High-temperature-resistant filtrate reducer for drilling fluid and preparation method thereof

A filtrate reducer and high temperature resistance technology, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of harsh production process conditions, inability to use and store for a long time, poor temperature resistance, etc., and achieve good salt resistance and fluid loss reduction performance, excellent high temperature resistance and salt resistance performance, strong and stable mud rheology effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

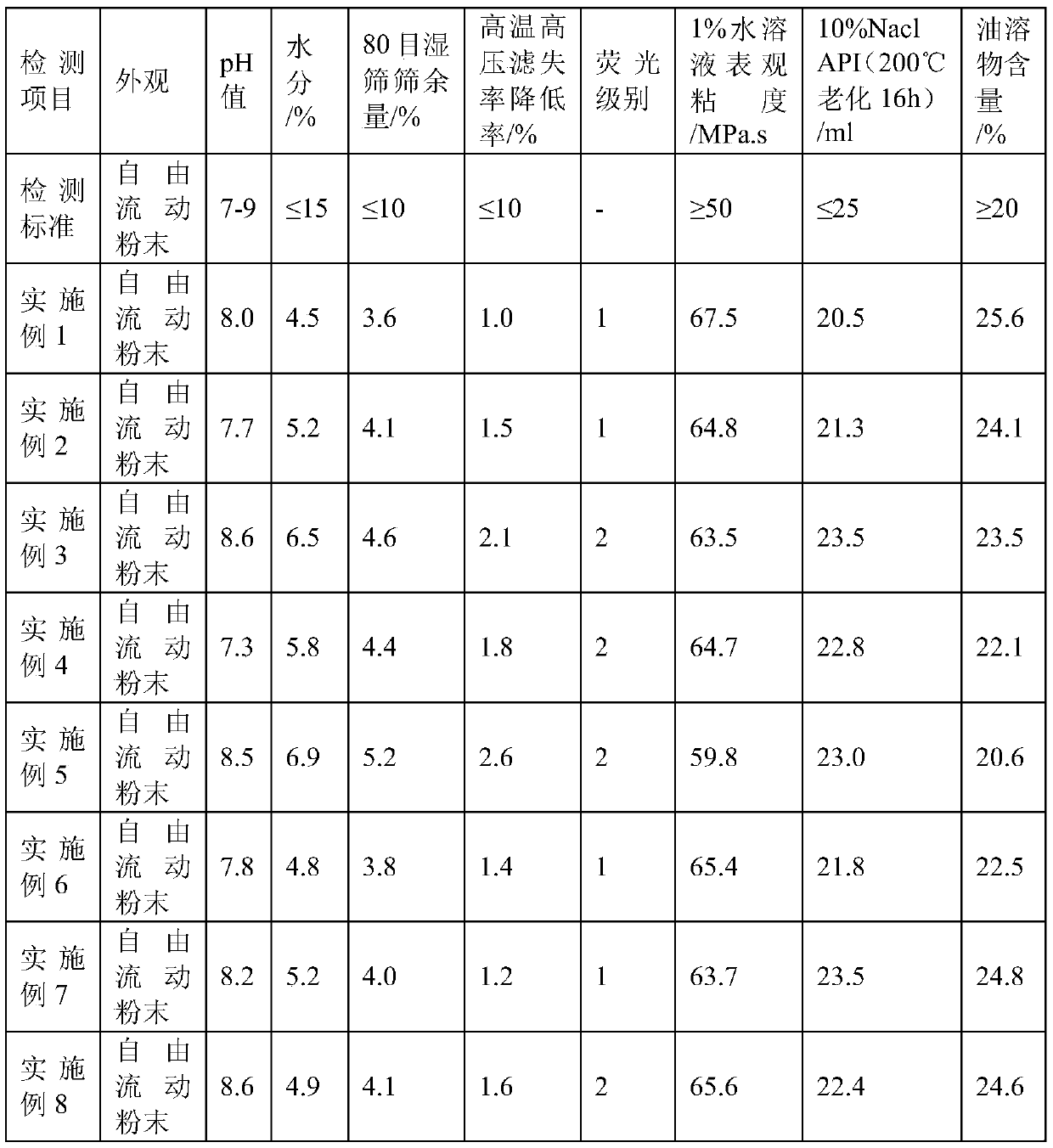

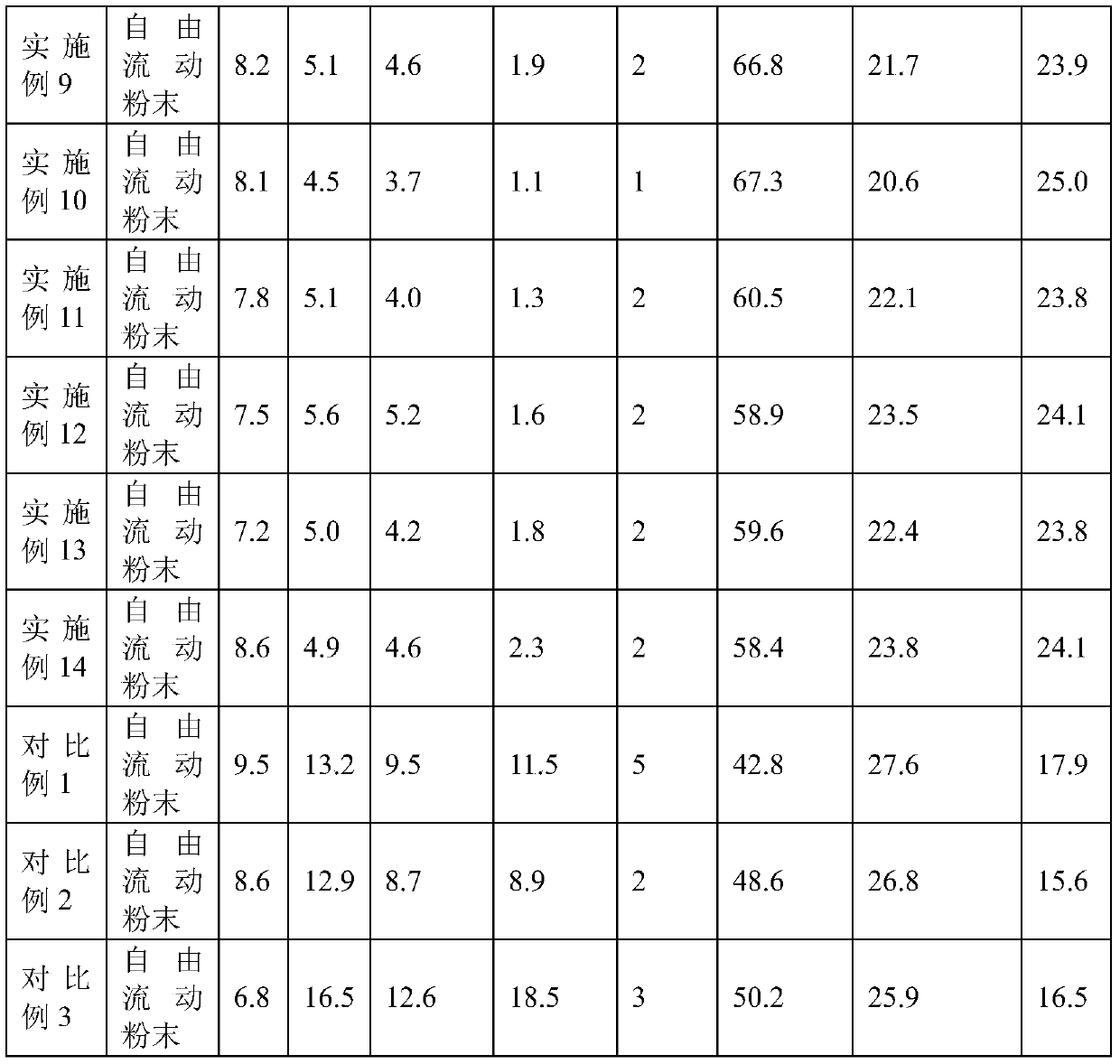

Examples

preparation example 1

[0035] The preparation method of the ethylenic monomer polymer is as follows: in parts by weight, sodium hydroxide is dissolved in water until the pH value of the aqueous solution is 9.5, and 60 parts of 2-acrylamido-2-methylpropane are added under stirring conditions. Sulfonic acid, the stirring temperature is 45°C, stirring for 18 minutes to dissolve it, then adding 50 parts of acrylonitrile and 28 parts of N,N,-dimethylacrylamide, stirring, adjusting the pH value of the solution to 8.5 during the stirring process, at 80 Stir at ℃ for 35min, add 4 parts of initiator A ammonium persulfate, stir and react for 50min at a speed of 4000r / min;

[0036] Then granulate in a twin-screw extruder, the extrusion temperature is 130°C, the screw speed is 400r / min, after granulation, it is dried and pulverized at 110°C, and passed through a 70-mesh sieve to obtain the vinyl monomer polymer.

preparation example 2

[0038]The preparation method of the ethylenic monomer polymer is carried out according to the method in Preparation Example 1, the difference is that sodium hydroxide is dissolved in water until the pH value of the aqueous solution is 9, and 50 parts of 2-acrylamido- 2-Methylpropanesulfonic acid, stirring at 40°C, stirring for 15 minutes to dissolve it, then adding 40 parts of acrylonitrile and 25 parts of N,N,-dimethylacrylamide, stirring, and adjusting the pH value of the solution during stirring 8.5, stirred at 75°C for 30 minutes, added 3 parts of initiator A ammonium persulfate, stirred and reacted for 40 minutes at a rotational speed of 3000r / min;

[0039] Then granulate in a twin-screw extruder, the extrusion temperature is 120°C, the screw speed is 300r / min, after granulation, it is dried and pulverized at 100°C, and passed through a 60-mesh sieve to obtain the vinyl monomer polymer.

preparation example 3

[0041] The preparation method of ethylenic monomer polymer is carried out according to the method in Preparation Example 1, the difference is that sodium hydroxide is dissolved in water until the pH value of the aqueous solution is 10, and 70 parts of 2-acrylamido- 2-Methylpropanesulfonic acid, stirring at 50°C, stirring for 20 minutes to dissolve it, then adding 65 parts of acrylonitrile and 30 parts of N,N,-dimethylacrylamide, stirring, and adjusting the pH value of the solution during stirring 9, stirred at 90°C for 40 minutes, added 5 parts of initiator A ammonium persulfate, stirred and reacted for 60 minutes at a speed of 4500 r / min;

[0042] Then granulate in a twin-screw extruder with an extrusion temperature of 140°C and a screw speed of 450r / min. After granulation, it is dried and pulverized at 120°C, and passed through a 80-mesh sieve to obtain vinyl monomer polymer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com