Preparation method of polyamide inhibitor for drilling fluid

The technology of polyamide and inhibitor is applied in the field of preparation of polyamide inhibitor for drilling fluid, which can solve the problems of limited adsorption capacity and loss of inhibitory effect, and achieve the effects of small influence on rheology, good inhibitory effect and good economic benefit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] a. Feed the dimer acid A and hydroxyethylethylenediamine B at a molar ratio of 1:1, heat to 60°C, and stir for 30 minutes until the materials are completely melted and mixed evenly.

[0022] b. Under the protection of nitrogen, keep the reaction temperature at 170℃ for 7 hours, and keep the water out.

[0023] c. After the reaction is over, cool the reactant to below 30°C to obtain a yellow viscous liquid as the final product.

Embodiment 2

[0025] a. Feed trimer acid A and hydroxymethyl ethylenediamine B at a molar ratio of 0.75:1, heat to 60°C, and stir for 30 minutes until the materials are completely melted and mixed evenly.

[0026] b. Under the protection of nitrogen, keep the reaction at 180℃ for 8 hours, and keep the water out.

[0027] c. After the reaction, cool the reactant to below 30°C to obtain a brown-yellow viscous liquid that is the final product.

Embodiment 3

[0029] a. Put the mixture of dimer acid A and trimer acid A (1:1) and hydroxyethylethylenediamine B at a molar ratio of 1:1.25, heat to 60℃, stir for 30min, until the material is completely melted, and mix Evenly.

[0030] b. Under the protection of nitrogen, keep the reaction temperature at 180℃ for 6h, and keep the water out.

[0031] c. After the reaction, cool the reactant to below 30°C to obtain a brown-yellow viscous liquid that is the final product.

[0032] Example performance evaluation method

[0033] 1. Rolling recovery experiment of polyamide inhibitor

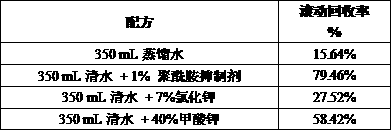

[0034] Take 4 parts of 350mL distilled water, of which 3 parts were added 1% polyamide inhibitor (Example 1), 7% commonly used inhibitor potassium chloride and 40% commonly used inhibitor potassium formate, in a low-speed agitator (1000rpm / min) and stir for 10 min. Pour four parts of liquid into the aging tank, and then add 50g of shale cuttings. The rolling recovery rate of four liquids was measured at 150℃, and the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com