Electrolytic force rheological polishing device for regulating and controlling performance of polishing solution based on conductivity

A polishing device and conductivity technology, applied in the direction of grinding/polishing safety devices, surface polishing machine tools, grinding automatic control devices, etc., can solve the problems such as difficult control of rheological properties and electrical conductivity of polishing fluid, and achieve lower temperature , weaken the rheological properties, reduce the effect of weakening the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

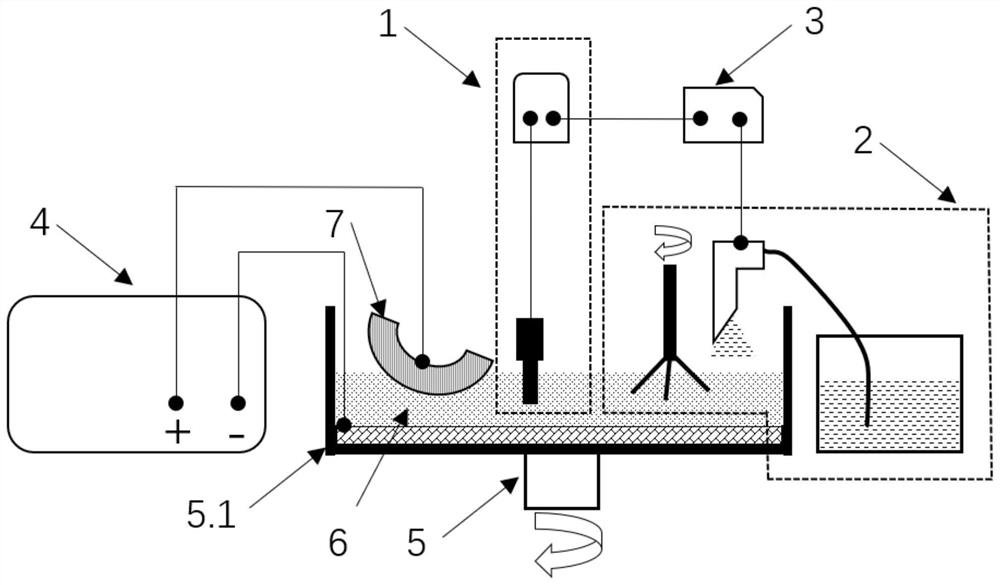

Method used

Image

Examples

example

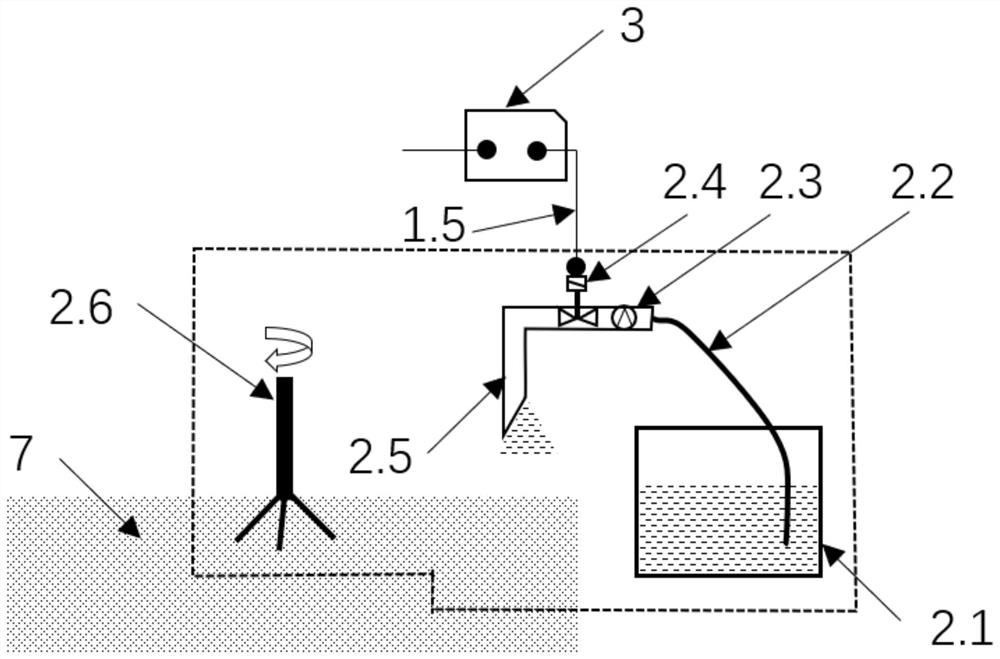

[0038] Example: non-Newtonian fluid with force rheological effect selects polyol solution with a content of 79%; pure water contains 10%; abrasive grains selects a silicon dioxide content of 10%; electrolytes include but not limited to sodium sulfate and contains 1%.

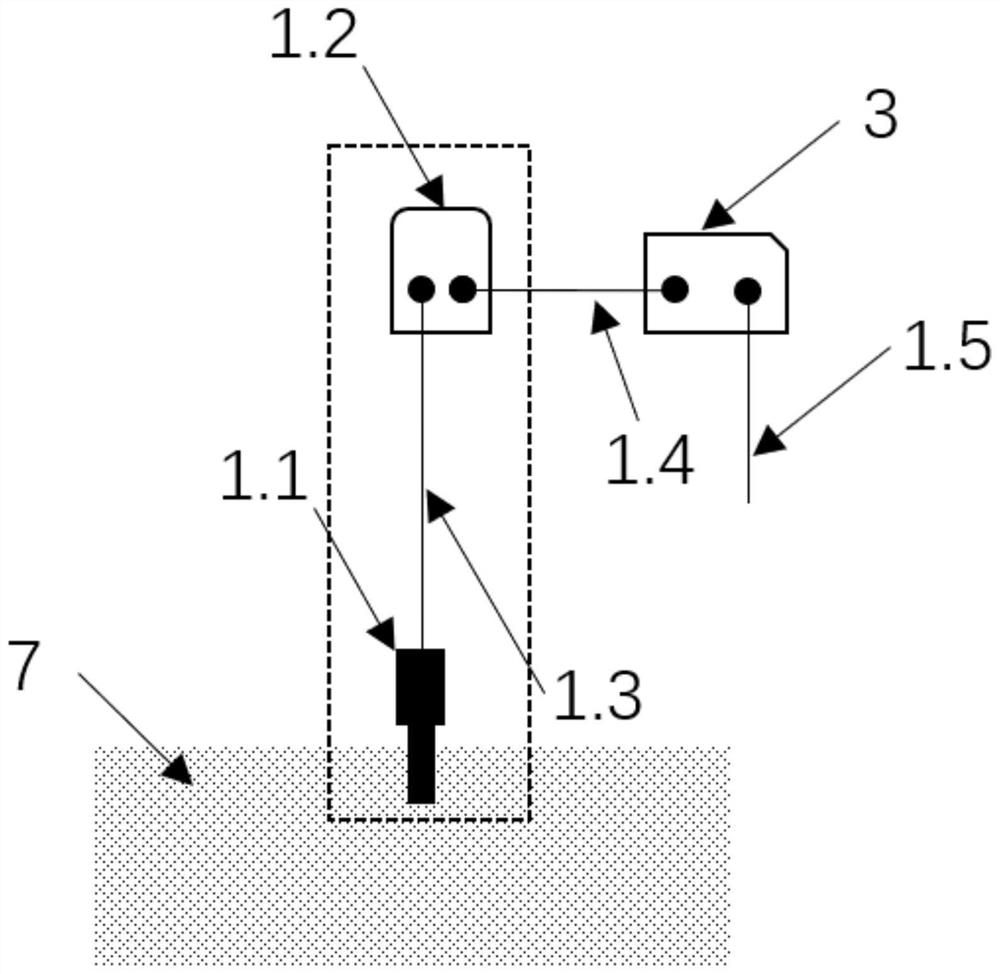

[0039] Further, the conductivity detection module 1 includes a conductivity electrode probe 1.1, a conductivity parameter analyzer 1.2, and a conductivity transmission data line 1.3; the conductivity meter electrode probe 1.1 is installed on the electrolysis-force rheological polishing machine 5 , the electrode probe 1.1 of the conductivity meter is inserted into the electrolytic-mechanical rheological polishing solution 6 . The electrode probe 1.1 of the conductivity meter is connected to the conductivity parameter meter 1.2 through the conductivity transmission data line 1.3. The conductivity parameter analyzer 1.2 can convert the electrical signal generated by the conductivity electrode probe 1.1 into conduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com