Guar gum grafted copolymer nanocomposite gel fracturing fluid and preparation method thereof

A graft copolymer and jelly fracturing fluid technology is applied in the field of guar gum graft copolymer nanocomposite jelly fracturing fluid and its preparation, and can solve the problem of insufficient viscoelastic performance and stability, temperature resistance and shear resistance. problems such as poor cutting properties, to achieve the effect of increasing interaction, stabilizing performance, and solving dispersion problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

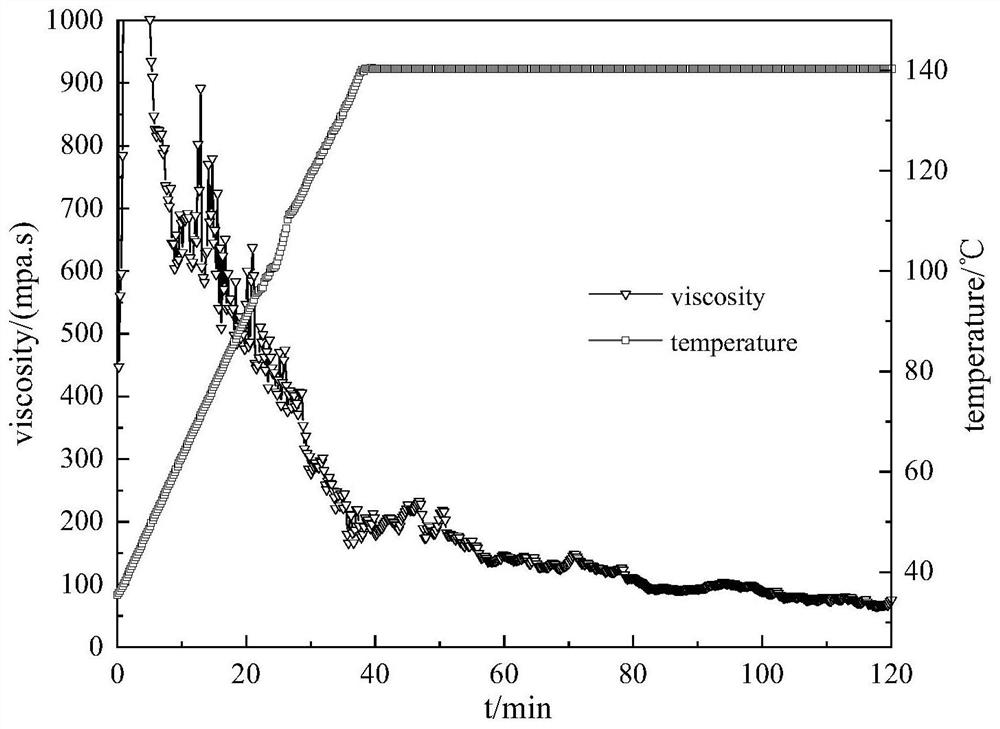

[0043] A kind of guar gum graft copolymer nanocomposite jelly fracturing fluid, comprises following mass percentage components: guar gum graft copolymer thickener 0.5%, nano silicon dioxide powder 0.1% and borax 0.3%, remainder The amount is water.

[0044] Wherein, the guar gum graft copolymer thickener is synthesized by the following components by weight: 3 parts of guar gum powder, 8 parts of acrylamide, 0.8 part of cerium ammonium nitrate and 900 parts of water.

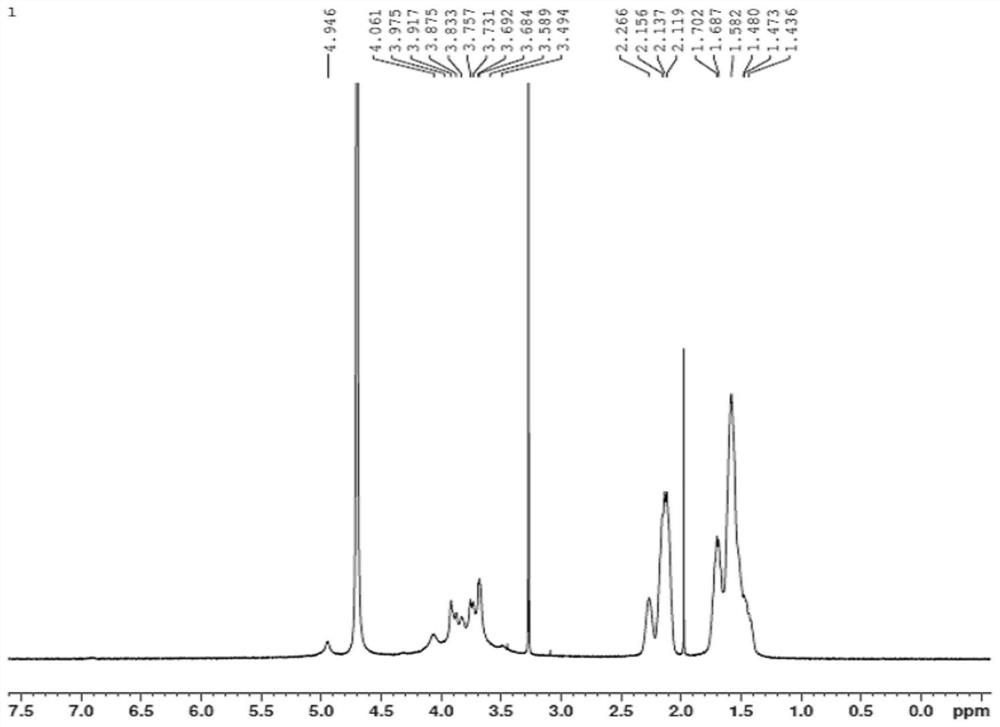

[0045] Guar gum graft copolymer thickener is synthesized by the following method:

[0046] (1) Slowly add guar gum powder under a water bath condition of 40° C. and 600 r / min, stir for 30 minutes and then stand at 30° C. for 4 hours to obtain an aqueous solution of guar gum;

[0047] (2) dissolving acrylamide in water, and adjusting the pH value to 7±0.5 with 25wt% sodium hydroxide solution to obtain a monomer solution;

[0048] (3) Add the monomer solution obtained in step (2) into the guar gum aqueous solutio...

Embodiment 2

[0055] A guar graft copolymer nanocomposite jelly fracturing fluid, comprising the following components in mass percentage: 0.6% of guar graft copolymer thickener, 0.1% of cellulose nanofiber and triethanolamine boron crosslinking agent 0.8%, the balance is water.

[0056] Wherein, the guar gum graft copolymer thickener is synthesized by the following components by weight: 5 parts of guar gum powder, 7 parts of acrylamide, 6 parts of 2-acrylamido-2-methylpropanesulfonic acid, nitric acid 1 part of ammonium cerium and 1200 parts of water.

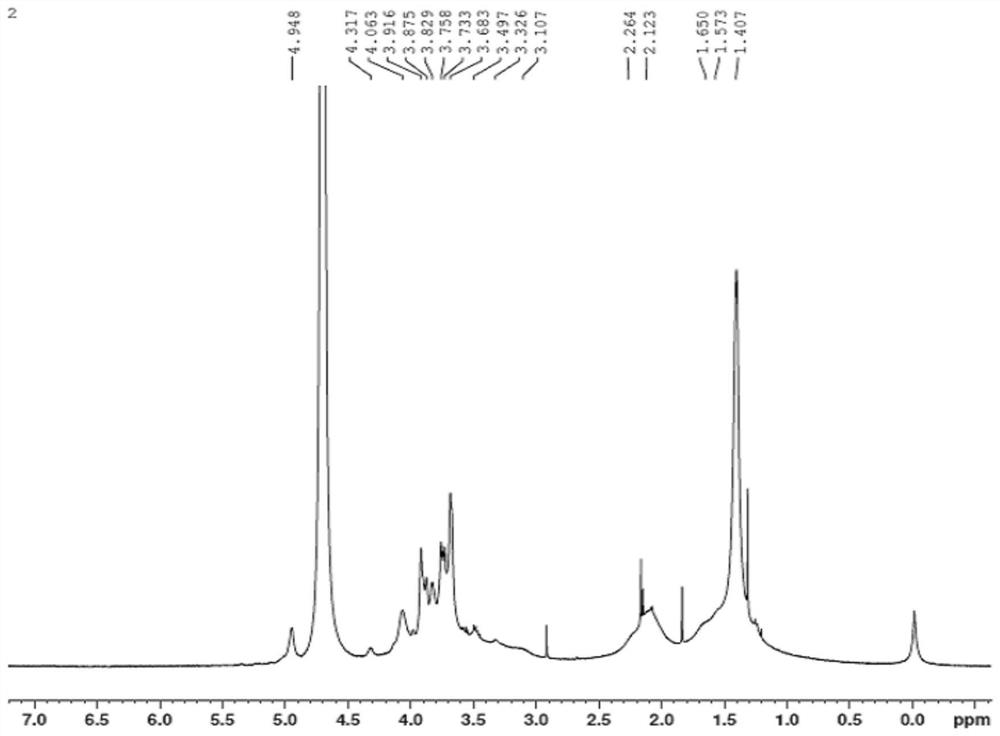

[0057] Guar gum graft copolymer thickener is synthesized by the following method:

[0058] (1) Slowly add guar gum powder under a water bath condition of 40°C and 800r / min, stir for 60min and then stand at 30°C for 4h to obtain an aqueous solution of guar gum;

[0059] (2) dissolving acrylamide and 2-acrylamido-2-methylpropanesulfonic acid in water, and adjusting the pH value to 7±0.5 with 25 wt% sodium hydroxide solution to obtain a monom...

Embodiment 3

[0067] A guar gum graft copolymer nanocomposite jelly fracturing fluid, comprising the following components in mass percentage: 0.5% of guar gum graft copolymer thickener, 0.2% of sodium montmorillonite powder and zirconium lactate crosslinking Agent 0.5%, the balance is water.

[0068] Wherein, the guar gum graft copolymer thickener is synthesized by the following components by weight: 6 parts of hydroxypropyl guar gum powder, 9 parts of acrylamide, 1 part of acrylic acid, 2-acrylamido-2-methyl 10 parts of propanesulfonic acid, 0.5 parts of potassium persulfate and 1000 parts of water.

[0069] Guar gum graft copolymer thickener is synthesized by the following method:

[0070] (1) Slowly add hydroxypropyl guar gum powder under a water bath condition of 40°C and 1000r / min, stir for 60 minutes and then stand at 30°C for 4 hours to obtain an aqueous solution of guar gum;

[0071] (2) dissolving acrylamide, acrylic acid, and 2-acrylamido-2-methylpropanesulfonic acid in water, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com