High-temperature-resistant fluid loss agent and preparation method thereof as well as water-based drilling fluid

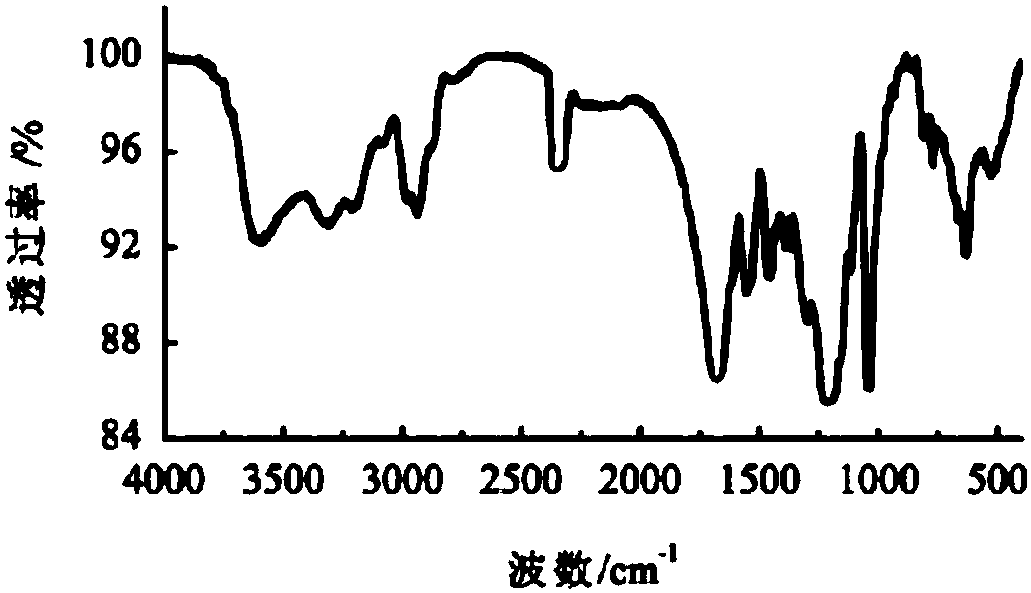

A filtrate reducer, high temperature resistance technology, applied in the field of petroleum drilling fluid, can solve the problems of easy decomposition, poor temperature resistance, weakened filter loss effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

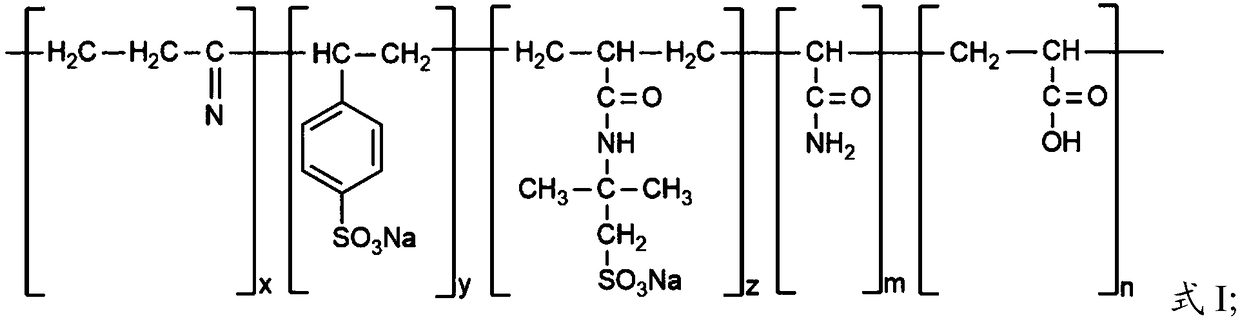

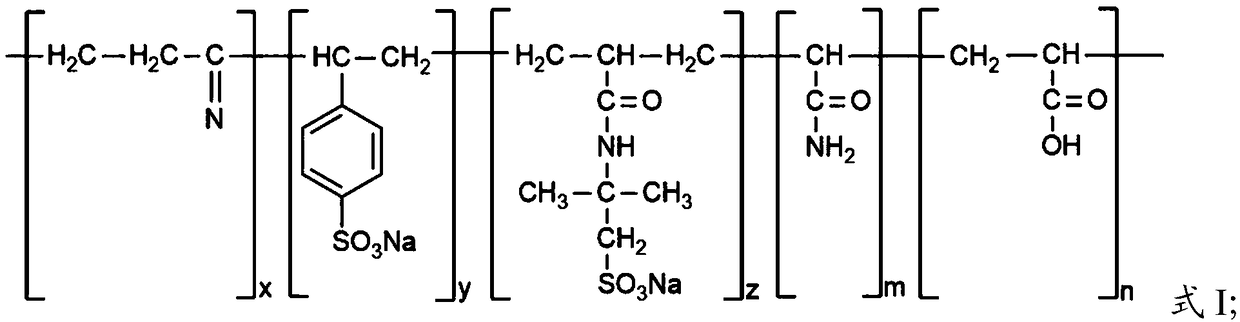

[0026] The present invention provides a kind of preparation method of anti-high temperature fluid loss reducer, comprising the following steps:

[0027] providing an aqueous solution of comonomers; said comonomers include acrylic acid, acrylamide, 2-acrylamido-2-methylpropanesulfonic acid, sodium styrenesulfonate and acrylonitrile;

[0028] adjusting the pH value of the aqueous comonomer solution to 8-9 by using an alkaline pH regulator to obtain an alkaline monomer solution;

[0029] Mixing the alkaline monomer solution with an oxidized initiator, a reduced initiator, and a molecular weight regulator, and performing a polymerization reaction to obtain a gel product;

[0030] The gel product is dried to obtain a high temperature resistant fluid loss reducer.

[0031] In the present invention, unless otherwise specified, the raw materials used in the preparation method are commercially available products well known to those skilled in the art.

[0032] In this application, un...

Embodiment 1

[0054] In parts by mass, add 130 parts of distilled water, 315 parts of acrylic acid and 315 parts of acrylamide into a four-neck flask equipped with a stirrer, reflux condenser, thermometer and heating device, start the stirrer, and stir until the monomers are completely dissolved. Add 145 parts of 2-acrylamido-2-methylpropanesulfonic acid and 235 parts of sodium styrenesulfonate, heat in a water bath to 60° C. and keep warm until the monomer dissolves to obtain a comonomer aqueous solution.

[0055] Adjust the pH value to 8-9 with NaOH solution. Simultaneously pass nitrogen to drive oxygen, add 1.5 parts of initiator ammonium persulfate to react for 5 minutes at 60°C, then add 1.5 parts of sodium bisulfite to react for 40 minutes, then add 1.3 parts of molecular weight regulator thioglycolic acid, react for 4 hours to obtain a gel shaped product.

[0056] The obtained gel-like product was dried in a drying oven at a constant temperature of 65° C., and after being dried to a...

Embodiment 2

[0060] In parts by mass, add 150 parts of distilled water, 325 parts of acrylic acid and 325 parts of acrylamide into a four-neck flask equipped with a stirrer, reflux condenser, thermometer and heating device, start the stirrer, and stir until the monomers are completely dissolved. Add 150 parts of 2-acrylamido-2-methylpropanesulfonic acid and 250 parts of sodium styrenesulfonate, and heat in a water bath to 60° C. to dissolve the monomers to obtain a comonomer aqueous solution.

[0061] Adjust the pH value to 8-9 with NaOH solution. Simultaneously pass nitrogen to drive oxygen, add 1.55 parts of initiator ammonium persulfate to react for 3 minutes at 60°C, then add 1.55 parts of sodium bisulfite to react for 30 minutes, then add 1.3 parts of molecular weight regulator thioglycolic acid, react for 4 hours to obtain a gel shaped product.

[0062] The obtained gel-like product was dried in a drying oven at a constant temperature of 65° C., and after being dried to a water cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com