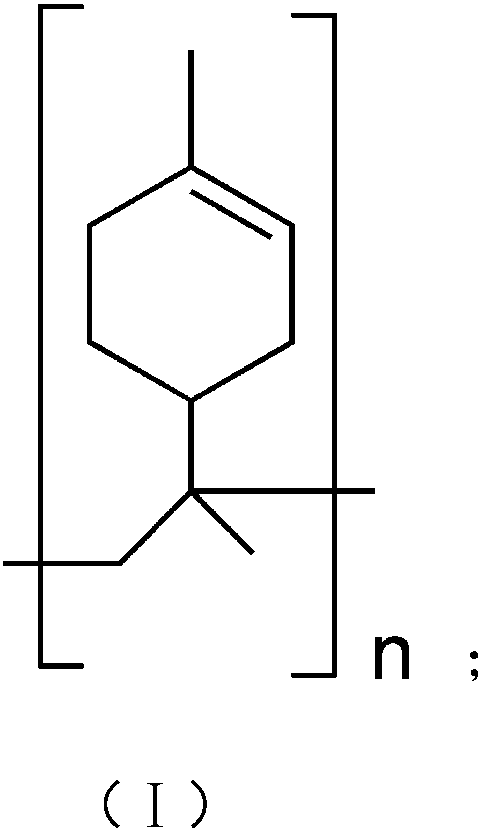

High-solid-content low-softening-point light-colored liquid terpene resin as well as preparation method and application thereof

A technology of terpene resin and low softening point. It is applied in the field of liquid terpene resin and its preparation. It can solve the problems of resin solid content reduction, influence on catalyst treatment, solidification and precipitation, etc., to improve processability and consistency, and increase raw material polymerization. Activity, effect of improving adhesion and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] An embodiment of the preparation method of the light-colored liquid terpene resin with high solid content and low softening point of the present invention comprises the following steps:

[0040] (1) In a 1000mL dry four-neck flask equipped with a stirrer, thermometer, calcium chloride drying tube and constant pressure dropping funnel, add 1.00g AlCl 3 , 300mL of dry toluene and 0.10g of phosphorus-containing inorganic acid light color agent, inject 0.05g of dichloroethane with a micro-syringe at the same time, place it in a low-temperature circulation pump, and pass through N 2 Exhaust the air, start stirring, slowly add 300g of refined masson turpentine into the flask through the constant pressure dropping funnel, control the reaction temperature at 50°C, add 1.00g of AlCl after 1 / 3 of the turpentine is added dropwise 3 and 0.05g of dichloroethane, add 1.00g of AlCl after adding 2 / 3 dropwise 3 and 0.05g ethylene dichloride, continue to drop the remaining turpentine, a...

Embodiment 2

[0043] The preparation method of the light-colored liquid terpene resin with high solid content and low softening point described in this embodiment comprises the following steps:

[0044] (1) In a 1000mL dry four-neck flask equipped with a stirrer, thermometer, calcium chloride drying tube and constant pressure dropping funnel, add 1.20g AlCl 3 , 300mL of dry toluene and 0.15g of phosphorus-containing inorganic acid light color agent, inject 0.09g of dichloroethane with a micro-syringe at the same time, place it in a low-temperature circulation pump, and pass N 2 Exhaust the air, start stirring, slowly add 300g of refined wetland turpentine into the flask through the constant pressure dropping funnel, control the reaction temperature at 50°C, add 1.20g of AlCl after 1 / 3 of the turpentine is added dropwise 3 and 0.09g dichloroethane, add 1.20g AlCl after adding 2 / 3 dropwise 3 and 0.09g ethylene dichloride, continue to drop the remaining turpentine, after the dropwise addition...

Embodiment 3

[0047] The preparation method of the light-colored liquid terpene resin with high solid content and low softening point described in this embodiment comprises the following steps:

[0048] (1) In a 1000mL dry four-neck flask equipped with a stirrer, thermometer, calcium chloride drying tube and constant pressure dropping funnel, add 1.50g AlCl 3 , 300mL of dry toluene and 0.12g of phosphorus-containing inorganic acid light color agent, inject 0.15g of dichloroethane with a micro-syringe at the same time, place it in a low-temperature circulation pump, and pass N 2 Exhaust the air, start stirring, slowly add 300g of refined Simao turpentine into the flask through the constant pressure dropping funnel, control the reaction temperature at 60°C, add 1.50g of AlCl after 1 / 3 of the turpentine is added dropwise 3 and 0.15g of dichloroethane, add 1.50g of AlCl after 2 / 3 of the dropwise addition 3 and 0.15g ethylene dichloride, continue to drop the remaining turpentine, after the drop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com