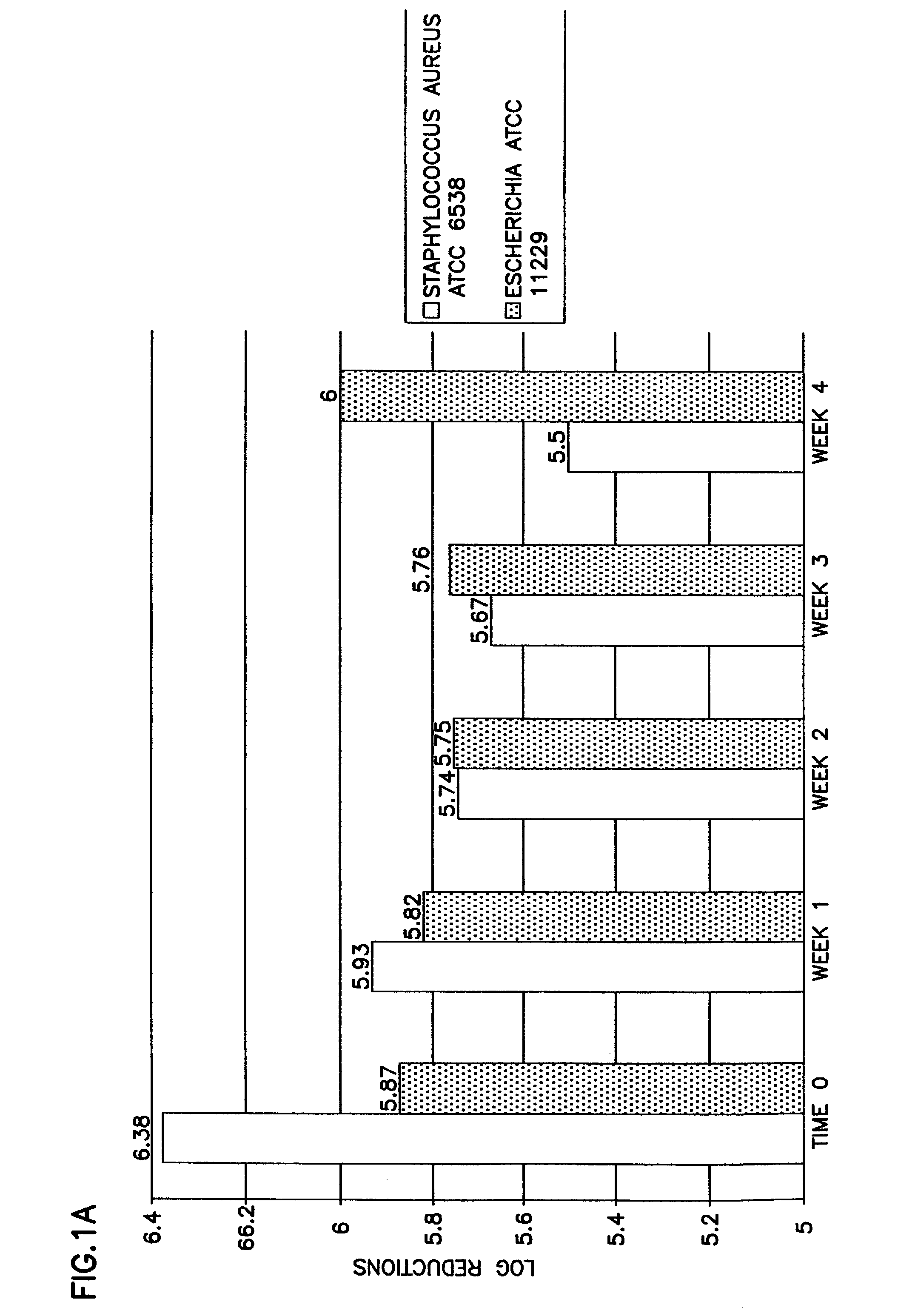

Acidic aqueous chlorite teat dip with improved visual indicator stability, extended shelf life, sanitizing capacity and tissue protection

InactiveUS6699510B2Enhanced softening and smoothing and characterImmobilizes mastitis treatmentAntibacterial agentsBiocideChlorine dioxideTissue protection

The mastitis control teat dip composition having a visible indicator aspect of the invention provides a softening, soothing, smoothing, relaxing property, a rapid initial kill, a useful highly pseudoplastic rheology, a barrier / film-forming capacity, a unique antimicrobial composition that is stable over an extended period of time, and unexpected long term microbial control when compared to the prior art materials disclosed in patents and used in the marketplace. The indicator aspect provides ease of visually detecting the material on the animal skin and can indicate efficacy of the material. The compositions of the invention are made by combining an aqueous liquid composition containing the visual indicator combined with the organic components which can be combined with a simple aqueous solution of a salt of chlorous acid, preferably an alkali metal chlorite. The materials after they are combined and blended into a smooth viscous material containing an emollient package generates active antimicrobial chlorine dioxide and can be immediately contacted with the target animals. The compositions of the invention provide stable visual indication, rapid initial kill, consistent long term kill with chemical and rheological stability.

Owner:ECOLAB USA INC

Low water stannous fluoride plus zinc citrate dentifrice with improved stability, rheology, and efficacy

ActiveUS9968803B2Efficient deliveryImproved rheological propertiesAntibacterial agentsCosmetic preparationsBULK ACTIVE INGREDIENTActive ingredient

A dentifrice composition having a low water phase comprising effective amounts of polyphosphate and ionic active ingredients.

Owner:COLGATE PALMOLIVE CO

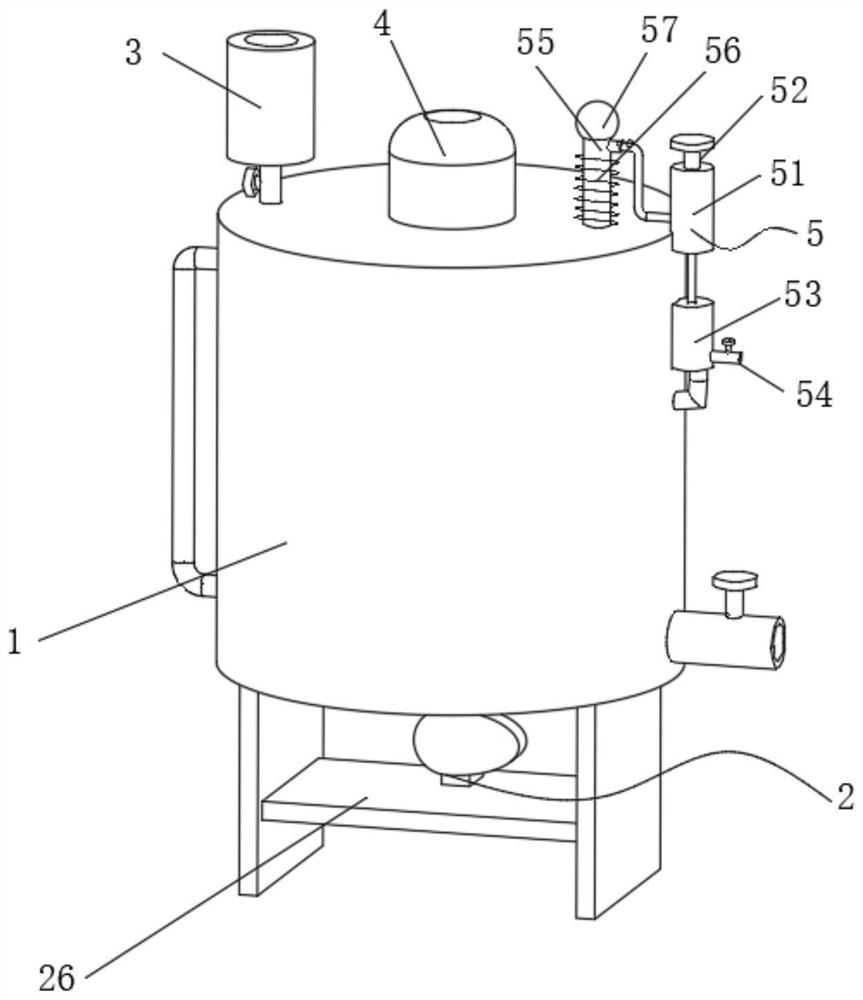

Oil-based polyamide assistant emulsifier for drilling fluids, and preparation method thereof

InactiveCN105907381AStrong emulsifying abilityHigh temperature resistanceDrilling compositionPolymer sciencePolyamide

The invention discloses an oil-based polyamide assistant emulsifier for drilling fluids, and a preparation method thereof. The oil-based polyamide assistant emulsifier is prepared through a dehydration polycondensation reaction of diacid anhydrides, polyalkenepolyamine and aliphatic acid, wherein a molar ratio of the diacid anhydrides to polyalkenepolyamine to aliphatic acid is 1:1:1.4-4. The emulsifier is a macromolecular polymer surfactant, per unit mass of the emulsifier contains more lipophilic and hydrophilic groups, and the emulsifying efficiency is high; hydrophilic groups in the molecular structure is an amido structure, so the emulsifier has good high-temperature resistance; and the emulsifier and a wetting agent have synergism, so the wetting reversal of solid phase surface is facilitated.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

Acidic aqueous chlorite teat dip with improved visual indicator stability, extended shelf life, sanitizing capacity and tissue protection

InactiveUS20030206971A1Reduce wasteReducing costly disposalUltrasonic/sonic/infrasonic diagnosticsAntibacterial agentsChlorine dioxideTissue protection

The mastitis control teat dip composition having a visible indicator aspect of the invention provides a softening, soothing, smoothing, relaxing property, a rapid initial kill, a useful highly pseudoplastic rheology, a barrier / film-forming capacity, a unique antimicrobial composition that is stable over an extended period of time, and unexpected long term microbial control when compared to the prior art materials disclosed in patents and used in the marketplace. The indicator aspect provides ease of visually detecting the material on the animal skin and can indicate efficacy of the material. The compositions of the invention are made by combining an aqueous liquid composition containing the visual indicator combined with the organic components which can be combined with a simple aqueous solution of a salt of chlorous acid, preferably an alkali metal chlorite. The materials after they are combined and blended into a smooth viscous material containing an emollient package generates active antimicrobial chlorine dioxide and can be immediately contacted with the target animals. The compositions of the invention provide stable visual indication, rapid initial kill, consistent long term kill with chemical and rheological stability.

Owner:ECOLAB USA INC

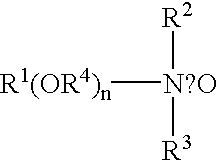

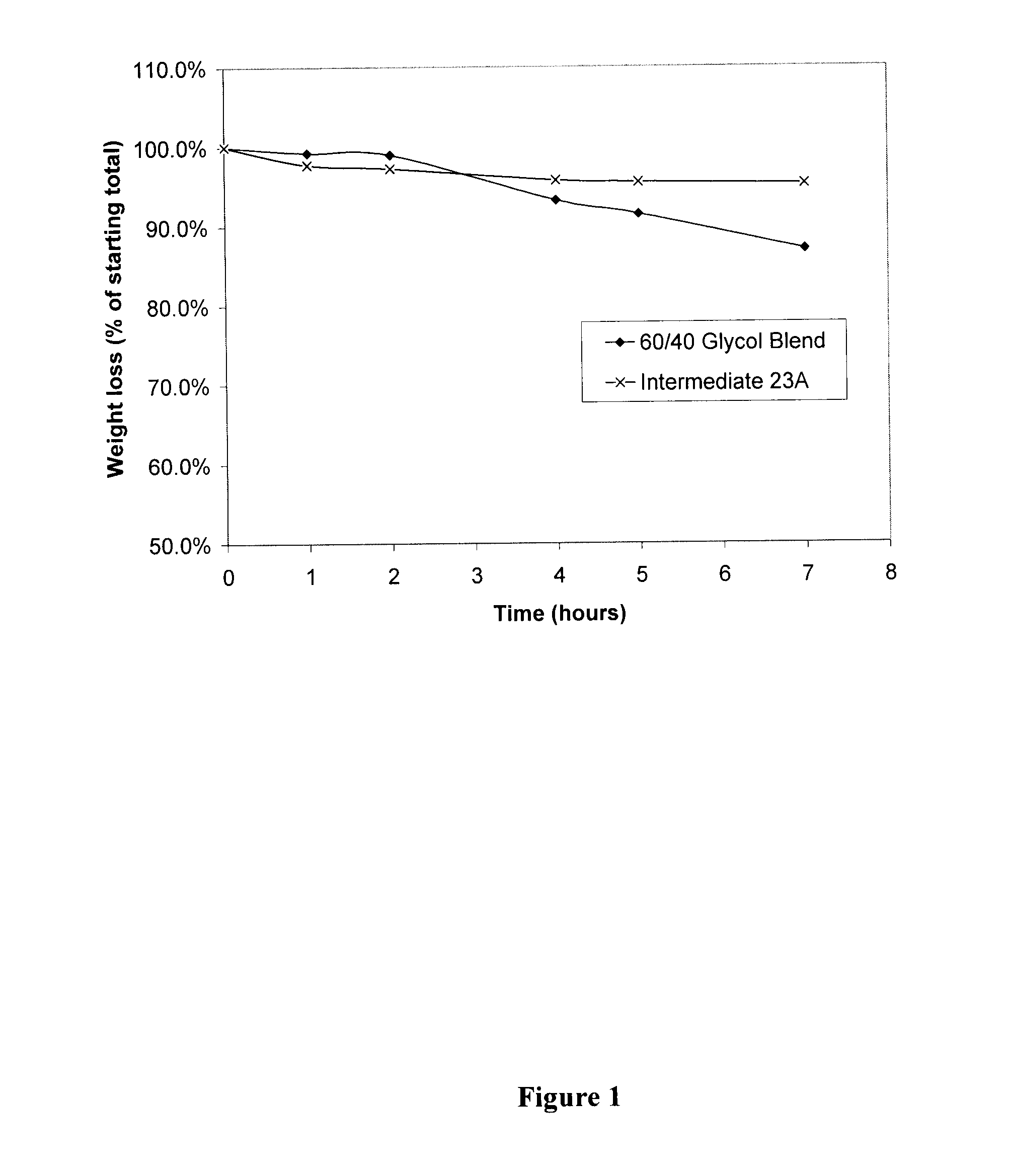

Esters for drilling emulsions and metal working fluids

ActiveUS20150210914A1Improved filtrate propertyStable rheologyTransportation and packagingMixingAlcoholEmulsion

The present invention relates to an emulsion comprising at least (a) an organic phase, (b) a water phase and (c) an ester based on an ether carboxylic acid and an alcohol. Also within the ambit of the invention is the use of an ester as defined in (c) as emulsifier, as a thickening agent and / or as an anti-foaming agent in particular in drilling emulsions and metal working fluids.

Owner:EMERY OLEOCHEMICALS GMBH

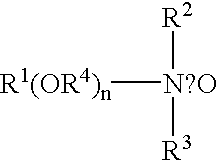

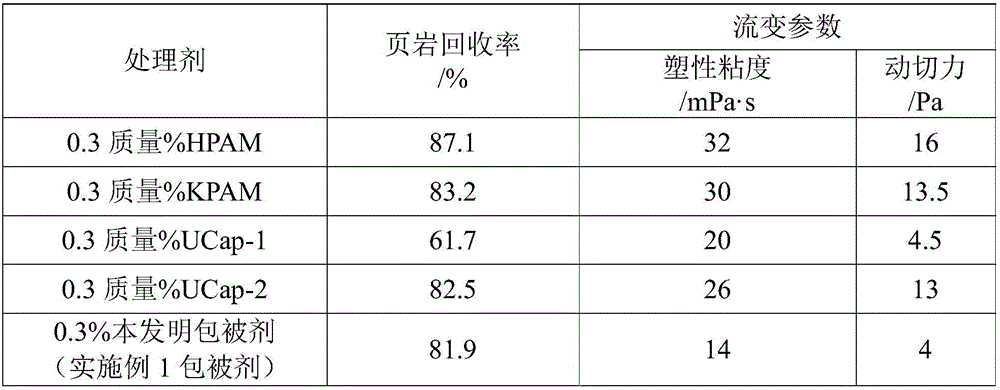

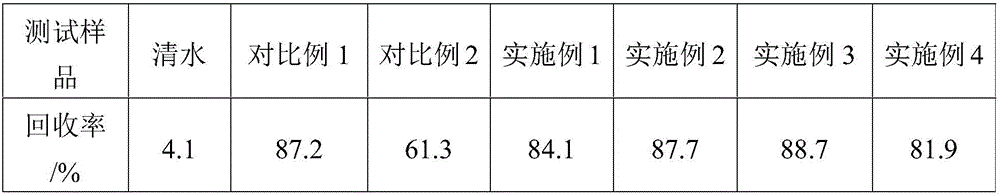

Coating agent and preparation method and application and drilling fluid used for petroleum drilling

ActiveCN106554462AAvoid instabilityAvoid severe viscosity build-up problems at low temperaturesDrilling compositionWell drillingPetroleum

The invention relates to the field of petroleum drilling, and concretely provides a coating agent and a preparation method and an application thereof and drilling fluid, the coating agent contains an acrylamide monomer structural unit shown as a formula (I), an anti-temperature monomer structural unit shown as a formula (II), and a cation monomer structural unit shown as a formula (III), wherein, R1 and R2 are respectively independent as H, C1-C15 straight chain or branched chain alkyl, and R3 is H or C1-C5 straight chain or branched chain alkyl. The drilling fluid has strong inhibition performance and stable rheological property.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

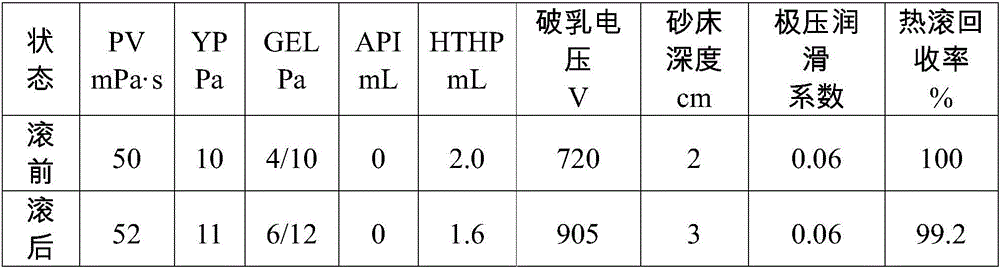

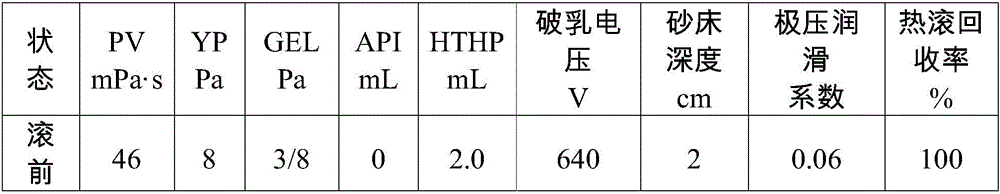

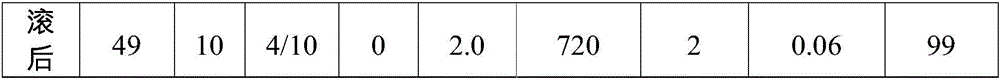

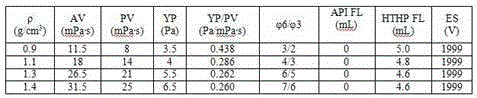

High water phase oil-based drilling fluid applicable to long horizontal section of shale gas and preparation method of high water phase oil-based drilling fluid

InactiveCN106634888ALow oil-to-water ratioReduce oil phase contentDrilling compositionAlkalinityFiltration

The invention provides a high water phase oil-based drilling fluid applicable to a long horizontal section of shale gas and a preparation method of the high water phase oil-based drilling fluid. The drilling fluid is prepared from oil, water, a high-efficiency emulsifier, a nanometer plugging agent, a tackifying and shear strength improving agent, a filtrate reducer, an activity control agent, an alkalinity regulator and a weighting agent, wherein a volume ratio of oil to clear water is 40:60-70:30, 3-5 g of the high-efficiency emulsifier, 2-4 g of the nanometer plugging agent, 1-3 g of the tackifying and shear strength improving agent, 3-5 g of the filtrate reducer, 15-20 g of the activity control agent, 2-5 g of the alkalinity regulator and 20-200 g of the weighting agent are added to every 100 mL of an oil and clear water mixed solution. A product of the drilling fluid has the characteristics of low oil-water ratio, high inhibition property, low shear rate, high viscosity, high electrical stability, high sealing property, good lubricity, low filtration loss, simple formula composition, and has the advantages of being environment-friendly, efficient, low in cost and the like.

Owner:中石化石油工程技术服务有限公司 +1

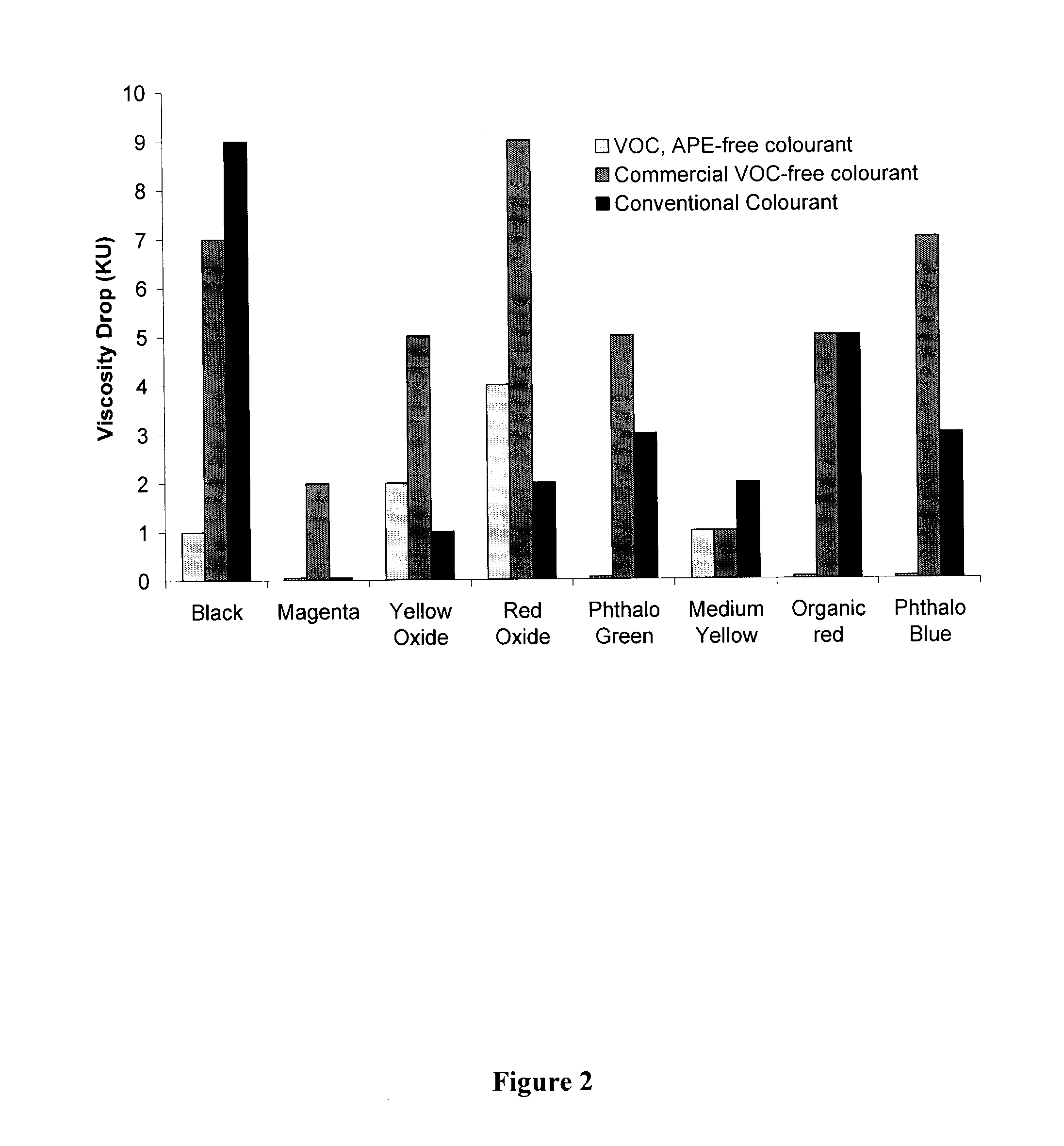

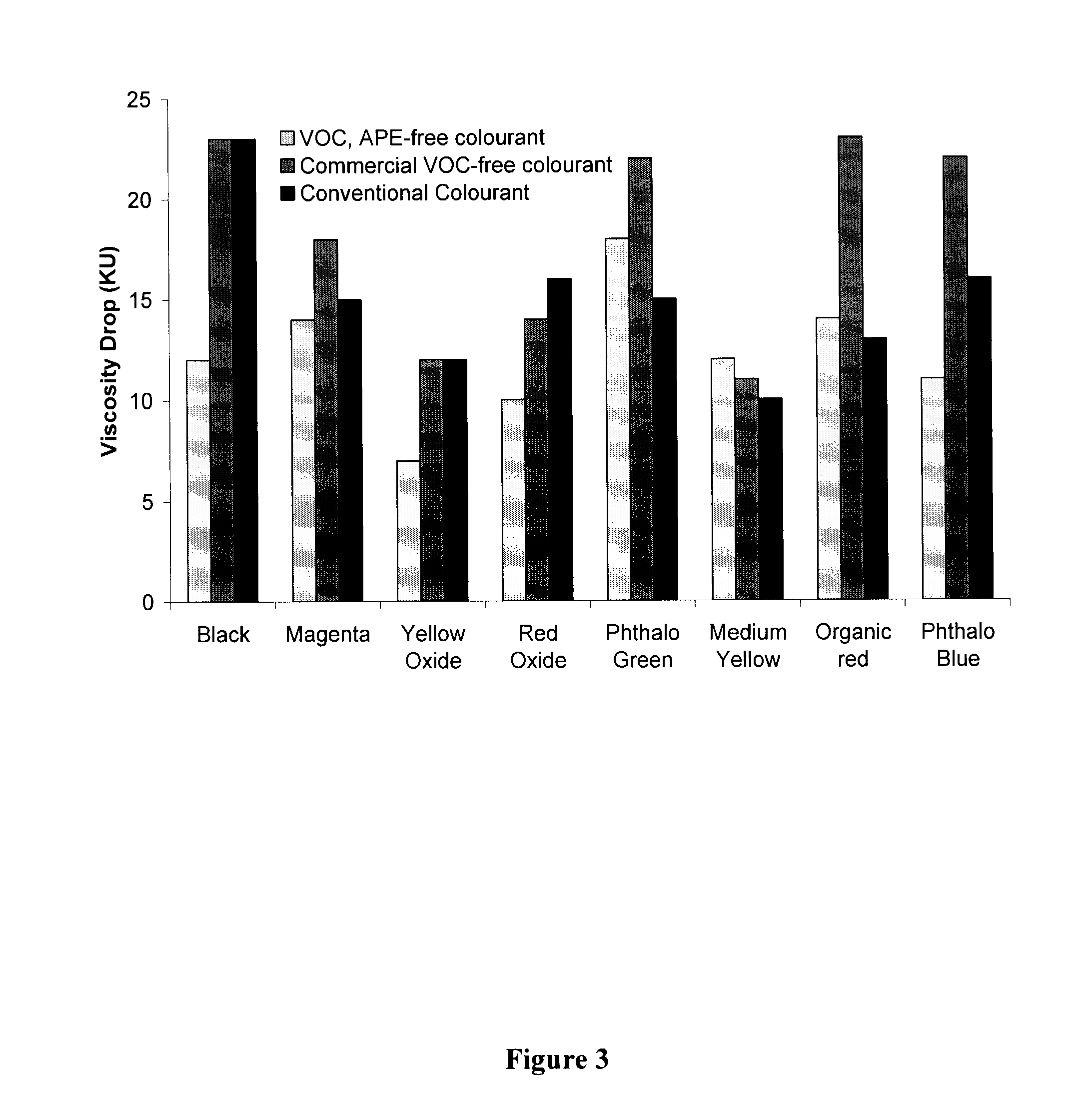

Low VOC and APE free universal paint colourant compositions

ActiveUS9080030B2Many typesSimple preparation processTransportation and packagingMixingWater basedOrganic solvent

The present invention relates to a universal colorant composition that is essentially free of volatile organic compounds (VOCs) and alkyl phenol ethoxylates (APEs). The present invention comprises a dispersing vehicle that comprises a low molecular weight carbamide compound, a C3-C5 polyalcohol, a polyethylene glycol, and optionally water. The dispersing vehicle provides excellent humectant and dispersing properties. The colorant composition comprising the dispersing vehicle maintains its stability and functionality following extended exposure to the atmosphere and / or temperature extremes. The present invention provides a colorant composition that is universally compatible with a wide variety of aqueous / water-based and organic solvent-based paints and coatings, while exhibiting physical and performance characteristics that are comparable to conventional colorant compositions that contain VOCs and APEs. A process for preparing a universal colorant composition for tinting a wide variety of aqueous / water-based and organic solvent-based paints and coatings is also provided.

Owner:LORAMA

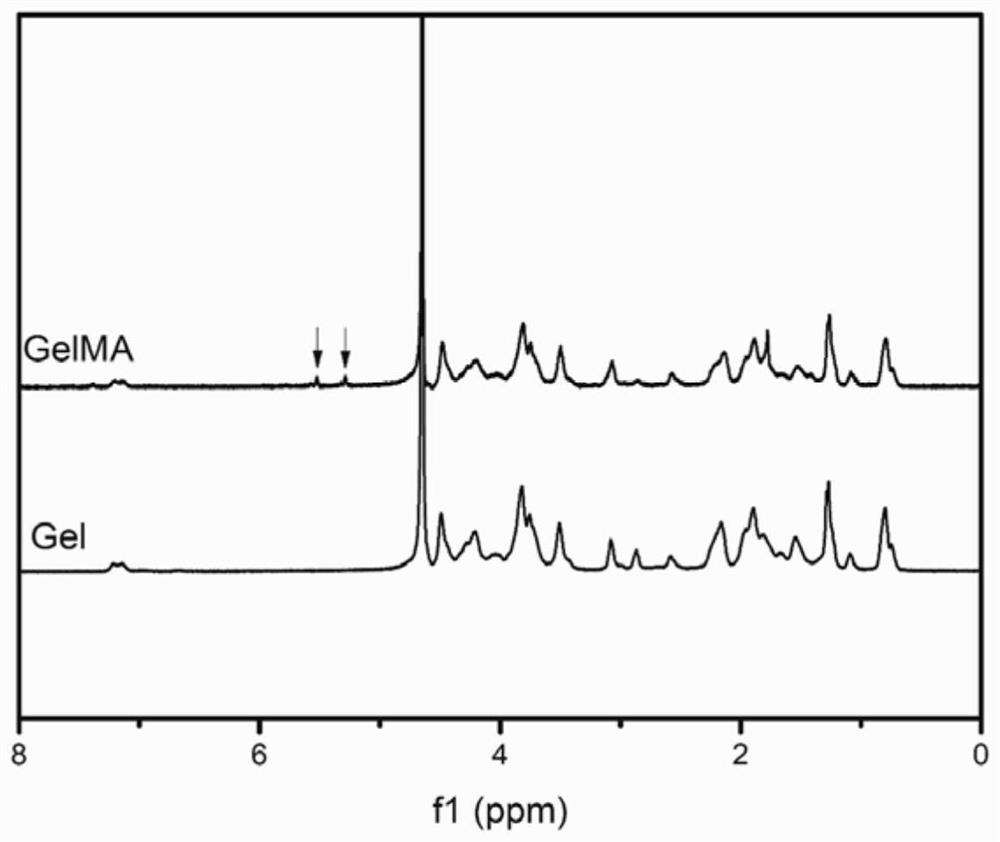

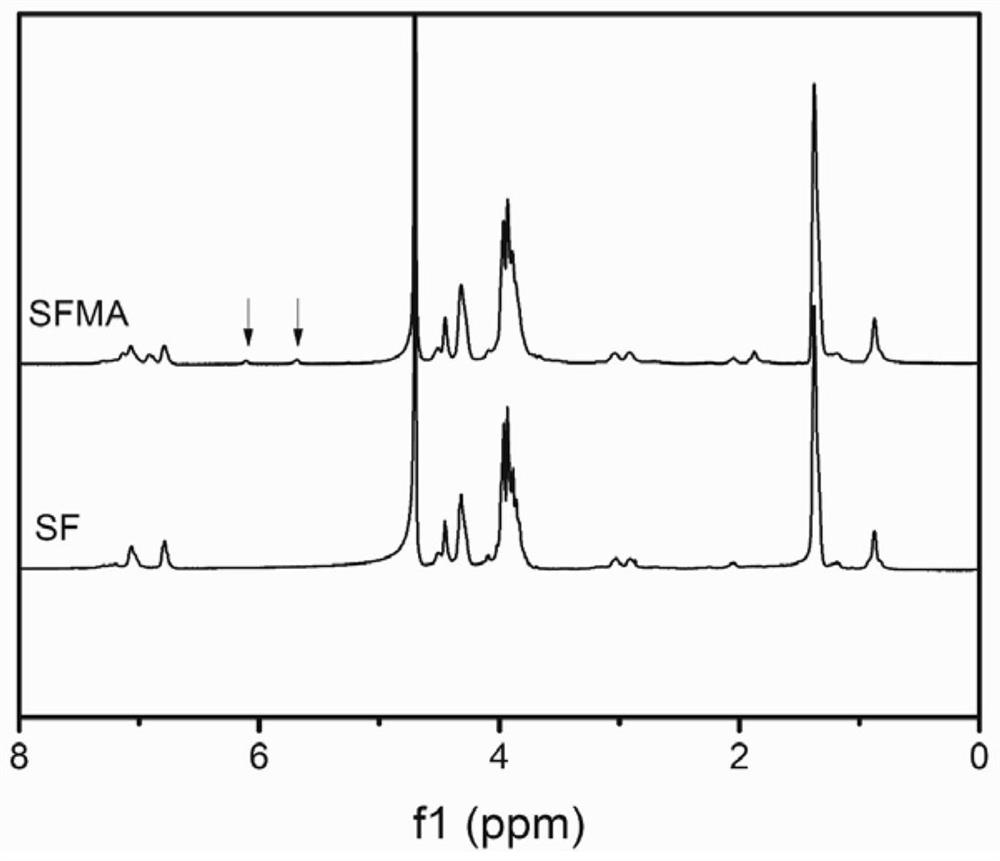

Gelatin-silk fibroin hydrogel loaded with adipose-derived stem cells and plasma as well as preparation method and application of gelatin-silk fibroin hydrogel

The invention relates to the technical field of medical biological materials, and particularly discloses gelatin-silk fibroin hydrogel loaded with adipose-derived stem cells and plasma as well as a preparation method and application of the gelatin-silk fibroin hydrogel. The hydrogel is prepared from the following materials: methacrylic acid gelatin, methacrylic acid silk fibroin and a photoinitiator, and in the hydrogel, the mass ratio of the methacrylic acid gelatin to the methacrylic acid silk fibroin to the photoinitiator is (100-150):(100-150):(0.5-1). The hydrogel prepared by the invention not only has stable rheological property, slow biodegradability and better mechanical property, but also can continuously release growth factors (the continuous release rate reaches 14 days) and obviously promote the proliferation performance of the adipose-derived stem cells, and the adipose-derived stem cells wrapped in the hydrogel have higher survival time, so that the growth factors can be continuously released, nd continuous proliferation can be realized in the hydrogel.

Owner:BEOGENE BIOTECH GUANGZHOU

Low Water Dentifrice Compositions

ActiveUS20180147125A1Stable rheologyHigh viscosityCosmetic preparationsToilet preparationsPolyphosphateNuclear chemistry

The present disclosure provides low water dentifrice compositions comprising an effective amount of a zinc ion source, a stannous ion source, a polyphosphate and an acid in a calcium pyrophosphate base. The acid lowers the pH of the composition to enable stabilization of the metal ions and extend shelf-life of the composition.

Owner:COLGATE PALMOLIVE CO

Preparation method of drilling fluid diluent compound methyl silicate

ActiveCN103059821AEnhanced inhibitory effectLow viscosityDrilling compositionPtru catalystSilicic acid

The invention relates to a preparation method of a drilling fluid diluent compound methyl silicate. The method comprises the following steps: (1) preparing methyl silicate: adding water in a reactor, then adding alkali, heating to 70-90 DEG C after the alkali is dissolved, adding methyl silicic acid, continuing heating to 90-110 DEG C, and reacting to generate methyl silicate, wherein the weight ratio of water to methyl silicic acid to alkali is 1: 0.1-0.3: 0.2-0.6; and (2) preparing compound methyl silicate: adding sodium silicate and low molecular weight polyacrylate in generated methyl silicate, uniformly stirring sufficiently, adding an organic tin catalyst, and reacting for 3-5 hours at 90-120 DEG C to obtain a liquid diluent product compound methyl silicate with effective substance content of 25-40%. The drilling fluid diluent methyl silicate has the advantages of good diluting effect, low cost, wide application range, and long stabilization time, and can resist high temperature of more than 150 DEG C.

Owner:DAQING HEZHENG CHEM

Preparation method of filtrate reducer for drilling fluid

ActiveCN105754564AStable rheologyImprove fermentation performanceDrilling compositionWater bathsWater based

The invention discloses a preparation method of a filtrate reducer for drilling fluid.The preparation method of the filtrate reducer for the drilling fluid is characterized by comprising the following steps: 1, dissolving 2.5-3.0 parts by weight of an alkaline substance A and 0.6-0.75 part by weight of metallic oxides in 100 parts by weight of water, and stirring until the alkaline substance and the metallic oxides are dissolved fully to obtain a solution a; b, adding 9-11 parts by weight of monomer C in the solution a, and stirring until the monomer C is dissolved fully to obtain a solution b; c, adding 18-22 parts by weight of monomer D into the solution, and stirring until the monomer D is dissolved fully to obtain a solution c; d, adding 0.9-1.0 part by weight of monomer E into the solution c, and stirring until the monomer E is dissolved fully to obtain a solution d; e, continuing stirring, and heating the solution d in water bath until the temperature reaches 70+ / - 5 DEG C; and f, maintaining the temperature to be 70+ / - 5 DEG C, slowly dropwise adding 0.08-0.1 part by weight of an initiator F into the solution d while stirring, and reacting for 4-5 hours to obtain a preliminary product.The filtrate reducer prepared by the method seldom affects the performance of the water-based drilling fluid, and resistance of the water-based drilling fluid to ultra-high calcium pollution can be enhanced effectively.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

High-temperature-resistant filtrate reducer for drilling fluid and preparation method thereof

ActiveCN109852353AGood filter loss reduction effectStrong ability to seal cracksDrilling compositionPolymer scienceFiltration

The invention discloses a high-temperature-resistant filtrate reducer for drilling fluid. The high-temperature-resistant filtrate reducer is prepared from the following raw materials in parts by weight: 35-55 parts of synthetic resin, 15-25 parts of aldehyde ketone resin, 45-65 parts of sulfonated asphalt formed by sulfonating natural asphalt, 5-15 parts of an initiator B, 10-20 parts of nano calcium carbonate, and 60-80 parts of an alkene monomer polymer. The invention also discloses a preparation method of the high-temperature-resistant filtrate reducer. The preparation method comprises thefollowing steps: stirring the sulfonated asphalt and the alkene monomer polymer at 45-60 DEG C for 30-40 minutes; adding an initiator B, stirring the components for 2-3 hours, then adding nano calciumcarbonate, heating the mixture to 95-120 DEG C, then adding synthetic resin and aldehyde ketone resin, stirring the mixture, carrying out heat preservation reaction at 100-110 DEG C for 4-5 hours, and drying the reaction product to obtain the high-temperature-resistant filtrate reducer. The high-temperature-resistant filtrate reducer has the advantages of excellent filtration reduction performance, stronger crack plugging capability, stable mud rheological property, stable well wall and excellent high-temperature resistance and salt resistance.

Owner:北京宏勤石油助剂有限公司

Oil-based drilling fluid and its preparation method

InactiveCN103911132AImprove stabilityEnhanced inhibitory effectDrilling compositionOrganoclayOil phase

The invention discloses an oil-based drilling fluid and its preparation method. The waste edible oil oil-based drilling fluid comprises the ingredients of waste edible oil, sulfite, a main emulsifier, an auxiliary emulsifier, organoclay, a filtrate reducer, a wetting agent and a barite; the preparation method of the waste edible oil oil-based drilling fluid comprises the following steps: preparing an oil phase by waste edible oil and sulfite, and then adding the main emulsifier, the auxiliary emulsifier, the organoclay, the filtrate reducer, the wetting agent and barite. The prepared trench oil oil-based drilling fluid takes waste edible oil as a base oil to substitute diesel oil or crude oil, the cost is low, the environment is friendly, the well wall stability is good, the inhibition performance is strong, lubrication performance and rheological performance are excellent, anti-sloughing inhibition performance and high temperature stability are good, construction requirement for the drilling well can be better satisfied, and the oil-based drilling fluid and its preparation method can provide a new approach for using the waste edible oil in the reasonable mode.

Owner:CNPC SICHUAN GASOLINEEUM GEOPHYSICAL PROSPECTING ENG TECH RES INST

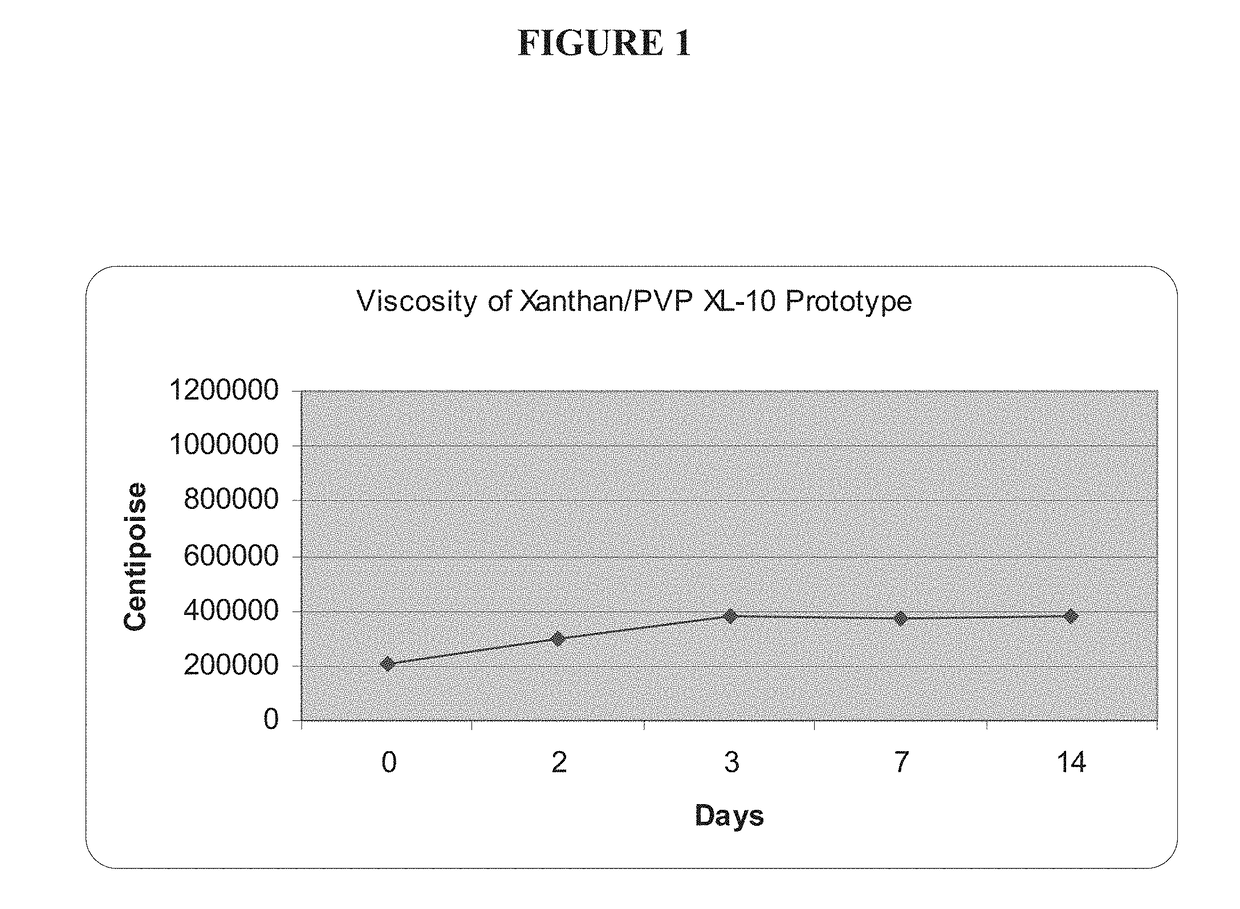

Spacer Fluid Additive

A spacer fluid comprises a fluid and a viscosity agent. The viscosity agent is a mixture of at least two polyvinylalcohol compositions. A first polyvinylalcohol composition comprises polyvinylalcohols having a first degree of hydrolysis and a second polyvinylalcohol composition comprises polyvinylalcohols having a second degree of hydrolysis. The first and second degrees of hydrolysis are substantially different such that the rheology of the spacer fluid is stable during temperatures changes.

Owner:SCHLUMBERGER TECH CORP

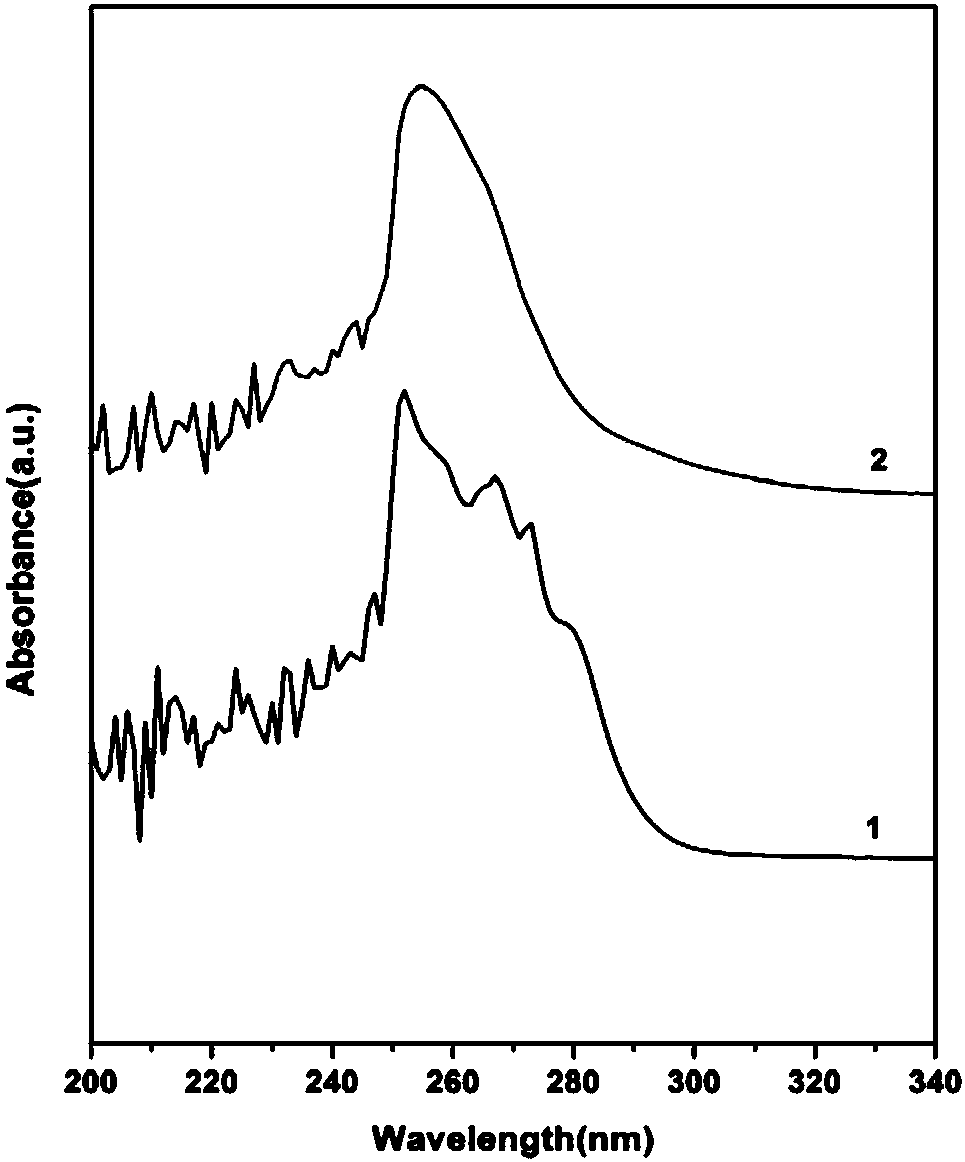

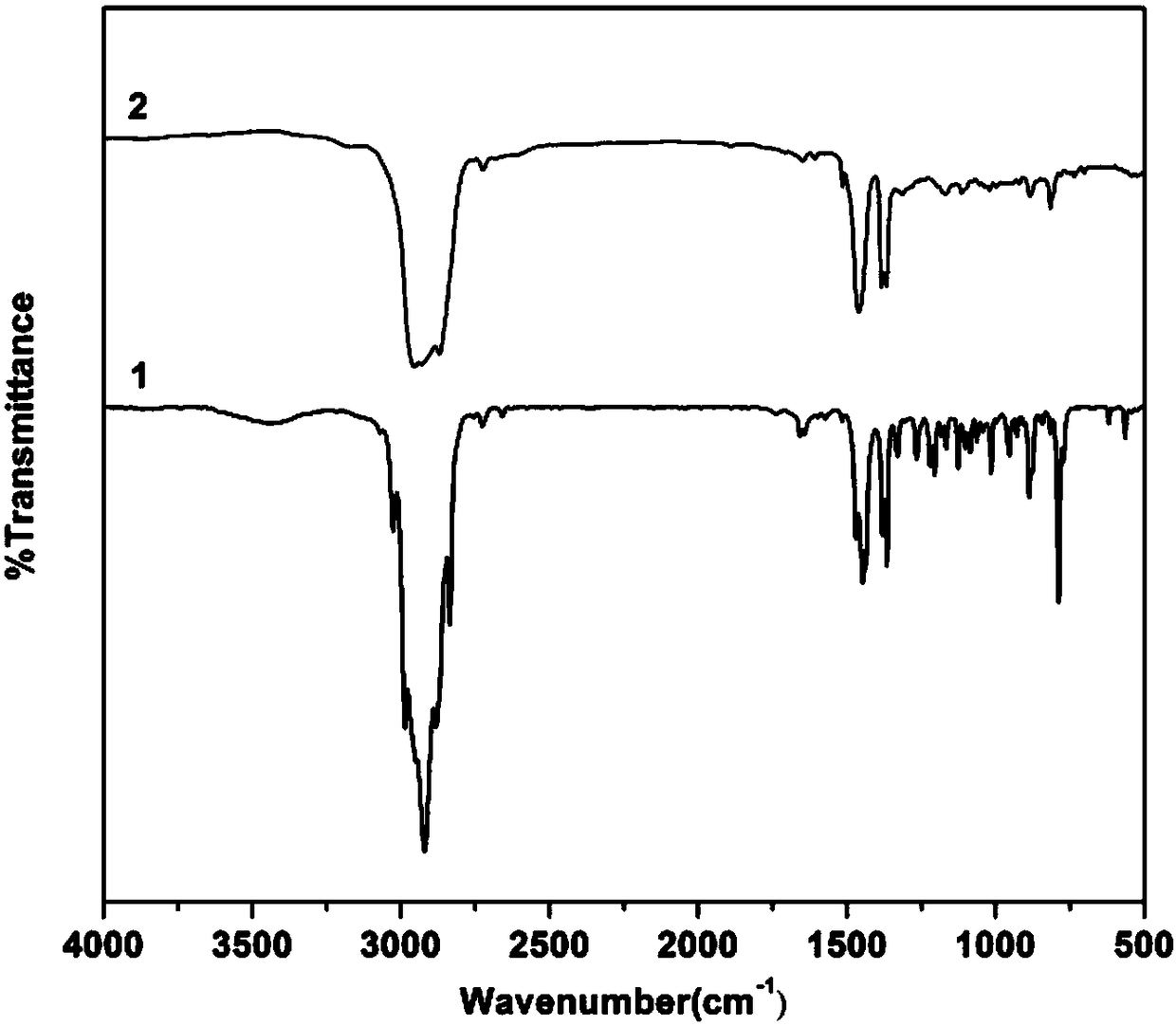

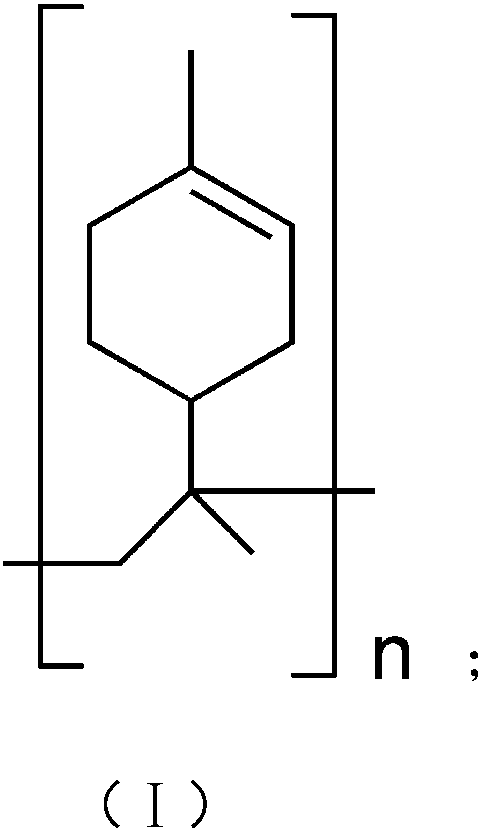

High-solid-content low-softening-point light-colored liquid terpene resin as well as preparation method and application thereof

The present invention discloses high-solid-content low-softening-point light-colored liquid terpene resin. The resin has a structure shown in a general formula (I), wherein n is an integer, and the value range of n satisfies a relationship of 2<=n<=5. The present invention also discloses a preparation method and application of the liquid terpene resin. The liquid terpene resin provided by the present invention has a solid content of 99% or more, a color (solid Gardner color scale) of less than a No.3 color and a softening point of less than 28 DEG C, can be used as a non-solvent type lubricantto be directly used in glass fibers to replace a paraffin latex liquid, can also be used as a liquid component of a tackifying emulsion to replace a low-molecular organic solvent or mineral oil, andis used as tackifying resin to be directly applied to a low-temperature-resistant adhesive.

Owner:吉安科茂树脂有限公司 +2

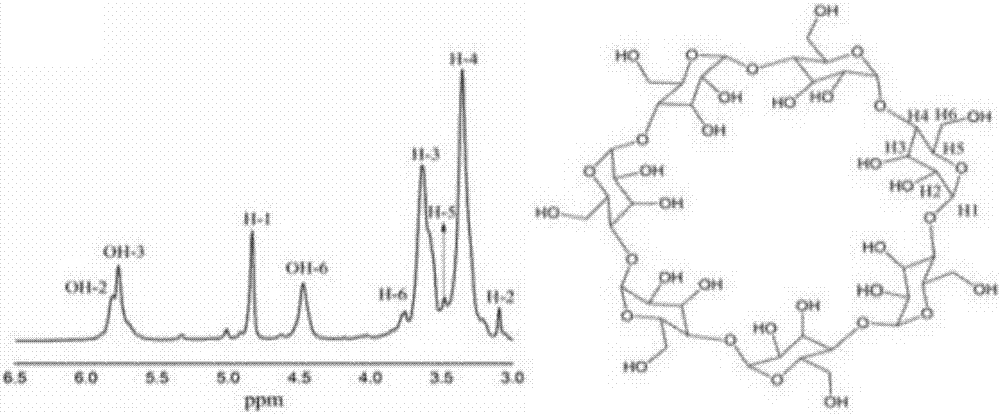

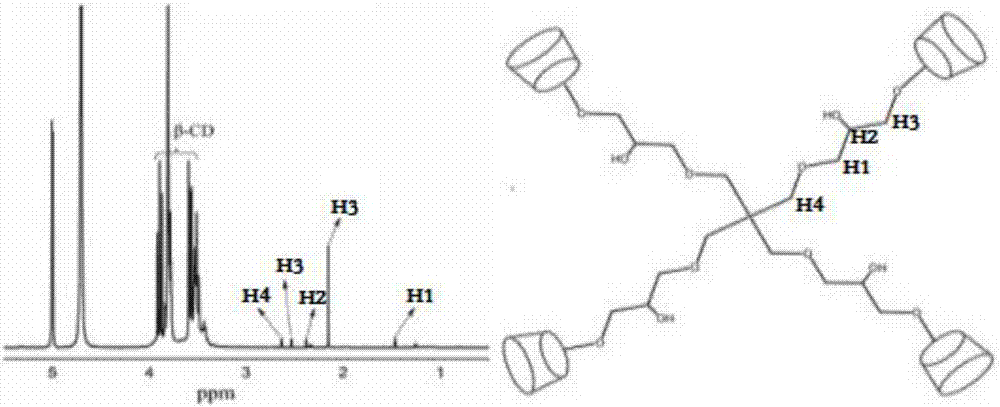

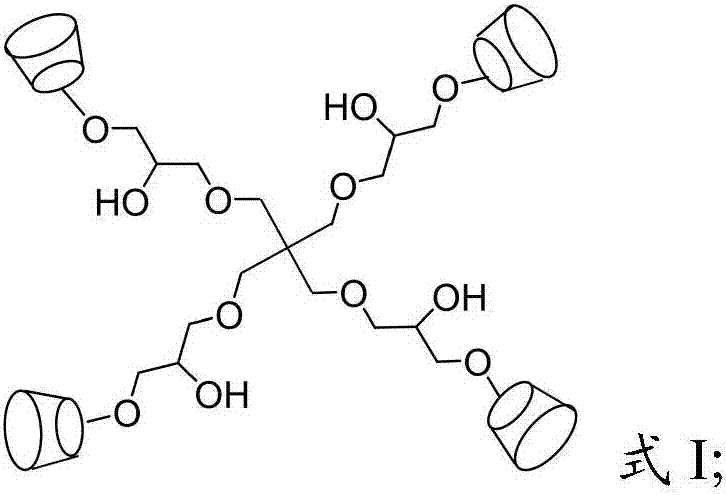

Neopentane beta-cyclodextrin hydroxypropyl tetraether and preparation method and application thereof

InactiveCN107011465AImprove high temperature resistanceImprove salt resistanceDrilling compositionSalt resistanceNeopentane

The invention provides neopentane beta-cyclodextrin hydroxypropyl tetraether and a preparation method and application thereof. The neopentane beta-cyclodextrin hydroxypropyl tetraether is a tetrapod compound, structurally comprises four beta-cyclodextrin groups, is high in beta-cyclodextrin group cavity proportion, can form a supermolecule clathrate compound with polymer or surfactant in drilling fluid, is high in high temperature resistance, good in salt resistance and stable in rheological property, can have an excellent filter loss lowering effect under the downhole high temperature condition and is promising in application prospect.

Owner:JILIN INST OF CHEM TECH

Low Water Stannous Fluoride Plus Zinc Citrate Dentifrice with Improved Stability, Rheology, and Efficacy

ActiveUS20180243589A1Efficient deliveryImproved rheological propertiesAntibacterial agentsCosmetic preparationsBULK ACTIVE INGREDIENTActive ingredient

A dentifrice composition having a low water phase comprising effective amounts of polyphosphate and ionic active ingredients.

Owner:COLGATE PALMOLIVE CO

Site treatment technique for environment-friendly polyether alcohol amine drilling fluid

ActiveCN106121568APulse signal transmission is normalStable rheologyFlushingSites treatmentSodium Bentonite

The invention relates to a site treatment technique for environment-friendly polyether alcohol amine drilling fluid and belongs to the field of exploitation of oil and gas fields. The site treatment technique for the environment-friendly polyether alcohol amine drilling fluid comprises the stage of mixing and converting, the stage of performance maintenance and the stage of well completion preparation. According to the stage of mixing and converting, drilling is conducted to a deep shale well section, the content of bentonite in original well slurry is reduced to be 20-30 g / l, formate and a tackifier are added into the well slurry till the mass content of the formate reaches 3% and the mass content of the tackifier reaches 0.2%, 400-500 kg of polyether polyols is supplemented into the drilling fluid each circulation cycle to guarantee that the mass content of the polyether polyols in the drilling fluid is 1.5%-2.0%, a capsulating agent, a polyamine inhibitor, a filtrate reducer and an anti-collapse agent are then sequentially added till the mass content of the capsulating agent in the drilling fluid reaches 0.2%-0.3%, the mass content of the polyamine inhibitor in the drilling fluid reaches 0.2%, the mass content of the filtrate reducer in the drilling fluid reaches 2% and the mass content of the anti-collapse agent in the drilling fluid reaches 1.5%, and are full circulated, the PH value of the mixture is regulated to 8-9 with caustic soda after system conversion is completed, and then the drilling fluid is thickened to the required density. The site treatment technique can be applied to drilling processes in different strata to achieve effective lubricating, prevent drilling tools from getting stuck and stabilize well walls.

Owner:CHINA PETROLEUM & CHEM CORP +1

Color paste formula for water-based paint and production process thereof

InactiveCN112409848AAchieve circular flowGood dispersionShaking/oscillating/vibrating mixersTransportation and packagingCarboxylic acidDetackifier

The invention discloses a color paste formula for a water-based paint. The color paste is prepared from the following raw materials in percentage by weight: 30-40% of color paste resin, 10-20% of toner, 2-4% of dispersing agent, 10-20% of titanium dioxide, 20-30% of deionized water, 5-8% of emulsifying agent, 2-3% of anti-sticking agent, 2-3% of thickening agent, 2-5% of carboxylic acid and 1-2% of defoaming agent. Deionized water is used as a solvent to play a role in dissolving all components, the emulsifying agent plays a role in emulsifying and providing a carrier, toner plays a role in coloring, the dispersing agent contributes to particle crushing of all the components, dispersion stability is guaranteed, all the components are evenly dispersed in a system, and the defoaming agent isused for preventing the foaming phenomenon in the stirring process. The color paste is high in coloring capacity, can be placed for a long time without mildewing, can keep stable rheological property, and is wide in application range, non-toxic and high in compatibility.

Owner:JIANGMEN SINOBLE TECH SHARES CO LTD

Polycarboxylate flow regulator for water-based drilling fluid and completion fluid with ultra-high temperature and ultra-high density and preparation method of polycarboxylate flow regulator

ActiveCN108641686AGood effectInhibition of hydration pulpingDrilling compositionWater basedUltra high density

The invention relates to a polycarboxylate flow regulator for water-based drilling fluid and completion fluid with ultra-high temperature and ultra-high density and a preparation method of the polycarboxylate flow regulator. A zwitterionic polycarboxylate multi-polymer with a comb type structure is produced from alkenyl benzene sulfonate, strongly hydrophilic cationic alkenyl quaternary ammonium salt and allyl polyoxyethylene ether containing a specific long chain structure by free radical polymerization in an aqueous solution. A molecular chain of the produced multi-polymer contains 7-20 structural units with weight-average molecular weight in the range of 6,500-12,500. The polycarboxylate flow regulator can greatly reduce viscosity and shear force of the water-based drilling fluid and completion fluid with ultra-high temperature and ultra-high density, improve the dispersion state of solid phase weighting materials in the water-based drilling fluid and completion fluid, improve the rheological property of the water-based drilling fluid and completion fluid with ultra-high temperature and ultra-high density, obviously reduce surface tension of the water-based drilling fluid and completion fluid with ultra-high temperature and improve lubricating performance of the water-based drilling fluid with ultra-high temperature and ultra-high density, has shale inhibition performance and high temperature stability performance, and can resist high temperatures of 251 DEG C or higher.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Preparation method of imidazoline inhibitor applicable to drilling fluid

InactiveCN107699214AStable rheologyFiltration performance is stableOrganic chemistryDrilling compositionChemistryDrilling fluid

The invention discloses a preparation method of an imidazoline inhibitor applicable to drilling fluid. The preparation method comprises the following steps: a. adding a material A and a material B into a reaction kettle according to a molar ratio of 2 : (1 to 2), and continuously stirring for fully mixing; b. cooling reactants to 100 DEG C or below; c. then, reducing the pressure to 0.5-0.7kPa, heating up to 240 DEG C, maintaining the temperature, and reacting for 2-8h; d. stopping heating, cooling to 120 DEG C, pouring the cooled product into a crystallization kettle, and cooling and condensing into a brown yellow material which is the product. The inhibitor prepared by the method provided by the invention is good in compatibility with a conventional water-based treatment agent, has little impact on the properties of water-based drilling fluid, and can effectively strengthen the inhibition ability of the water-based drilling fluid, thus achieving the effect of inhibiting the hydrationdispersion of water sensitive formation minerals; therefore, the well drilling cost is lowered, and the well drilling safety and speed are guaranteed.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

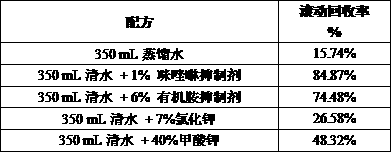

Preparation method of polyamide inhibitor for drilling fluid

InactiveCN107841298ARolling recovery rate (150°C) increasedStable rheologyDrilling compositionViscous liquidClay minerals

The invention discloses a preparation method of a polyamide inhibitor for drilling fluid. The preparation method comprises the following steps: (a) feeding a substance A and a substance B into a reactor according to the molar ratio of (0.5 to 2):1, heating to 60 DEG C, and stirring for 30 minutes till the materials are completely melted and mixed uniformly; (b) under the condition of nitrogen-gasprotection, carrying out insulating reaction for 5-8 hours at the temperature of 150-180 DEG C, and separating out water; (c) after the reaction is ended, cooling reactants to below 30 DEG C and obtaining yellow or brown-yellow viscous liquid, namely a final product; the substance A is dimer acid, trimer acid or a mixture of the dimer acid and the trimer acid. The polyamide inhibitor prepared by adopting the method has the characteristics of high-temperature resistance, obvious inhibition effect and slight influence on the rheological property and the like, is applicable to various water-baseddrilling fluid systems, not only can prevent the problem of well-wall instability caused by hydrous dispersion and expansion of clay minerals of the water-sensitive formation, but also can stabilizethe rheological property of the drilling-fluid system effectively and avoid the property from being out of control.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

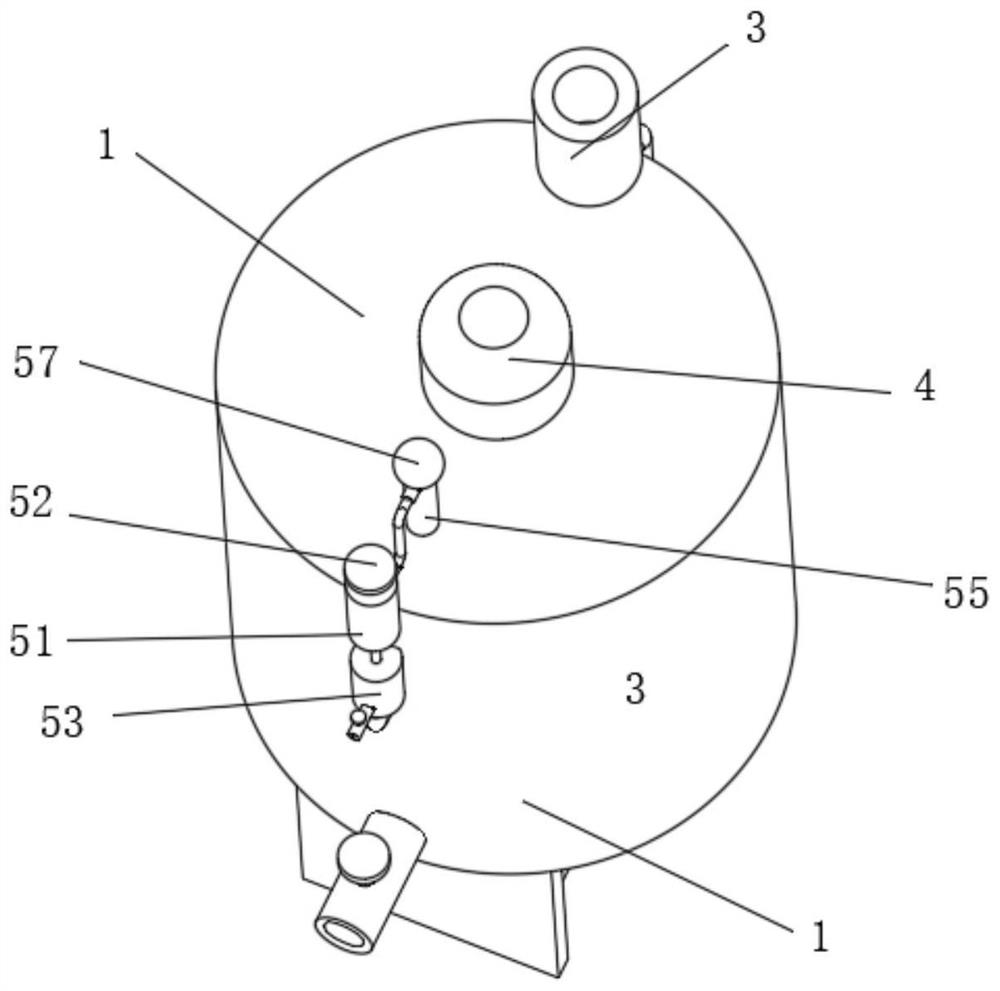

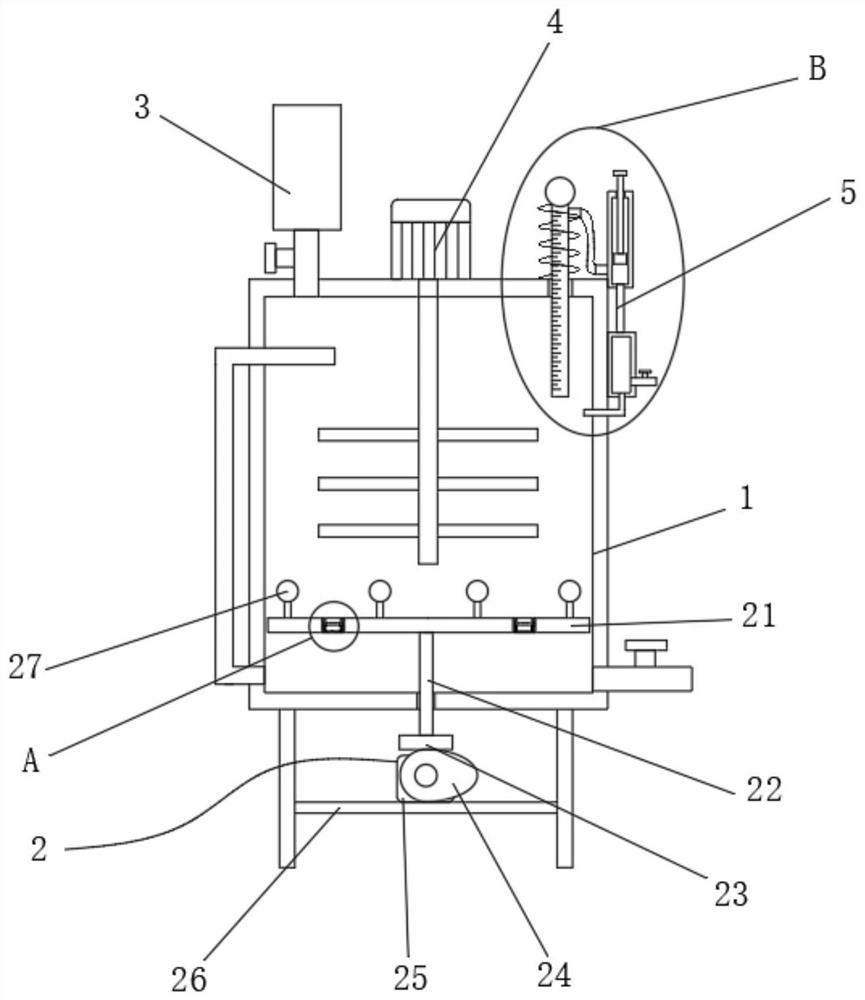

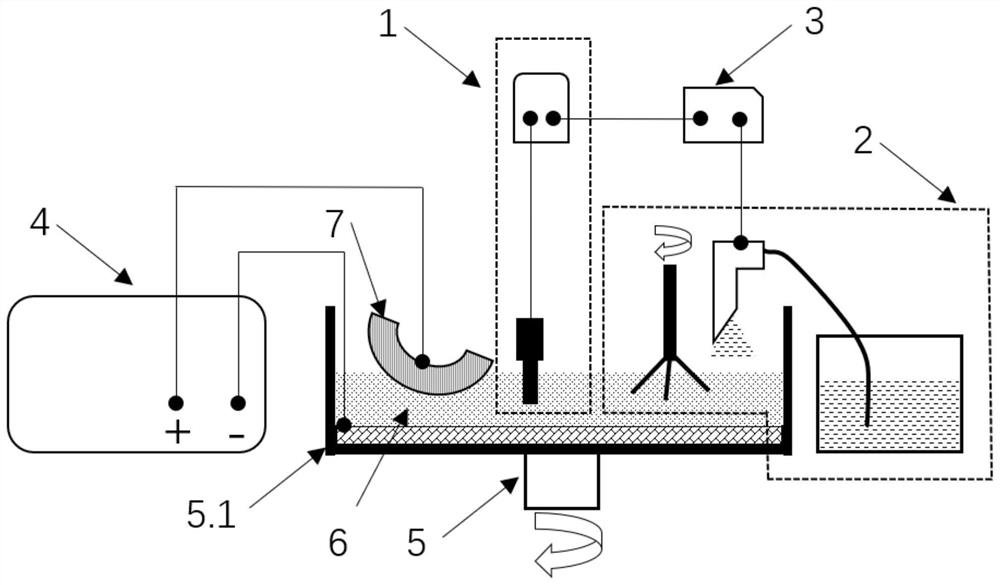

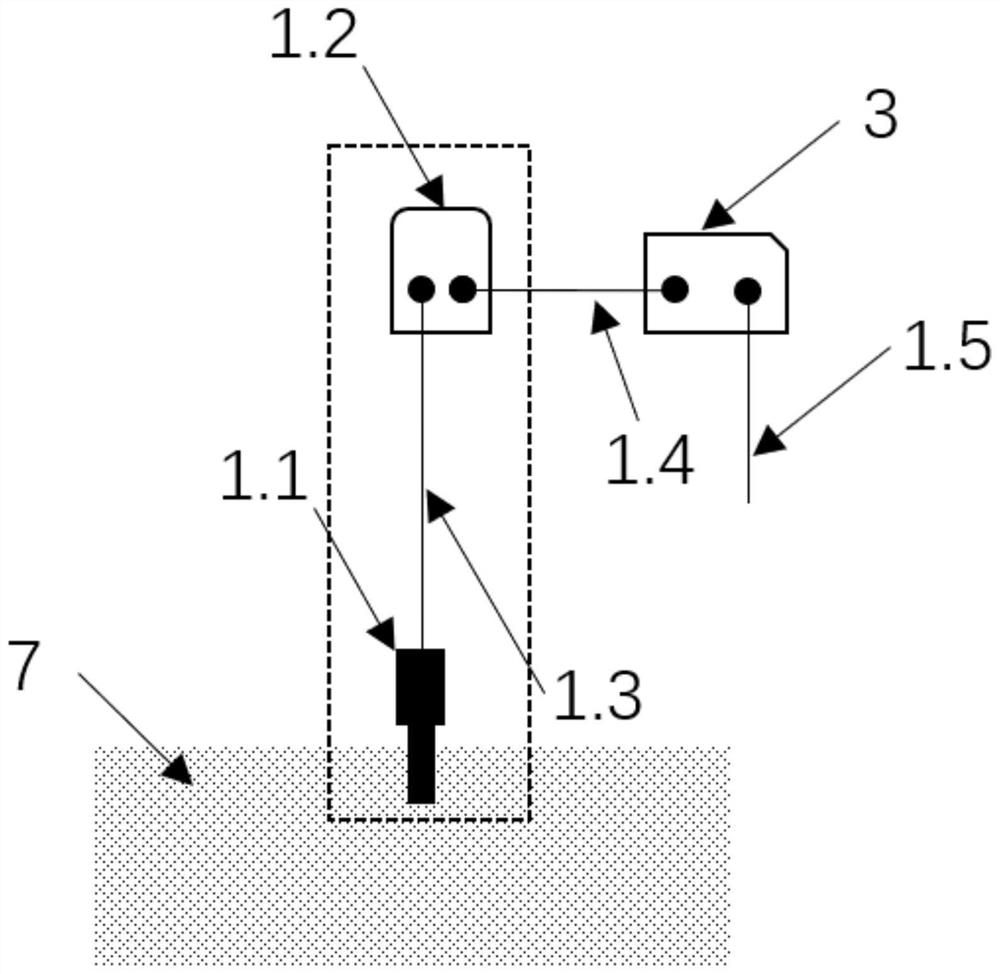

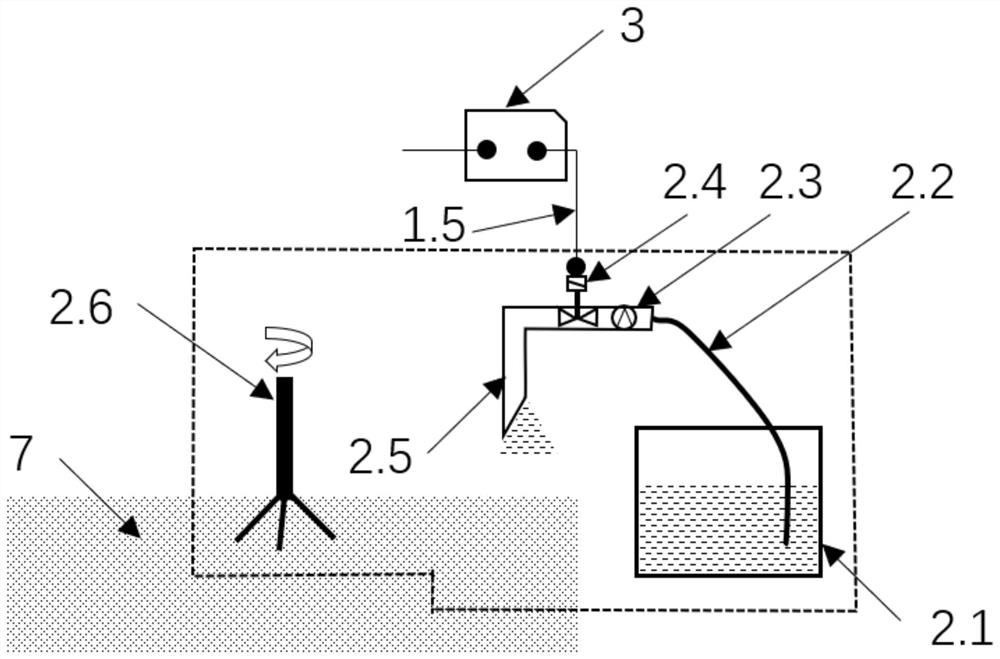

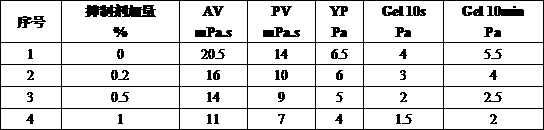

Electrolytic force rheological polishing device for regulating and controlling performance of polishing solution based on conductivity

PendingCN112975588AStable rheologyImprove conductivityPolishing machinesElectrolysis componentsElectrolysisPolishing

The invention relates to an electrolytic force rheological polishing device for regulating and controlling the performance of a polishing solution based on conductivity. The electrolytic force rheological polishing device comprises a conductivity detection module, a purified water filling module, a feedback control device, an electrolytic power source, an electrolysis-force rheological polishing machine and an electrolysis-force rheological polishing solution, and a polishing tank of the electrolysis-force rheological polishing machine is filled with the electrolysis-force rheological polishing solution. The polishing machine rotates to drive the polishing tank and drive the polishing solution to move relative to a workpiece, and the electrolytic power source can electrolyze the workpiece during polishing. The detection end of the conductivity detection module is located in the electrolysis-force rheological polishing solution, the purified water filling module is located on the side edge of the electrolysis-force rheological polishing machine, and the conductivity detection module and the purified water filling module are both connected with the feedback control device. In the polishing process, the water content percentage of the electrolysis-force rheological polishing solution is kept stable, the rheological property and the conductivity of the force rheological polishing solution are actively and accurately regulated and controlled, it is guaranteed that the polishing performance of the device is stable in the working process, and ultra-precision machining of a complex curved surface is achieved.

Owner:ZHEJIANG UNIV OF TECH

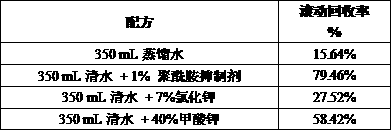

Preparation method of tetrahydroglyoxaline inhibitor applicable to drilling fluid

InactiveCN107721929AHigh recovery rateStable rheologyOrganic chemistryDrilling compositionWater basedViscous liquid

The invention discloses a preparation method of a tetrahydroglyoxaline inhibitor applicable to a drilling fluid. The preparation method comprises the following steps of a, adding 150mL of substance A,150mL of substance B and 26.8g of substance C in a beaker; b, using 8 to 12mL of water for dissolving 7.6g of substance D, and dropwise adding 1 to 2 drops of sodium hydroxide solution; c, using thesodium hydroxide solution for adjusting a pH value of a reaction mixture to 8, filtering for removing separated white solid, distilling off the substance A, the substance B and water, and obtaining apale yellow viscous liquid; d, using chloroform for extracting to obtain a product 1; e, adding 13.6g of product 1 and 7.4g of substance E in to a three-necked flask, and obtaining an orange-yellow viscous transparent liquid; f, using ethyl acetate as an eluent, and obtaining a product 2; g, adding 60mL of substance B and 5.8g of substance F into the three-necked flask, and obtaining a pale yellowviscous liquid; h, extracting with acetone, removing a solvent, using benzene for recrystallizing, and obtaining a white product. The polyamide inhibitor prepared by adopting the method has the characteristics of high temperature resistance, remarkable inhibitory effect, less influence on rheological property, and the like, and is applicable to various water-based drilling fluid systems.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com