Site treatment technique for environment-friendly polyether alcohol amine drilling fluid

A polyether alcohol amine, on-site treatment technology, applied in earthwork drilling, wellbore flushing, wellbore/well parts, etc., can solve problems such as repeated fluctuations in rheological properties, large consumption of drilling fluid materials, and impact on environmental performance. Achieve the effect of smooth water supply of drilling fluid pump, weak foaming phenomenon and heavy workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

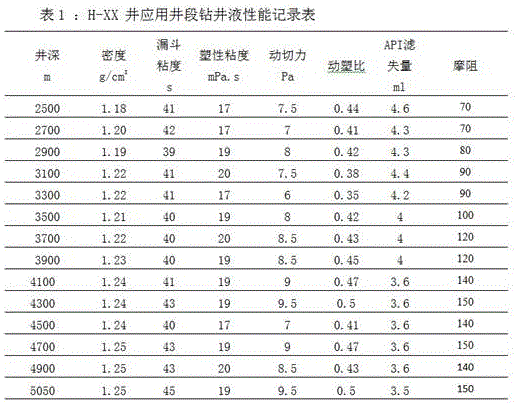

[0017] Take the field construction of a certain H-XX well in Jiangsu Oilfield as an example to further illustrate the field construction method of the present invention.

[0018] Well H-XX was completed with a drilling depth of 5050m, predicted formation temperature at the bottom of the well was 142°C, three open hole sections were opened at 3150m, the maximum well deviation was 57°, and the horizontal displacement was 831.31m. The drilling fluid system of ordinary soil slurry + composite metal ion polymer is used in the first section of 0-495m well depth, and the composite metal ion polymer drilling fluid system is used in the second section of 495-1900m well depth. In case of collapsible mudstone and sand-mudstone interbedded.

[0019] 1. Drilling fluid requirements for the third open-hole well section: implement technical measures for drilling fluid in the block, and take the collapse prevention of the whole well section and ensure the wellbore regulation as the focus of dr...

Embodiment 2

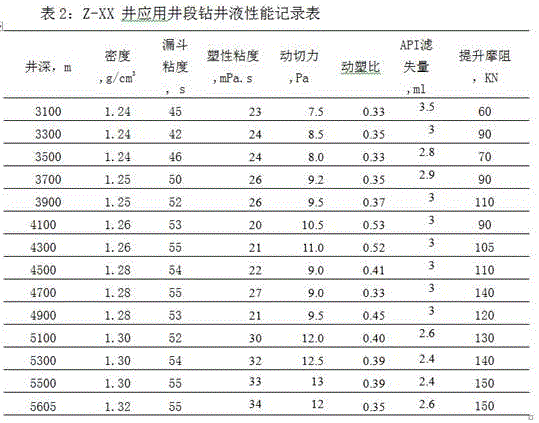

[0036] The present invention is further illustrated by taking the field construction of a certain Z-XX well in Jiangsu Oilfield as an example.

[0037] Well Z-XX has been drilled to a depth of 5605m, the predicted formation temperature at the bottom of the well is 149°C, the maximum well deviation is 62°, and the horizontal displacement is 1203.5m. Drilling with clean water in the 0-196m well depth of the first well opening section, ordinary soil slurry + composite metal ion polymer drilling fluid system in the 196-1802m well drilling section of the second well opening section, and composite metal ion polymer drilling fluid system in the 1802-2967m well opening section of the third well opening section , the 2967-5605m well depth of the fourth well section adopts the environment-friendly polyether alcohol amine drilling fluid system.

[0038] 1. Mixing and conversion of drilling fluid: Drill the cement plug four times, drain the contaminated drilling fluid, dilute with clean w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com